: Security measures

The most important thing is safety. The manufacturing process involves forging, grinding and immersing the metal in chemicals, so it is important to use the proper equipment to ensure safety.

For the forge welding phase (forge welding), many people who do any forging work know the basic safety gear: gloves, apron, closed boots, etc. However, the conditions are not always met. Everyone knows eye protection is important, but for this type of work you need a special kind of protection. The above and only photo in this section is of neodymium glasses. The reason for this is that such glasses are simply necessary for such work.

Experts often neglect this protection, but do not repeat after them. The heat required for forge welding creates radiation that can cause vision loss over the long term. Neodymium glass, however, blocks most of the radiation and keeps your eyes safe. Please note: Neodymium glasses are not the same as welding helmets or sunglasses. By using them in forge welding, your pupils will dilate and your eyes will receive even more radiation.

The process of making a knife in a workshop

We have already visited the forge and seen how damascus strips are made, now let's see what happens to them next.

First of all, you need to use a special pattern to trace the outline of the future blade on the workpiece, cut it off from a strip of metal forged in a forge and cut it along the contour.

In the photo (from left to right): marking the workpiece, the workpiece and the pattern, cutting along the contour.

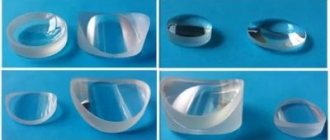

Forging metal using a mechanical hammer allows for slight differences in the thickness of the metal in the forged plate; therefore, it is necessary to align the blade along the plane. After this, the blade is given geometry according to the pattern and drawing, and it is also at this stage that, for example, cutting is done using biconcave lens technology.

In the photo (from left to right): a cut blank, alignment on a plane, giving geometry to the blade.

After the steps described above, we get a blade that is already quite close in appearance to what we are used to seeing on store shelves, but rather rough-looking and without a pattern. The blade must be polished to a mirror finish. Next, the workshop mark is applied (the area for applying the mark is preheated) and holes are made for the rivets if all-metal installation is provided.

In the photo (from left to right): grinding, stamping, drilling holes for rivets.

Not a single blade will have the declared properties if it is not hardened. We move on to the next stage of thermal hardening. The blade is hardened in a thermal furnace at a certain temperature and receives a blade hardness of 62 HRC on the Rockwell scale. After this, the surface is cleaned from scale using a sanding belt and the blade would have become a finished product, if not for one small thing - there is no design. The pattern that makes Damascus - Damascus, manifests itself when the blade is exposed to nitric acid; all the manipulations in the forge with various steels, welding and twisting them, were needed precisely for this moment, to reveal the pattern.

In the photo (from left to right): thermal hardening, descaling, etching of the design.

Actually, the blade is almost ready; all that remains is to sharpen the sharpening angle; let’s pay a little attention to the handle. We install the handle in two versions with a shank and all-metal installation. With the all-metal version, I think no questions should arise; holes for the rivets are drilled and the pads are attached to them. All-metal construction is the most reliable type of fastening, but most people prefer the more traditional fastening with a shank. For a material such as birch bark, celmet installation is almost impossible.

In the photo (from left to right): firing of the shank, the handle disassembled, the handle before turning.

For installation, the shank is annealed, the metal is tempered for drilling holes, a pin is attached to the rivet - the guard and handle can be attached. And the last stage is shaping the handle - the knife is ready. All that remains is to give it the required sharpening angle to the cutting edge, depending on its purpose.

I am attaching a number of photographs that were not included in the main description; unfortunately, the originals were large in size, so all the photographs in the article had to be compressed for normal loading on mobile devices and tablets, so I had to abandon enlargement by clicking.

Damascus steel made from balls and steel powder

I present to your attention a high-quality stylish knife made of Damascus steel that you can make with your own hands.

