In everyday life, a powerful power source with a fixed voltage is often needed. It can be used as a charger, to power audio equipment (amplifiers), etc. It is advisable to make such power supplies using a pulse circuit. This circuitry allows you to create lightweight and powerful DC voltage sources. The complexity of the circuit begins to fade into the background compared to its advantages already at load currents of more than 2A. You can make a switching power supply with your own hands if you have the equipment and certain qualifications.

Types and principle of operation of switching power supplies

The basic operating principle of a switching power supply (SMPS) is that direct voltage (rectified mains voltage or from a third-party source) is converted into pulsed voltage with a frequency of up to hundreds of kilohertz. Due to this, the winding parts (transformers, chokes) are light and compact.

Fundamentally, IIPs are divided into two categories:

- with pulse transformer;

- with storage inductance (it can also have secondary windings)

The former are similar to conventional transformer mains power supplies; their output voltage is regulated by changing the average current through the transformer winding. The latter work on a different principle - they are regulated by changing the amount of accumulated energy.

Based on other characteristics, IIP can be divided into unstabilized and stabilized, unipolar and bipolar, etc. These features are not of such a fundamental nature.

High voltage direct current (HVDC) source. Scheme

HVDC power supply design.

Circuits such as Geiger counters, Nixie tubes, and sensors require high voltage direct current (HVDC) supplies.

There are various types of HVDC power supplies available in the market, including voltage doubler, closed loop converter, and boost converter. Some of them have low current output.

But with the right calculations using basic upconversion formulas, we can achieve HVDC supplies capable of clean, high current capacity.

Here is a boost converter design using the MC34063 DC/DC converter. The author's prototype is shown in Fig. 1. Products for inventors.

Structural and schematic diagram of the main parts of the block

Generalized block diagram of a pulse power supply.

A surge filter is installed at the input of the power supply. In principle, it does not affect the operation of a homemade or industrial switching power supply - everything will function without it. But you cannot abandon the filtering circuit - due to the extremely nonlinear shape of the consumed current, pulsed sources intensively “sprinkle” interference into a 220-volt household network. For this reason, devices running on the same network on microprocessors and microcontrollers - from electronic watches to computers - will malfunction.

Network filter circuit.

The purpose of the input device is to protect against two types of interference:

- common-mode (asymmetrical) – occurs between any wire and the ground (case) of the power supply unit;

- differential (symmetrical) – between the power wires (poles).

The filter, like the entire power supply, is protected at the input by fuse F (fuseable or self-recovering). After the fuse there is a varistor - a resistor whose resistance depends on the applied voltage. As long as the input voltage is normal, the resistance of the varistor is high and it has no effect on the operation of the circuit. If the voltage increases, the resistance of the varistor drops sharply, which causes an increase in current and the fuse burns.

Capacitors Cx block differential noise at the input and output of the filter in the range up to 30 MHz. At a frequency of 50 Hz their resistance is high, so they do not affect the mains voltage. Their capacitance can be selected from 10 to 330 nF. Resistor Rd is installed for safety - the capacitors are discharged through it after the power is turned off.

Common-mode interference is suppressed by a filter on Cy and L. Their values for the cutoff frequency f are related by the Thompson formula:

f=1/(2*π*√L*C) , where:

- f – cutoff frequency in kHz (the conversion frequency of the pulse generator is taken);

- L – inductance of the inductor, μH;

- C – capacitance Cy, µF.

The common mode choke is wound on a ferrite ring. The windings are identical, winding on opposite sides.

Common mode choke design.

Unlike the output filter, the rated current of the power supply unit does not affect the calculation of the noise protection filter elements, with the exception of the wire with which the inductor is wound.

After the filter, the mains voltage is rectified. In most cases, a standard full-wave bridge rectifier is used.

