Operating principle and main elements of an infrared heater

To make an infrared heater from scrap materials, it is necessary to study the operating principle. How can you do something you know nothing about?

All heated bodies radiate heat, just like the Sun does. The rays emanating from a heat source are electromagnetic waves that heat bodies encountered in their path: pieces of furniture and people. In this case, the air does not heat up: the air receives only part of the heat during heat transfer from already heated bodies. Infrared heaters operate on the principle of thermal radiation, which includes two main elements:

- Radiation source . In industrial heaters, these are thin metal filaments that heat up when an electric current passes through them, or lamps (incandescent, halogen, quartz and others);

- Reflector . This is a highly reflective body, the function of which is to reflect infrared rays to disperse heat throughout the apartment or form separate heated zones.

Advice! To check the effect achieved by the reflector, take some food foil and hold it near your hand for a while. You will feel the heat, which is reflected and directed towards you.

Another important part in industrial infrared fireplaces is the controller, which regulates the degree of heating of the emitter. It may not be present in homemade designs. But its installation gives the advantage of being able to set the desired temperature range. The controller automatically causes the device to heat up if the temperature drops below normal, and cool down if the temperature exceeds it.

If you study the infrared ceiling heater, the operating principle will be the same as that of the floor/wall design. The only difference is in the installation method of the IR fireplace. But it depends on him which zones in the room will be more comfortable.

The figure shows the advantage of infrared heaters: heat reaches physical bodies and is absorbed by them, remaining there. Therefore, it may be warmer on the floor than under the ceiling. And when heating a house using the convection method, the floor is always cold: the coating itself does not receive heat. Heat is carried by air, which, when heated, rushes upward, and a new portion of cold air falls down.

How much light and heat does a light bulb provide?

Therefore, we will consider another more efficient and durable design, assembled on the basis of simple incandescent lamps.

An ordinary light bulb with an incandescent filament is the most accessible source of not only light, but also heat. Of its entire radiation spectrum, we see only a small part.

Everything else is hidden from us in the infrared region.

As an efficient light source with its efficiency of 3%, the light bulb is no good.

But if we consider it from the point of view of heat, then the efficiency is already approaching 100%.

How to increase the efficiency of the light? For example, you can increase the voltage.

However, at the same time, its lifespan will sharply decrease. She will live with you for literally a few hours.

But if you do the opposite, that is, reduce U=220V by half, this will sharply reduce the light output by five times. But at the same time, almost all the useful energy will go into the IR spectrum.

Of course, it will not increase, and its overall level will fall from its original values. However, the level of the visible spectrum will drop even more. The whole point here is that your assembly should primarily heat, not shine.

The most important and significant advantage of this is the increase in lamp life to almost 1 million. hours (over a hundred years).

That is, you buy it once and you can use it for the rest of your life! How can you reduce the voltage at home without any regulating devices, like LATR?

Cheap and cheerful

Typically, devices that are heated by electricity are used as an emitter - incandescent filaments or lamps. But the simplest version of the emitter is a heating radiator. This is the same physical body as the Sun. And it can also emit heat. Stand by the radiator and feel the emanating heat - this is radiation. It just spreads in all directions. Why heat the walls if you can direct the rays towards the living space?

Take the foil, smooth it well to improve the reflective effect and stick it on the wall behind the radiators and radiators. As a result, the heat that the walls could receive will be directed in the opposite direction - towards you. This method helps to get up to 20% more heat without any tricks. The only drawback is the ugliness of the reflective screen: it spoils the interior.

Attention! Instead of foil, you can use heat insulators with a reflective screen. A striking example is the material penofol, one or both sides of which are foil-coated.

Incandescent lamp + regulator = IR device!

IR heaters for apartments (houses), premises - choice, characteristics

Answer

Posts: 12 • Page 1 of 2 • 1 ,

Incandescent lamp + regulator = IR device!

