How to make a smelter for aluminum and other metals

The indoor ornamental plant shown in the video is actually a cleverly disguised smelter. This idea will be a real boon for those who from time to time work with metal in order to make another craft from aluminum or other metal at this cheap smelter, but there is not enough space in the workshop or at home to have its own place for each thing.

You will find some inventions for yourself in this Chinese store.

Products for inventors.

Using a melting furnace

We pour coals inside the container, pour lighter fluid over them and set them on fire using a gas can with a burner.

Close the lid. We connect a hose to the tube to supply air inside the combustion chamber.

Then you need to wait a while until the desired temperature is reached inside the chamber.

We install a crucible made from an old fire extinguisher inside the furnace. We fill it with aluminum blanks. When the aluminum melts, remove the crucible and pour the liquid metal into the mold.

It is advisable to place the mold itself in water - it will cool faster. The result is an aluminum ingot. Smooth and neat.

DIY mini aluminum smelter

Aluminum is used in the production of parts in blacksmithing. The peculiarity of such an alloy is that it has low weight, a high degree of ductility, and good conductivity of heat and electricity.

With all these qualities, the alloy in question can be called a low-melting material, which significantly increases its popularity. To carry out work on creating parts from aluminum by bringing the alloy to a plastic state, a forge is used.

For many years, people have considered the question of how to make a forge for melting aluminum and the result of a huge number of attempts has become structures that you can create with your own hands.

Homemade forge for melting aluminum

Purpose and classification

A metal smelting forge is a furnace that has been used in blacksmithing for many years. However, the small efficiency indicator determined that it was not used in the production of products from the alloy in question in industry. There is the following classification:

- By type of housing: open and closed. Open has a completely open top. The closed version has a closed top.

- At the installation location: stationary and personal forging.

Closed type forge Open type forge

To remove gaseous combustion products, a special pipe is created if the work is carried out indoors. The open type does not have a pipe, since combustion products escape without being drained.

General operating principle

With your own hands, using scrap materials, you can create an effective system that will allow you to carry out forging work. There are a huge number of types of designs that you create with your own hands. A professional forge has the following elements:

- the table is made of fire-resistant material;

- there is a firebox with a grate;

- air chamber to improve fuel combustion efficiency;

- air drainage with supply air duct;

- valve for regulating air supply;

- tent;

- window for feeding workpieces;

- umbrella;

- chimney;

- crucible;

- hardening bath;

- gas-air chamber.

An example of a furnace design for aluminum smelting

The type of forging equipment in question can be called a classic forge, which is used in blacksmithing. It is quite difficult to create it with your own hands, but you can create a simpler design for melting aluminum.

Brick construction

It is better to make it yourself using scrap materials. A mini forge of 6 bricks is suitable for obtaining various parts that are used to decorate metal objects, buckets or other parts. The creation process can be divided into the following stages:

- We create the body from fireclay bricks. Such a brick can withstand exposure to high temperatures for a long time. When choosing a brick, you should pay attention to the fact that it should not have damage or defects. This is because cracks will lead to heat loss.

- We create the grid grate shelves from scraps of steel pipes. Steel pipes should be of small diameter. Fusible material options cannot be used.

- The grate is made from steel strips, the thickness of which is 4-6 millimeters.

- We twist the grate at an angle with a screw.

- The fuel can be coal or coke.

- Ignition is usually carried out using a blowtorch. You can also use a gas burner.

- A window under the nozzle must be created when using a blowtorch. This is because the forge emits a lot of heat, which can cause the lamp tank to explode.

This type of design, which you can quickly create with your own hands, should be used exclusively outdoors, since there is no umbrella with a chimney. During smelting, a large amount of combustion products is released.

When considering the question of how to make a forge for melting aluminum, we note the possibility of creating portable versions.

An example is a portable version of the track, which with additional elements are installed on a common base. The lining is represented by fireclay marl with fireclay sand.

Another design element can be called an air supply system to the track, for which you can use, for example, a manual siren. It can run on coke or charcoal.

, please select a piece of text and press Ctrl+Enter.

How to make a furnace for melting and hardening metal with your own hands

Unlike industrial equipment, a homemade furnace for melting metal is a compact device. Such portable equipment can be used to smelt, harden or smelt non-ferrous metals.

