Circular drill device

A ballerina drill for wood is made from carbon, tool, and alloy steels, which are not suitable for processing hard materials: metal, tile, porcelain stoneware.

But they cut drywall and plastic easily. The two-incisor ballerina looks like an ordinary compass. But the design is much more complex. The bracket and cylindrical shank are manufactured in one piece. There are two holes in the bracket. A centering drill is installed in one. A rod is installed in the second. Both are secured with screws.

To set the required diameter, the cutters move along the rod. It has a vernier scale on it. The tool holders are also secured with screws. The incisors are shaped like a knife. The oblique edge of the cutter should be directed in the direction of rotation, clockwise.

If the drill becomes dull during operation, it can be easily replaced. If the cutters are dull, then, having the skills to work on a sharpening machine, you can refill them. The shank of the structure is fixed in the chuck of an electric drill. It is worth remembering that the small power of a power tool may not be enough to work with a ballerina, unlike metal drills.

How to drill a large hole in tiles

The need to drill large-diameter holes in tiles arises when preparing a place for installing pipes and other plumbing communications, as well as for installing electrical sockets. To drill such holes in tiles, special tools are used, which can be a tubular drill, a ballerina drill for tiles, etc.

The ballerina, with which you can create holes of various diameters in tiles, is somewhat reminiscent in its design of an adjustable drill bit used for working with wood products. The ballerina works on the principle of a compass: the central drill serves to center it, and the working cutter, which can move along a special bracket, cuts a hole of the required diameter on the surface of the tile. By adjusting the position of the cutter, it is possible to obtain holes whose diameter is in the range of 30–90 mm.

Drilling a hole with a ballerina

At the same time, the ballerina is unproductive, since you can only work with it at low drill speeds. Moreover, such a tool is not very convenient to use, since it is quite difficult to hold it in one position.

More effective (but also expensive) is a circular tile drill, which is often called a tubular drill. Its cutting part can be coated with diamond or tungsten carbide.

Drilling tiles with a tubular drill without a center begins at low speeds, slightly deflecting the drill from a vertical position

When using a tubular drill, you should adhere to a number of rules:

- perform drilling at a rotation speed not exceeding 500 rpm;

- intensively cool the tool during processing;

- use the tool only on a stationary drilling machine, if its design does not provide for it.

DIY wood ballerina

A popular building material, which is natural wood, has unique characteristics and durability, and can be easily processed with various carpentry tools. Among the large list of devices, the ballerina drill for wood has special properties, allowing you to make through or blind round holes of different sizes.

How to properly cut metal with an oxygen propane cutter

- 1 Technology of gas cutting of metal parts

- 2 Types of gas cutting of metal

- 3 Oxygen-propane cutting of metal: features of equipment settings and the principle of operation of the cutter 3.1 Technology of cutting metal with gas

- 3.

2 Advantages and disadvantages of gas cutting

- 7.1 Features of the work

Gas cutting is a process of separating metal elements into small fractions. This technology is implemented by using a directed oxygen flow with an admixture of gas, the formation of which requires special equipment.

What gases are used

Acetylene and propane are most often used as a mixture of gas and oxygen. In addition, coke oven gas can be used. Machines and machines for gas cutting supply gas to the surface of the part with subsequent heating.

As a result, metal sheets are separated, pipes, blanks and other elements are cut. The technology is actively used in industry, as it allows working with large metal structures.

Necessary equipment

Gas cutting of metal can be performed automatically or manually.

The necessary equipment is a gas cutter, with the help of which a directed flow of the mixture is formed, which acts as a cutting tool. In the video there is a story about the Fast and Furious cutter:

Gas cutters

This device allows you to direct an oxygen-gas jet at a metal part to achieve the release of acid on the cut surface. During operation, the metal layers are heated to their full depth, which leads to a through cut.

Gas cylinders

The design of the cutting installation includes gas cylinders.

Their capacity depends on the expected volume of work.

If you plan to cut metal with propane, then one cylinder should contain oxygen and the other should contain propane gas.

Oxygen reducer

Mixing of gas from cylinders is carried out through a hose equipped with an oxygen reducer. Using this device, you can control the force with which the oxygen stream is supplied, depending on the task at hand.

In addition, the reducer allows you to control the burning rate of the workpiece and maintains constant pressure in the system.

If, during the process of cutting metal with a cutter, the oxygen consumption drops below the set level, the part will quickly cool down and the process will be interrupted.