How to make a line transformer with your own hands. What can be made from a line transformer

Home / PC hardware

Probably everyone who has ever worked with high-voltage equipment is familiar with this device. It is a blocking generator, the load of which is the primary winding of the line generator. The generation frequency is somewhere around 20 kHz. It depends on the size of the gap in the liner core. The larger it is, the higher it is. However, the optimal gap size is 0.1-0.5 mm. In the absence of a gap, the core becomes very hot due to its oversaturation. Now to the diagram. The circuit is incredibly simple, and is probably the simplest circuit for creating high voltage :))) Resistors R1 and R2 must have a power of at least 2, and preferably 10 watts. VT1-type transistor KT805 - for output power up to 30 watts and 2N3055 - for output power up to 120 watts. It must be installed on a radiator with a usable area of at least 500, and preferably 1000 sq.cm (for a power of 120 watts). It must be said that with the KT805 transistor you cannot supply more than 12 V to the circuit. That is, it is possible, but the transistor may not withstand it. I myself burned as many as five KT805 transistors in this way. It is better to place the power supply next to the generator. Any transformer with an output voltage from 12V to 36V and a current of at least 3 A is suitable for it. The diode bridge must be assembled from powerful diodes, for example D242. One thing can be said about a capacitor - the larger the capacity, the better. However, 10000 uF 50 V is quite enough. With low-voltage power supply, the capacity can be reduced to 2000 microfarads. It is better to take a line reader from a black and white TV; I personally used the TVS-110LA line reader. The liner should be redone: I. Disassemble the core into 2 U-shaped halves; II. Remove the primary windings (they are no longer needed); III. Make a frame for new primary windings from thick cardboard; IV. Wind new primary windings: a) 1-2 - with a wire 0.6-0.8 mm thick, 2-3 turns; b) 3-4 - wire 1-1.5 mm thick, 5-6 turns; The windings must be connected one to one as in the diagram, otherwise it will not work. V. Place the primary windings on the core together with the step-up winding and fasten the core. The entire structure is mounted on a stand made of a reliable dielectric, for example, plywood. Don't be lazy to make a normal device. If you’re lazy, you’ll make “a bunch of parts in a candy box,” and it’ll cost more. I was personally convinced of this by burning three transistors:(( After assembly, the device should be plugged into the network. If everything is assembled correctly, then between the terminals of the step-up winding, when they approach each other by 5-10 mm, an arc is formed that stretches to 2 or more centimeters (depends on the power of the power transformer and the number of turns of the secondary). If there is no arc, then you should swap pins 1-2. If even after this there is no discharge, then most likely either the transistor is burnt, or the winding is burnt:((( I also want warn that if you, holding the plasma ball with one hand, accidentally touch the radiator with your hand, the transistor will die immediately, so it is better not to touch it with your hands while the line operator is working.

EXPERIMENTS WITH THE STRIKE: 1) Plasma ball. For this experiment you will need a regular light bulb. One terminal is grounded, the other is connected to the light bulb, and beautiful discharges are formed inside it. WARNING: At high power, discharges can cause the lamp to become very hot and cause burns. Also, do not touch the lamp with a metal object, because the arc will melt the glass and ruin the lamp. 2) Jacob's Ladder. These are two electrodes located as in the figure. An arc appears at the lowest point, the air heats up and rises, the arc also rises and goes out, then the process repeats. 3) Multiplier. It connects as shown in the picture. It is better to take the UN 9-27 multiplier. At the output of the multiplier, the discharge will be bright blue and three times longer than without it. ATTENTION: At the output of the line reader, the voltage is high, but the current is small. It can give you a strong electric shock and cause burns. However, the line current will never kill you :))) But the multiplier capacitors produce a current sufficient to cause your death =(((

The application of this device is very extensive. It is not limited to powering plasma balls and Jacob's ladders. It can be used as a gas lighter (it does not require much power), an air ionizer (you will have to assemble a multiplier for negative voltage, UN 9-27 will not work, it has a positive output voltage). Some say that not all line writers work in this scheme. This is an absolute lie. Not only line switches will work, but also any transformers with a ferrite core. You just need to know that line printers with a built-in multiplier are now sold. The device will work, but it will not power a plasma ball or Jacob's ladder. But if this is not necessary, then you can use this device as a low-power 12 V - 220 V converter, for example, to power an electric razor or light bulbs (in case of a power outage). To do this, you need to replace the line winding with a homemade one. At the same time, an electric razor requires direct current; it is necessary to install a diode bridge to rectify the current at the output. So, for assembly you will need: 1) Lineman; 2) Transistor KT805 or 2N3055 and a radiator for it; 3) Powerful resistors 27 Ohm and 240 Ohm; 4) Step-down transformer; 5) Rectifier diodes; 6) Electrolytic capacitor 10000 uF 50 V; As well as a piece of plywood, screws, nuts and other small items. GOOD LUCK!!!