Melting metal and cast iron

A furnace for melting metal is a body made of fireclay bricks. The binding element is clay. The firebox is designed to burn coal. There is a hole at the bottom through which the air is blown into the inferno.

At the bottom there is a cast iron grate called a grate. Coke or coal is laid out on it. It can be removed from the old stove. Sometimes refractory bricks are laid on edge when forming the body.

The finished structure is fastened from the outside with a metal belt.

A furnace for melting metals must have a crucible. It can be an enameled or cast iron cauldron. The location of the crucible is next to the burning coke. To improve airflow, a fan is installed nearby. The equipment is used for steel smelting, but can be used as a furnace for cast iron smelting.

Electric furnaces for melting metal

The basis of such a stove is asbestos, which can be replaced with tiles. Electrodes installed in a melting furnace with your own hands must have a voltage of 25 V.

They are made in the following order:

- They are machined from the brushes of an electric motor.

- 6 mm holes are drilled into the assembly.

- A wire with a cross section of 5 mm is passed through them.

- A nail is driven in to secure the wiring.

- In order to improve contact with graphite, the file makes notches.

Mica is placed inside the furnace as a heat insulator. When connecting to the network, you need to use a step-down transformer. After production, the oven turns on and runs for some time in idle mode.

Muffle furnace

Muffle furnaces are often used for heat treatment of parts. Such equipment is characterized by a wide temperature range, from 20 to 1000 degrees.

A muffle furnace for hardening metal operates on different types of energy. However, at home it is better to use a unit that runs on electricity. Hardening is carried out in the furnace muffle.

A muffle furnace is made with your own hands in several stages:

- The muffle is made from fireclay bricks. Due to the round shape of the oven body, their corners are beveled. In each brick, grooves are selected where the spiral is laid.

- If the muffle furnace for melting is made from an oven, then the inside is lined with fire-resistant bricks. Grooves for the spiral are cut into the masonry.

- The chamber, made of refractory brick, is placed in a housing made of steel. Insulation is placed on the bottom. The gap between the side walls of the chamber and the housing is 4 cm, where the insulation is inserted. The top consists of 2 layers of metal and insulation.

- Holes are drilled in the housing, and the ends of the spiral are brought out through them, which are connected to the network cable.

- When using an oven, no insulation is required. It is already provided for in it.

Aluminum smelting

Making a furnace for melting aluminum with your own hands is a real thing. In industrial production, units with the name - rotary-type ovens - are very expensive.

To understand how to make a furnace for melting aluminum, you need to understand their operating principle. There are several types where non-ferrous metal is melted.

Mini oven

Take a car wheel and bury it in the ground so that the top cut does not protrude outward. A hole is made in the middle for the pipe. One end is passed into the hole, and the other is brought out. A cooler is placed on it to pump air. The smelter is filled with coals and aluminum scrap. Air is supplied and the temperature rises.

Metal tank

You can make a furnace for aluminum from a metal tank. For example, the body of a top-loading washing machine. The interior of the structure is lined with refractory bricks. A pipe for air supply is mounted below. Thus, portable equipment is obtained.

From the bottle

One of the unusual ways in which aluminum is melted. Nichrome wire is wound around the bottle. The surface of the bottle is first lubricated with oil. A mixture of liquid glass and clay is applied on top.

Drying is carried out for a week. Then another layer of wire is wound and clay is applied. After 7 days, the bottle is removed and only the heat-resistant shell remains.

Voltage is connected to the ends of the wire to glow the nichrome, and raw materials are loaded into the hearth.

Lead smelting

An electric furnace for melting lead consists of the following elements:

- A round casing made of stainless steel, inside of which there is insulation. It is attached with brackets to the wall.

- An industrial heating element is supplied from below.

- There is a rotary type valve on top.

- A sensor that is located 3 cm from the bottom.

- There is a temperature regulator on the side.

By setting the regulator to a certain temperature, we warm up the device. The lead inside melts. At the end of the melt, a mold is placed underneath and the valve opens. Molten lead fills the interior of the mold.

Popular steel casting methods

Steel casting is a process that produces alloys with different chemical compositions. Technologies have been developed where charge, used metal products and cast iron are used as raw materials. The resulting blanks comply with GOST parameters.