DIY making

When you don’t have a device at hand that can cut a circle from wood or other material, you can try to make it yourself. To do this, you will need a collet holder and a set of the required size of feather drills. A collet holder is a clamping mechanism that is used to clamp a rotating cutting tool. It can be made from a bolt, the diameter of which depends on the chuck of the rotator, machine tool or drill. The head of the bolt needs to be cut off and sawed crosswise along the thread side.

The center drill is sharpened into a cone, and the cutting drill into a wedge. In this case, the end of the center drill should be 3-5 mm longer.

The drill is held in place by two nuts: one is a clamping nut, the other is a guide. If holes with a constant radius are cut, then the drill can be welded to the holder.

Design and principle of operation

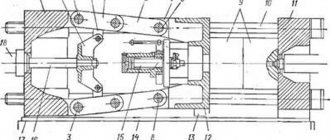

The design of a circular drill is quite simple and mainly consists of three parts:

- a drill responsible for centering the device;

- a fastening rod of a certain length on which the cutting elements are installed;

- cutters equipped with a device for attaching them to a rod, their number ranges from one to three.

This design is used on single and double cutter models. If there are three cutting elements, then in this case the cutters are fixed on a round disk, and to change the radius they move along the grooves. Additionally, some models can be equipped with a protective cover that protects the working person from flying chips or sawdust. It also protects the worker from being hit by fragments when the device is destroyed.

Now let's see how to drill. The central drill needs to be drilled at a pre-designated point. If the materials are durable, for example, iron, tiles or laminate, then it is better to first mark the drilling location with a regular drill. This is done for convenience so that the “ballerina” does not slip on the surface and scratch the top layer.

Next, we cut a path of the radius we need

Again, here you need to pay attention to the material in which the holes are drilled. If it is a tile, then to prevent damage to the facade surface you need to drill at low speed and lubricate the tile with water or machine oil

This will prevent damage to the tiles and the scattering of fragments. Tile panels must be laid on a flat surface, otherwise they will crack under force.

If the tile is already attached to the walls or floor, then you only need to cut through it, and then replace the “ballerina” with a concrete drill. When drilling laminate or veneer, it is difficult to go through the top layer, but then it goes easier. There are no special instructions for wood, iron, plastic and drywall. The last stage is removing the cut out objects.

In addition to the basic instructions, there are a few additional nuances.

- In no case should you put pressure on the tool or lean on it with your whole body: this can damage the device and split the material in which the hole is made;

- “impact” or “perforator” modes cannot be used, only drilling;

- there is no need to let the “ballerina” overheat: high temperatures can deteriorate the coating of the incisors;

- if drilling is difficult, then you should add speed.

To protect your health when working with a device for drilling circular holes, you need to follow simple rules:

- Before starting work, you need to check whether all components of the device are securely fastened;

- You should wear goggles or a mask to protect your eyes;

- clothing should not contribute to getting into the rotating elements;

- If possible, be sure to install a protective grille on the ballerina.

Types of instruments

In addition to the classic two-cutting version of a circular drill, there are one- and three-cutting models. In the design of a single-cut drill, the cutting part is directly fixed to the rod. The cutter and centering lance are equipped with carbide plates. They make it easier for a ballerina to work on tiles.

In three-incisor models, the incisors are mounted on a round platform on which there are grooves. The cutters move along these grooves. They have a scale. Correctly set size allows you to cut more accurately and quickly.

Currently, some models are equipped with a protective grille made of plastic. It improves work efficiency and convenience.

The ballerina for metal is equipped with plates made of hard alloy with sharpening of a cutting turning tool. High cutting force dictates the use of stationary or portable radial drilling machines. Basically, holes are cut in galvanized sheets, the thickness of which does not exceed one millimeter.

Adjustable tool overview

Ballerina design

A variety of drills are used to make holes in wood, as well as in wood-based panels (plywood, OSB, fiberboard/chipboard). In this case, the diameter of the groove being formed is limited by the diameter of the drill itself, so that very often the capabilities of standard devices are insufficient.

The solution in such a situation is to use a ballerina - a special drill with movable cutting elements. It has a rather complex design, but at the same time significantly expands our capabilities in drilling holes.

Photo of the most common model

The main elements of the device are:

- The central part, which includes a small diameter twist drill, a “body” in which the cross rod is fixed, and an end piece for clamping into the drill chuck.

- A horizontal bar (often with millimeter markings) along which the cutting elements move.

- Two cutters secured to the rod with hex screws. In preparation for work, the cutters are moved apart to the required width and clamped in a strictly vertical position.

Note! Sometimes fixation is carried out not with hex screws, but with standard clamps for a Phillips screwdriver. The reliability of such a connection is much lower, and it is not so convenient to use, so it is better to find a hexagon model.

