How to make a snowmobile from a scooter with your own hands

Dear visitors to the “ Samade Friend ” website, today we will look at one of the options for assembling a snowmobile from a scooter with your own hands. Mainly that no fundamental changes have been made to the design and the scooter can be easily converted from a snowmobile into an all-terrain vehicle) A moped or scooter is an excellent and moderately economical means of transportation, both in the city and in rural areas. This type of transport is especially popular among teenagers, because it is an intermediate link between a bicycle and a real motorcycle) With the onset of cold weather, motorcycles are placed in the garage and remain there until spring, but not in our case, because a scooter is made into an excellent snowmobile for fishing trips)

Homemade ATV from a scooter

Homemade ATV made from a scooter: photo of production with a description of the homemade product, as well as video testing.

The author decided to accustom his son to technology from a young age; for this, the craftsman assembled an ATV from a scooter with his own hands. To build the homemade product, we bought a broken scooter, wheels from a walk-behind tractor, and some spare parts from a children's ATV.

Below are a few photos of the vehicle assembly.

The front suspension is made, the levers are homemade, the steering knuckles are from a children's quad.

The rear axle with a star is mounted on housing bearings.

The engine with variator remained from the scooter.

The author installed wheels from a walk-behind tractor.

The result is this mini ATV.

The craftsman named his homemade product “Egorushka.”

We recommend watching a video of a homemade ATV.

Homemade snowmobile on tracks with your own hands from a walk-behind tractor: video, drawings, photos

As soon as winter begins in our country, given the climate, two-wheeled vehicles are put away in the garage until spring. It may be impossible to use a car for transportation due to heavy snow. And here, a snowmobile on tracks, which you can make from a walk-behind tractor with your own hands, comes to the aid of all motorists who want to move along a snowy road.

Not everyone has the opportunity to buy an additional vehicle, but everyone can independently construct a homemade tracked snowmobile from a walk-behind tractor.

Practical information

Making your own snowmobile from any scooter? It's a simple matter, if you have the desire. Approximate speed of the latter? 40-60 km/h. If we take into account the weight of the finished converted unit and the weight of the passenger? The speed of the snowmobile will be within 20–45 km/h. Moreover, this takes into account the use of the original engine. Its advantages include that it is quiet, has a CVT gearbox, forced cooling, light weight, electric ignition, consumes little fuel, and does not vibrate. In general, a real find for DIYers.

The only thing that can significantly reduce the power of the unit and increase the weight of the entire structure? These are snow-filled pockets that are included in the design of the scooter. To prevent this from happening, you can make a casing with your own hands that will cover the upper part of the caterpillar:

- take polycarbonate, organic glass, any other plastic;

- from the taken sheet we cut out the sides of the future casing;

- we fasten them using hot glue and plastic corners;

- take flexible and thin plastic, if possible, and cut out a strip whose width is equal to the width of the casing;

- we assemble everything into corners and coat the joints of the parts with plasticine;

- Now we cut out pieces corresponding to the casing from fiberglass, coat them with resin, and then lay them tightly on the structure;

- After a day, everything will dry, and it will be possible to trim the resulting protective casing as needed.

With my own hands, as you can see, I managed to turn an ordinary scooter into a snowmobile. Minimum investment of time, effort, money? This is what distinguishes this design from others. And, by the way, this power unit is quite capable of pulling both a sled with children and a loaded cart.

What you might need

In order to make a homemade moped, you first need to decide on the parts that will be used during assembly. In most cases, the basis of the design is an unnecessary bicycle. You immediately need to think about where all the details will be placed. The most bulky of them is the engine. It is usually located in the rear trunk or at the bottom of the frame. If the frame has such a structure that placing the engine will create inconvenience when moving the moped, then it can be made separately. This will require welding work. The frame should be made from bicycle parts that are specially designed for the appropriate load. If necessary, you can change the geometry of the desired part. For this, a stop is used and the use of water pipes is strictly prohibited, since they do not have sufficient strength. Such a homemade moped will not go far. Engine mounts can be cut from sheets of iron with a thickness of at least 5 mm and welded to the frame.

How to make a homemade snowmobile, options from a scooter

In good weather, a motorcycle scooter with a small engine capacity has always been in demand not only among young people, but also among adults. Because it was distinguished by its ease of operation, lightness and good speed. But unfortunately, when cold weather sets in, due to the small diameter of the wheels, riding a scooter becomes very uncomfortable, and in snowy weather, even wearing winter tires is completely unrealistic.

Having studied various motorcycle magazines, it was noticed that there are caterpillar movers on sale; they can be installed instead of the rear wheel, which will lead to the transformation of the motorcycle into a snowmobile.