Damascus steel is a steel that is heterogeneous in its composition. This is achieved through forging, where different grades of steel are mixed. And if such a metal is then immersed in acid, a unique pattern is formed on it, since each steel changes its color differently. In this instruction we will look at how you can make Damascus steel yourself. More modern technologies will be used here. We will get Damascus by dismounting two or three types of steel. Steel powder and steel balls will be used as a base here. It is thanks to the balls that we will get an interesting pattern. In principle, the forging process is not complicated, but it requires a forge, an anvil, and some experience. Working with hot metal is very dangerous, so you must follow all safety rules. So, let's move on to making a knife!

Materials and tools that were used by the author:

List of materials:

— steel tube (preferably carbon steel); - steel balls; — steel powder; - some sheet metal for plugs; - wood for linings; — brass rods or bushings for pins; — oil for wood impregnation; - epoxy adhesive.

List of tools:

— forge furnace, anvil and hammer; — belt grinder; — acid for steel pickling; - Bulgarian; - drill; - welding machine; - caliper; - hardening oil, electrical tape and more.

Knife making process:

Step one. Forming a blank

First of all, we need to make a blank from balls, steel powder and a piece of pipe, from which the blade will then be made. To do this, pour powder and balls into a steel pipe. You need to fill it in portions, that is, a few balls, then a little powder, and so on. The balls must first be washed well in soapy water so that there are no traces of oil on them. You can also wash them in acetone. We weld the bottom of the pipe using round steel.

As for the metal of the pipe, it is desirable that it is also carbon steel.

Well, then we weld the other end and send the whole thing to the oven. You need to warm it up until it glows yellow and with this heating we perform forging. We crush metal from different sides. It is extremely important for us to mix all the metals together. You will need to heat the workpiece more than once, but forging is never easy. After this we get excellent metal for the knife.

Step two. Checking the metal

When you think the workpiece is ready, you need to check the quality of the metal. First, take a grinder and cut off the edges of the plate. The metal must be uniform, without holes or other defects. Next, we go through the contour with a belt sander. Similarly, we check whether we have mixed the metal well. If everything is fine, you can move on to the next step - forming the profile of the knife.

Step three. Blade profile

The author sets the profile of the blade by forging. First we form the tip of the knife, and then we can make bevels on the blade. We approach the formation of bevels responsibly; the blade should be smooth, but not too thin. There is no need to rush in this matter; we work with a hammer on both sides.

Finally, you will need to separate the blade from the handle. To do this, we work with the sharp part of the hammer. If everything looks great, make sure your blade is straight. At this point the forging can be completed.

The first thing the author does is normalize the metal after forging. To do this, you need to warm it up and let it cool gradually. The author places the blade in a bag of coal and sends it to the oven. Next, the workpiece can be hardened; to do this, we heat the blade again and immerse it in oil. The procedure can be repeated several times, but usually once is enough. If after this the blade cannot be taken with a file, then the steel is hardened. However, there is one pitfall here: if the steel is not released after hardening, it will become brittle. That is, we need to make the metal a little softer so that it springs and does not break. A household oven is quite sufficient for this. It needs to be heated to a temperature of about 200°C and the knife needs to be heated for about 1-1.5 hours, depending on the thickness of the metal. If the tempering was successful, the blade should become straw-colored. Now your knife will be able to withstand enormous bending loads as well as shock loads.

Step six. Grinding and drilling holes

After hardening, there will be a coating on the metal that needs to be cleaned off. We put a not too large belt on the draw machine and grind it. If desired, the blade can be made as shiny as a mirror.

We also need to drill holes for the pins in the handle. But it is very difficult to do such a procedure with hardened metal. In this regard, we take a gas burner and warm up the handle. Let it cool gradually. After this, the metal will be drilled using ordinary metal drills. That's all, now all that remains is to make the handle. Wrap the blade with electrical tape or masking tape to avoid cutting yourself during subsequent work.

Step seven. Let's prepare the pads

Overlays can be made from various materials, it can be plastic, textolite, bones, horns and much more. In our case, this is the most popular and sought-after material – wood. We select a board from a beautiful type of wood with a beautiful pattern and make two overlays. If desired, you can glue some other material onto the lining so that the handle is combined.

