The operating principle of all types of rocket designs is approximately the same:

- Solid fuel (firewood) is placed in the firebox.

- Ignition is in progress.

- When heated by flame and combustion, gases are produced.

- Their movement begins along the vertical section of the pipe.

- The supply is provided by a special channel through which “secondary air”, which is already heated, quickly moves.

- Heated gases rise to the base of the pipe.

The basic operating principle is similar to pyrolysis boilers. As a result, at the outlet of the furnace, the maximum possible temperature is reached in the upper part of the structure. It is used for heating, heating water, and cooking. For convenience, you can make a special platform for placing containers by attaching it to the top of the pipe.

A big and significant advantage for the user of a rocket stove is its efficiency - firewood, as well as other types of solid fuel, are consumed little, the efficiency is high (about 65%). In order to improve the quality of functioning, it is enough to throw sawdust, paper, branches or dry grass into the firebox.

What is a rocket stove?

The jet furnace received its original name due to the special design of the body - the traditional form of the device is made from sections of metal pipes connected to each other by a weld. Outwardly, it resembles a rocket launcher. A simplified model of the stove can be assembled in a few hours.

The heating device becomes reactive as a result of the peculiarities of the combustion process of the fuel material, when at a certain moment of operation, with a high supply of air mass into the fuel chamber, the stove begins to create a powerful hum and vibration.

Important! The humming mode of a rocket furnace is characterized by irrational fuel consumption during its combustion. The economical heating mode ensures quiet operation of the heating unit.

Principle of operation

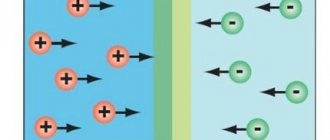

Despite the fact that the rocket furnace is quite simple in design, its operating principle is based on the following processes:

- Natural circulation of heated gases and air inside the channels. This means that the device does not require additional blowing, and the internal draft is created by the smoke exhaust system. The higher the chimney, the stronger the draft.

- Afterburning of unexhausted gases (pyrolysis process) is carried out with a small supply of oxygen into the fuel chamber. It ensures a rapid increase in the efficiency of the device and efficient consumption of fuel material during the combustion process.

The furnace firing process itself is carried out as follows:

- Firewood is placed in the fuel compartment and ignition is performed.

- Next, the standard operating mode of the furnace is set, in which the vertical part of the structure, the chimney pipe, is completely heated.

- Sufficient heating of the stove body ensures the ignition of volatile substances in the chimney and rarefaction of air in its upper part.

- Natural draft increases, which leads to the flow of air into the fuel compartment and increases the efficiency of the combustion process.

- To maintain complete combustion of the fuel material, the furnace structure must be equipped with a special zone for afterburning pyrolysis gases.

A simple version of a rocket stove made from a profile pipe is intended for cooking and heating food, as well as for heating garden houses, cottages and camp baths.

Heating unit with bench

A rocket stove with a stove bench is a device that can create a comfortable environment in one room. Such a unit cannot be used to heat several rooms, let alone the entire house.

Arranging such a long-burning unit with your own hands requires precise calculations - its power and the maximum permissible length of the hog on which the stove bed is located depend on the size of the stove body

It is also important to select the correct pipe cross-section for installation of the structure. Mistakes will result in the jet furnace becoming overgrown with soot in a short time or roaring loudly during operation due to turbulence in gas flows

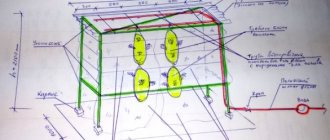

Design of a stove with a stove bench

Dimensions and proportions of the structure

To build a rocket stove with your own hands, you need to prepare detailed drawings, indicating the dimensions of all elements. At the project preparation stage, calculations are made based on the basic values to which all others are tied.

Basic calculated values are

:

- D – diameter of the drum (furnace body);

- S is the internal cross-sectional area of the drum.

Calculations of design parameters are carried out taking into account that

:

- The drum height (H) ranges from 1.5 to 2 D.

- The coating of the drum is carried out at 2/3 N (if its edge is planned to be shaped, then 2/3 of the height should be the average).

- The thickness of the coating layer on the drum is 1/3 D.

- The internal cross-sectional area of the vertical channel (riser) is 4.5-6.5% of S, the optimal value is in the range of 5-6%.

- The height of the vertical channel is the maximum, as far as the furnace design allows, but the gap between the upper edge of the riser and the drum cover must be at least 70 mm for normal circulation of flue gases.