The casting process produces products of varying quality. It depends on the manufacturing method. It is important that harmful impurities that make the alloy brittle are disposed of. This happens due to their oxidation, when iron interacts with oxygen.

History and essence of technology

In ancient times, steel was produced in shaft furnaces using the cheese-blowing method. Charcoal was used for this. Iron was mined from ore. At the same time, small pieces of cast iron were used as raw materials. Melting was carried out in crucibles. The quality of the resulting material was high, but low-productivity. However, this is exactly the method used to obtain Damascus steel.

Later, cast iron was processed using critical processing. It was being refined in a screaming throat.

In the 18th century, puddling technology began to be introduced. The starting material was also cast iron. The disadvantage of the technology was low productivity.

The open-hearth production method was developed in the 19th century. It turned out to be so successful that it was used for 100 years. And only then in the 50s it was replaced by the oxygen converter process.

The importance of steel in global industry

Steel is a material that is of utmost importance. A rare design can do without it. If we compare steel production with all non-ferrous metals, then its total output is 90%. Industrialization creates a constant demand for such material. It is in demand in any industry.

No production can do without bolts, nuts, washers or nails. Steel is used in large-scale projects. First of all, these are bridges, where the basic foundation is a metal frame. Aviation cannot do without it. A large amount of material goes into laying the rails. Even if the product is made of plastic or other non-metallic material, it may have a steel skeleton.

Certain grades of steel are used for the production of air ducts necessary for ventilation systems. Sheet steel is used as the starting material.

Characteristics of steel

The basis of any grade of steel is iron and carbon. The amount of the latter varies within 0.1–2.14%. The higher its content, the better the quality of the steel. If the amount of carbon exceeds 0.6%, the alloy is called high-carbon. When the percentage of carbon exceeds 2.14, the material is called cast iron.

When steel is melted, alloying additives are added to it, which changes the mechanical properties of the alloy. These include:

- chromium;

- tungsten;

- cobalt;

- titanium;

- vanadium.

Tin cans and other scrap are recyclable! How to make a furnace for melting aluminum with your own hands

Aluminum alloys have a low melting point and good machinability of parts. And there is always a lot of aluminum scrap on the farm.

Therefore, aluminum is often melted at home to replace non-standard or small parts of mechanisms: a blank is cast, and then processed on a lathe. Sometimes souvenirs and small interior items are made from aluminum with their own hands.

Melting furnace structure

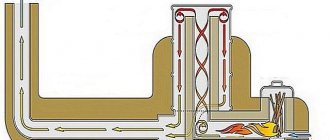

Homemade furnaces for melting aluminum consist of a body - a metal cylinder (2) lined with refractory (fireclay with sand or concrete).

Inside the mine there is charcoal (8) , which serves as fuel. A crucible (3) is installed in it - a container in which the metal will be melted.

The crucible can be a thick tin can, a teapot or any stainless steel container.

In the lower part of the shaft (6) there is a hole for air injection (7) through the lattice base (4) , which allows you to maintain combustion and regulate the temperature in the furnace.

A hair dryer or a vacuum cleaner pipe is used as a blower. The damper (5) is necessary to remove excess air.

For furnaces with a capacity of several tens of kilograms, a lid (1) to quickly and evenly heat the metal. In small ovens you can do without it.

The furnace elements should not deform or melt when heated. Therefore, the use of aluminum bodies, tubes and crucibles is unacceptable. steel or cast iron to build the structure .

Reference. Natural gas or electricity are also used as fuel for aluminum smelting .

How to make a furnace for melting metal?

Creating a small unit that can melt several kilograms of aluminum scrap is not a difficult task. To lay out the stove in the garden you will need the following materials :

- red bricks - 20-25 pcs. ;

- tall tin can - 1 pc. ;

- grill grate - 1 pc.;

- dryer - 1 pc. ;

- a piece of pipe with a diameter suitable for the outlet of the hair dryer - 1 pc. ;

- roll of electrical tape;

- a piece of steel wire 30-50 cm long ;

- charcoal for ignition (the amount depends on how much aluminum needs to be melted).

The bricks will serve as both the body and the refractory coating of the furnace, and the tin can will act as a crucible.

Two holes are made in the upper part of the jar opposite each other, and a wire is threaded . It will be possible to lift and remove the crucible with the melt from the furnace.