Attention! The multiplier produces a very high DC voltage! This is really dangerous, so if you decide to repeat it, be extremely careful and follow safety precautions. After the experiments, the multiplier output must be discharged! The installation can easily kill the equipment, shoot digitally only from afar, and conduct experiments away from the computer and other household appliances.

This device is the logical conclusion of the topic on using the TVS-110LA line transformer, and a generalization of the article and forum topic.

The resulting device has found application in various experiments where high voltage is required. The final diagram of the device is shown in Fig. 1

The circuit is very simple, and is a regular blocking generator. Without a high-voltage coil and multiplier, it can be used where high alternating voltage with a frequency of tens of Hz is needed, for example, it can be used to power an LDS or to test similar lamps. Higher AC voltage is obtained using a high voltage winding. To obtain a high DC voltage, an UN9-27 multiplier is used. Fig.1 Schematic diagram.

Photo 1. Appearance of the power supply on TVS-110

Photo 2. Appearance of the power supply on TVS-110

Photo 3. Appearance of the power supply on TVS-110

Photo 4. Appearance of the power supply on TVS-110

Sometimes it becomes necessary to obtain high voltage from scrap materials. The line scan of domestic televisions is a ready-made high-voltage generator; we will only slightly alter the generator. You need to remove the voltage multiplier and horizontal transformer from the horizontal scan unit. For our purpose, the UN9-27 multiplier was used.

Literally any horizontal transformer will do.

The horizontal transformer is made with a huge margin; TVs use only 15-20% of the power. The stitcher has a high-voltage winding, one end of which can be seen directly on the coil, the second end of the high-voltage winding is located on the stand, along with the main contacts at the bottom of the coil (13th pin). Finding the high-voltage terminals is very easy if you look at the circuit of the line transformer.

The multiplier used has several pins; the connection diagram is shown below.

Voltage multiplier circuit

After connecting the multiplier to the high-voltage winding of the line transformer, you need to think about the design of the generator that will power the entire circuit. I didn’t bother with the generator, I decided to take a ready-made one. An LDS control circuit with a power of 40 watts was used, in other words, just LDS ballast.

Ballast is made in China, can be found in any store, the price is no more than $2-2.5. This ballast is convenient because it operates at high frequencies (17-5 kHz depending on the type and manufacturer). The only drawback is that the output voltage has a higher rating, so we cannot directly connect such a ballast to a line transformer. For connection, a capacitor with a voltage of 1000-5000 volts, a capacity of 1000 to 6800 pF, is used. The ballast can be replaced with another generator, it is not critical, only the acceleration of the line transformer is important here.

ATTENTION!!!

The output voltage from the multiplier is about 30,000 volts

, this voltage can be deadly in some cases, so please be extremely careful.

After turning off the circuit,

a charge remains in the multiplier;

short-circuit the high-voltage terminals

to completely discharge it. Do all experiments with high voltage away from electronic devices. In general, the entire circuit is under high voltage, so do not touch the components during operation.

The installation can be used as a demonstration high-voltage generator, with which a number of interesting experiments can be carried out.

“Audio & Video” - information on new audio, video equipment and accessories

: reviews of equipment (

video cameras

,

TVs

,

radios

,

DVDs

, etc.), tests, reviews, advice, everything that will help you navigate and make the right choice of this or that audio or video equipment.

Today, flat-panel LCD (LDC, TFT) or plasma digital TVs appear in almost all homes. And the good old tube ones go into exile in country houses, move to balconies, sheds or simply to a landfill.

And only radio amateurs consider an old TV that has become unnecessary as a source of radio components.

One of the key elements, without which the operation of a kinescope is impossible, is a line transformer.

This is the main part of the line scanning unit, which allows you to generate a very high voltage (about 25-30 thousand volts) at the anode of the kinescope.

This element looks like this (the image is given as an example, there are different types and types of these transformers).

Rice. 1. Linear transformer

Shouldn't you throw it away? With the right approach, it can find its place in everyday life. In extreme cases, it is perfect for experiments with high voltages.

What can be done from a liner

The first thing that comes to mind as devices with high voltages are plasma balls (Tesla coils) and “Jacob’s ladders”.

The first ones look like this.

Rice. 2. Plasma ball

Here, a budget incandescent lamp acted as a ball.

And the second one is like that.