- Ballerinas can also have a simpler design: an L-shaped movable cutter is attached to the central part. However, most often such devices are used not for processing wood, but for drilling tiles or clinker tiles.

Model for tiles with one cutter

An important factor determining the quality of a ballerina is the material from which it is made. Professional tools that are used for processing hardwood are made of high-strength steel with an anti-corrosion coating, and the cutters are equipped with carbide surfacing.

The price of ballerinas without coating is usually lower, but they do not last long, since cheaper metal is used for their production.

Use for drilling holes

One of the obvious benefits of adjustable wood drilling jigs is their ease of use.

The work of making a hole is carried out as follows:

Start processing

- On a board or sheet of plywood we mark the center of the future groove.

Note! It is important to ensure that the thickness of the material being processed does not exceed the value specified in the ballerina’s passport. For most devices, this figure does not exceed 15-30 mm, so to drill thicker boards you need to use other devices.

- Using a hex wrench, loosen the mounting screws and install the cutters on the rod so that the distance between them corresponds to the desired diameter. At the same time, we make sure that the cutting elements are positioned strictly symmetrically.

- We tighten the screws with a wrench, fixing the cutters on the rod in the selected position (the distance for most models is from 30 to 120 mm).

- We insert the ballerina into the drill chuck.

- We place the drill at the mark opposite the center (it can be marked with a punch or passed with a drill of a smaller diameter), after which we begin processing. We increase the pressure on the drill gradually so that the load on the cutting edges does not increase.

Result of work

After the hole is made, we remove the ballerina with a piece of wood or plywood from it. The edges must be filed to remove burrs.

Features of working with the tool

The principle of working with a circular drill is simple. A hole is drilled using a centering drill, and then the cutters are put to work. They gradually make a narrow groove, gradually cutting through the material in a circle to the full depth.

The materials used in working with the ballerina are varied: wood, fiberboard, chipboard, MDF, plasterboard, plastic. One common point is that the thickness of the part should be no more than 15-20 millimeters. This parameter is limited by the length of the incisors. Usually the manufacturer indicates the maximum drilling depth on the packaging. If you try to drill into thicker material, you may experience problems with ragged edges.

The use of a tool with one cutter is characterized by runout. This is caused by a lack of balancing relative to the longitudinal axis of the drill. The beating will be especially noticeable when cutting large diameter holes. Cut holes using a drill at low or medium speed. When working on a drilling machine, such problems do not arise.

Also, a laminated or veneered surface can cause inconvenience when working. After passing through the decorative layer, drilling proceeds without problems.

A feature of the circular drill can be considered the ability to adjust the diameter. The distance between the cutters can be set using a scale on a rod or more accurately using a caliper. This is convenient if you need to make a hole without gaps for a pipe or round part.

The spacing of the cutters relative to the center is adjusted individually. It is necessary to align the cutting parts as accurately as possible. This will eliminate unnecessary effort during operation and extend the life of the tool.

Purpose and application features

The main and only purpose of this special tool is to cut neat round holes with a diameter of up to 300 mm. The materials subjected to processing are different - wood, plywood, chipboard, MDF, fibreboard, plastic panels, plasterboard. There is a similar tool for cutting holes in ceramic tiles and similar hard materials. All of them have one thing in common - the thickness of the slab should not be too large. The accompanying documents with which the ballerina wood drill is sold most often indicate a maximum material thickness of about 15 mm.

Experts note that a peculiarity of the use of ballerinas with one cutter is quite high beats due to the asymmetry of the design and a noticeable lever that counteracts rotation. Therefore, such devices are used, as a rule, in stationary drilling machines. This not only reduces the risk of the workpiece being torn off, but also saves the worker’s hands.

There are, however, many places where you have to work with hand drills, screwdrivers or a hammer drill. In this case, a two-incisor system is used, since the two incisors largely compensate each other. But even in such cases, caution, attention and accuracy are required. It is also necessary to give the tool a “rest”, since drilling holes is about 150–200 mm. create a significant load on it. The breaks allow the incisor (or incisors) to cool down. In general, this is not a device that tolerates haste and inattention. The presence of a laminated coating or veneer on the material also does not simplify the task - special care is required and the use of an output lining is required. Operating at too high speeds is not recommended; as a rule, 1000–1400 rpm is sufficient.

How to choose and what to pay attention to

Choosing a high-quality circular drill is quite easy

The main thing is to know the main points that you should pay attention to first, but also not to lose sight of the little things

The design is a very important point: a wood ballerina comes with one chisel or two or more. For frequent use, it is better to purchase an option with two or three cutting elements. It is easier to work with such devices and the quality of the processing performed will be at an acceptable level.