- The length of the flame pipe (fire duct) must be equal to the height of the vertical channel.

- The cross-sectional area of the fire pipeline is equal to the corresponding indicator of the riser. Moreover, it is recommended to use a square-section profile pipe for the fire pipeline; in this case, the stove operates more stable.

- The cross-sectional area of the blower is ½ of the cross-sectional area of the firebox and riser. For stability and smooth adjustment of the furnace mode, a rectangular profile pipe with an aspect ratio of 2:1 is used, which is laid flat.

- The volume of the secondary ash pan depends on the volume of the drum minus the volume of the riser. For a stove from a barrel - 5%, for a stove from a gas cylinder - 10%. For containers of intermediate volume, it is calculated according to linear interpolation.

- The cross-sectional area of the external chimney is 1.5-2 S.

- The adobe cushion under the external chimney should be 50-70 mm thick - if the channel is made of a round pipe, the counting is from the lowest point. The thickness of the cushion under the chimney is halved if the bed is mounted on wooden floors.

- The thickness of the coating layer of the stove bench above the chimney duct is 0.25 D if the drum is from a 600 mm barrel, and 0.5 D if the drum is from a 300 mm cylinder. If you reduce the coating layer, the structure will cool faster after heating.

- The height of the external chimney pipe should be at least 4 meters.

- The length of the flue, on which the length of the stove depends: for a stove from a barrel - up to 6 m, for a stove from a cylinder - up to 4 m.

A long-burning rocket stove made from a 600 mm diameter barrel reaches a power of about 25 kW, and a heating rocket made from a 300 mm barrel reaches up to 15 kW. The power can be regulated only by the volume of fuel; such a stove does not have air regulation, since the additional flow disrupts the stove mode and provokes the release of gases into the room. Changing the position of the blower door regulates not the power, but the operating mode of the furnace.

Lining features

The quality of the riser's thermal insulation directly affects the efficiency of the heating unit. In our area, lightweight fireclay bricks ШЛ and river sand with an admixture of alumina are available for lining. The lining should have an external metal casing, otherwise the materials will quickly absorb carbon deposits and the furnace will roar during operation. The end of the lining is tightly covered with oven clay.

Proper execution of lining

When using hewn fireclay bricks, the remaining cavities are filled with sand. If only sand is used for lining, it is sifted to remove large debris and covered in layers - each approximately 1/7 of the height of the pipe. Each layer is compacted tightly and sprinkled with water to form a crust. The backfill must be dried for a week, and then the end must be covered with a layer of oven clay. Then the construction of the rocket furnace with your own hands continues according to the drawings.

Advantages and disadvantages

The long-burning rocket stove has gained particular popularity and demand due to its positive characteristics:

- Affordable design and easy assembly. The simplest version of the stove can be made at home from available materials in a few hours.

- Effective heat transfer using various types of wood fuel - firewood, chips, branches, bark and shavings.

- Wide functionality. Possibility of using the device for space heating, cooking and water heating.

- Complete combustion of fuel with the possibility of afterburning pyrolysis gases. This allows you to increase efficiency and at the same time avoid carbon monoxide poisoning.

- Possibility of refilling fuel without interrupting the work process.

- There is no need to create forced draft in the chimney system. High level of self-regulation of the operating modes of the device.

An ergonomic stove can be installed in any room, and lightweight structures do not require additional reinforced foundations.

Despite the significant advantages, such a unit is not without some disadvantages:

- Lack of possibility to automate the combustion process. Homemade stoves require constant human control over the placement of fuel material.

- There is a high probability of getting burns due to significant heating of the metal structure.

- The device is not intended for heating large residential buildings and stationary bath complexes.

- The design of the stove requires the use of well-dried fuel, since excess moisture can lead to back draft in the chimney.

- Unaesthetic appearance of the finished device.

Design

The rocket-type stove has a fairly simple design, which is made from pipes of the required diameter.

The fuel chamber is a horizontal section of pipe into which fuel is placed. In some cases, the oven may have a vertical loading option. In this case, the device consists of three structural elements - two vertical pipes of different heights mounted on a horizontal pipe. The short section of the pipe is the fuel compartment, the long section is the chimney.

To ensure increased efficiency, rocket furnaces may have additional design elements:

- Fuel compartment (vertical or horizontal position) – for loading fuel.

- Afterburner (horizontal) – for fuel combustion and thermal energy accumulation.

- The ash compartment is for afterburning pyrolysis gases that are formed during fuel combustion.