Sergey N » March 17, 2014, 11:40

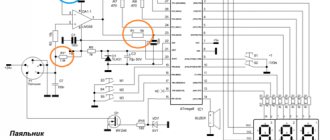

5 years ago I had only 3 battery sections in my apartment, and the apartment was a corner one. To say that it was cold would be an understatement!) I figured out how to warm myself up; at that time there was no money for a heater. I took a halogen lamp with a reflector, attached a battery of capacitors to it in the gap and placed it under the table. The result is an IR device that does not burn oxygen. True, its power turned out to be small, only 150W.

The most economical gas heaters + reviews - https://www.optcentre.ru/topic/3185-otzy ... #entry4007

Sergey N

Messages: 2684 Registered: March 11, 2012, 23:18 From: Kazan

Return to top

Incandescent lamp + regulator = IR device!

Sergey N » March 17, 2014, 11:44

I also wanted to add - the lamp works forever in this mode! You can take a bi-projector of 1 kW each and run it. You get a decent 500W of power (at full heat). Such devices can be used for safe drying of paintwork, walls, and basements. So, according to the passport, the distance from the end of the spotlight should not be less than 1 m if the lamp operates at 230V. I had somewhere between 80-100V on it Attachments light_equipment_clip_image001_0001.jpg (28.83 Kb) Views: 3756

The most economical gas heaters + reviews - https://www.optcentre.ru/topic/3185-otzy ... #entry4007

Sergey N

Messages: 2684 Registered: March 11, 2012, 23:18 From: Kazan

Return to top

Incandescent lamp + regulator = IR device!

Anatoly » Mar 20, 2014, 01:22

Sergey N wrote: About 5 years ago I had only 3 battery sections in my apartment, and the apartment was a corner one. To say that it was cold would be an understatement!) I figured out how to warm myself up; at that time there was no money for a heater. I took a halogen lamp with a reflector, attached a battery of capacitors to it in the gap and placed it under the table. The result is an IR device that does not burn oxygen. True, its power turned out to be small, only 150W.

150 W is pretty decent power. I wonder what the temperature was on the surface of the lamp??? In fact, Ilyich incandescent lamps with a power of 150 W burn oxygen very well. If possible, then look at the ceiling or wall on which such a lamp is placed. And you will see that the ceiling is turning black with soot as a result of burning dust. On the wall there is a black trail of soot again. A friend of mine used a red lantern for photo printing as a local heating device. True, I put a 25 W light bulb there. The lantern was metal, the glass was red, and it was used instead of a heating pad... Anatoly Messages: 1707 Registered: April 3, 2013, 01:23

Return to top

Incandescent lamp + regulator = IR device!

Bibikin Ivan » March 20, 2014, 11:28

A friend of mine used a red lantern for photo printing as a local heating device. True, I put a 25 W light bulb there. The lantern was metal, the glass was red, and it was used instead of a heating pad... An interesting invention! 25W is a small power, plus red glass, which further attenuates radiation. This is how it works with dust burning. I also noticed more than once that burnt dust remained on the ceiling, and attributed such phenomena to convection. The temperature of the lamp is not 600C to burn oxygen and fry dust, and there is no smell of burning during its operation. Idk.

We are moving to live on a desert island! With us?! — https://www.neobitaemyi.ru/

Bibikin Ivan

Messages: 1662 Registered: May 16, 2012, 14:10 From: Moscow

Return to top

Incandescent lamp + regulator = IR device!

Anatoly » March 22, 2014, 00:17

Bibikin Ivan wrote: A friend of mine used a red lantern for photo printing as a local heating device. True, I put a 25 W light bulb there. The lantern was metal, the glass was red, and it was used instead of a heating pad... An interesting invention! 25W is a small power, plus red glass, which further attenuates radiation. This is how it works with dust burning. I also noticed more than once that burnt dust remained on the ceiling, and attributed such phenomena to convection. The temperature of the lamp is not 600C to burn oxygen and fry dust, and there is no smell of burning during its operation. Idk.