It would not be superfluous to be able to replace individual parts. Inexpensive circle drills can have a solid shank with a permanent center drill and rod.

Metal, its quality determines its strength and ability to withstand workloads. High-quality tools are made from high-strength steel or alloys. The shank and cutter holders are shaped using a machine tool. The rod is usually stamped and made of the same metal.

Cheap options often use soft metal or alloys, which can be brittle. Under load, parts may become deformed or break. Such a tool will not last long and it will also be difficult to achieve accuracy from it.

The quality of workmanship, the main feature is the absence of backlashes and distortions. All parts must fit together and be securely fastened with fixing screws.

The markings of a high-quality ballerina's barbell are stamped. Sometimes the divisions are highlighted with bright paint for better visibility.

Cutters and high-quality cutting elements are made from hardened tool steel. They are secured to the holders with rivets or soldering. Solid cutters with holders (made of the same metal) quickly become dull and are not durable.

Manufacturer, when choosing any tool and consumables, preference should be given to well-known and long-proven brands and brands. The most common are Topfix, Stayer, Irwin, Strum.

Purchasing an adjustable circular drill for use at home, or if you need to drill several holes, is completely worth it. This eliminates the need to purchase an expensive tool that may only be needed a few times.

How to choose the right one

When purchasing a drill, be sure to evaluate the configuration of the ballerina. Three-cut drills are considered the most reliable and in demand.

They have good mounting screws that firmly secure the working cutters. The length of the working cutters should be 4-5 mm less than the length of the centering cutter.

Some models use standard clamps to secure the incisors. They require a Phillips screwdriver and are much less reliable than models with hex screws.

- For drilling tiles, it is better to choose a ballerina with two incisors. With its help, you can make a hole with a diameter of up to 160 mm, whereas when working with a single-cut tool, the maximum diameter will be only 120 mm.

- A double-sided wood ballerina will allow you to make a hole with a diameter of up to 300 mm. And for working with thin (less than 5 mm) sheets of wood, a special drill is included in the kit.

- To work with hard surfaces (metal, porcelain stoneware, stone), use a one-sided ballerina. Before drilling begins, its central axis is securely clamped in the drill chuck.

On the brackets of branded ballerina models there is a ruler with clearly visible divisions. As a rule, the movement of the cutters is carried out synchronously. You should also pay attention to the width of the incisor run (it can be up to 150 mm). This parameter determines the radius of the future hole. Usually, the quality of the working surface (wood, metal, tile) is taken into account when choosing the permissible width of the cutters.

Some models are equipped with a protective plastic grid that holds large sawdust.

Criterias of choice

Before choosing a “ballerina”, you need to know its main advantages over other devices for cutting large holes, be it crowns, jigsaws, etc.

Advantages of adjustable circular devices:

- the ability to replace the central drill or lateral incisors at any time;

- reliability of design;

- if necessary, cutting elements can be sharpened;

- adjustable hole width.

Now let's look at the parameters you need to pay attention to when purchasing

- Reliability. It is unlikely that you will be able to determine this criterion visually, so it would be better to check the quality certificates for the products from the seller. For low-quality goods, they most likely will not be available.

- Workmanship. Before purchasing, you need to carefully inspect the device for shells, chips and other flaws. The cutters must be well and accurately sharpened. If the drill is very long, then you need to check whether it is even. Usually these defects are visible immediately and by eye.

- Package. Quality products from well-known manufacturers usually come with bright and good packaging. There will be no grammatical errors in the text accompaniment. None of the well-known brands can afford to package their products poorly.

- Price. Cost can also be considered an indicator of quality. Inexpensive models last a very short time.

Famous brands care about their reputation, and their products will meet all quality criteria. Therefore, it is better to contact official dealers so that the money is not wasted.

The following video talks about the ballerina drill.

What is a ballerina

The cutting tool, commonly called a ballerina, also has a more professional name - “circular adjustable drill with cutters.” The drill is located in the central part of the tool and is used to center the hole. The radius of the circle that the cutters will describe is measured from the center line of this drill.

To equip ballerinas, drills of the first or auger type are used, since a conical tool does not cope well with ceramic materials and can slide off their surface. The result of such slipping can be damage to both the tool itself and the surface of the tile.