The air will be supplied from the hairdryer turned on in cold air mode. tape a piece of pipe to the outlet of the hair dryer with tape or tape - this will be the air duct.

Such a simple furnace design is convenient because no tools are actually required to create it; everything is done by hand.

Important! Do not use zinc-coated , as toxic zinc fumes will be released when melting aluminum.

Brick well installation plan

- One row of bricks is laid out in the form of a rectangular well . The internal dimensions of the hole should be approximately the length and width of one brick .

On one side, two bricks are laid out to form a corridor for the air duct. The width of the corridor is equal to air supply tube - A grate is installed on the laid out row .

Instead of a grill grate, you can use any metal lid or plate with holes for air supply. - A second row is laid on the grate , without any gap for the air duct.

Photo 1.

Completed brick well for the smelting furnace. The edges are reinforced with metal strips, the air duct opening is visible.

- An air duct is created . A piece of pipe is attached to the hairdryer with tape or tape . To ensure the strength of the structure, the connection point is wrapped in thick paper and then connected with adhesive tape . Electrical tape is a more elastic material compared to adhesive tape, so it is more convenient to work with. The cold air supply button is also secured with tape on the hairdryer. The finished mechanism is brought to the bottom row of bricks.

- In the stove well, coal is poured onto the grate and melted for ignition. The hair dryer turns on, which activates the combustion process.

Advice. The intensity of the air supply can be adjusted by changing the operating mode of the hair dryer , as well as the distance between the pipe and the window for the air duct.

- The tin can is installed on the top row of bricks using a wire threaded through it. Like a pot over a fire, it hangs over the grate.

- After lighting the furnace and installing the crucible, two more bricks are placed in the third row so that a square hole is obtained from a rectangular hole. This will fix the can inside the housing and heat up the oven space faster.

you can load scrap into it for remelting. A sign that the jar is warming up is its redness.

Important! It is recommended to melt aluminum in a heated crucible . When loading cold scrap into a cold can, there is a greater chance that the container will burn out and the aluminum will leak out of the can directly onto the coal.

The principle of the design and operation of such a furnace is very simple and does not cause difficulties. However, it is always worth remembering safety precautions :

- work in fire-resistant gloves;

- avoid water getting into the melt;

- do not use materials containing toxic substances.

Two-can design

Another type of homemade furnace for melting aluminum is a design made from two large cans . One of them serves as a body in which a hole is cut for air supply, and the bottom of the second can with holes serves as a divider .

A crucible is installed inside the jars.

Such a device is very compact , and small volumes of metal can be melted even in a ventilated garage. However, the design is not stable or fireproof , and will only last a few cycles.

Possible problems and their solutions

A carelessly assembled appliance will result in inefficient operation of the oven and make it dangerous to use. Here are a few points to pay attention to:

- Slots and gaps in a brick building. They can be caused by chips on bricks or loose fit of refractories to each other. Gaps reduce fuel efficiency and reduce combustion intensity and temperature. Aluminum in a crucible may simply not melt.

Therefore, after laying out each row, a visual check is carried out for the presence of holes. The holes are covered with a sand-clay mixture or covered with fireproof material .

It is recommended to use concrete mortar only in the case of a stationary unit that is not planned to be disassembled. But you should not use asbestos sheets and chips in places where the stove is heated, because this material is a carcinogen.

- Violation of the horizontal level of the building. Misalignment reduces the stability of the structure and creates conditions for uneven distribution of coal. The result is uneven heating of the crucible and the metal in it.

The laying of each, especially the bottom row of bricks, is controlled by the level . You can also check horizontality by placing a jar of water on the grill . On a flat surface, the top edge of the water will be parallel to the edge of the can.

Check out the video on how to make an aluminum smelter.

Do-it-yourself aluminum furnace - easy!

The desire to have a small melting furnace at home is easily feasible and does not require large investments, knowledge or time to build.

You can independently build a unit with a capacity of up to 10 kg of molten metal and make souvenirs, accessories or blanks for small aluminum parts.

The temperature reached in a home furnace allows you to melt most aluminum alloys in a short time ( several tens of minutes depending on the volume of scrap).