It's burnt dust. And that’s right, first the dust rises to the lamp by convective flows, then it burns, then again, due to covection, it goes up and is safely deposited on the walls and ceiling along the movement of the convective air flow. This phenomenon manifests itself especially well in entrances, since there is more than enough dust there and the lamps burn without turning off for quite a long time. The temperature on the surface of the lamps reaches 400 C, and this is already the burning temperature of wood. My sister personally “hung” my trousers on a floor lamp for local illumination with a 60 W bulb. The result was a nice hole. In addition, a warrant officer I know decided to quickly dry his wet gloves... There was almost a fire... And incandescent lamps in my practice were used by guest workers from Moldova. A few bricks, one 500 W lamp and dinner is guaranteed... It didn’t come to automation... but they used 100% lamps with a “regulator”... Anatoly Messages: 1707 Registered: Apr 03, 2013, 01:23

Return to top

Incandescent lamp + regulator = IR device!

Igor_01 » March 27, 2014, 12:16

pm If the list goes on, I can add that my brother used to solder using a halogen lamp, albeit with a reflector. The temperature rose to +350C, I once dried something with this lamp and burned the keyboard. The surface temperature of metal halide lamps can reach 600C. I’ve even seen lamps with fused end caps, it gets so hot in them! So the insidiousness of the IR spectrum should not be underestimated! Attachments 209187047.jpg (228.4 Kb)

Climate equipment supply network - https://www.optcentre.ru/topic/1842-nuzh ... ht/?p=2605 - https://www.optcentre.ru/

Igor_01

Posts: 2010 Registered: Apr 13, 2012, 12:23 PM

Return to top

Incandescent lamp + regulator = IR device!

Anatoly » March 27, 2014, 20:00

Igor_01 wrote: If the list continues, I can add that my brother used to solder using a halogen lamp, albeit with a reflector. The temperature rose to +350C, I once dried something with this lamp and burned the keyboard. The surface temperature of metal halide lamps can reach 600C. I’ve even seen lamps with fused end caps, it gets so hot in them! So the insidiousness of the IR spectrum should not be underestimated!

Yeah... The picture shows a lamp for a car headlight... Such lamps have two spirals and if one burns out, you have to replace the lamp with a new one. And the high beam power is 90 - 100 W. Therefore, it is possible from such waste lamps to build a heating garland with a power of 1 - 1.5 kW, and it will also provide light... And if you install a regulator, it will turn out to be a functional IR device... Anatoly Messages: 1707 Registered: Apr 03, 2013, 01: 23

Return to top

Incandescent lamp + regulator = IR device!

Bibikin Ivan » March 28, 2014, 08:29

Halogen lamps are dangerous, the glass temperature can reach 600C, which is significantly higher than standard incandescent lamps and even 220V halogen lamps. But in my opinion, for IR devices it is better to use high-power lamps with a developed filament, it will produce more heat. And car H4 lamps are better only for light. By the way, if one of the spirals burns out, this one can be used for a long time, say, in a chandelier at home! And in 99% of cases the low beam filament burns out, but the powerful 100W high beam remains intact!

We are moving to live on a desert island! With us?! — https://www.neobitaemyi.ru/

Bibikin Ivan

Messages: 1662 Registered: May 16, 2012, 14:10 From: Moscow

Return to top

Incandescent lamp + regulator = IR device!

Anatoly » March 28, 2014, 6:49 pm

Bibikin Ivan wrote: Halogen lamps are dangerous, the glass temperature can reach 600C, which is significantly higher than standard incandescent lamps and even 220V halogen lamps. But in my opinion, for IR devices it is better to use high-power lamps with a developed filament, it will produce more heat. And car H4 lamps are better only for light. By the way, if one of the spirals burns out, this one can be used for a long time, say, in a chandelier at home! And in 99% of cases the low beam filament burns out, but the powerful 100W high beam remains intact!

