How to learn to cut at a 45 degree angle with a circular saw - tips for beginners

Probably everyone who makes repairs on their own has encountered the need to cut a board or pipe or trim a baseboard.

In practice this turns out to be quite simple. The most convenient tool for this is a circular saw. In this article we will tell you how to learn how to cut at a forty-five degree angle with a circular saw - tips for beginners.

A circular saw, compared to some other electric tools, is more efficient.

Long sawing technique

The most difficult stage of the process is making the first cut. To do this you need:

- install a leading ruler, which consists of two boards that are fastened together at an angle of 90 degrees;

- after this, it is necessary to place the sawn log on the supports and fix it;

- then it is important to check whether the log is level;

- at the next stage it is necessary to secure the leading ruler to the supports using self-tapping screws;

- After this, you can start creating the first cut.

Types of saws

Several types of saws are produced, differing in scope and characteristics. The main use of a circular saw is cutting boards.

Let's get acquainted with some types of circular saws:

- 12.5 cm pruning saws with fine-toothed blades. As a rule, the blade is located on the left side of the motor, which would make it more convenient to observe how the blade moves. There is a 120V AC model, as well as a battery that works with different DC voltages;

- saws about 17 cm for cutting lumber to length. Works well with longitudinal cutting, cuts plywood, composite material;

- saws measuring 19 cm or skill saws. They are used to cut materials more than 5.5 cm thick. They are intended for sawing materials of load-bearing structures, as well as for longitudinal cutting. Available with a set of blades that can be used for cutting composite material, concrete, metal, etc.;

- saws of 20 and 25.5 cm in size are designed for cutting large lumber of wood up to 10 cm thick to length. Such instruments are heavier and larger in size. They are mainly used on an industrial scale;

- 22 cm models with a worm drive, equipped with a gearbox and motor. They are often used for longitudinal cutting of lumber or for cutting plywood sheets for formwork. Here the blade is located on the left side of the motor.

Functions of hybrid models

Sometimes situations arise when it is necessary to trim or unravel boards. For such purposes, it is best to use combination cutting saws. Hybrid versions of the tool do an excellent job with simple standard work. Their main working elements are a cutting disc and a riving knife.

In order to unravel boards using this tool, the tool kit includes a special table for the workpiece being processed. Hybrid saws are very popular among consumers who want to purchase a quality woodworking machine at a low price.

According to professional craftsmen, hybrid models of trimmers cannot compete on equal terms with specialized ones, since they are not able to provide high processing accuracy and cannot be called sufficiently reliable.

Therefore, the hybrid model will not be suitable for owners who are looking for an inexpensive alternative to specialized wood cutting saws.

Tips for beginners when choosing

It is important that when purchasing, pay attention to the characteristics of the saw.

So, for example, most models can be adjusted from 90 to 45 degrees, which makes it possible to saw beveled ends, hip rafters and cut at an angle of forty-five degrees. Almost all saws have a screw with a lever to loosen the bolt, which holds the blade at the desired angle for cutting. Some models have a scale showing the blade angle from 0 to 45 degrees.

When purchasing, be sure to pay attention to such an indicator as saw depth

Note: The cutting depth of circular saws varies from 30 to 130 mm.

You need to know what thickness of boards you will be working with. The choice of saw blade is also very important. For a neat cut, a disc with a larger number of teeth is suitable. If the disk has sparse teeth, the cutting will be faster, but the cut will be rougher.

Cuts with such a saw, as a rule, are smooth and there are practically no chips

How to adjust the dust for an even cut?

The saw blade must stand strictly perpendicular to the support platform. This can be seen both in the position of the disk and in the degree scale on the adjusting arc. If the disk is at an angle:

- The locking screw is released.

- The platform tilts to the desired position.

- The screw is fixed.

You should be more careful with tightening. On some models, if it is too heavy, the thread can be stripped or the head can break off.

Then it depends on how and what generates dust.

How to cut an unedged board?