Rice. 3. Jacob's Ladders

However, in addition to “toys”, more useful things can be done based on the liner:

1.Lighters (for household gas stoves);

2. Air ionizers;

3. Generators for igniting gas-filled lamps;

4. Welding machines (only with full rewinding of transformers).

But since the latest products are not as “spectacular” as the first, let’s look at a couple of examples with beautiful current arcs.

Tesla coil / plasma ball from a regular incandescent lamp

Since the secondary winding will be customized to suit your needs, only a line transformer that has access to the windings, for example, TVS90, TVS-110, etc., will be suitable for experiments. (from old Soviet TVs).

The schematic diagram is shown below.

Rice. 4. Schematic diagram

The secondary winding of the liner is left “as is”, and the primary winding is rewound (or wound over the existing one, if the design of the transformer allows). Make 5 turns of a thick wire with a diameter of about 2 mm (or several, but so that the total cross-sectional area is not less than the specified one). It is best to use insulated wire.

Please note that the lamp may not even be working (with a broken or burnt out filament). So it can actually get a second life.

The LC filter resistor may become quite hot, this is normal. This element should be designed to dissipate approximately 1-2 watts of power.

Another weak element of the circuit is the field-effect transistor. It must be installed on the heat sink using thermal paste (for better temperature conductivity). The heat sink area should be calculated from the 80 W figure received from the transistor.

This is the beauty that comes out in the end.

Rice. 5. Plasma ball

We are not talking about the film of the same name, or the stairway to heaven, but about an interesting phenomenon with electric arcs.

The fact is that during a breakdown, energy (heat) is released, which is transferred to the surrounding air. That, in turn, heating up, according to the law of convection, begins to rise upward, and with it the breakdown discharges between the two conductors rise (after all, the resistance of warm air is less than that of cold air).

So, here's the diagram.

The horizontal transformer itself undergoes the same “refinement”. The primary winding is made with your own hands from thick copper wire. For example, TVS -110L/6 can be used as a “donor”. 5 turns are wound.

The amplifier discussed in the previous diagram for the ball is already integrated into the UC3845 PWM controller.

The breakdown occurs at a distance of approximately 1.5-3 cm. It is at this distance that the electrodes should be installed.

The result may be something like this: a miracle.

Rice. 7. Jacob's Ladder

Safety precautions

The output from the transformer produces a voltage of several thousand volts with a current strength of 90 mA (this is enough to be fatal under certain circumstances).

Do not touch live parts under any circumstances, especially at the output of the line transformer.

If exposed to arcs for a long time, the glass of the lamp may melt, so do not touch it with your hands for a long time.

When turning on the device, it is best to perform all actions with one hand, after putting on dry shoes with rubber soles.

Linear transformers are among the most commonly used by high voltage hobbyists, mainly due to their simplicity and availability. Every CRT TV (big and heavy) that people throw away now has such a transformer.

Unlike many transformers found in other electronics, which are designed to handle regular 50Hz alternating current, and step-down transformers, a line transformer operates at a higher frequency, around 16KHz and sometimes higher. Many modern line transformers produce direct current. Old line transformers produced alternating current, which allowed you to do anything with them. AC line transformers are more powerful because they do not have a built-in rectifier/multiplier. DC line transformers are easier to find and are recommended for this project. Make sure your line transformer has an air gap. This means that the core is not a closed circle, but rather resembles the letter C, with a gap of about a millimeter. Almost all modern horizontal transformers have it, so if you are using a modern horizontal transformer, you don’t have to check this.

This circuit uses the 2N3055 transistor, which is what builders of line transformers love and hate. They are loved for their availability and hated because they usually stink. They tend to burn out quite spectacularly, but the circuit works incredibly well with them. The 2N3055 got a bad reputation when used in simple single-transistor circuits in which high voltage is present across the transistor. This circuit adds several parts that significantly increase its power output. The theory of operation of the circuit is written below.

Scheme

There are very few elements in this circuit, and they are all described on this page. And many parts can be replaced. The value of the 470 Ohm resistor can be changed. I used a 450 ohm resistor made from three 150 ohm resistors connected in series. Its value is not critical for the operation of the circuit, but to reduce heating, use the maximum resistor value at which the circuit operates. The lower resistor value can be changed to increase power. I'm using a 20 ohm resistor made from two 10 ohm resistors connected in series. The lower its value, the higher the temperature and the shorter the operating time of the circuit.