Of course, the quality of the resulting metal differs from industrial quality . Aluminum melted at home contains an increased amount of oxide films, contaminants, and is less stable in chemical composition. But it will still be suitable for use at home.

Cladding rules and complexity

If the basic rules of cladding are violated, difficulties may arise. The creation of the first row is considered the most problematic. It must be checked for height. For corners, you should choose metal corners, as their plastic counterparts can cause deformation. For complete gluing it will take from 24 to 36 hours, since a break should be taken after every fifth row. The correctness of gluing is checked after each row. And after finishing the cladding, the seams are carefully rubbed down.

DIY aluminum smelter

The indoor ornamental plant shown in the video is actually a cleverly disguised smelter. This idea will be a real boon for those who from time to time work with metal in order to make another craft from aluminum or other metal at this cheap smelter, but there is not enough space in the workshop or at home to have its own place for each thing.

You will find some inventions for yourself in this Chinese store.

Inventors shop at a budget Chinese online store.

Required funds

In this project, we use equal proportions of sand and gypsum to make a simple melting pot that's powerful enough to melt scrap metal in a second, and nice to look at so you don't have to hide it. This is a mini metal smelter.

First we need large bags of sand and plaster. Both can be bought at a hardware store. We also need a 9 and a half liter metal bucket and a blanket to cover our work area with, because most likely we will get it a little dirty. A two and a half liter bucket can be used as a measuring bucket, but you will soon see that it has a more important purpose.

DIY electronics in a Chinese store.

Job.

For our refractory lining we use the following recipe: 4.2 liters of gypsum, 4.2 liters of sand, and 3 liters of water. When the water touches the dry mixture, the countdown begins. We'll have about 15. So let's start mixing everything up. It is very important that all the dry mixture gets wet, getting rid of lumps as quickly as possible.

After a couple of minutes of stirring, the mixture should be fairly runny and roughly the same color. After making sure that there are no lumps left, we proceed to transfusion. Carefully pour the mixture into a metal bucket, being careful not to spill anything. Enough mixture to fill the bucket, leaving about 8cm at the top.

Now we can take a plastic measuring bucket and use it to form the center of the smelter. You can fill it with water to add weight, but sand or rocks will also work.

When we push the bucket, the mixture rises, but does not spill out. The mixture has already begun to harden. So let's move the bucket up and down to level it out.

You need to hold the bucket in this position for 2-3 minutes, during which time the plaster will harden enough for the bucket to remain in place.

It takes about one hour to fully cure, but the plaster is soft enough to trim. If you dampen a rag and gently rub it over the top, you can smooth out the plaster very nicely and give it a nice texture. Once you're done, leave everything to dry for about an hour.

Melting crucible from a fire extinguisher

Why not turn that old fire extinguisher into a melting pot? You can tell that it is made of steel because if you put a magnet near it, it will be attracted. This does not happen with aluminum.

Having released the pressure in the cylinder, we unscrew the top valve so that we can easily and safely cut it with a hacksaw, which took less than a minute. For the crucible we will use the bottom part because it is essentially a steel container 8 cm in diameter and 13 cm high. Good size for our homemade mini smelter.

By this time the plaster should be well hardened. Let's pour out the water. Next, use a pair of tongs or something similar to gently pull one side of the bucket toward the center. Now, if you grab it with both hands and twist it a little, the bucket will come loose and be pulled out easily.

We've achieved an amazingly smooth surface that makes our homemade melting pot look surprisingly professional.

Air supply hole

All we need is a hole for the air supply and a cover. Let's take care of them. The three and a half inch hole saw attachment works great for this tube. By placing the center of the bit on the top line of the bucket, you can begin to carefully cut through the metal.

When we go through the metal, we need to tilt the tool down about 30 cm, which is easy because the plaster has not yet fully hardened and cuts like butter. Now we have a hole that the blower tube fits into perfectly.

It will be placed a few centimeters from the bottom.

Blower

Now, if the crucible fails and the molten metal pours out, in the smelter the metal remains inside and does not flow out through the tube. A leaf blower is very easy to make. First you need to take a 3 cm tube, it will be located next to the hot coals.

You will also need a 3 cm PVC pipe. As you can see, the threaded coupling from one end is screwed onto a metal tube, and the adapter from the other end is simply screwed onto a PVC tube.