Ballerina on tiles differs from a nozzle designed for drilling holes in wood materials

Use of special drills

Special drills for ceramic tiles are used in cases where it is necessary to create a hole of small diameter. As such a tool, if you need it to make just a few holes in the tile, you can use a regular wood drill, sharpening it sharper, but a metal drill equipped with pobedit tips is better suited for these purposes. The resources of the latter, if it is provided with high-quality cooling, will be enough to make more holes.

Among the inexpensive drills for ceramics, with which it is convenient to create holes for dowel fasteners, spear-type tools should be distinguished. Using one such drill, the diameter of which can be up to 12 mm, you can create up to five holes in the tile. When using this tool, you should keep in mind that you can drill tiles with it only at low speeds of the drill.

Varieties of spear-shaped drills for tiles and ceramics

You can also drill tiles to accommodate dowel fasteners using drills equipped with carbide plates and toothed cutters. The latter differ from conventional carbide-type drills in that their cutting plates have a one-sided and sharper sharpening. The disadvantages of using such tools are that it is quite difficult to obtain a high-quality result with their help, and before drilling, the center of the future hole must be punched.

A pen tool for drilling tiles is more convenient to use. The advantages of such a drill are that before using it there is no need to pre-core the tile, and it is much easier to aim it at the center of the future hole. Using tile drills, the cutting part of which is shaped like a feather, you can make holes with a diameter of up to 30 mm.

The most expensive, but also characterized by the longest service life, are spear-shaped drills, the cutting part of which is coated with diamond. It is advisable to purchase such expensive and reliable drills when a large amount of work needs to be done with their help.

Tubular tile drills with diamond coating

Experts advise adhering to the following recommendations when drilling holes in tiles intended to accommodate dowel fasteners.

- Once the tiles already attached to the concrete wall have been drilled through their full thickness, the tile drill should be replaced with a concrete tool. In this case, the drill or hammer drill can be set to impact mode. This approach can significantly extend the service life of a drill designed for working only on tiles.

- To prevent accidental damage to a tile fixed to a concrete base when driving in a dowel, the hole in it must be larger in diameter than in the concrete.

- In order to drill a hole in the seam between two tiles without damaging them, you should choose a tool whose diameter is smaller than the width of the seam.

- When hammering in a dowel, you must act very carefully so as not to accidentally damage the surface of the tile.

Types of products and their features

Let's look at what options you can find in our retail network and how they differ from each other.

Feather drills

The most common and budget option, which is quite convenient for even inexperienced craftsmen to work with. And you can also master this simple process with your own hands.

Let's look at the main advantages of this solution:

- The diameter range varies from 10 to 60 mm.

- The work is done quite quickly, but the quality of the hole is low, and it is unlikely to achieve an ideal result.

- The maximum drilling depth is approximately 150 mm.

- Products are sold either in sets of 5-6 pieces or individually, so you decide which option is right for you.

- If necessary, you can buy an extension that clamps the drill and increases its length by 300 mm.

Large sizes are usually sold individually, small sizes are usually sold in sets.

It is impossible not to mention such an interesting option as an adjustable pen drill; this type of product can make holes with a diameter of 22 to 76 mm. The work is carried out at low speeds using fairly powerful power tools.

Adjustable nib – a new word in products of this type

Forstner drill

This product option is used very widely in furniture production due to a number of undoubted advantages:

- The edges of the hole are perfectly smooth, which is not possible with other options.

- High reliability and long service life allow such devices to be used for years.

Massive nodes are very reliable

- The size range varies from 10 to 60 mm.

- The standard drilling depth is about 10 cm, but if desired, you can additionally purchase a 300 mm extension.

- This is the only option with which you can drill blind holes, because the centering pin protrudes only a couple of millimeters.

Screw drills

This option is very popular among those who drill large-diameter holes in wood to a considerable depth. To use them, you don’t need special instructions; just connect the unit to the power tool and you can start working.

The features include the following:

Spiral fixtures are available in a wide range of sizes

- This option is available in three lengths: 220, 450 and 600 mm. The last type is the most popular, since it can be used to effectively drill thick materials.

- It is best to use a drill with a rotation speed of 800 rpm. This allows you to carry out work most efficiently, but at the same time the power indicators of the power tool must be high.

- If you need to drill holes in log houses through 2-3 logs, then you shouldn’t even consider other options; this solution is optimal in all respects.

- The hexagonal shank allows you to securely fix the unit in the drill chuck.

All craftsmen who build log houses use this option.

Circular adjustable designs

The popular name for this device is wood ballerina. The design is a kind of compass, in the middle of which there is a centering drill, and cutting elements move on the crossbar, which can be installed in different positions.