The capacitor located next to the transistor (0.47 µF) can be replaced to increase power. The higher its value, the higher the output current (and arc temperature) and the lower the voltage. I settled on a 0.47uF capacitor. The number of turns on the feedback coil (three-turn coil) can change the power output. The more turns, the greater the current, but not the voltage.

This circuit differs from the more common single-transistor casser in that a diode and a capacitor are added to it, which is connected in parallel with the diode. The diode protects the transistor from voltage surges of reverse polarity, which can burn the transistor. You can use a different type of diode. I used a GI824 diode taken out of the TV. When choosing a diode, pay attention to the voltage and switching speed. To find out if your diode is suitable, find the datasheet for the BY500 diode, and then for your diode and compare the parameters. If your diode is comparable to or better than this one, then it is suitable.

The capacitor is the key to high power output. The transistor generates a frequency set mainly by the primary coil and the feedback coil. The capacitor and primary winding form an LC circuit. The LC circuit operates at a specific frequency, and if you tune the circuit so that this frequency is the same as the transistor frequency, the output power will increase significantly. The theory of an LC circuit is similar to that of a Tesla coil. This circuit can be customized by changing the capacitor value and the number of turns on the primary/secondary windings. This circuit requires a powerful power supply, which is described below.

power unit

The circuit requires a powerful DC power supply with an output voltage of 12 to 30 volts and 1 to the number of amps you desire. It's a good idea to make a regulated power supply so that the circuit receives exactly the voltage it needs. If the circuit is not assembled correctly and a power supply like this is used, the circuit will burn out. But regulated voltage is not necessary for normal operation.

I used a 300 watt transformer from the amp. It has windings for 2, 4, 15, 30 and 60 volts. The circuit requires 12 to 18 volts for the 2N3055. I often run the circuit at 30V, but not for long, and the transistor is mounted on a powerful radiator. At 15V, the circuit can operate indefinitely, since after 30 minutes of operation, the temperature did not exceed room temperature.

The alternating current from the transformer goes to a 400 W bridge rectifier mounted on the radiator, and from it to a 7800 uF 70V capacitor to smooth out the voltage. Using similar components, you can make your own power supply.

Also, switching power supplies or UPS can be used as a power supply. They are found in laptop chargers, car battery chargers and computer power supplies. They often have a 12V output and a current of up to 10A, which is suitable for this circuit.

This is a very simple circuit to assemble. My assembly is not an instruction or an example, but you can repeat it. Everything is mounted on a piece of MDF, and the elements are laid out loosely to minimize interference from nearby wires and allow for cooling. Use stranded wire. Numerous photographs show in detail the various elements of the circuit, which are often more useful than words.

One of the most important points in the assembly is the transistor heatsink. 2N3055 is manufactured in the TO-3 package. You can buy TO-3 radiators, but they are a little hard to find. I used a heatsink from a computer processor with holes for its contacts on the flat side. Wires from the contacts pass between the blades. The transistor is attached to the radiator with self-tapping screws. Remember to use thermal paste between the transistor and the heatsink. The wires going to the line transformer are attached to it using alligator clips so that line transformers can be changed for experiments.

Another important point is the windings of the line transformer. Enamel insulation of copper wire is good, but it is better to add additional insulation between the core and the windings. The core may have sharp edges, and if the enamel is peeled off, a short circuit may occur. When winding the coils, I removed the metal clamp holding the halves of the transformer together, wound the coils, and then installed it again. On some transformers this is not possible, and the wire will need to be wrapped around the core. The windings must be wound out of phase, which means they wind around the core in opposite directions. This is shown in the photographs.

Usage

When using this circuit, do not perform any manipulations with the connected wires. Also check the temperature of the transistor and resistors during operation, but do this only when the device is unplugged. If any element is noticeably warm, then do not turn on the circuit until it cools down. Capacitors can retain a dangerous charge, so be careful.

Also, wear rubber-soled shoes when working with high voltages and touch the device while it is on with only one hand. Make sure the circuit has been connected to ground after operation to avoid electric shock. Do not attempt to configure an enabled circuit.

There are many things you can do with this circuit, such as using it to power a Tesla coil, melt salt, or just have fun with electric arcs.

