When to choose a cordless angle grinder

Many gentlemen cannot immediately decide which grinder (angle grinder) they want to have. To do this, it is important to know what materials and to what depth you will use it for cutting. The diameter of the circle installed on the power tool depends on this. It is also important to know the power required by your future power tool. Stationary angle grinders have more weight and impressive dimensions. However, their power and functionality are much greater.

– Hitachi GDSL

Price: 5200 rubles

An excellent power tool from Hitachi, with which you can cut or grind metal away from the electrical network. The model boasts extremely fast battery charging - only 45 minutes, as well as fairly compact dimensions - the length of the device does not exceed 30 centimeters, which is incredibly convenient in limited space.

The equipment of the device can hardly be called rich, but everything you need is in place - two 3Ah batteries, a charger, a key, a second handle and the grinding disc itself. The lack of keyless replacement of the attachment is unlikely to please professionals who have to quickly perform a large volume of varied work, but for household needs such a cordless angle grinder is perfect.

Hitachi G14DSL

Wood lathe

Creating products from wooden blanks is impossible without a woodworking machine. As a working surface of the machine, you can use a workbench made of wood with a flat surface.

According to the dimensions of the tool, make a bed from a lath in which the screwdriver will be located and fixed. A regular clamp is used for fixation. The bed is attached to the base using self-tapping screws or a clamp.

Into the screwdriver chuck

a mandrel with teeth is placed. To make the tailstock, 2 bars with an adjustment screw, sharpened to the dimensions of the cone, are suitable. The headstock is attached opposite the screwdriver

. In this case, its axis should be at the same level with the headstock adjusting screw.

Use a clamp to secure the back stop to the base of the future machine. A simple wood lathe is ready to use.

Homemade grinder powered by 12 volt battery

The grinder is a modern tool that is used by almost all iron masters. It is used to cut material, sharpen tools, and polish parts. But there are situations when there is no 220 V network or it is located far away and there is not enough cable to connect.

homemade grinder , running on 12 V, which can be connected to a small battery or to the car’s network. The advantages of such a tool are its quiet operation, which allows you to use it without fear of problems with your neighbors.

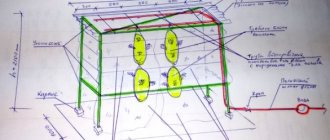

The homemade product is driven by an electric motor 775, operating from 12...24 V. It has a cooling fan, the armature is located on bearings. All this makes the motor long-lived even with active use.

In addition to the electric motor, prepare: an adapter for an angle grinder; connector through which the power source is connected; paint; switch; wires; self-tapping screws; cogs. The body is made from various PVC parts used for installing water supply, sewer, and electrical networks. Tools used include a hacksaw, glue, drill, caliper, drill, and marker.

READ How to Disassemble the Gearbox of a Makita 9565 Grinder

For the body (handle), PVC parts are prepared: a piece of pipe; 90° connecting angle; adapter for smaller diameter. The adapter is glued to the corner, then a piece of pipe is glued to its free end. Get an elegant handle.

They make a protective shield that will protect the worker from sparks and disk fragments. Use a PVC plug with an 11 cm diameter. A hole is drilled in its center with a diameter equal to the size of the part protruding from the engine housing (next to the shaft outputs). On the sides of it there are two more holes for mounting screws. Through the latter, the engine is attached to the shield.

Using a grinder, cut off a segment (approximately 3.5 cm high) of the protective cover, forming a working area for the disk. In this case, the mounting holes must be parallel to the cut and remain on the part.

Cut a piece of PVC pipe. Glue it to the outside of the protective cover so that the segment does not interfere with the installation of the motor. In the craft, it will be located inside this segment, which, in addition, ensures the connection of the knot with the free end of the corner in the handle.

At the free end of the corner of the handle, closer to the bend, a series of holes are arranged in a circle, which will ensure heat removal from the running engine. To it, closer to the edge, an additional short handle from a piece of pipe of a smaller diameter is glued vertically.

The surfaces of all plastic parts of the handle and protective shield are painted with aerosol paint. The color is chosen from those you like.

The engine is secured with screws from the back of the protective casing. Insert the latter into the free end of the corner on the handle - connect the parts with screws (better, it allows you to disassemble the tool in the future), by gluing.

The end of the handle is closed with a plug in which a switch and a power connector are placed. Suitable holes are pre-arranged for these parts; installing the connector with glue. Before installing the plugs, solder the wires coming from the engine to the connector.

The motor shaft is equipped with an adapter, securing it with a screw having a hex head. Secure the disk and try to work.

Flaws

To objectively assess all the qualities of an angle grinder from a car battery, it is important to know its shortcomings. And this device has a lot of them. Indeed, due to its portability, all the important parts of this type of angle grinder are made small, which is why many parameters of the device lag behind the stationary type in efficiency.

The main disadvantages of a cordless angle grinder are:

- Low power. This tool is not suitable for sawing thick materials and metal structures. The design is more suitable as an auxiliary tool. Moreover, after just a few minutes of operation, the power of the angle grinder drops sharply, the speed decreases, and the battery runs out.

- Expensive. If you buy a professional device, then its price will consist of the price of the grinder itself and the battery. When purchasing a tool made in China, no one can vouch for the quality of the grinder. A homemade angle grinder can be very useful for its owners. However, for this you need to have certain skills and mastery.

- The battery lasts no more than 30–60 minutes of operation. At the same time, it takes a long time to charge (2–4 hours). Thus, for normal continuous operation you need to have at least 2-3 batteries and chargers. And for this price you can buy a corded angle grinder along with a generator.

- Very hot when charging. At the same time, additional fire protection measures increase the cost of the device.

- It is difficult to find spare parts for such a homemade or purchased device. It will not be possible to repair it at a service center.

- The fragility of the structure due to the material used to make the case (plastic) in purchased cordless angle grinder models. When purchasing or making metal models, the weight of the structures will be significant, and it will be very difficult to hold the device in one hand.

- Small variability of models. There are not many options for homemade models with such a drive, which makes it difficult for many users to choose the right functionality for themselves.

Unfortunately, having weighed all the advantages and disadvantages of a battery-powered angle grinder, most men do not consider it necessary to bother with its manufacture or spend money on its purchase. More often they opt for a networked angle grinder.

How to power an angle grinder from a car

#1 OFF SITE Ervin

- User

- Registration: 23 Jun 2014

- 72 messages

- Car: Pajero 1, TLC 70, Jimny

- Name: Ervin

- Gender: Man

- City: Kyiv

The question of how to feed an angle grinder on expeditions arose.

Judging by googling, a regular car inverter is not the best solution.

Now I'm looking at inverter generators.

I would like to fit in $300

Who can advise what?

#2 OFF SITE Des

- Car: Suzuki Samurai 3.5 pcs