Step nine. Knife assembly

The knife can be assembled by drilling holes for the pins in the plates and assembling the handle using epoxy glue. Tighten the handle well with clamps so that everything sticks together well. The author used brass tubes with steel inserts as pins. When the glue dries, cut off the excess wood and begin sanding. We carry out rough work on a tape machine, and it is also very convenient to have a drill for this. Well, finer processing can be done manually using very fine sandpaper.

We sand the wood well and then saturate it with oil to protect it from moisture. That's all, the knife is ready!

Website about DIY inventions

How to sharpen a Damascus steel knife

To sharpen a Damascus knife with your own hands, you need to consider the following nuances:

- part of the blade with nicks and chips needs to be cut down for alignment;

- sharpening the knife is done slowly and carefully so that one layer of the layered structure does not bend onto another - for this, abrasive materials with successively decreasing grain size are used;

- sharpening is carried out diagonally - sharpening the blade lengthwise is ineffective;

- sharpening grooves and stripes spoil the design of the product - they need to be polished with a fine-grained material;

- The sharpened knife must be wiped with a napkin; you can use lemon zest.

Sharpening a knife made of pre-Mas steel.

Blanks for the production of Damascus

Any craftsman can make Damascus steel at home; alloy kits are used for this. They contain soft and hard inclusions. By combining them with each other, they achieve blades with pronounced structural patterns.

The following combinations are used, shown in the table. Some workshops offer their own options. The proposed schemes give the best performance.

When starting production in your own workshop, it’s easy to find out how much the finished product costs. Many online shopping sites list prices. As you gain experience and improve the quality of the product, you can increase the price of your products.

Video: how to make Damascus steel?

What is real damascus and damask steel

Previously, the technology for making such weapons was kept secret - only craftsmen knew how to make Damascus steel, and the products themselves were highly valued and incredibly expensive. However, even now knives made from these materials are an expensive pleasure, so a considerable percentage of models belong to the category of collectible weapons.

Damascus

The technology for producing Damascus steel involves forging twisted carbon steel rods/plates. Due to forging, the layers are flattened and become very thin - the multilayer structure provides the blade with the necessary strength characteristics.

Bulat

Unlike Damascus, damask blades are made by casting. According to the technology for preparing damask steel, high- and low-carbon steels are used - as a result of melting, the melt with a low carbon content contains partially molten particles of the high-carbon component.

The difference between damask steel and damask

The advantages of damask steel and Damascus steel have divided lovers of such weapons into two camps. So when choosing, buyers rely more on personal preferences. As mentioned above, even by external signs (by drawing), clearly identifying these materials is not a problem.

Damask steel.

How to make Damascus steel: a simple composition for forging with your own hands

The modern shade of Damascus steel is different from the original Damascus of the past. Historically, Damascus was considered crucible. It had a very high carbon content and had a distinctive surface due to its crystalline structure.

Damascus steel got its name because the Crusaders on their way to the Holy Land acquired new blades from this superior steel (superior to medieval European steel) in the city of Damascus. However, the modern version of steel has little in common with the past and looks more like acid-etched steel.

Damascus, shown here, is one of the more modern options. Cable damascus is perhaps one of the easiest ways to forge damascus with a complex pattern. Unlike other methods, this method does not require folding and essentially has a ready-made shape.

: Forge welding

After placing the product in the oven, heat it until it turns bright orange or yellow. Once it reaches the appropriate temperature, let it sit for another minute or so to allow all the metal to absorb the heat and heat evenly.

The cable must be twisted before the shots can be made. It is filled with empty space, which is bad for forge welding. Secure one end of the cable in a vice or similar and use whatever handy tool you find suitable (I used pliers) to twist the sections in the direction the cable is already twisted.

This step may require several reheats. Continue twisting the cable until it stops curling. Make sure the cable does not bend as this will make the whole process much more difficult.