Ivan!!! You won’t be able to use such a car light bulb in a chandelier at home... Firstly, the base is not the same at all... Well, unless you have car headlights in your home chandelier... Then yes, this is a way out. Secondly, you need a voltage of 12 volts. And for this you will have to at least install a transformer or turn on a 1.5 kW oil heater as ballast. There are electronic ballasts and simple ones... And there are also very powerful factory ballast modules. For example,... [Now any fantasy has the right not only to life, but also to practical implementation... Incandescent lamp + adjustable module = real IR device!!! All that remains is to start... Anatoly Messages: 1707 Registered: Apr 03, 2013, 01:23

Return to top

Incandescent lamp + regulator = IR device!

Senya » May 29, 2014, 11:43 pm

Why do homemade devices even need any kind of regulators?

I just can't understand this. Make a garland from a bunch of light bulbs, put two toggle switches and you can turn your power as you want without any regulators. Since the brightness of the glow changes, your IR device will fully meet all your requirements. The most important thing here is fire safety and correct orientation of the filaments. In general, there is prospects for creating a homemade adjustable IR device. Good luck! Senya

Return to top

Answer

Posts: 12 • Page 1 of 2 • 1 ,

Return to Infrared heaters

Who's at the conference now?

Registered users: no registered users

Switch to mobile style

The old Soviet reflector is in use!

A homemade infrared heater can be made from an old Soviet-made reflector. In addition to this, you will need:

- Nichrome thread;

- Steel rod;

- Fireproof dielectric (ceramic plate is suitable).

To make an IR fireplace from these things, follow the instructions:

- Remove dirt from the reflector;

- Check the plug, cord and terminals to turn on the coil (they must be intact);

- Measure the length of the spiral that is wound around the reflex cone;

- Cut a steel rod the same length as the spiral;

- Wind a nichrome thread onto the rod so that there are 5 turns for every centimeter;

- Carefully remove the rod from the nichrome winding;

- Place the spiral on a plate (another dielectric) so that the turns do not touch each other;

- Connect the ends of the nichrome spiral to the mains;

- Now the heated spiral will easily fit into the grooves of the cone from the reflector;

- Connect the ends of the spiral to the contacts.

The nichrome filament glows better than the spiral that was in the device before our manipulations. As a result, we get a powerful emitter, the energy of which is reflected from the walls of the reflector and hits opposing bodies, which begin to absorb heat.

Video material

These are just four simple ways to create an infrared heater with your own hands. In fact, there are much more of them. The question involuntarily arises: do you need it? There’s a lot of fuss, and it’s not a fact that everything will work out as it should. But:

- Firstly, knowledge is never superfluous.

- Secondly, you kill two birds with one stone. You get a useful device and get rid of a bunch of unnecessary junk.

Maybe it's worth a try?

Heater glass + aluminum foil

You will need:

- Foil;

- Two glasses of the same size;

- Paraffin candle;

- Sealant;

- A wire with a plug at the end;

- Cotton napkin;

- Boxed;

- Cotton swabs;

- Any device for holding a candle.

Step-by-step instruction:

- Clean the glass with a napkin from paint, dust, grease;

- Light a candle. Place it in a glass, candlestick, or simply drip paraffin onto a flat surface and quickly place the candle on the puddle;

- Smoke the glass on one side by passing it over the fire at the same speed. The soot will lie evenly if the glass is cooled before the procedure. The dark layer will eventually become a conductive element;

- Run cotton swabs around the perimeter of the glass pieces so that you get a frame of clean glass 0.5 centimeters thick;

- Measure the width of the smoked rectangles on the glass with a ruler;

- Cut two rectangles of the same width from foil - these will be electrode strips;

- Take one glass and place it with the smoked side up;

- Apply boxing agent to it and place rectangles of foil on the edges so that they extend beyond the glass;

- Place the second glass on top with the smoked side down and press well so that the structure sticks well;

- Along the perimeter of the “layer cake”, spread sealant at the joints of the glass;

- Check the power of the structure. If it is not higher than 100 W per square meter of room, then the heater can be connected to the network using a wire and plug;

- To connect to the network, use a wooden block with metal plates reinforced at both ends. Solder a plug to one contact. If you install the glass on a block so that the foil coming out from the sides fits tightly to the metal contacts, you get a full-fledged heater.