Lid

Let's go even further. Let's make a lid that will help maintain the temperature. We need a pair of 10 cm U-bolts. Place them vertically in a wide bucket filled with half the initial volume of our mixture. After an hour, the plaster will harden and can be easily removed from the bucket. And now the lid for the melting pot is ready.

Pressure relief hole

You need to make a hole to relieve pressure. it can be done before hardening, but you can drill it with a drill with an 8-centimeter attachment. Once the hole is made, you will have a lid that looks like a huge donut. This design allows you to relieve pressure and melt the metal without even removing the lid.

Conclusion

If you light a fire, you will see that the inside becomes so hot that the soda can melts in a second and the crucible fills with liquid aluminum. With a mini-smelter like this, we can melt aluminum in our backyard and cast anything we can think of.

Best of all, when you're not smelting scrap, the smelter doesn't take up space or be noticeable. You can insert a potted plant inside and instantly turn it into a piece of decor. This pot-turned smelter is more than it seems. Just make sure your smelter is stable, this is extremely important for safety reasons.

By the way, you can try using the smelting furnace as a blacksmith's forge or even as a barbecue, because after all, it runs on coal.

Now you know how to use widely available materials to make a mini smelter that is powerful enough to melt metal in seconds and at the same time pleasant enough to look at that you don’t have to hide it. Translated and voiced by the Science and Technology channel.

Another publication contains more useful information about aluminum products.

DIY mini aluminum smelter

Aluminum is used in the production of parts in blacksmithing. The peculiarity of such an alloy is that it has low weight, a high degree of ductility, and good conductivity of heat and electricity.

With all these qualities, the alloy in question can be called a low-melting material, which significantly increases its popularity. To carry out work on creating parts from aluminum by bringing the alloy to a plastic state, a forge is used.

Quality and safety

Quality depends not only on the skill of the builder. It is important to take care of the preparation of materials and tools, as well as personal safety. All work should be carried out in special protective clothing. Special attention should be paid to protecting the skin of the face and hands from mixtures. For this you will need special glasses and construction gloves. They will avoid not only contamination, but also possible allergic reactions.

Cladding stoves with artificial stone is a modern solution for a private home, affordable. You can do it yourself and not spend a lot of time on it. If you follow the rules of work, the result will please the eye for decades.

DIY furnace for melting aluminum: types, manufacturing features and reviews

To make a muffle furnace for melting aluminum on your own, you need to become familiar with its basic elements, after which you can begin selecting materials, preparing tools, and the assembly itself. But first, it’s worth considering its purpose in order to understand whether it is suitable for achieving your goals.

Brief description of muffle furnace

The main purpose of a muffle furnace is to heat metal. Using such a device can help melt metals such as aluminum or copper, as well as other non-ferrous materials. In addition, with its help you can successfully carry out the operation of firing ceramic products and drying them.

Cremation can also be carried out. It is worth noting that there is a wide variety of muffle furnaces. They can be electric, gas, air and some other types. They also differ significantly in the type of construction.

They are standard vertical or horizontal, as well as tubular.

The main difference between a muffle furnace and a conventional furnace for melting aluminum with your own hands is that it has a special section called the muffle. This area allows you to protect the metal that is being processed.

Basic structural elements and materials for assembly

The main element is, of course, the heater. It is best to choose an electric one. Its greatest advantage is that it is very easy to operate. In addition, there are such details as a heating chamber and a special heat accumulator. In order to successfully melt aluminum, heat control must be in place. This will help make the process continuous.

If you have to melt several different materials, then the aluminum itself should be subjected to the process not just once, but several times. In this mode of operation, it is necessary to ensure that the heat accumulator also functions as a regulator. This is necessary in order to maintain the desired temperature of the aluminum after melting.

In order to make a stove for melting aluminum, you need to prepare the following materials:

- grinder, wire and metal bucket;

- seven bricks;

- construction-type safety glasses, a few unnecessary pieces of metal;

- hammer and other standard tools.

Start of assembly work

Assembling a homemade furnace for melting aluminum begins with the following:

- You need to take 7 prepared bricks, which will play the role of a temperature accumulator.

- Using a grinder, a compartment is built on each side of the brick. The result should be a space that will be used for an electric type heater. To increase the strength of the structure, you can take wire and wrap the entire structure with it.