Trimming the wane of a board a manual circular saw can be done in two ways:

How to trim a hand-held circular saw quickly and accurately

- By marking with a pencil (marker, sharp tool, etc.).

- Along the guide. To do this, a block, corner or factory guide rail is attached to the board with clamps or self-tapping screws. Dust, presses the edge of the saw platform to the guide.

Cutting along a guide usually produces a smoother cut.

We also recommend reading a useful article with reviews of the most popular and best circular dusts for the home.

How to make a cut at an angle of 45 degrees?

This angle is found in the manufacture of various products. Let's start the cutting work. First, the saw blade moves ninety degrees. Depending on the model, there is a bolt with a red handle on the side of the sole that needs to be loosened.

After which the sole is shifted at an angle of forty-five degrees and the bolt is fixed back. We take a piece of chipboard as a blank. We fix it with clamps on the tabletop so that the part that we will cut off extends beyond the table.

Afterwards the ruler is set. It is usually included with the circular saw. The saw has 2 marks zero and 45. We will cut off 30 millimeters, for which we combine the three on the ruler with the mark forty-five on the sole. Then you need to tighten the bolt that secures the ruler.

Next, the sole must be positioned so that the ruler rests against the edge of the workpiece. The saw is started and after it is fully untwisted, pressing the ruler tightly against the edge of the workpiece, they move in the forward direction.

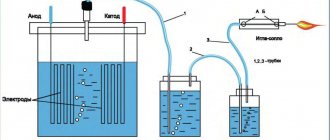

Features of sawing logs using a chainsaw

Creating additional equipment for sawing logs is quite simple:

- To create a support, a frame is used, which can be created from the legs of a school desk. The most suitable pipes are with a square cross-section of 20 × 20 mm.

- When constructing the frame, it is necessary to create 2 clamps and secure the crossbar at one end. This element must have holes for tie bolts. A protrusion for the tire is created in the middle.

- In order to cut a log lengthwise, it is necessary to construct a support frame, the width of which must be at least 8 cm in length.

- For ease of operation, a handle should be welded to the frame.

- Before carrying out work, you must carefully check whether the frame is securely fastened to the tire.

Using a homemade tool is quite simple. Before sawing, you need to install 2 sawhorses - they will be used as a support for the log. In addition, a metal strip or flat board , which will serve as a guiding element.

Lightweight nozzle

Such devices are often used, but they should only be used when creating boards for fences or sheds. This is due to the fact that the attachment is secured to the tire only on one side.

Tips for using a circular saw

If, when cutting, the edges turn out to be torn and chipped, you need to do the following:

- We take a small sheet of hardboard 6mm.

- We glue this sheet to the base with tape.

- With the saw turned on, we immerse the disk into the hardboard to obtain a cut with zero clearance.

Precision cutting template

How to make a straight cut? A certain device is made with a small allowance, after pressing the circular saw against the stop, we saw off the edge of the base to the required length. The sawed edge determines the line for cutting with a circular saw.

A mark is placed on the board where the cut was made. By pressing the lower stop of the device against the board, the edge is leveled. Due to the fact that the saw first passes through the device, cutting the boards is more accurate.

Making a straight cut using a circular saw

To make a guide, take a piece of plywood from twenty-five to thirty centimeters wide. It must be secured along the intended cutting line.

If it is necessary to cut long materials, a lot of time is spent on measuring and installing a straight guide on the marking line. To simplify this process, it is possible to make a template with your own hands, for example, from fiberboard. The edge of the template is aligned with the mark on the workpiece, and a straight guide is attached to the reverse side, which must be secured with a clamp.

A similar template can even be used to work with a jigsaw or router.