If you have like-minded people in this matter, then it is best to take a track from the Buran snowmobile (photo 1); it will work perfectly, since one track will produce 4 suitable for a scooter. The cost will be 2.5 times cheaper than tracks taken from a motorcycle. But for one scooter it will cost too much.

Making a snowmobile from a scooter with your own hands

In good weather, a motorcycle scooter with a small engine capacity has always been in demand not only among young people, but also among adults. Because it was distinguished by its ease of operation, lightness and good speed. But unfortunately, when cold weather sets in, due to the small diameter of the wheels, riding a scooter becomes very uncomfortable, and in snowy weather, even wearing winter tires is completely unrealistic.

Having studied various motorcycle magazines, it was noticed that there are caterpillar movers on sale; they can be installed instead of the rear wheel, which will lead to the transformation of the motorcycle into a snowmobile.

If you have like-minded people in this matter, then it is best to take a track from the Buran snowmobile (photo 1); it will work perfectly, since one track will produce 4 suitable for a scooter. The cost will be 2.5 times cheaper than tracks taken from a motorcycle. But for one scooter it will cost too much.

Soon, after contacting a company that deals with propulsion kits, I received one not very wide track and a plastic ski without fastening.

No changes will be made to the basic design of the scooter, so that in warm weather it is always possible to replace the installed tracks with wheels.

We purchase in the store a driven sprocket from a Buran snowmobile, 2 wheels from a regular scooter for children and 2 small wheels from a cart, with roller bearings. Next, instead of the drive wheel on a scooter, we put a wheel of a much smaller diameter, for example from a sports car, in order to replace the gear ratio. This is done because in a scooter transmission the gear ratio is usually calculated for its operation on excellent roads at an approximate speed of up to 40-60 km/h. Of course, when driving in snow, the load on the engine increases significantly and its power most likely will not be enough, and such a high speed can be dangerous on slippery roads.

We take the drive wheel disk of the moped and cut out the brake drum with splines for the drive shaft, and to attach a disk of smaller diameter, we drill a hole in the drum (photo 2).

To ensure that the caterpillar does not slide off the wheel and does not slip while moving, we make hooks (photo 3) from plastic water pipes, which in turn are inserted into a hole on the caterpillar.

It is necessary to make a bandage of the required diameter from flat roofing metal, attach the hooks to it using furniture bolts (photo 4), they must be at the same distance from each other and at a pitch that will correspond to the location of the caterpillar holes. Using the same bolts, we fasten the wheel, having first put a bandage on it (photo 5). We get a soft driving track sprocket from a regular wheel.

We connect the driving sprocket of the Buran snowmobile with 2 rubber wheels from the trolley with M8 bolts, we get a driven sprocket, and for the axle we take a stud with an M10 thread (photo 6).

To make the frame of a tracked mover, you will need metal corners and square pipes (photo 7). The dimensions of the frame and the parts that go with it will need to be selected independently, depending on the track you choose and the brand of your scooter.

You can take a homemade ski from wood or a plastic one from a children's scooter, attaching a metal cut to the bottom so that the scooter does not lose control on an icy road. The ski must be secured to the front fork of the scooter through a special rack. It will have 2 degrees of freedom of movement, due to which when the scooter is tilted in any direction, the ski will remain on the snow with its entire plane.

We install a wide platform under the feet and a small decorative shield for the front fork. For long trips in adverse weather, it is necessary to install a windshield.

Tools and materials

The required components will be:

supporting elements (wheels, runners or tracks of your choice);

gear and transmission links;

fuel tank;

steering controls;

the frame on which all other components rest.

Most often, snowmobiles are not mounted on tracks or skis, as is usually thought, but on wide pneumatic wheels.

Many craftsmen use bicycle or motorcycle rims.

But the most passionate people make them with their own hands. The following can be used to make tracks:

Additionally you will need:

a star transmitting and receiving impulse;

one or more seats;

fasteners (nuts, bolts, screws);

We're starting to remodel

So what is the main goal? To use the scooter for its intended purpose in the summer and as a snowmobile in the winter, minimal changes will need to be made to the design. Namely ? remove the wheels and install a ski in place of the front one, in place of the rear one? mover.

We fasten the ski with our own hands using a stand, in which the left and right sides work separately, independently of each other (or, in other words, a frame made of corners on top, and a rod below). This type of design is extremely safe because, firstly, it helps the ski stay on the snow surface. Secondly, the scooter-snowmobile will not spontaneously go sideways, will not become uncontrollable on ice, and the wear of the ski when moving on asphalt is minimal. Besides, a rod? According to its function, it must be a skate, not straight, but semicircular, so that the steering wheel can freely turn in different directions both on snow and ice.

