When building a house, you often cannot do without a crane. For example, raise the blocks to the second floor, lay concrete floor slabs or throw boards on top for the rafter system. For this purpose, truck cranes are used, which are rented. But there are a number of jobs for which hiring equipment for a long time will ruin you. Therefore, users of the portal, in order to simplify and reduce the cost of building a cottage, make homemade mini-cranes. One of the successful models was designed and assembled by a FORUMHOUSE member with the nickname Kirill.

Kirill

I am building a large house from aerated concrete. When the blocks were delivered and unloaded, I realized that lifting and putting them down was long, difficult and tedious. I don’t want to make a double-layer wall from two blocks - a structural one and a lighter thermal insulation one. I decided to assemble a homemade crane. I thought a lot about the design and chose the best option for my task - a mobile crane with scaffolding for ease of work.

Homemade crane for laying blocks.

Machine structure

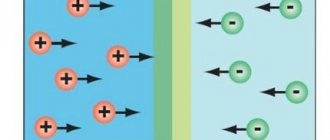

The operating principle of a crane is based on the physics of simple mechanisms. The simplest version of the crane is a stick placed on a fulcrum in such a way that the free ends have different lengths. Now if you hang a load on a short lever, it will take less effort to lift it. The most common design is one that uses, in addition to levers, a system of blocks.

A do-it-yourself crane is an indisputable assistant in small-scale construction. When constructing a private house, the use of bulky industrial cranes is not required. The height of the houses rarely exceeds 2 floors, and the weight of the lifted load is 200 kilograms.

Crane diagram

Although there are many variations of lifting mechanisms, a classic crane consists of the following parts:

- An arrow with a block attached to its end. Depending on its length, the height to which the load can be lifted is determined.

- Platform. The boom and counterweight are attached to it. It is the main part of the crane and is subject to significant loads. Therefore, when manufacturing a platform, it is important to pay special attention to its strength.

- Counterweight. Serves for crane stability. Defines the maximum load weight that the crane can lift. Stackable counterweight options are available to provide maximum stability.

- A guy wire connecting the boom and the counterweight. Allows you to adjust the tilt of the boom and move the load in both vertical and horizontal planes.

- Winch with cable. It is the lifting mechanism itself. The power of the winch determines how much weight the crane can lift.

- Stand with a rotating mechanism. It is necessary to turn the crane to the sides.

- The support cross, which is the base of the crane. Sets the stability of the entire structure. When manufacturing it, you should also pay attention to its strength.

Types of lifts and methods of use

Lifts can be factory-made or home-made. By material - metal or wood. The first ones are stronger and more reliable, and will last much longer, the second ones are cheaper and easier to make.

The most commonly used lifts are driven by a mechanical or electric winch. But there are other types of lifting mechanisms.

For example, this could be a simple mechanism consisting of gears - there are holes in the support post for the gear teeth.

There may also be scissor-type lifts for gypsum boards - the support posts fold and unfold when the lead screw rotates.

For work in rooms with high ceilings (for example, more than 3 meters), you can use a homemade lift with a hydraulic drive - based on a jack.

There is another option - a lift without a drive. This design consists of two racks with support beams for drywall.

A sheet of gypsum plasterboard (or other sheet metal)

material), and then each beam is lifted one by one by hand and fixed with wooden wedges.

Lifts are also distinguished by design features: for example, with a telescopic stand or with two scissor-type stands.

The base of the device may also differ. For example, in most cases tripod lifts are used.

But there are also structures with only two supports (usually homemade). True, they are inconvenient because they do not allow you to drive close to the wall.

In practice, most often there are lifts with a working platform in the form of a longitudinal beam and transverse slats. But some home craftsmen make a platform in the form of a rectangular frame adjustable in width and length (from corrugated pipe or metal corners).

In some designs, the working platform can be fixed not only horizontally, but also at different angles.

By default (as implemented in inexpensive designs), the working platform can only be fixed horizontally. However, it is also rotatable - it tilts 90 degrees to make it convenient to install a sheet of drywall.

Conventionally, lift designs are classified into three main groups:

- wall - for attaching gypsum boards to the wall;

- ceiling;

- universal (these include designs with an adjustable rotary table).

In addition to installing drywall, hoists can be used to lift

heavy and large objects (for example, chandeliers), as well as lifting and subsequent installation of metal profiles for fastening gypsum boards.

You can also use the lift for unwinding rolled materials (wallpaper, fiberglass) and as a temporary support.

The working platform can be designed for a specific size of drywall (as a rule, this applies to home-made structures, when there is no point in making custom platforms), or it can be adjustable - “tailored” for gypsum boards of different formats. The last option is the most convenient and optimal.

terms of Use

To operate lifting mechanisms safely, certain rules must be followed.

Homemade Pioneer crane

These rules apply to any lifting device:

- The load capacity must not be exceeded. A load that is too heavy may damage the device.

- The base must be stable. Homemade lifting devices should be located on a previously prepared hard horizontal surface.

- In bad weather conditions, you should also refrain from working with the crane. Strong winds will throw the crane off balance, and poor visibility may make it difficult to see people under the boom.

- Before operating a crane or lifting device, it is necessary to conduct an external inspection to identify any malfunctions. If malfunctions are detected, operation of the crane is prohibited.

- It should be remembered that when working with the lift, you should not make sudden movements. The load must be lifted smoothly. And most importantly, do not stand under any lifted load.

FakeHeader

Comments 39

oh, this will come in handy now, thanks)

I respect people with hands! yyyy

Yes, this is not for you to make a rake out of chairs on the press.

yyyy not rakes but daisies yy

“Lovely”! What about painting?