The following factors can be considered features of this solution:

- With its help it is very good to process sheet materials and products up to 20 mm thick. The design copes well with both wood and fiberboard, chipboard, plywood and other similar options.

- The range of possible hole diameters is quite wide and ranges from 30 to 130 mm. This is much more than all the options described above, and the only drawback can be considered the small processing depth.

- The kit should include a hex wrench for adjusting the position of the cutting units and a center punch for making marks on the surface. It is recommended to carry out work at low speeds, since during the drilling process the cutting elements are subjected to very strong loads and can simply break.

Read also: How to melt steel at home

This is what ballerinas look like when working with wood

Important! You can find many fakes on sale that are short-lived and do a poor job, so you should be especially careful and scrupulous when choosing this option (see also the video in this article).

How to drill a hole in a large diameter tree? Read about it below.

Hole drills for wood

The second name for devices of this kind is tree crowns; they are widely used due to a number of advantages:

- Possibility of drilling diameters from 19 to 127 mm, you will not have a question about how to drill a large hole in wood, the work will be simple and fast.

- Products are sold in sets of 12 or 6 pieces, allowing you to have a wide range of accessories on hand for all occasions. Of course, the cost of such a set will be quite impressive, but you will once and for all solve the problem with devices for creating large holes in wooden structures.

Any person who works with wood or wood-based materials quite often needs to drill a round hole of large diameter in a sheet plate. Of course, you can use a jigsaw and cut out the required circle with it, but this is not always convenient. In such situations, a wood ballerina is used, which is a special device for producing precisely round holes of large diameters.

Where and what drill is best to buy?

As for foreign-made tile drills, the domestic market offers mainly American, Polish and German models. Their price is much higher than domestic ones, and the packaging is more beautiful. In terms of quality, they are not much different from Russian ones. Therefore, there is no need to overpay. A separate price category consists of the so-called “professional” tile drills. Not everyone can afford them. But they are also very easy and convenient to work with. Their appearance is also simply amazing. The soldering of the plates is carried out with the highest degree of care and precision, the joints are almost invisible. The tip is sharpened in such a way that it is simply impossible to replicate at home. In addition, these tile drills also differ from ordinary ones in that they have a set service life, during which they cannot become dull. After its expiration, the drill loses its “professional” status and, after sharpening at home, can be used as usual.

Specifications

Carbon steel is used to make the device. It is an alloy of carbon and iron. The amount of carbon determines the strength of the tool, its ability to resist load. For greater wear resistance, less sensitivity to overheating and deformation, some manufacturers add chromium, silicon, tungsten, vanadium, and molybdenum to the alloy. For example, the P6M5 marking indicates that the steel from which the cutter or drill can be made contains 6% tungsten, 5% molybdenum, this increases strength.

For strength and increased service life, the drill tip can be tipped with carbide. Such devices give a cutting depth of 30 mm, and without soldering - 25 mm.

Comfortable operating speeds for the tool will be from 1000 rpm to 1400 rpm.

The ballerina, depending on the functional accessory, makes holes whose radius ranges from 20 to 150 mm, while the diameter of the cut circle will be 2 times larger. For example, using a tabletop drilling machine or drill, a ballerina for metal allows you to cut or drill holes in metal with a radius from 22 to 105 mm. The thickness of the material being processed should be up to 14 mm. The material can be steel, cast iron, brass, bronze, aluminum.

Ballerina circular drill bit for wood

Drills are intended for drilling holes in wood materials and wood using woodworking tools. Their main technical characteristics include: type and geometry, material and heat treatment, workmanship and accuracy.

- Characteristics of metal for drill

- Types of ballerinas

- For woodworking

- Drilling drywall

- Tile tool

- Specifications

- DIY making

- Disadvantages of the device

- Safety precautions

Characteristics of metal for drill

The drilling process is the mechanical and physical impact of the drill, therefore the raw material from which it is made must have properties such as:

- Strength. This will ensure drilling through thick layers of wood.

- Fatigue strength. It characterizes the drill’s ability to withstand cyclic loads when in contact with wood.

- Plastic. Allows you to carry out operations to prepare the drill for work.

- Hardness. Determines the durability of the metal.

- Heat resistance. Preserves the mechanical properties of the drill when heated at high drilling speeds.

- Corrosion resistance. Possibility of drilling into raw wood.

For woodworking

In a home workshop, when working with wood material, you may need a tool for cutting round holes. These tools include a drill, which in everyday life craftsmen who work with wood or wood-based materials call a ballerina. The exact name of this device is a circular drill.