Attention! To calculate the power of a structure, use a multimeter to measure the resistance of the conductive layer. Since the current strength in the circuit depends on the load, it is better to calculate the power using a more stable parameter - this is the voltage, which in the network is equal to 220 Volts. To do this you will need the formula: N=U*U/R .

N – required power. U – voltage (220V). R – measured resistance. Example: when measuring, we got 24 Ohms. Substitute into the formula: N=220*220/24. We get 2016 watts. This is enough to heat a room with an area of 19-20 square meters.

If your power is more than 100 watts per square meter, then it needs to be reduced by increasing the resistance (we cannot change the network voltage). If the power is very low, then it needs to be increased.

What to do if the power is not suitable?

Now let’s talk about how to make an infrared heater with your own hands of the required power. To do this, you need to know the area of the room you want to heat. For example - 15 meters. Now you need to calculate the maximum permissible power at the rate of 100 watts per meter. Since we have 15 of them, the power will be 15 * 100 = 1500 Watts (it is necessary to count in them, despite the fact that in the passports of electrical appliances it is indicated in kW).

If the voltage is constant (220 Volts), then you can calculate the required resistance. To do this, we derive the resistance from the formula given above: R=U*U/N. Substituting the calculated power and voltage into the formula, we get: R= 220*220/1500=32 Ohms (approximately).

In the example above we had 24 ohms. This means that the resistance needs to be increased. To do this, you need to reduce the width of the smoked strip on the glass. This comes from the formula R=l*p/S . Where l is the length of the conductive layer (a constant value, because we will not cut glass), p is the resistivity (constant), S is the cross-sectional area of the conductive layer, which depends on its width. The wider the layer, the lower the resistance, the narrower it is, the greater it is.

Conclusion! To achieve the required resistance, you need to select it experimentally, making the soot strip narrower or wider, depending on whether you need to increase or decrease the resistance. In this case, each time you will have to disassemble the glass structure.

Operating principle

Unlike a conventional heater, an infrared heater does not heat the air in the room. It heats objects caught in the path of infrared rays. And they, in turn, share their heat with the air.

The main components of an infrared heater are:

- Heating element-emitter.

- Reflector (reflective part).

What to assemble an IR heater from?

- To make your own reflector, use polished steel or aluminum. The reflector is designed to direct the radiation flow to the desired area.

- The heating elements in an infrared heating device are lamps: quartz, carbon or halogen.

Differences between heater lamps, or which ones to choose

In order to personally understand which lamps are best to take to make an infrared heater with your own hands, let’s look at some of their features:

- The cost of devices with halogen lamps is lower than carbon and quartz lamps.

- There is a myth that a quartz heater has a beneficial effect on people's health. This statement has nothing to do with the truth.

- Despite all its cheapness, a halogen device has a significant drawback: when it operates, the lamp glows. Naturally, it is not suitable for either a child’s room or a bedroom.

Important! In addition to the reflector with the emitter, the infrared heater is equipped with a thermostat and a fire hazard sensor. The thermostat is designed to maintain the set temperature, and the sensor automatically turns off an overheated device.

Now, armed with basic knowledge about the operation of an infrared heating device, let’s move on to making it ourselves.

Heater based on laminated plastic

To assemble a homemade infrared fireplace you will need:

- Laminated paper plastic - 2 pieces with an area of 1 square meter;

- Boxed;

- Graphite (you can buy powder or get it from old batteries, from a pencil - but you will have to crush it);

- Copper plates;

- Wood;

- Plug with cord.