We continue to make a vehicle with our own hands, and now it’s the turn of the caterpillar, which stands in place of the rear wheel.

So, you will need a driven sprocket from a Buran snowmobile, two wheels, small, with roller bearings, a wheel with the diameter of a moped. So, we cut out the splines with the brake drum from the moped wheel and, having drilled a hole in it, insert a smaller disc there. To prevent the mover from sliding off the resulting wheel, we make similar hooks with our own hands from the plastic water pipes that were used for the caterpillar.

We take roofing metal and make a bandage out of it with our own hands, for which we attach hooks to furniture screws at a distance, taking into account the location of the holes on the caterpillar. That is, by attaching the bandage to the moped wheel with hooks, we get a drive sprocket for the propeller.

Now you will need to connect the Buranov star with two roller wheels with M8 bolts, and a pin (M10 thread) will be used as an axis. A square pipe and metal corners are suitable as a frame for the caterpillar. It is difficult to name any specific dimensions, since in this matter it is necessary to proceed from the brand of the scooter itself and from the size of the track.

Do-it-yourself snowmobile from a moped

If you live in a village or town, or maybe there is simply a lot of snow falling in your area, a snowmobile from an old moped will become a real helper for you.

To make such a snowmobile you will need:

- The V-50 engine (Sh-58 - Sh-62 is also suitable), which will have a working carburetor, air filter and ignition coil.

- Front fork.

- The rear fork is from an old moped (no matter what brand).

- Motorcycle shock absorber.

- Two liter canister and fuel tap.

- Steering wheel with the ability to control the carburetor flap, clutch and brake.

- Two wheels from any old moped.

- A set of steel pipes from which the frame will be welded.

- Welding machine.

The diagram shows that a moped-snowmobile is not very different from a regular one . Only the ski instead of the front wheel gives it away. And the rear wheel is installed in a pendulum fork not by mounting with side shock absorbers, but with a central one.

1 — rear fork, 2 — seat cushion, 3 — fuel tank (from a canister), 4 — reinforcing gusset (steel sheet 2.5 mm thick), 5 — seat base (box made of sheet duralumin), 6 — frame spinal tube ( steel pipe with a diameter of 36 2.5 mm), 7 - steering wheel, 8 - reinforcing gusset (steel sheet 2.5 mm thick), 9 - front fork (from mopeds such as "Riga", "Karpaty" or "Verkhovyna"), 10 - rubber guy-shock absorber, 11 - bracket (pipes - 22X2 mm in diameter, supports - 2.5 mm thick steel, gusset - 3.5 mm thick steel). 12 - wad (glued from plywood blanks, the sole is a steel sheet 0.8 mm thick), 13 - engine (type V-50 or Ш 58 - Ш-62), 14 - vertical frame pipe (steel pipe with a diameter of 36X2.5 mm ), 15 — rear engine mounting bracket (steel sheet 2.5 mm thick), 16 — shock absorber (from motorcycles like “Minsk” or “Voskhod”), 17 — snow chain, 18 — rear wheel.

Before you start assembling such a unit, you should make a model of it. From thick cardboard you need to cut out all the parts that will make up the moped-snowmobile, and fix them on a piece of plywood as you see fit. It is also advisable to cut out the silhouette of the “driver” - this will help avoid stupid design mistakes. The entire structure will be connected by a frame of two pipes. So first you need to collect it.

The frame is welded from longitudinal and vertical pipes. The longitudinal tube houses the steering button, the upper mounting unit, and the seat box. And on the vertical pipe are located the rear engine mounting unit and the axis of the pendulum fork. The optimal frame should be of minimal size and weight, but not lose rigidity and strength. Everything is welded together first with several welding “points” and, if everything corresponds to your “drawing”, all joints are welded. Make sure that the structure does not warp. After this, clean all welds and sand the pipes. Prime the frame and paint it with air-drying alkyd enamel.

The ski can be cut from pieces of plywood glued together. Then edge the sole with a thin steel sheet. You need to put a snow chain on the rear wheel. It can be made in the image of a car chain - assembled from links of a steel chain.

Since this snowmobile does not have footpegs, you will have to use your feet for balance. Therefore, you should wear mini skis. You can make them by cutting off children's skis.

Do not forget - the brake on a moped-snowmobile is only on the rear wheel.

To clear snow, you can attach a bucket and a cargo sled to the moped. The bucket is a piece of plywood bent and fixed like a snow shovel. A sled is a simple plywood box that sits on skis.