List of radioelements

| Designation | Type | Denomination | Quantity | Note | Shop | My notepad |

| Bipolar transistor | 2N3055 | 1 | KT819GM | To notepad | ||

| Rectifier diode | BY500-200 | 1 | 200 B | To notepad | ||

| Electrolytic capacitor | 4700 uF 25V | 1 | To notepad | |||

| 0.47 µF 200V | 1 | To notepad | ||||

| Resistor |

Inverter circuits

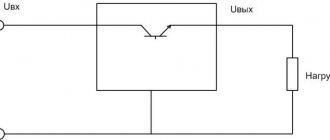

The resulting rectified voltage is supplied to the converter (inverter). It is performed on bipolar or field-effect transistors, as well as on IGBT elements that combine the properties of field-effect and bipolar ones. In recent years, high-power, low-cost insulated gate field-effect transistors (MOSFETs) have become widespread. It is convenient to build key inverter circuits on such elements. Switching power supply circuits use various options for connecting MOSFETs, but push-pull circuits are mainly used due to their simplicity and the ability to increase power without significant modifications.

Push-pull scheme

Push-pull converter circuit.

A push-pull inverter (push - push, pull - pull) is an example of a push-pull converter. Transistor switches operate on the primary winding of the transformer, consisting of two half-windings I and II. The transistors open alternately for a given period of time. When the top transistor in the circuit is open, current flows through half-winding I (red arrow), when the second one flows through half-winding II (green). To avoid a situation where both switches are open (due to the finite speed of the transistors), the control circuit creates a pause called Dead time.

Transistor control taking into account Dead time.

This circuit works well at low supply voltage (up to +12 volts). The downside is the presence of surges with an amplitude equal to twice the supply voltage. This entails the use of transistors designed for twice the voltage.

Bridge circuit

The push-pull bridge is free from the main drawback of the previous scheme.

Push-pull bridge inverter circuit.

Here, a pair of transistors T1 and T4 , then T2 and T3 (the key control signal is generated taking into account Dead time). In this case, the primary winding is connected to the power source first on one side, then on the other. The pulse amplitude is equal to the full supply voltage, and there are no voltage surges. The disadvantages include the use of four transistors instead of two. In addition to increasing the size of the power supply, this leads to doubled voltage losses.

Half bridge circuit

In practice, a half-bridge inverter circuit is often used - to a certain extent, a compromise between the previous two circuits.

Half-bridge circuit.

In this case, one side of the winding is switched by alternately opening transistors T1 and T2, and the other is connected to the midpoint of the capacitive divider C1, C2. Advantages of the scheme:

- unlike push-pull, there are no voltage surges;

- unlike bridge, only two transistors are used.

On the other side of the scale, the transformer winding is powered by only half the supply voltage.

Single-ended circuits

In the circuitry of converters, single-cycle circuits are also used - forward and flyback. Their fundamental difference from push-pull ones is that the transformer (more precisely, its primary winding) simultaneously serves as a storage inductance. In flyback circuits, energy is accumulated in the primary winding during the open state of the transistor, and is transferred to the load through the secondary winding during the closed state. In direct thrusters, energy accumulation and release to the consumer occur simultaneously.

Two phases of operation of a flyback single-cycle inverter.

Universal converter type

In order to make a step-up voltage converter with your own hands combined with a step-down voltage converter with your own hands, you will need to make some improvements and elements such as:

- high-voltage converter device up to 400 kiloVolt;

- module for enhancement;

- low-voltage conversion device 5Volt to 1.5Amp;

- 500W boost converter;

- voltage regulation kit.

The compact device produces high power with a single-cycle operating mode. Typically, such standard devices are capable of performing only one function. Increase or raise the voltage. A universal proprietary solution can combine these two features.

To test self-made devices, a variety of power supplies are used. The devices can be charged and used for various tasks.

Power transformer

The power transformer operates at high frequencies (up to several tens of kilohertz), so it can be made on a core made of ferrite rather than transformer iron. Also, due to the increased frequency, its dimensions will be smaller than that of a network one, designed for conversion at a frequency of 50 Hz. The calculation of a pulse transformer is quite extensive. You can understand it for general development, but for practical purposes it is better to use some program, including online services.

Interface of the Lite-CalcIT program.

The Lite-CalcIT program is popular. She can calculate a transformer for an existing core, or she can select the optimal one based on the entered data.

Testing the converter in action

The inverter can withstand 10 minutes of continuous operation, after which the transformers begin to require cooling. The transistors do not heat up too much - the heatsinks remain almost cold. Most of the heat is generated on the bridge rectifier, which can get quite hot - it also has a large radiator.