Source: domsdelat.ru

Trimming device for circular saw

It is not difficult to make a trimming device for a circular saw in your workshop, having in your hands a steel rod 250 mm long, 6 mm thick and 18 mm wide. This device will help you cut off the ends of workpieces on a circular table at different angles. The first thing you need is to make a slot (groove) along the entire length of the circular table; the depth and width of the slot (groove) must correspond to the dimensions of the metal rod. Place the slot away from the saw blade, but no closer than 40mm to the saw blade, the slot should be parallel to the saw blade. An affordable and reliable way to make a slot (groove) is to use a stop and a router with a radial cutter. In the absence of such tools, a hand-held circular saw will help make cuts, and a chisel will help remove wood from inside the cuts. Note: It is important that the slot (groove) ideally matches the dimensions of the rod in width and height.

Combination miter saw - both lengthwise and crosswise

ImhoDom › Forums › hands from shoulders › Combined miter saw - both along and across

- This topic has 2 voices and 1 reply.

- The science

Manufacturers of such tools rightly expect that they should be constantly used not only by workers in specialized workshops, but also by household users. Therefore, there are a significant number of modifications of combination miter saws on the market of varying power, capabilities and prices. Nevertheless, structurally all these devices are approximately the same, and consist of the following components:

The bed is made of high-strength aluminum alloys and has a developed surface for securely securing the saw to a workbench or table.

A rotary table with which you can angularly move a workpiece to a given angle.

Adjustable guides ensure adjustment of the unit for processing workpieces of the required width.

A tool head equipped with a measuring scale that can be adjusted to the required cutting angle.

An electric motor on the axis of which a saw blade is mounted.

Pulling mechanism. Saws with broaching of the source material allow you to process workpieces of increased width.

Measuring laser head, with which the accuracy of the cut is controlled.

Control panel (some versions of combined miter saws provide a soft start function for the engine).

Saw blades with different diameters, thicknesses and tooth pitches are used as replaceable technological equipment, with smaller pitches designed for cutting non-metallic workpieces.

Among the manufacturers of combined miter saws are foreign brands Bosch, Metabo, DeWolt, Makita, as well as domestic brands Enkor, Zubr, Interskol (the latter produces products of joint Chinese-Russian production), etc.

Step by step guide

The modern market offers the buyer a wide range of products, including high-quality products and inexpensive analogues. But, sometimes, the cost of a specialized tool is greatly inflated. As for homemade products, it is possible to make a miter saw from a manual circular saw with your own hands at home.

Miter saw

Exactly how to create a crosscut with your own hands is described in detail below.

Material and tools:

- plywood sheet;

- galvanizing;

- two furniture guides or pipe;

- connecting elements;

- electric drill;

- jigsaw for wood;

- sawing disc;

- pliers;

- knife, tape measure;

- glue.

A window or door hinge can be used as a shelf stop.

For reference! Some craftsmen install a motor from a washing machine. Such machines are used for cutting.

Preparing the base

You need to take a sheet of thick plywood and make a cut in it to move the disc. The base must be massive to support the shelf with the saw. The dimensions of the base depend on the purpose of the future structure.

It is better to carry out the work according to a pre-drawn drawing or diagram. A special groove is prepared at the base along which the saw blade will move.

Deformed sheets with damaged integrity are not allowed to be taken into work.

Grinder cutter

Determining shelf height for cross movement

The location of the structural element can be on the right or left side of the table. The height of the shelf should be chosen so that the toothed disc does not cut the base.

Shelf design

A piece of thick plywood or chipboard that is installed along the cut under the toothed disc. Fastening is carried out at the corners with self-tapping screws to a certain height. The shelf can be reinforced with a second layer of plywood sheet.

Setting limiters

After securing the shelf, you should begin installing the saw. It must be fixed in such a way that it fits into the cut and does not catch anything. Limiters are used for this. The material is the same plywood. The restraints are secured with glue.

Setting guides for workpieces

It is made from a piece of plywood or chipboard no less than 10 centimeters wide. Its length is 15-20% longer than the table. The strip is secured with clamps in two places. The guide changes position at the desired angle.