When working in snow, use only first gear. If the engine won't pull, install a much larger diameter sprocket on the rear wheel.

Preparation for work

Before you start assembling a motorized dog with your own hands, you must decide on its characteristics. It is important to decide what load capacity the equipment will have, what engine it will power, and what type of transmission will be used in the design. The mechanic needs to decide whether the engine will be started with an electric starter or manually.

When motorized dogs are made with your own hands, they are usually supplemented with devices that will respond to the owner’s needs. This may include:

- winch;

- circuit protection;

- additional light.

You may need a motorized towing vehicle in the form of a pusher. All these characteristics will allow you to determine the required set of tools and materials.

ATV from a scooter: assembly features

An ATV is a useful household, fashionable and functional appliance. Therefore, scooter owners dream of switching from two-wheeled to four-wheeled motor vehicles. It is quite possible to make an ATV from a scooter with your own hands. To do this, you need to prepare the appropriate components and tools. This is a fascinating process that will result in a universal self-propelled vehicle.

The scooter is a lightweight motorcycle that can easily make an excellent ATV. The engine of this scooter is located under the seat, which is an advantage, since the all-terrain vehicle will have to be driven on rough terrain, rocky or muddy roads. The motor in this design will be reliably protected from dirt and moisture entering the system.

The scooter turns into a lightweight ATV that has all the advantages of popular all-terrain vehicles. The low weight is explained by the absence of a heavy body, which guarantees the maneuverability of the motorcycle, as well as its low inertia. Another advantage of an ATV assembled from a scooter is the fact that even one person can pull it out of a hole or sticky mud. This technique is perfect for both entertainment and simple household tasks. For example, with the help of such an ATV it will be possible to transport small loads. The advantage of motor vehicles assembled from a scooter is low fuel consumption.

Motor

An ATV with a scooter engine will not differ in significant power. But when driving off-road, the driver will be able to get his share of drive. Once the frame is assembled, the motor can be mounted on it. This is a painstaking process that requires accuracy from the master. The motor must fit firmly into its seat. Otherwise, it will be subject to strong vibrations.

The motor shaft must be connected to the gearbox on the rear axle. To do this, you need to attach a chain drive to the gear. The transmission is installed immediately after this, bringing all controls, including those from the engine, to the frame. The pedals and control levers are secured to the appropriate seats.

Gearbox and brakes

If the quad is assembled on the basis of a car, the chain drive is replaced. This greatly simplifies vehicle maintenance. A manual transmission is installed, as it improves maneuverability. The input shafts are directed to the front and rear axles. Wheels can be removed from small cars: Oka, Niva.

The brake system is selected taking into account the mounted wheels. The steering knuckles are removed from the Niva or Oka. To assemble an all-wheel drive model, you will need: car steering, transmission drive and differentials. In this case, the frame is not used. It is better to weld the structure to suit the engine size.

The suspension is also removed from the car. A gearbox is installed on the front-wheel drive model. The next stage is the manufacture of the body. For this you will need fiberglass, fiberglass. Experts advise using the first material, as it is easier to work with.

A drawing is pre-prepared and body elements are cut out from polystyrene foam. To fix them together, glue or foam is used. Fiberglass is glued to the foam. The resulting structure is attached to the frame. The body is well dried, primed, sanded and painted.

Tires of the required size are selected. If the vehicle will be used off-road, it is necessary to create the appropriate ground clearance (distance from the bottom to the surface of the earth). For this, R17 wheels are installed.

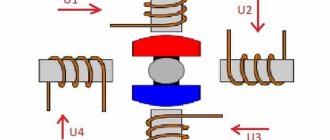

The resulting ATV is equipped with turn signals, headlights, a dashboard, and a battery. Electrical equipment is connected according to a pre-designed diagram. For this, wiring and a multimeter are used to check the voltage in the network. The next step is to install the seats. The vehicle is checked for serviceability, and the data displayed on the drawings is compared. A quadric, correctly assembled, is not inferior in technical and operational characteristics to finished vehicles.

DIY tracked snowmobile from a walk-behind tractor

To make a tracked snowmobile from a walk-behind tractor with your own hands, simple materials are used. The frame is made of stamped channels and square pipes. Round water and gas pipes were used to make the shafts. The engine was used from the Neva walk-behind tractor.

The snowmobile looked a little rough. But after conducting winter tests, good driving characteristics were revealed: speed, cross-country ability. It is also light and compact, and quite economical in fuel consumption. The original design assumed an asymmetrical engine arrangement. This provided a number of advantages: during maintenance - good access to the engine; convenient starting and gear shifting; redirecting the chain drive directly to the track drive shaft.