- The outer body of the furnace is for thermal insulation of the structure.

- A lounger is a platform for resting in a lying or sitting position.

- Chimney pipe - for removing fuel combustion products and creating natural draft.

- A hob is a horizontal platform for cooking food or heating water.

What is the working principle?

The meaning of the functioning of a rocket stove is taken from other types of stoves and there are 2 options:

The design will work using the pyrolysis method.

- Natural gas and smoke circulation from within the system. A similar principle is used in a potbelly stove. Very often, such a stove design is suitable for people who plan to cook.

- Pyrolysis. The working principle of a rocket stove is based on the natural afterburning of unburned gas under conditions of limited oxygen supply to the combustion area. This option is not used for cooking, since it is impossible to create the necessary conditions, so it is considered an excellent option for home heating.

to come back to the beginning

DIY making

A homemade stove made from a used gas cylinder is an affordable option for a wood-burning stove, which is designed for efficient heating of rooms and economical fuel consumption.

To make a stove at home, you will need:

- Empty cylinder body – 2 pcs.

- Metal pipe for creating a vertical chimney channel (diameter - 12 cm).

- Profile pipe for making a firebox and loading chamber (length 100 cm, cross-section - 12x12 cm).

- Metal pipe cuts: short by 80 cm (diameter - 15 cm) and long by 150 cm (diameter - 12 cm).

- Steel sheet (thickness 3 mm).

- Metal rods.

- Insulating heat-resistant material (perlite).

- Welding equipment.

- Bulgarian.

- Personal protective equipment – glasses and gloves.

To ensure correct assembly of the stove, it is recommended to prepare a working drawing indicating the exact dimensions of all structural elements of the device.

Step-by-step instructions for making a rocket stove:

- Three sections are cut from the profile pipe - two of them are 30 cm long and one for the sunbed is 35 cm. Using a grinder, a rectangular hole for the fuel compartment and a semicircle for the vertical pipe are made from the blank for the sunbed.

- One 30 cm blank is cut longitudinally and welded to the fuel compartment to create an air channel.

- The fuel compartment is connected to the pipe by hot welding.

- The grate is made from fittings, and doors are made for the fuel chamber and ash pan.

- Next, a secondary chamber is made for afterburning pyrolysis gases.

- A hole is made at the bottom of the cylinder for the fuel compartment. On the outside of the cylinder, an elbow is fixed for a pipe with a diameter of 12 cm for the chimney.

- A hole is cut at the bottom of the pipe to clean the chimney.

- A piece of pipe with a diameter of 15 cm is placed on top of the pipe and welded to the cylinder.

- The free space between the two pipes is filled with insulation, and the edges are closed with a weld.

- In the second cylinder, the bottom is cut off and a hole for the valve is welded. It will be used for afterburning pyrolysis gases.

- Both cylinders are fixed to each other in a special groove using two welded rings so as to ensure the tightness of the finished structure. The groove is sealed with an asbestos cord.

Important! Before you start firing a homemade rocket stove, you need to carefully check the quality of the connecting seams and the tightness of the structure. Air masses must not penetrate uncontrollably into the operating installation.

How to install Buleryan

The main stages of installing a Buleryan heater

- When choosing a place to install the stove, the main thing is to ensure free air convection for better heating of the room.

- The boiler gets very hot during operation, you need to provide a fireproof place for it.

- Under the boiler and in front of the firebox, it is necessary to place a metal sheet on the floor to prevent fire.

- It is recommended to install the stove no closer than 30 cm to the wall and with a distance of at least 60 cm from furniture and other objects.

- if the boiler is located in the corner of the room, then it is advisable to protect the walls with fireproof materials (metal, stone, brick).

- We put the Buleryan stove 20 cm from the floor for natural air convection, for this we mount a stand.

Boiler stand Buleryan

Chimney device

Types of chimney installation: one of them is classic (or traditional). This installation method is used at the initial stage of building a room. The chimney pipe is located vertically and passes through all ceilings.

Types of chimney devices

This method excludes the horizontal arrangement of any nodes. The second method is used at any time, at any stage of the construction of the premises, even after the construction is completely completed. This method is called coaxial; it works more efficiently than the traditional one, as it ensures high-quality removal of combustion products and is less fire hazardous.

Distributing heat throughout the rooms of the house

For the most effective use of the Buleryan stove, in order to heat not one room, but several or the entire house, corrugated pipes can be connected to the heat exchange pipes coming from the stove.