Useful: Do-it-yourself air ozonizer (for home or car)

The inverter is capable of delivering large discharges due to its significant current efficiency. The maximum length of an extended zipper is just over 20 cm.

We will also show oscillogram signals: The first is a sinusoid on an LC circuit without a lit arc. The last screenshot shows a sequence of pulses on one of the field keys.

Snubber

To compensate for current and voltage surges that inevitably arise when switching the primary winding of a transformer, damper circuits are used, called snubbers in English technical literature. Such circuits can be installed along the power supply (parallel to the primary winding of the transformer) or separately on each switch. The design of snubbers can be different, but the most widespread are dampers in the form of a sequential RC chain (diagram b in the figure).

Various damper schemes.

There is no substantiated method for calculating a snubber. To do this, it is necessary to take into account all parasitic inductances (windings, tracks, capacitors) at many frequencies and for unknown wave impedances. Therefore, all existing calculations are empirical in nature.

The main (and only) active element of the damper is the capacitor. It “absorbs” impulse emissions. The resistor only worsens the damping properties, but limits the current through the capacitor, which can reach significant values, albeit for a short time. This scheme is more relevant in thyristor converters.

You can find out what a snubber or damper is by watching the video.

The RCD snubber circuits (c and d in the figure) contain diodes. They can be useful for limiting reverse polarity pulses in thyristor and bipolar transistor circuits. If the switches are assembled on field-effect or IGBT transistors, then there is no point in installing valves - they duplicate the diodes present inside these transistors.

The capacitance of the capacitor is selected in the range of 0.1–0.33 μF. In 90+ percent of cases this is enough. An increase or decrease in value is used for keys operating under non-standard conditions (increased conversion frequency, etc.)

Verification methods

An oscilloscope is used to check the device. The device is connected to the output of the secondary circuit through a 10 ohm resistor. The need to replace or repair the device arises when the following deviations are detected:

- the appearance of a short circuit between the turns, with the test device displaying a “rectangle” in case of large interference. If the specified check does not show a malfunction, the deviation may be several fractions of a volt;

- if there is no voltage at the output, a complete replacement of the output coil is required due to a broken wire;

- after removing the 10 Ohm resistance, a load of up to 1 kOhm is created on the secondary coil and the output voltage parameters are measured. If everything is in order, it matches the input characteristics. If there is a deviation, repair or complete replacement is required.

Other malfunctions are less likely to occur and are not difficult to determine independently by a person with an initial level of knowledge in the field of electrical engineering.

If a breakdown of the transistor is suspected, this element is removed and the operation of the device is checked without it. If the specified characteristics are significantly exceeded, the element must be replaced with an identical one.

Rewinding a reel is a rather labor-intensive operation. Therefore, it is easier to replace the circuit than to restore it.

Also, during the inspection, faults may be indicated by traces of burning on parts and visible broken contacts. Faulty elements should be replaced; it would not hurt to additionally solder the contacts.

Rectifier

The voltage of the secondary winding must be rectified. For levels up to 12 volts, it is advisable to use a full-wave, midpoint circuit.

Diagram of a rectifier with a midpoint and the passage of current through it.

The advantage of this circuit is that the current flows in each direction through only one diode, and the voltage drop across the valves, in contrast to the classic bridge circuit, is half as much. This can significantly reduce the required number of turns of the secondary winding. The same purpose is served by the use of Schottky diodes and assemblies of them.

Bridge rectifier circuit and current flow through it.

If the output voltage of the power supply is higher than +12 volts, then saving 0.6 volts becomes insignificant, and you can make a rectifier according to the standard circuit and use a transformer without a tap.

If the output of a switching power supply must be bipolar, tapping from the midpoint again becomes rational. In this case, 4 diodes and radiators for them are saved at once - the gain in size can be significant.

Bipolar rectifier with midpoint.

Frequent breakdowns and repair methods

Line-type transformers often fail. Further operation of the TV in this situation is impossible. Replacing the device is associated with difficulties caused by their high cost. Some models of such transformers are difficult to find.

The repair process requires replacement of the defective circuit. During operation, the following malfunctions may occur:

- circuit break;

- breakdown of the sealed housing;

- interturn short circuit of windings;

- Potentiometer contact breakage.