But during testing, when moving on loose snow, when making a turn, the snowmobile often fell over. Because of this circumstance, it was decided to place the engine in the center of the front of the snowmobile. The design has been improved, especially the front of the frame. An intermediate shaft was also installed, which transmitted torque from the engine to the track. In addition, modernization was carried out, which improved the driving performance, comfort and reliability of the snowmobile.

Manufacturing

Making a snowmobile from a scooter with your own hands is not that difficult. No special adjustments to the original design are required. In this case, it will be possible to easily replace tracks with wheels and back when the weather changes. It is recommended to take tracks and driven sprockets from Buran snowmobiles. Additionally, a pair of wheels from a children's scooter and a pair of medium-sized wheels from any cart (with the addition of roller bearings) are used.

The drive wheel must be replaced with a propeller of a much smaller diameter. This is due to the need to adjust the gear ratio.

The fact is that when driving in snowy areas, the load on the engine increases. Excessive speed is also a source of risk.

How to make a snowmobile

You can make a snowmobile from different vehicles that are in the garage.

From a motorcycle

You can make a snowmobile from a motorcycle using different models. The most popular are IZH and Ural. The advantages of such a rework are that no special changes need to be made. If the product is in good condition, you can even keep the original frame.

The conversion technology is as follows:

- Make a rectangular frame from metal pipes or appropriate corners. Its optimal dimensions are 150*43.5 cm.

- In addition to the IZh motorcycle, it is necessary to make a steering beam. It is made from metal corners. The optimal dimensions are 50*50*5 mm. Additionally, the beam is sheathed with metal plates.

- After this, it can be installed horizontally on the drilling machine. Treat the connection area. Do the same with the frame. In these places you need to make special grooves for reliable fixation. Additionally, attach a corner to the front frame.

- Now you can attach the seat for motorcyclists.

- You need to make holes in the side members.

- A channel must be placed between the front and middle parts of the frame to strengthen the structure.

- Regardless of whether the snowmobile is made from a Ural or another model of motorcycle, it is necessary to select a track sprocket and rubber band in advance. The optimal dimensions are 220*30 cm with a thickness of no more than 1 cm.

- Before installation, it is recommended to cover the track with nylon, which will allow the material not to delaminate during operation.

- Now you can move on to the transmission. It consists of two parts. The first, the front axle, is the drive axle. It is made of a tubular shaft, a track sprocket and a roller. The second is the rear axle. It is made from a caterpillar drum and a tubular shaft.

- You need to complete the snowmobile manufacturing process by welding sheet metal skis.

When converting a motorcycle into a snowmobile, it is important not to change the steering system. In the final product, this part must perform its original functions.

The principles of modification are the same, they do not depend on the vehicle model. But the snowmobile from the Ural motorcycle will be heavier.

From Zhiguli

The design of the car is characterized by simplicity, ease of operation and high maneuverability. To make it you need to follow the instructions:

- Frame assembly. It's better to make it from pipes. The frame consists of front and central beams (steel pipes with a diameter of 5 cm), two lower diagonal elements (bent pipes with a diameter of 3 cm) and a rear strut. Welding is used to fix the elements.

- Installation of steering columns. To do this, you need to place two bushings on the front beam.

- Fixing the axle shaft. It is located on the rear frame; first you need to weld the body under it. It is made from a metal pipe with a diameter of 6 cm. Secure the axle shafts using bushings and electric rivets.

- Installing a car engine. First you need to make the front and rear fastening units on the central beam of the frame. First they need to be placed on the engine itself, and only then welded to the frame.

- In a homemade snowmobile, you can install large diameter wheels or skis made of sheet metal. In the first case, the rear and front wheels need to be connected in pairs with a metal pipe. At the same time, make grooves in the hub for the bearings, which are subsequently secured with spring rings. Additionally, install a spacer between the bearings.

- Install a sprocket on each wheel depending on the expected maximum speed. This snowmobile can be used at any time of the year. For a snowy winter, a design in which the front wheels are replaced with skis is suitable.

- Installation of the steering system. It is taken whole from a car, for example, from a Zaporozhets, or a motorcycle. The choice depends on personal preference. In the first case, gas, clutch and brake pedals are additionally installed. The gearbox is controlled using a lever and a rigid rod.

- Installation of a snowmobile cabin, the role of which is played by the car body.

In a similar way, you can assemble a structure from Oka with your own hands.

From a moped

The easiest way is to make a snowmobile from a scooter with your own hands. This is due to the fact that no special changes will be made to the design. This will allow you to use it as a snowmobile in winter, and as a moped in the warmer months.