Classification

In fact, all types of trimmers can be divided into two groups - household and professional. They differ in their dimensions, weight and capabilities. Finding out which instrument is in front of us is quite simple. To do this, it is enough to determine the diameter of the saw blade: if it is less than 250 mm, then this saw model belongs to the household class, and is characterized by its small size, the ability to process workpieces with a width of no more than 240...250 mm, as well as a relatively low-power drive (up to 1200...1500 W ). Combined miter saws, designed for professional use, are equipped with a more powerful electric motor (up to 2500 W), an electronic start system, and - most importantly - a significantly increased service life.

An important parameter of combined miter saws is the design and dimensions of the saw blade (all manufactured equipment has a standard range of diameters: 210, 250, 305 mm). In particular, there is a relationship between the diameter of the saw blade and the engine speed: as the thickness and diameter increase, the speed decreases. This is due to a sharp increase in the moment of inertia of the rotating parts of the drive, which negatively affects the starting conditions of the engine. However, as the speed decreases, the quality of the cut deteriorates. Therefore, manufacturers have to find a compromise between the above parameters. Typically, with a disk diameter of up to 250 mm, the speed is 5500...6000 min-1, and in professional models it is reduced to 3500...3800 min-1.

Professional equipment

Now let's talk about professional equipment. Let's consider the cross-cutting saw ZUBR ZPTP-255-1800. The tool is used for cutting wooden parts and thin-walled metal. Why combined? This is because it can be used to both trim workpieces and work like a circular machine.

Main advantages of the model:

- Mobility;

- Compactness;

- Functionality;

- Safety system.

This machine combines a crosscut and a circular saw at the same time. The adjustable head position allows for high quality cuts. The machine allows you to make longitudinal cuts at any given angle. The equipment is equipped with a locking mechanism for turning on the drive and raising the protective casing. This model has the ability to connect an industrial vacuum cleaner to keep the workplace clean.

You can buy a circular cross-cutting machine for around 15 – 20 thousand rubles.

Another good option from all the gray mass of equipment is the Makita MLT100 table miter saw.

It is used both in everyday life and in professional production in workshops and workshops. The design of the machine allows it to be moved on a special trolley and can be easily mounted in a designated place on a workbench. The sliding table allows you to work with large workpieces. The table can be rotated both to the side and forward. The long service life of this equipment is increased due to the high quality of parts and materials used during assembly.

Allows you to make cuts both vertically and at a specified angle. The high precision of cutting parts is due to the presence of clamps, guides, scales with degrees and a ruler. The equipment combines a cross-cutting machine and a circular saw at the same time.

A separate advantage is the presence of an engine speed stabilization system, which in turn plays an important role during the initial start-up of equipment.

Electric brake included. There is a connector for connecting a dust removal device, useful for large volumes of work.

How to learn to cut at a 45 degree angle with a circular saw - tips for beginners

Probably everyone who makes repairs on their own has encountered the need to cut a board or pipe or trim a baseboard. In practice this turns out to be quite simple.

The most convenient tool for this is a circular saw. In this article we will tell you how to learn how to cut at a forty-five degree angle with a circular saw - tips for beginners.

A circular saw, compared to some other electric tools, is more efficient.

How to cut a board straight

How smart and quick-witted our people are!

Sergey Burkov:

How to unravel a 3-meter board so that both resulting halves are, for example, 10 mm thick

BANDIT#:

you explain it like to schoolchildren, with a countersunk head, etc.

COMPUTER:

What if

the board is 2 meters long?

How are you going to put her on the butt? Nikolay Sitkov:

Ha, I’m NOT smart enough for a hacksaw, although I’ve encountered this problem more than once. That’s a good thing.

How so?:

Christmas trees, keep your fingers, bro. I wouldn't do that)))

Workshop on the balcony:

Simple, cheap and cheerful :))). like

Mike VIZ:

Hello, you have already seen this circular in your frame several times. Is it AEG or another company? Can shoot a review, I choose myself dust, I would like to hear advice from an experienced person on what to pay attention to.

Types of saws

Several types of saws are produced, differing in scope and characteristics. The main use of a circular saw is cutting boards.