The design of the tool is a bracket, along the axis of rotation of which the drill is fixed. It marks the center of the hole and provides rotational support for the entire fixture.

At the edges of the bracket there are two carriages in which the cutters are fixed. The bracket rod is marked, so the carriage with cutters can be installed with high precision.

Before starting work, the lateral incisors are moved apart to the required distance. They are pressed to the bracket with screws.

There are other modifications of the woodworking ballerina with one, two or three cutters. The bracket can be replaced with a disk, in special slots of which cutters are placed to adjust the diameter. A hole can be drilled straight or at an angle in the axis into which a cutter is inserted, adjusted with a locking screw. It provides the size of the diameter of the resulting circle.

The tail of the axis can be round or specially shaped for fixation in the SDS chuck. To remove a straight or rounded chamfer, where necessary, knives of various shapes are used.

In addition to wood, the material with which this device works can be drywall, plastic, rubber, tile, or metal.

Drilling drywall

For installation of various equipment in plasterboard with a diameter of up to 100 mm, a ballerina for plasterboard is designed.

It is a leg with a centering tip, above which there is a mount for the rod, rotating around its axis.

In order to hold the tool, at the end of the central post there is a handle with a notch along the side surface. At the other end of the rod there is a disk cutter.

The device works as follows:

- a tool is drilled in the center of the proposed hole;

- the rod is set at the distance of the required radius;

- The specified hole is cut using circular movements, the edges of which do not require finishing.

The advantage of a ballerina drill for drywall, compared to other tools for the same work, is that:

- the device quickly cuts a hole;

- the disk cutter does not require sharpening;

- despite the intensity of work, all devices do not become loose;

- The rod mount prevents the cutter from moving randomly, changing the cutting geometry.

Tile tool

During construction or renovation work, it may be necessary to make a round hole in the tile. This is necessary for installing a socket, switch, leading plumbing pipes or other elements through the wall.

To work with tiles, single-cut, double-cut and three-cut annular drills are actively used.

The use of these devices promotes a perfectly even cut of tiles without chipping the enamel. By arranging and fixing the cutters at the required distance, you will get a hole of the required diameter and size. Using a circular drill will significantly save time and reduce labor costs. The operation of the instrument is similar to how a ballerina dances.

Drilling process steps:

- On the face of the tile, mark the center of the hole.

- Fix the tile.

- Place the cutters or cutter in the desired position.

- Treat the cut area with machine oil.

- Start carving at low speed.

- To finish the carving, you need to turn the tile over to the other side and continue drilling.

- Use a file to finish the edges of the hole.

Specifications

Carbon steel is used to make the device. It is an alloy of carbon and iron. The amount of carbon determines the strength of the tool, its ability to resist load.

For greater wear resistance, less sensitivity to overheating and deformation, some manufacturers add chromium, silicon, tungsten, vanadium, and molybdenum to the alloy.

For example, the P6M5 marking indicates that the steel from which the cutter or drill can be made contains 6% tungsten, 5% molybdenum, this increases strength.

For strength and increased service life, the drill tip can be tipped with carbide. Such devices give a cutting depth of 30 mm, and without soldering - 25 mm.

Comfortable operating speeds for the tool will be from 1000 rpm to 1400 rpm.

The ballerina, depending on the functional accessory, makes holes whose radius ranges from 20 to 150 mm, while the diameter of the cut circle will be 2 times larger.

For example, using a tabletop drilling machine or drill, a ballerina for metal allows you to cut or drill holes in metal with a radius from 22 to 105 mm. The thickness of the material being processed should be up to 14 mm.

The material can be steel, cast iron, brass, bronze, aluminum.

DIY making

When you don’t have a device at hand that can cut a circle from wood or other material, you can try to make it yourself. To do this, you will need a collet holder and a set of the required size of feather drills.

A collet holder is a clamping mechanism that is used to clamp a rotating cutting tool. It can be made from a bolt, the diameter of which depends on the chuck of the rotator, machine tool or drill.

The head of the bolt needs to be cut off and sawed crosswise along the thread side.

The center drill is sharpened into a cone, and the cutting drill into a wedge. In this case, the end of the center drill should be 3-5 mm longer.

The drill is held in place by two nuts: one is a clamping nut, the other is a guide. If holes with a constant radius are cut, then the drill can be welded to the holder.

Disadvantages of the device

In addition to the advantages , working with circular drills has its disadvantages. These include:

- thread breakage of the clamping screw;

- vibration when using a single-cut tool;

- cutter wear;

- difficulty of working with a three-cut device;

- intermittent operation to avoid overheating of the nozzle;

- frequent breakage of a cutter or drill, including during operation;

- breakage of the material during the drilling process.