Converting a scooter into a snowmobile is carried out using the following technology:

- Prepare all the details in advance. You will need a caterpillar, skis (plastic ones are possible), a driven sprocket of the intermediate shaft from a Buran snow scooter, 2 wheels from a children's scooter and 2 wheels with bearings.

- Now you can start remaking the moped. For a scooter rider it will be easy. The drive wheel must be removed and replaced with another one of smaller diameter in order to replace the gear ratio. This will reduce the maximum possible speed for scooters of this design, since when driving on snow, the load on the engine increases, which means that high speed can be detrimental to it.

- Cut a hole for the shaft from the drive wheel disk, and then make hooks for the caterpillar. Make a bandage from a sheet of metal and attach the hooks to it. The result should be a wheel with hooks.

- Connect the drive sprocket to the wheels with bearings.

- Make a frame from metal corners.

- Attach the ski to the front fork through a special rack. This will allow you to leave the ski on a flat surface when tilting the snowmobile.

- Make a small cover over the caterpillar to prevent snow from getting into the body kit.

- Make a platform for your feet from a metal sheet.

From the cultivator

A snowmobile made from a cultivator can be wheeled, tracked or combined. The advantage of this design is that there will be a minimum of rework work. It is easiest to make a wheeled one, but homemade tracked snowmobiles are also easy to make from this product. To do this you will need:

- Make a frame for a snowmobile from metal pipes. You can use corners instead. The frame should be in the shape of a rectangle.

- Attach the seat to the base. It can be a box or any similar device.

- Make skis from sheets of metal and then weld them to the frame.

- The resulting structure can be attached to a motor cultivator. Now you can pour gasoline into the tank and use the product for its intended purpose.

From Friendship

The Friendship chainsaw has a powerful engine that can propel a small vehicle. Therefore, you can make a mini snowmobile based on it if you follow the instructions:

- Frame assembly. To do this, you need to prepare steel corners measuring 50*36 cm or sheets with a thickness of more than 2 mm in advance. Angles are used to assemble the middle part of the frame, and sheets are used for the front and back. The metal is bent at an angle of 90° to ensure the required rigidity of the structure.

- Make two through holes that are necessary for attaching the track shaft and track guide wheels. The last parts are installed on both sides of the side members and are designed to adjust the track tension.

- Brackets for installing track rollers are attached to the bottom of the side members. It is better to fix these parts by welding.

- Place the rollers in rubber covers and fix them on five axes, placing them at the bottom of the grooves. The axles themselves can be attached with nuts or bolts.

- Now, between all the elements, install bushings, which are recommended to be made of duralumin.

- Make three racks from metal corners. The chainsaw gearbox will be located on them. To strengthen the structure, you can use scarves.

- Now you can install the seat on the frame. It should be located between the middle and rear parts of the structure.

- The steering wheel will be located in front of the frame. You first need to make a hole for it. A pipe with control handles can act as a steering wheel. To create a control system, it is still better to take equipment from a motorcycle or moped.

- Now you need to make the drive shaft. To do this, you can take a metal pipe into which you insert a round flange to fix the gears.