Let's get acquainted with some types of circular saws:

- 12.5 cm pruning saws with fine-toothed blades. As a rule, the blade is located on the left side of the motor, which would make it more convenient to observe how the blade moves. There is a 120V AC model, as well as a battery that works with different DC voltages;

- saws about 17 cm for cutting lumber to length. Works well with longitudinal cutting, cuts plywood, composite material;

- saws measuring 19 cm or skill saws. They are used to cut materials more than 5.5 cm thick. They are intended for sawing materials of load-bearing structures, as well as for longitudinal cutting. Available with a set of blades that can be used for cutting composite material, concrete, metal, etc.;

- saws of 20 and 25.5 cm in size are designed for cutting large lumber of wood up to 10 cm thick to length. Such instruments are heavier and larger in size. They are mainly used on an industrial scale;

- 22 cm models with a worm drive, equipped with a gearbox and motor. They are often used for longitudinal cutting of lumber or for cutting plywood sheets for formwork. Here the blade is located on the left side of the motor.

About choosing a saw model

Typically, recommendations regarding choosing a power tool model come down to comparing power, functionality and similar characteristics

We will not repeat these generally correct tips, but we will draw the attention of our readers to the main thing

Therefore, we strongly advise you to first determine more precisely for what purpose and for what work the tool is being purchased, and only then choose a specific model.

A circular saw is mainly used in “manual mode”, that is, the master holds it in his hands and moves his hands along the part being cut. For comfortable and fatigue-free work, the saw should weigh as little as possible and fit comfortably in the hand.

For a miter saw that is intended to be used in a carpentry shop, the recommendation is exactly the opposite: choose a saw that is as large as possible. It is preferable to buy a saw with a broaching mechanism, which allows you to cut workpieces of significant width and diameter.

Tips for beginners when choosing

It is important that when purchasing, pay attention to the characteristics of the saw.

So, for example, most models can be adjusted from 90 to 45 degrees, which makes it possible to saw beveled ends, hip rafters and cut at an angle of forty-five degrees. Almost all saws have a screw with a lever to loosen the bolt, which holds the blade at the desired angle for cutting. Some models have a scale showing the blade angle from 0 to 45 degrees.

When purchasing, be sure to pay attention to such an indicator as saw depth

Note: The cutting depth of circular saws varies from 30 to 130 mm.

You need to know what thickness of boards you will be working with. The choice of saw blade is also very important. For a neat cut, a disc with a larger number of teeth is suitable. If the disk has sparse teeth, the cutting will be faster, but the cut will be rougher.

Cuts with such a saw, as a rule, are smooth and there are practically no chips

Advantages and disadvantages

Homemade trims have both strengths and weaknesses. Therefore, before starting to manufacture a machine, we advise you to compare the list of advantages and disadvantages. This may make you give up the idea of assembling the machine

, or vice versa, be sure to try to trim the pipes without outside help.

The strengths of homemade cross-cutting machines include:

- To manufacture a cross-cutting machine, you will need to invest much less money than in the purchase of factory equipment for trimming wood, pipes, polymers, etc. On average, craftsmen spend 500-1000 rubles to re-equip a grinder into a machine;

- You can choose the operating parameters for your future cross-cutting machine. These characteristics include the depth of cut, the diameter of the discs, the power of the electric motor, the dimensions of the working surface, etc.;

- The assembled devices have a simple design. Since you assembled and disassembled the tool yourself, there will be no problems troubleshooting.

But there are also disadvantages, among which these stand out.

- For homemade machines, old, unnecessary materials and tools are usually used. This negatively affects the quality and service life.

- They rarely have high power.

- In some cases, savings on the purchase of a factory

machine become imaginary, since a lot of money is spent on repairs, modernization, and maintenance of a home-made machine. - You are taking a safety risk with a homemade trimmer.

How to make a cut at an angle of 45 degrees?