Corrugated pipes are distributed in rooms

The pipes are routed accordingly through the walls of the premises, if necessary through the ceiling. Decorative grilles are installed in the rooms to receive warm air.

Heat distribution between rooms in a large house

However, it should be taken into account that the air leaving the furnace has a fairly high temperature; when passing pipes through partitions and ceilings, the conditions that are provided for the installation of chimneys must be observed. The photo below shows several wiring options.

Heat distribution from a common box

Galvanized or corrugated pipes are used for wiring.

Efficient heat distribution between rooms

Improving the stove design

Buleryan stone finishing

Very often, Buleryan is a design element, especially when it comes to a country house or a chalet-style house.

Brick screen for Buleryan stove

But if we are talking about a homemade device, its aesthetic parameters are of course inferior to products made in production.

Buleryan in the interior of a country house

The most successful way of decoration is to use brick or decorative stone.

Buleryan in the interior

To do this, it is not at all necessary to completely cover the stove with bricks; it will be enough to decorate the walls around the boiler or make a background wall-screen behind which the stove itself will be.

Decoration of the Buleryan stove

The photographs show interesting design options for our heater.

Buleryan boiler in a country house

How to properly sink a rocket?

To obtain the maximum heating effect, the rocket-type furnace should be thoroughly heated before the main loading of fuel material. For this, flammable materials are used: paper, wood chips, dry shavings, sawdust, cardboard, reeds or straw, which are placed in an open ash compartment.

Warming up the system will lead to the appearance of a characteristic sound - a quiet or loud hum. Next, the main fuel is added to the heated device to obtain the required amount of thermal energy.

The combustion process itself is carried out according to the following scheme:

- Opening the door to the ash compartment.

- Adding fuel material to maintain optimal combustion temperature.

- With the appearance of a hum in the furnace, the blower closes until it completely switches to silent operation.

Important! If a closed air valve has led to a decrease in flame intensity, it must be opened to increase draft and enhance the fuel combustion process.

Other types of rocket stoves

Based on the basic design of the rocket stove, other versions of heating devices with higher efficiency were created, which are intended for outdoor use and indoor use as a source of heating and hot water supply.

Stove-stove

The device is intended for cooking and winter preservation, equipped with an extended hob designed for several containers.

A distinctive characteristic of the rocket cooker is that the vertical channel with the fuel chamber is located at the bottom of the cooking surface. In this case, hot air from the firebox quickly heats the surface, and in order for the stove to remain hot as long as possible, fuel gases accumulate inside the horizontal channel. The remaining gas mixture is discharged into a vertical smoke channel connected at an angle to the hob.

For ease of use, the stove is equipped with stable supports, so it can easily be used on any surface, both indoors and outdoors.

Stove with water circuit

Such a unit is equipped with a heat exchanger that is connected to the heating system: radiators, pipes and a water tank. It is designed to create a complete autonomous heating system for a small garden or country house.

Structurally, the stove consists of the following functional elements:

- The vertical fuel compartment and fire channel made of brick are laid out on a solid concrete base. At the bottom of the structure there is an ash pan with a door for removing ash.

- Vertical steel channel with thermal insulation gasket, protected by an outer metal casing.

- Heat exchange unit with a water circuit mounted on a metal casing.

A distinctive feature of the furnace is the creation of a water jacket, when instead of air, a liquid coolant circulates through the pipes, providing effective heating of the premises.

General principles

The portable portable stove "Robinson" was made on the basis of a heating rocket stove. The same principle is applied: firewood burns in the bunker-fuel compartment, the fire, due to the air flow, enters the combustion zone - a horizontal section of the pipe and partially rises up the smoke tube. First, while the stove is not heated up, all the energy is spent on heating the chimney. Then, when it warms up, the gases from high temperatures ignite again, and secondary combustion of the gases occurs. Modern gas-generating pyrolysis boilers are designed according to the same principle.

How does a rocket stove work?

In the Robinson oven, everything is a little simpler: we don’t need to heat the room. Its main task is to heat water and cook food. But the principles remain the same: the fire must heat the chimney, and its length must be enough to burn off the gases. Therefore, for normal performance, adhere to the following proportions:

- The length of the chimney must be at least 2 times the length of the horizontal (sloping) section.

- The height of the fuel compartment is approximately equal to the length of the horizontal section. Therefore, in the Robinson stove, the firebox is made at an angle of 45°, although the fuel compartment can be located at an angle of 90°, but it is not very convenient to place fuel this way.

- The cross-section of the chimney should not be smaller than the size of the firebox.