To work with a circular drill, you need a good tool, high-quality material, and work skills.

Safety precautions

When working with the device, you need to remember your safety:

- Before starting work, you need to check the fastening of all elements.

- Eyes should be protected from chips with goggles.

- Clothing should not allow you to get caught in the rotating elements.

- The drill should rotate as it approaches the material, this prevents it from quickly becoming dull.

- It should be taken into account when working that the hardness of the drill material must be higher than the hardness of the workpiece material.

- If possible, use a ballerina with a protective grille.

How the tile cutting process is performed

There is a certain algorithm that should be followed when using a tool for drilling holes in tiles, like a ballerina.

- First of all, on the front side of the tile it is necessary to mark the center of the future hole, for which you can use a regular core.

- The cutter or cutters of the ballerina, which will do the main work of cutting the material, are installed and fixed at the required distance from the axis of the central drill.

- It is advisable to lubricate the area of the tile on which the cut will be made with machine oil. In this case, you should make sure that it does not fall into the center of the circle, which can lead to the drill slipping.

- The drill, located and rotating in the center of the future hole in the tile, must pass through its surface before the cutters, so it must be longer than their protruding part.

- The tile in which the hole is made using a ballerina must be firmly fixed on a flat surface of a wooden board or drywall. To ensure such fixation, you can use ordinary clamps.

- Drilling the hole is carried out at low speeds of the tool, and it is advisable to constantly water the groove formed on the tile with machine oil.

- After the cut in the tile has been made to more than half its thickness, and the central drill has passed through the material being processed, the product is turned over and similar processing is performed on its reverse side.

- The tile is drilled to the end from the back side, and the edge of the resulting hole, which may not be too smooth, is processed using a file, emery cloth or a grinding machine.

Despite the fact that the holes made with the help of a ballerina do not have very smooth edges, it is quite reasonable to use it to perform not too voluminous work. In addition, the uneven edges of the holes will later be hidden by external panels of electrical outlets and other decorative elements.

Peculiarities

The main feature of the ballerina drill (its full name sounds more than impressive - “adjustable circular drill with cutters”) is the ability to change the diameter of the circle being cut. The distance between the cutting elements can be adjusted using an auxiliary scale on the mounting rod. If maximum accuracy is required, then you will have to use a caliper. This is quite convenient when it becomes necessary to make a hole for a pipe or other round part without backlash.

The second distinguishing feature is the number of incisors. It can be from one to three, and the quality of processing of the edges of the cut holes depends on this. If you purchased an adjustable drill with one cutting element, then you need to be prepared for the tool to “beat”. Vibration increases with increasing diameter of the cut hole: the larger it is, the higher the runout. This is due to the fact that there is no balancing relative to the longitudinal axis.

Ballerina design

- Centering drill.

- Working incisors (from one to three)

The main drill can be firmly fixed on the work surface (drilled) and prevent the tool from slipping when working with tiles or laminated surfaces. The cutters move in a circle and cut a groove in the working surface. The drill is driven using power tools (drill, machine, hammer drill) or manually (using a brace).

A tool with replaceable cutters is used to work with surfaces of varying strengths - from soft plastic to porcelain stoneware. The master can independently set the working cutters to obtain a hole of a given diameter. This operation can be performed using an adjustable wood ballerina.

Characteristics of metal for drill

The drilling process is the mechanical and physical impact of the drill, therefore the raw material from which it is made must have properties such as:

- Strength. This will ensure drilling through thick layers of wood.

- Fatigue strength. It characterizes the drill’s ability to withstand cyclic loads when in contact with wood.

- Plastic. Allows you to carry out operations to prepare the drill for work.

- Hardness. Determines the durability of the metal.

- Heat resistance. Preserves the mechanical properties of the drill when heated at high drilling speeds.

- Corrosion resistance. Possibility of drilling into raw wood.

We are sure that you will find this article useful about what types of concrete drill bits are available for a rotary hammer.

How to drill a hole with a feather drill?

For successful drilling with feather drills, secure the wood firmly in a vice and press the tip of the drill bit against the surface of the material. Then drill (at low speed) the hole until the tip of the drill appears at the bottom of the wood.

Interesting materials:

What is waste paper at school? What is a router on a computer? What is mental meaning? What is Mercy Baku? What is the place for mandatory fingerprint registration? What is a pronoun and examples? What is the International Olympic Movement? What is MI Credit Xiaomi? What is Micro-ATX? What is mycorrhiza and what benefits does it bring to the participants in this process?