Making a snowmobile from a moped

Making a snowmobile from a moped

Is it possible to make a simple winter moped that could become not only entertainment, but also an assistant for those who live in villages and towns? “Such a moped could also be used for snow removal,” writes Slava Polkovoy from the Pskov region, “after all, after a snowfall, you spend hours clearing debris near your house.” Indeed, why not? After all, two horsepower contained in the cylinder of a moped engine is a good help. If you make a tractor with such a motor, it will help you not only remove snow from the paths with a simple plow, but also take it on a sleigh to a designated place. So, a winter moped. You will need the following purchased components and assemblies: engine type V-50 (or Sh-58 - Sh-62) with the necessary equipment: carburetor, air filter, ignition coil; front fork from “Verkhovyna”, “Riga” or “Karpaty”; rear pendulum fork from any moped; a shock absorber from a Minsk or Voskhod motorcycle, as well as a plastic canister with a capacity of about two liters and a fuel tap with a sump. In addition, there is a steering wheel with a carburetor throttle control handle and clutch and brake control levers. Well. of course, a pair of wheels - for example, from a Riga-made mini mokika or a motor scooter. For the frame, select steel (preferably seamless) pipes of various diameters. Clearly, stock up on a welding machine. Look at the picture. As you can see, a “winter” moped is not too different from a regular one, except that instead of a wheel, a ski is installed in front (which, however, can easily be replaced with a wheel when summer comes). And further. The rear wheel, equipped with snow chains, is mounted in a pendulum fork not with two side ones, as on serial mopeds, but with a central shock absorber from a motorcycle. If you are not going to completely copy our moped, I can recommend a completely universal method for designing and manufacturing two-wheeled machines. To begin, cut out from thick cardboard the silhouettes of all available purchased components and assemblies - the engine with clearly marked mounting units, the front fork, the fuel tank, the exhaust pipe and muffler, the rear pendulum fork, the shock absorber, the rear wheel. Now lay out the silhouettes on a large sheet of paper or plywood and find for them the only possible position that your design instinct, design taste and common sense will tell you. Don’t forget that the driver is also included as a “component element” in the “person-vehicle” system. That is, it makes sense to cut out an articulated silhouette model from thick cardboard in accordance with your anthropometric dimensions - it will help avoid mistakes when configuring the car . So, the silhouettes have taken their place on the plaza sheet. Fix them on it (say, with a couple of small nails) and outline with a colored pencil. Now you can draw a frame that will unite all the units as a whole. Its basis will be two pipes - the spinal (longitudinal) and vertical. On the first, the steering column, upper engine mounting unit and seat box are mounted. On the second, the rear engine mounting unit and the axis of the pendulum fork are mounted. To create a frame of an optimal configuration that combines all these elements means to make it as simple as possible, with minimal dimensions and, accordingly, mass. But at the same time as strong and rigid as possible. Having determined the configuration and location of the frame elements using the selection method, draw it on a plaza drawing (take a pencil of a different color). Next, you should draw the mounting components for installing the engine, brackets for fixing the shock absorber, the position of the saddle cushion - and the life-size plasma drawing of the moped is basically ready. Let's move on to the second stage - making the moped frame, and then assembling the car. First, the pipes - spinal and vertical - are adjusted directly according to the drawing. Then they are tacked together with several welding “spots”. Also adjust the reinforcing gussets, engine mounting units, steering column, and pendulum fork mounting units. Having carefully checked the conformity of the frame to the plaza drawing, as well as its symmetry relative to the longitudinal plane, weld all joints sequentially with step-by-step control of the frame's fidelity to the drawing. This will then avoid distortions of the entire structure. The seams of the welded frame are cleaned with a file, the pipes are sanded, after which the metal is primed and painted in two or three layers with air-drying alkyd auto-enamel. The front steerable ski of a winter moped is made of wood. Of course, the best one will come from a piece of mountain debris, but you can glue it together from several layers of plywood, and then edge the sole with a thin steel sheet. The snow chain is assembled from links of a steel chain of suitable size. You can, of course, simply wrap the wheel with such a chain, but a more reliable option is a composite bandage similar to a car chain made from individual elements. Please note that winter mopeds do not have footrests. The fact is that the driver has to help himself with his feet while driving to maintain balance, so it is best to put miniature plastic skis on them or, as a last resort, make “skis” from scraps of children’s skis. Their length is no more than 400 mm. I note that the brake on the moped is only on the rear wheel with manual drive. To work in tandem with a moped, make two trailers - a “snow plow” and a cargo sled. The first is for clearing paths. It consists of two boards with a cross section of 30X300 mm and a length of about a meter connected in the shape of the letter A, with a jumper approximately in the middle of this letter A. Of course, such a “plow” can only remove freshly fallen snow. The cargo sled is an ordinary plywood box mounted through spacer bars on two children's skis. Of course, carry out all work on cleaning and transporting snow in first gear. If the engine starts to “sneeze”, you will have to install a larger diameter sprocket on the rear wheel. That's all.

Yes, when switching to the summer version of the moped, standard footrests and, preferably, a foot brake are installed on it.

The numbers in the figure show: 1 - rear pendulum ailment, 2 - seat cushion, 3 - fuel tank (from a plastic canister of suitable volume and dimensions), 4 - reinforcing gusset (steel sheet 2.5 mm thick), 5 - seat base ( box made of sheet duralumin), 6 - frame spinal tube (steel pipe with a diameter of 36 2.5 mm), 7 - steering wheel (from Monica "Karpaty"), 8 - reinforcing gusset (steel sheet 2.5 mm thick), 9 - front vipka (from mopeds of the "Riga", "Karpaty" or "Verkhovyna" type), 10 - rubber guy-shock absorber, 11 - bracket (pipes - 22X2 mm in diameter, supports - 2.5 mm thick footing, gusset - thick steel 3.5 mm). 12 - wad (glued from plywood blanks, the sole is a steel sheet 0.8 mm thick), 13 - engine (type V-50 or Ш 58 - Ш-62), 14 - vertical frame pipe (steel pipe with a diameter of 36X2.5 mm ), 15 — rear engine mounting bracket (steel sheet 2.5 mm thick), 16 — shock absorber (from motorcycles like “Minsk” or “Voskhod”), 17 — snow chain, 18 — rear wheel.