- A metal bucket that has been prepared can be used as a fireproof chamber. If there is no suitable one, then you can make a camera yourself.

Housing assembly

Even a simple furnace for melting aluminum - such as a muffle furnace, for example - requires a housing. In this case, it can be made from a piece of unnecessary sheet metal, the thickness of which will be from 1 to 1.5 mm. It is worth noting that a layer of rust will be needed here.

Another important point concerns the height of the bucket. This parameter should be with a certain margin, since the working chamber will be mounted on a layer of bricks plus thermal insulation. Next you will have to roll the metal sheet into a pipe.

This process is quite problematic, and therefore it is recommended to use special rings made of reinforcement.

To complete the construction of a furnace for melting aluminum with your own hands, you need to do the following:

- The prepared rings are put on a twisted sheet of metal and connected around the circumference.

- The bottom for the furnace body can be assembled from the same sheet of metal that was already used for the pipe. It is mounted by welding to the lowest ring.

- It is necessary to make a special hole in one of the bricks through which an electric heater can be placed directly inside the working chamber.

- For ease of laying out, you should immediately number the bricks, and then start laying them out. It is necessary that they fit very tightly to each other. The resulting design of a furnace for melting aluminum, made with your own hands, must be very stable.

- A heating coil must also be attached to the bricks.

- To install a spiral heater, you need to make several grooves and install bricks along them.

- You can also cut grooves in the right places using a grinder. It is recommended to use eye and respiratory protection during operation.

- Most often, the material for the spiral is either nichrome or fechral.

- The spiral must be wound very carefully and in such a way that the turns are close to each other. The distance is necessary to avoid short circuiting.

- The entire structure should be coated with the solution.

In this way, you can make a muffle-type furnace for melting aluminum with your own hands.

Advantages of artificial stone

Expensive natural materials are being replaced by budget analogues that are not inferior in their characteristics. Artificial stone is a material that has a number of advantages:

- the technology of finishing a bathhouse stove with decorative stone is simple due to the softness of the mechanical characteristics; To prepare the material, a grinder is enough;

- the entire sequence can be carried out with your own hands without the involvement of trained craftsmen, which allows you to save;

- the composition of the finishing stone includes soft and fairly light fillers, which lighten the overall weight of the structure;

- a wide selection of textures, shapes and colors allows you to choose a pattern to suit any interior;

- artificial stone is cheaper than natural stone, which reduces the cost of the finished product;

- Decorative stone allows you to embody any design ideas.

Artificial stone is an easy-to-use material with many advantages.

Types of stone suitable for finishing stoves There are many types of stone for finishing on sale. However, not all of them are suitable for finishing a stove, as they cannot withstand sudden temperature changes. The surface cladding is made only from porcelain stoneware, gypsum stone or on a concrete base. Each of the materials has its own characteristics.

Porcelain tiles

In most cases, “artificial stone” refers to ceramic granite. This material is an analogue of ceramics or glass, exceeding them in strength. It is produced at high temperatures, but during the operation of the fireplace it does not react to temperature changes. In addition to this property, porcelain stoneware has other advantages:

- resistance to mechanical loads;

- variety of shapes and colors;

- strength;

- natural imitation of natural stone.

The composition of porcelain stoneware includes: clay of various types, feldspar, pigments and mineral additives. They improve the characteristics of the material.

concrete stone

Also popular is artificial stone, consisting of cement, sand, dyes, fillers, plasticizers and water repellents. These materials are affordable and have good quality characteristics necessary for long-term operation of the interior heating element.

Gypsum-based stone

Gypsum artificial stone is a durable decorative material suitable for cladding a stove or fireplace. Various imitations made to look like natural stone are on sale.

The material has a number of advantages:

- ease of installation;

- light weight;

- environmental friendliness;

- aesthetic appeal.

Gypsum tiles can be made by hand, which expands the possibilities of decoration.

Material selection criteria

In order not to make a mistake with your choice, you should pay attention to the following aspects:

- price. Russian-made decorative stone is not inferior in characteristics to foreign analogues, and it is cheaper;

- manufacturer. It is better to give preference to proven brands that have been present on the building materials market for a long time;

- compliance with the requirements: heat resistance, strength, wear resistance;

- presence of markings on the packaging, as well as certificates;

- date of manufacture. Finishing with too “fresh” materials will not give the desired result;

- If the level of preparation for cladding with your own hands is low, it is better to choose slabs of blurred shapes in order to hide the flaws in the masonry by grouting the joints using a bag.