The first two of these faults are quite easy to identify based on the results of an external examination. Repair is carried out by replacing failed elements, the search for material for which does not present any particular problems, since it is not difficult to find in any radio goods store.

Also read: Isolation transformer

Finding a short circuit between the turns of the windings is somewhat more difficult. Such a malfunction can be determined by the squeaking sound produced by the transformer during operation. In this situation, diagnostics are performed using a special device.

Filter

The output voltage must be filtered - it contains a large number of conversion products. Since the inverter operates at a fairly high frequency, filters containing not only capacitors, but also small-sized chokes with relatively low inductance become effective.

L- and U-shaped LC filters.

To calculate the filter elements, it is necessary to specify the pulsation coefficient Kp. It is selected from the expected load:

- sensitive equipment for radio reception, preliminary stages of audio equipment, microphone amplifiers - Kp = 10-5..10-4 ;

- audio frequency amplifiers – Кп=10-4..10-3 ;

- middle and low class receiving and sound reproducing equipment – Kp=10-2..10-3 .

For an L-shaped filter installed after a full-wave rectifier, the following relations apply:

- L*C=25000/(f2+Kp);

- L/C=1000/R2н.

In these formulas:

- L – inductance of the inductor in µH;

- C is the capacitance of the capacitor in microfarads;

- f – conversion frequency in Hz;

- Rн – load resistance in Ohms.

For U-shaped filter:

- С1=С2=С;

- L/C=1176/R2н.

The dimension of the values is the same as for the previous filter.

Manufacturing a high-voltage module from an energy-saving lamp

And such a device can be easily made with your own hands. But where can I get a high-voltage module? You can use a regular incandescent light bulb. At first we wind no more than 80 skeins. The second layer is 400-600 turns. Between each layer, do not forget to insulate with tape.

To test the device, we connect it through a 35 W limit light bulb. The result is a fairly powerful high-voltage ignition module.

Circuits and manufacturing of switching power supplies

Switching power supplies are assembled on various element bases. Typically, specialized microcircuits specially designed for creating such devices are used to build SMPS. Except for the simplest blocks.

Powerful pulse unit on ir2153

Simple power supplies can be built on the IR2153 chip. It is a powerful integrated driver with a timer similar to the NE555. The generation frequency is set by external elements. The microcircuit does not have inputs for organizing feedback, so current and voltage stabilization cannot be obtained using the PWM method.

Pin layout of the IR2153 chip.

The assignment of the pins is given in the table.

| № | Designation | Purpose | Purpose | Designation | № |

| 1 | Vcc | Power supply for logic and drivers | Power output switches | Vb | 8 |

| 2 | Rt | Frequency setting resistor | Top Driver Output | HO | 7 |

| 3 | Ct | Frequency setting capacitor | Top Driver Power Return | Vs | 6 |

| 4 | COM | General | Bottom Driver Output | L.O. | 5 |

Internal circuit of IR2153.

To better understand the operation and pin assignments, it is best to study the internal circuitry. The main point that you need to pay attention to is that the output switches are assembled using a half-bridge circuit.

Using this chip you can assemble a simple power supply.

Scheme of a simple power supply based on IR2153.

The IR2153 is powered by 220 volts through a quenching resistor R1, a diode rectifier VD3, and a filter on C4. The generation frequency is set by elements C5, R2 (with the values indicated in the diagram, it turns out to be about 47 kHz). A transformer can be considered a program. The author's version used a power transformer from a computer power supply. The standard windings have been removed, the primary is wound into two cores with enamel insulated wire with a diameter of 0.6 mm.

Other breakdowns

There are many reasons why TDKS does not work. Experienced radio amateurs can help you examine common faults.

If a transistor is broken in the device, you need to remove it and measure the collector voltage without it. If the indicator is determined to be too high, it is adjusted to the required value. If it is impossible to perform such a procedure, you need to change the zener diode in the power supply. You definitely need to install a new capacitor.

It is recommended to check soldering on all connectors. If necessary, it is strengthened. If such a problem is detected on the capacitors, they are soldered off. Examination may reveal blackening. You will need to purchase a new part. If the rectangular capacitors are swollen, they should also be replaced. If rosin remains are visible, they should be removed with alcohol and a brush.

If the transistor constantly breaks through in the line scan, the type of malfunction should be determined. The breakdown can be thermal or electrical. It is a faulty transformer that leads to such a problem.