This angle is found in the manufacture of various products. Let's start the cutting work. First, the saw blade moves ninety degrees. Depending on the model, there is a bolt with a red handle on the side of the sole that needs to be loosened.

After which the sole is shifted at an angle of forty-five degrees and the bolt is fixed back. We take a piece of chipboard as a blank. We fix it with clamps on the tabletop so that the part that we will cut off extends beyond the table.

Afterwards the ruler is set. It is usually included with the circular saw. The saw has 2 marks zero and 45. We will cut off 30 millimeters, for which we combine the three on the ruler with the mark forty-five on the sole. Then you need to tighten the bolt that secures the ruler.

Next, the sole must be positioned so that the ruler rests against the edge of the workpiece. The saw is started and after it is fully untwisted, pressing the ruler tightly against the edge of the workpiece, they move in the forward direction.

Trimming from various scrap metals

The cutting frame is made of metal

This is a fairly heavy crosscut on a stationary metal table. It will take some effort to control it. But in the end, the saw mechanism moves smoothly, without jerking, and trimming with your own hands is easy.

Specifications:

- electric motor power - 2.2 kW;

- disk revolutions - 2800;

- cutting depth 80 mm.

Materials and tools required for assembly:

- 900 W electric motor;

- a metal sheet;

- metal corner;

- channel;

- hinge group;

- powerful spring;

- Bulgarian;

- welding machine;

- file.

The bed is made from adjustable supports, a metal corner and posts from an old bed. The working surface is a metal sheet like a table surface, in which we cut a hole, and process the edges with our own hands using a file.

- The pendulum stand for the saw is welded from a channel mounted on a sheet of metal; its height is about 80 cm.

- The stand for the electric motor is made in the form of a movable metal plate mounted on hinges. When installing an electric motor, a spring is used as a stabilizer. Then you can do without a pendulum and belts.

- The tension belts are adjusted with a conventional hinged bolt, and the pendulum for the mechanism is also made of metal.

- As an operating tool, a disk with a diameter of 420 mm is installed on the trimmer.

Tips for using a circular saw

If, when cutting, the edges turn out to be torn and chipped, you need to do the following:

- We take a small sheet of hardboard 6mm.

- We glue this sheet to the base with tape.

- With the saw turned on, we immerse the disk into the hardboard to obtain a cut with zero clearance.

Precision cutting template

How to make a straight cut? A certain device is made with a small allowance, after pressing the circular saw against the stop, we saw off the edge of the base to the required length. The sawed edge determines the line for cutting with a circular saw.

A mark is placed on the board where the cut was made. By pressing the lower stop of the device against the board, the edge is leveled. Due to the fact that the saw first passes through the device, cutting the boards is more accurate.

How to choose the right trimmer

Choosing a suitable model that suits the purpose of use is not so easy. When studying various models, you just need to follow a number of simple rules:

- Before you go to the store, find out why you need a wood trimmer and under what conditions it will be used.

- Be especially careful when selecting saw blades. For rough cuts, it is best to choose discs with large teeth. Fine-toothed blades are good if you want to make finishing cuts.

- The tool you purchase must be safe. Therefore, we advise you to give preference only to those models that are equipped with a special protective casing.

- If you want to get a mobile miter saw for wood, then you should look for a suitable model among the line of small-sized and lightweight devices.

- An important characteristic to consider when choosing a machine is the ergonomics of the saw. We are talking about parameters such as power and disk rotation speed. For domestic use, models with low power are best suited. But you don’t have to pay much attention to the disk rotation speed, since it is the same for all models.

Summing up

A wood miter saw is one of the most popular tools not only in industry, but also in households. However, it is important to understand that it belongs to a class of highly specialized equipment that is ideal for performing operations such as trimming and unraveling boards. Therefore, it is not advisable to use it to perform other tasks.

When choosing this equipment for a home workshop, you need to remember not only the purpose of using the cutting saw, but also the operating conditions. All this will further help you choose the right saw blade in order to perform operations on processing wood products most efficiently and with less time.

Miter saw