If you take these tips into account, there will be fewer problems when doing the work yourself.

Preparation for finishing

First you need to calculate the amount of material. If the stone will cover the entire area of the walls in the hallway, you should subtract the area of the openings and add 10%! (MISSING) If the decor will be located around openings, niches, in separate fragments on open walls, draw a rough sketch of the decoration and take measurements of each area. Then the area is summed up and 10-15% of the trimming is added. When purchasing material, you should remember that the amount of stone with an angular shape is calculated in linear meters, and of a regular shape - in square meters.

Artificial stone in the hallway

Additionally you will need:

hacksaw or grinder (depending on the type of stone); Bulgarian simple spatula 7-9 cm; Spatula notched spatula 15-17 cm; Notched trowel level; Professional cast Kapro level long ruler; pencil; paint brushes; varnish; file; acrylic primer. Acrylic primer for walls

Artificial stone can be attached using liquid nails, cement-based or gypsum-based glue. The glue consumption must be indicated on the packaging, so when purchasing, you should know exactly the finishing area and take it with a small margin.

Liquid Nails

If you use gypsum stone, you will need a special miter box with high sides for cutting.

Plastic miter box

When everything you need has been purchased, you should start preparing the surface.

Step 1. Dismantling the coating

Dismantling the coating

If the stone covers the hallway walls completely, the old coating is removed completely to the base. If separate areas are intended for decoration, the coating must be dismantled very carefully.

On the wallpaper, mark the boundaries of the finish with a pencil and carefully trim it with a utility knife, leaving a margin of 1-2 cm wide for stones. The wallpaper glue is soaked in water and removed with a spatula, the walls are thoroughly washed

They also remove the paint if it is peeling or cracked, and clean off any loose plaster.

Step 2. Leveling the walls

putty

The stone should be laid on a flat, smooth surface - this will facilitate the work process and increase the strength of the decorative coating. Therefore, all small cracks, gaps, and depressions are filled with putty, and if there are differences of more than 5 mm, it is better to plaster the entire area

Particular attention should be paid to doorways: deep cracks may form around the perimeter of the frame, for sealing of which it is recommended to use a cement solution

Step 3: Priming

Padding

Dry walls must be lightly sanded to smooth out the unevenness of the puttied areas, and then wiped with a rag to remove dust. After this, the surface is treated 1-2 times with an acrylic primer. If there is wallpaper around the perimeter of the areas to be treated, the primer should be applied so as to cover an edge 1 cm wide - what will be hidden under the cladding.

Why do you need to melt aluminum at home?

The temperature characteristics of aluminum processing make it possible to melt it at home, using only available materials. And here three questions arise at once:

- What is it for?

- What is needed for this?

- How to do it right?

The first question can be answered without much difficulty - for sale to a collection point for non-ferrous metals, or for the manufacture of your own products and mechanical parts from aluminum, if you have a lathe and the skills to work with the material.

Communities › Garage Business › Blog › Furnace for melting aluminum... (Part I - Preparing the base of the furnace...)

Those who follow the BZ probably remember about my COMPRESSOR

... I haven’t written anything about him for a long time, since there wasn’t much to write about.

It works, no problems observed. The only thing that was a little unsatisfactory was that the calculated output power value did not correspond to the actual one. The explanation is simple - the speed on the pulleys of two compressors is: for the First - 1650 rpm, for the Second - 1750 rpm. Raising the speed means changing at least two pairs of pulleys. And they simply cannot be found in this size. Therefore, I have long set this goal, to install a third compressor from ZIL 131 on the same compressor frame

... and spin it from the same engine.

Since I had plenty of compressors, thanks for this to Azat, aka

Yasny, it was decided to equip the installation with this very compressor. The problem came out “unexpectedly” - a couple more pulleys are needed for the engine and the compressor. Given that there is not much space, they should not be of a standard size. You will have to make it to order. After talking with turners of all levels, it turned out that turning a single-groove pulley costs 300 rubles. But the blank is made of color. meta of this diameter costs from 3-5 thousand.