If everything is there, start assembling:

- Mix graphite powder with bauxide to form a thick mass with high resistance;

- Place the plastic sheet with the rough surface facing the table;

- Apply bauxide mixed with graphite onto the plastic using zigzag strokes;

- Prepare the second sheet of plastic in the same way;

- Glue both plastic sheets together, pressing them tightly together;

- On opposite sides of the plates, attach copper plates that will act as terminals;

- Build a wooden frame into which you will need to insert the resulting structure;

- Allow the future heater to dry;

- Measure the conductor resistance and calculate the power.

Attention! Here, the calculation of power and resistance is carried out using the same method as in the previous case. Only the resistance will depend not on the width of the conductive layer, but on the graphite content in the box. The more powder, the higher the resistance, and vice versa.

You will have to disassemble and reassemble the structure several times before you experimentally achieve the required power. Only then can you connect the device to the plug and connect it to the network for operation.

Rules for using a halogen heater

Ceiling models are the easiest to maintain and only require cleanliness. Experts recommend installing wall and floor devices at a distance of 1 m from objects.

Placing any items directly on the heater is prohibited. It is also impossible to cover a halogen device. This may cause a fire. To avoid thermal burns to the skin, do not touch the device during operation.

A halogen device emits short light waves, which negatively affects the human body. Therefore, experts recommend not to be under the influence of direct radiation.

Attention! In the case of a large room area, preference should be given to two low-power halogen heaters instead of 1 powerful one. This will reduce the influence of harmful factors.

Safety precautions when operating a halogen heater are mandatory

Preference should be given to models whose housing is grounded, has a thermostat and a safety button.

The device should be promptly cleaned of accumulated dust, as it can be a source of ignition.

The heater body must be equipped with a front protective mesh.

Mini heater made from a shoe polish can

Prepare materials:

- Flat shoe polish box;

- Two conductors;

- Can;

- Graphite powder;

- Sand;

- Plug.

Step-by-step instruction:

- Wash the box;

- Mix sand with graphite powder, taking them in equal quantities;

- Pour the mixture into the box, filling it halfway;

- Cut a circle out of tin;

- Attach a wire to it;

- Place the circle on top of the graphite-sand mixture;

- Add enough sand and graphite until the jar is full;

- Close the jar with a lid to create pressure inside;

- Connect the second wire to the body of the can and connect it to the network using a plug (you can use a car battery).

To regulate the degree of heating, screw the lid of the jar looser or tighter to change the pressure inside. The tighter the jar is twisted, the stronger the heating, and vice versa. But do not allow it to overheat, at which point the jar begins to emit yellow or orange light rays. In this case, the contents inside the can are sintered, causing the efficiency of the heater to decrease significantly. To improve performance after sintering, you need to shake the jar vigorously - then the graphite-sand mixture will again become loose and suitable for work.

How to choose a halogen heater

When choosing a heating device, be guided by the following requirements:

- 10 m2 requires 1000-1300 W of power;

- the case must be aesthetically pleasing, functional, have an insulator, a safety button and a grounding device;

- device reliability;

- safety of the inner flask;

- the device must have an overheating sensor and a temperature control toggle switch;

- quality of halogen device, manufacturer's reliability, warranty service.

Advantages of homemade heaters

A do-it-yourself dacha heater and homemade heating devices for the home have one undeniable advantage over their factory-made counterparts. The first ones are made from improvised means, and therefore their cost is low. On the other hand, homemade equipment must be made in strict accordance with the rules for the safe operation of electrical and gas appliances. Today you can make your own IR heaters, which are considered the most effective and inexpensive. If you need a device with increased power, you can make an oil radiator at home. There are schemes for making home convectors and portable stoves for tents.

The need for comfortable warmth increases in the off-season and with the onset of cold weather. But not all homeowners have the opportunity to purchase reliable factory-made heating equipment, the cost of which is often inflated. In this case, an alternative option is a homemade heater made from available materials, which can easily cope with the task.

Infrared device option 3

Its manufacture requires the use of graphite. In addition to this, you need to prepare:

- A flat box, such as shoe polish.

- Pure river sand.

- Fork.

- Two wires.

- Pliers.