3. SLAVETS, engineer

How to make an ATV from a scooter?

To assemble an ATV from a light scooter, you need to prepare a number of tools. Welding equipment and a grinder must be used in the work. You will also need a variety of hand tools, from screwdrivers to wrenches.

The workshop is equipped in a heated, well-ventilated room or outdoors under a canopy in the summer.

To make an ATV from a scooter with your own hands, the design drawings will need to be examined in detail before starting work. It is best to develop the scheme yourself, working out every detail of the future system.

You need to start assembly with the frame, which is taken from the donor scooter. It will need to be modified, additionally boiled and a trunk located in the front or rear made.

Additional material will definitely be needed to assemble the frame. It should be a thin-walled pipe with a round or square cross-section. It should not be heavy, otherwise the weight of the ATV will be large. Because of this, it will lose maneuverability and controllability, and too much load will be placed on the engine. Because of this, it can fail quite quickly.

It is not recommended to use water pipes, as they are very fragile and are not suitable for such purposes. To install all the necessary components and mechanisms, brackets are welded to the frame.

DIY scooter trike

Added: 06 Oct 2016, 17:21

Figure 14 shows two rotors, the top one that burned out, the bottom one new. Why do I not recommend rewinding the rotors? If you look closely at the lower rotor, you will see a gray plaque; on the upper one it is simply not visible. The rotor was balanced at the factory; when rewinding, it is not always possible to balance it and the electric drive can quickly fail.

• Shuttlecocks are circles with different inner radii. The width of all shuttlecocks is the same - 10 cm. The circle must be cut in one place along the shared thread. The flounce is sewn onto the inner line of the circle.

Step two

By the way, there is an easy way to check the functionality of the power supply. To do this, it must be disconnected from the motherboard. Simply disconnect the connectors of the wires leading from the block to the plateau. Connectors can be 20 or 24 pins (4 or 6). To check whether the unit is working, you need to short-circuit contacts 14 or 15 with each other (if the connector is twenty-pin) or 16 and 17 (if it is twenty-four pin). That is, green (sometimes gray) and black wires are connected to each other. Then the unit itself is connected to the network through an outlet. If the cooler fan starts working, then everything is in order, it is not the cause. You need to look for other damage. You can also sew a blanket envelope for a newborn. Compared to the previous version, it has a simple and easy to sew pattern. This envelope is very easily transformed into a baby blanket, then, if necessary, reassembled into an envelope. Sewing it will take a small amount of time, but the convenience of this item is undeniable.

Proper installation of door hinges ensures correct functioning of the door. Make a ponytail that was fashionable in the 60s with a backcomb at the crown from an ordinary ponytail.

Each of us remembers the New Year celebration, especially the beautiful Christmas tree with toys, garlands, confetti and candles. In order not to buy a real Christmas tree or make some addition to it, it is possible to create Hand Made decorations for the holiday from what you have on hand. This craft will surely delight your family and friends.

To obtain a polyline, perform the following steps: Hello! I have two LED table lamps. Both burn well and very brightly. But yesterday I needed to transport them from one city to another, and after transporting one of the lamps began to burn very dimly, and then stopped altogether. I tried unplugging it from the socket and plugging it back in and turning it on. The LEDs lit up, but very very faintly, but two LEDs now don’t light up at all. Tell me, please, is it possible to somehow fix the lamp? And what caused this breakdown? Could it be that I hit the case and now it doesn't work? Thank you in advance for your response!

If we continue the topic of choosing gifts for the older generation, then this task is quite difficult. Not every dad, who has long since become a grandfather, can be gifted a parachute jump or quad biking. A photo book would be a good gift for parents for the New Year. As a rule, on the eve of the New Year holidays there is usually a lot of work in photo workshops, so you should start thinking about ordering such a gift as early as possible. To order a photo book, you will need to select the most interesting photos together, come up with text for each page of the book, you can add photos of parents with their grandchildren, brothers and sisters, and friends. Of course, you will have to spend a lot of time, but such a gift will make an indelible impression, becoming one of the most original and unforgettable. As an alternative, you can give a photo frame with pre-uploaded photos as a New Year's gift.

transparent glass container with a lid. There were a variety of doll designs, but they all had one common feature - the absence of a face. This is easy to explain: through facial features, a doll can be exposed to dark forces and bring negative energy into the house.