- A sheet of tin with dimensions not exceeding the same characteristics of the box.

The production of an infrared heater includes the following steps:

- Removing cream residue from the box and washing it. It should look like a mirror.

- Grinding graphite and mixing it with sand. Proportions: one to one.

- Place the prepared mixture in a container. Only fill half the box with the mixture.

- Cutting a circle or square from a sheet of tin. The blank must match the shape of the box and be placed in the middle of the box.

- Attaching one of the wires to a tin circle. To do this, use pliers. Next, the sheet metal with pliers is installed.

- Cutting a small hole in the side wall. It is necessary for the wire output.

- Further filling of the box with graphite and sand. The mixture is poured so that a dome-shaped top is formed.

- Blockage of the structure with a lid. The latter is pressed tightly, compressing the graphite with sand. Due to this, excess pressure is formed in the middle.

- Connecting the second wire to the box body.

- Installation of plug or terminals for battery. They are installed at the ends of the wires.

The made IR device is very easy to use and can be suitable for any room. especially for the garage. It is small and installation is very easy. It is able to work for a long time, because there is virtually nothing in it to burn out. Thanks to this, there will be no need for frequent repairs.

To control the IR heater, you need to change the position of the lid. The closer it is to the base, the greater the pressure inside becomes and the more the entire structure heats up. To reduce power, unscrew the lid or lift it higher.

Over time, its contents “sinter.” Therefore the power decreases. A small repair to restore power involves loosening the graphite. You can also shake the heater.

What is warmer, a convector or an infrared heater Infrared electric heater Convective infrared heater Infrared gas heater

Solid fuel heating of the garage

The easiest way to organize economical heating of a garage in winter is to use solid fuel equipment.

Firewood is quite cheap, burning with it is very easy, simple and relatively safe. And to burn them, you can build a stove of any type. If you need to organize homemade heating in the garage as cheaply and quickly as possible, it is best to turn your attention to a potbelly stove type stove. A potbelly stove is the simplest heating unit

Structurally, it consists of two parts - a combustion chamber and a chimney. The ash pan door and the loading door are located at the front. A chimney is diverted from the rear. You can create a potbelly stove for organizing heating in the garage from a variety of materials:

A simple potbelly stove is usually the most commonly used unit for heating a garage, due to its unpretentiousness and low cost of fuel.

- From an old gas cylinder;

- From a steel can;

- From an old barrel;

- Made from sheet iron.

There are dozens and even hundreds of drawing options, so there will be no problems with assembly.

The most economical way to organize autonomous heating in a garage is to use a Buleryan solid fuel stove. This oven is a convection oven, it is characterized by very high performance and can be used to heat any technical premises. Buleryan can be purchased ready-made or assembled yourself. When creating garage heating with your own hands, remember that Buleryans are pyrolytic - this ensures maximum heat transfer and long-lasting combustion.

Making heating in the garage with your own hands is not difficult - all you need is to have at your disposal the appropriate equipment or tools for its manufacture. For example, we can assemble a fireplace-type stove in the garage. Having found the drawings, nothing will prevent you from making a homemade Buleryan or installing a fireplace stove with a water circuit - this option is useful when creating heating in large areas.

If you want to heat your garage as economically as possible, use ready-made factory equipment - solid fuel boilers, including pyrolysis ones, will be waiting for you here. In addition to them, it remains to lay pipes and install radiators, for example, heating registers made of large diameter pipes. Factory equipment for heating systems has a higher efficiency, which will affect efficiency.

Making an oil heater with your own hands

Homemade register with heating element and air vent.

Firstly, the container for the future radiator must be absolutely sealed. Otherwise, the coolant will leak out, which will lead to overheating of the heating element (heating element). Therefore, you need to master some techniques for properly welding metal. We talked about them in the article about welding pipes for heating.

Secondly, the coolant here should be mineral oil, if possible transformer oil. It should fill the heater tank to 85%. The rest of the space is left for air. It is necessary to prevent water hammer. Thirdly, in the case of using a cast iron tank for the heater, a steel heating element is used. For a stainless steel tank, a copper heating element is suitable. Magnesium anodes cannot be used in this system.

Use a sketch.

Source materials:

- old, cast iron radiator or steel pipes with a diameter of 15 cm, pipes with a diameter of 7 cm;

- heating element;

- transformer oil;

- thermostat;

- two-core cord with a plug at the end;

- pump up to 2.5 kW.

You will have to work using a welding machine, a drill, a set of drills and electrodes. Pliers will come in handy. Making an oil heater for

The heating element is inserted into the lower end.

Do-it-yourself apartments begin with preparing the tank. If you took an old cast-iron battery, it must be disassembled into sections and thoroughly cleaned of dirt and rust, and be sure to degrease the inner surface. If you need a heater of increased power, then prepare a welded structure from prepared pipes, where pipes of larger diameter are located horizontally.

Pipes of smaller diameter serve as bridges between the main ones. The coolant will circulate through them. You need to remember that in the lower pipe you need to leave a hole for installing the heating element. If there are several heating elements, they are located on different sides of the tank and should not touch. A hole is also left for the pump. The heating element is securely fastened with bolts. The hole for it can be made with a grinder or autogens.

If a do-it-yourself room heater turns out to be voluminous and natural circulation of coolant in it is impossible, resort to the help of a pump. It is located at the bottom of the equipment. The pump should not come into contact with the heating element.

After installation of structural elements, the equipment is checked for leaks. If the result is satisfactory, then the coolant is filled. The drain hole is securely sealed with a plug. The equipment is connected to the electrical network in parallel. The circuit is supplemented with a bimetallic thermostat made from a regular iron. Before the first start-up, the installation is grounded. Homemade oil heaters for the home: the video will explain in detail their structure and installation rules:

Principles of snake bending

It is necessary to base this scheme on the type of battery

The covers are cut according to glass parameters. Contaminants are removed from them. Ears are attached to one covering. Their parameters: 2.5 x 5 cm. The basis of such a film is copper foil. It is glued with superglue. The ear extends onto the lining by 5 mm. Protrudes 2 cm.

The formation of the snake must be done on a special template. For ponytails, a minimum of 5 cm is allocated. The bitten ends of the nails are used. They are ground to roundness.

The wire is wound onto the template. It must be annealed to fix the shape.

A voltage of 5-6 V is applied to the snake. When the material has a shine with a cherry tint, the thread should cool completely. This operation is repeated 3-4 times.

A plywood strip is placed on the snake. The snake is pressed with your fingers. Slowly unwind the tails that were wound on the nails (nail diameter - 2mm). Each ponytail needs to be straightened and molded. The nail retains 25% of the twist. The remainder is cut flush with the extreme side of the template. And the remaining 5 mm of the tail should be cleaned using a sharp knife.

The snake is carefully removed from the mandrel and attached to the substrate. The leads are in contact with the lamellas. You need to remove the snake with two knives. The blades are inserted from the outside under the bends of the branches on nails (1 mm)

Then the winding heating thread is carefully lifted and lifted. The snake is placed on the backing and slightly bent. The leads are in the center of the lamellas

The leads appear in the center of the lamellas.

Nichrome is soldered to copper. The solder medium is conductive paste. Liquid solder is dripped onto a clean contact (1 drop). Through a piece of polyethylene, this area is pressed down with a weight. When the paste becomes hard, the weight and polyethylene are removed.

Next comes work on the emitter. A 1.5 mm layer of silicone sealant is pressed onto the center of the snake. Then the operation is repeated, but the layer is already 3-4 mm. The sealant fills the contour of the substrate. The distance from the edges is 5 mm.

The glass is carefully applied. Pressed down. It should fit tightly

Next is waiting for the silicone to dry. It's about a week

It should fit tightly. Next is waiting for the silicone to dry. This is about a week.

Then the excess sealant is removed with a razor. Sealant leaks from the lamellas are also eliminated.