Each time, before putting the cable into the fire, you need to sprinkle it with borax until the metal becomes homogeneous. To ensure that the borax sticks to the metal, pour it in at a time when the product is bright red. An important point: when borax melts, it becomes corrosive and can damage the inside of your forge, so make sure the bricks in your forge are fireproof.

Additionally, hot borax on your skin can be quite painful and may leave scars, so be sure to wear appropriate gear. The last part of forge welding is the weld itself. When the item is hot, you can start hitting it. The idea is to first knock it out into a square block shape. When you hit, you have to watch the cable turn. Personally, I prefer to start in the middle and work my way to the ends.

Impacts will cause the fibers to separate from each other, so it is necessary to reduce the distance from the first impact to the next as much as possible. You will understand that the product has become homogeneous by the changed sound that will be produced when struck. Initially, it will be duller, but as soon as the metal becomes homogeneous, the sound will become bright and ringing. Once it becomes homogeneous, you can begin to shape it into the desired shape.

Step-by-step technology for making damask steel from bearings

Products from finished ingots or billets are produced in the following sequence.

The inner ring of the bearing is made of ShKh-15 alloy. It is sawed with a grinder cutting disc and sent to the forge for heating. The desired heating temperature is 900…950 ⁰С.

The workpiece is held on the anvil with blacksmith tongs. By beating off the bulges with a hammer, a strip is formed from the ring.

Remove depressions from the strip.

The grinder gives the desired shape.

The workpiece is held in place using a special mandrel. A constant angle allows you to create identical slopes on both sides.

The final shape of the product is obtained by turning.

GOI paste and an auxiliary velvet roller help polish the surface.

After polishing, a finished blade is obtained. All that remains is to make the handle, bolster and sheath. Then the product can be considered finished.

When the blank is ready, it's time to forge the blade

We pull off the body, the nose of the future blade and the shank. You can also forge descents, but in this case the metal pattern will be poorly revealed.

Fig. 20. (blade after forging).

Fig. 21. (blade after forging).

We polish the future blade and trim the ends

Figure 22 (blank).

Then we put a mark, weld the shank and mark future descents

Fig. 23. (blank).

Figure 24. (blank).

After that, on the grinder, we roughly form the descents.

Fig. 25. (blade before hardening).

It's heat treatment time

We do normalization in order to remove stress from forging and refine the grain of the metal. Next is quenching: heat it in a quenching forge to the quenching temperature and lower it into a container with oil heated to seventy degrees. After which we conduct a vacation - heating to a temperature of two hundred degrees and holding for two hours.

Figure 26. (quenching forge).

Types of patterns

As a result of the technological process for creating Damascus steel, a unique pattern is formed on the surface - a pattern. There are several types.

Wild Damascus

The most common and easiest to manufacture. It got its name due to its disordered pattern. A package of strips from several grades of steel is welded into a single block. They bend it repeatedly and forge it again. The layers of metal mix randomly. The pattern is formed randomly and looks heterogeneous.

One of the most ancient varieties of Damascus steel. It is highly popular among collectors due to the unique design of each product: knife, saber, dagger.

Stamped

A variation of traditional damask. The pattern is more uniform. Geometric shapes alternate: circles, stripes, rings. Includes two manufacturing methods:

- The metal package is welded in advance. The stamp strikes are applied in a given order. The finished product is polished. Excess metal is removed from the surface in order to more clearly demonstrate the relief and pattern.

- The pattern is applied to the bag using a metalworking method - with a milling cutter or drill. Then the package is forged.

Stamps (stamps are a German word, from which the name is derived) are divided according to the type of drawing:

- reticulate;

- stepped (staircase);

- wavy;

- rhombic;

- ringed

The patterns are similar to wood veneer or circles on water.

The types of patterns are in turn divided into a wide variety of patterns. A master blacksmith can stand out with his specific signature style. In the USA, damask with a peacock eye pattern, products with a pattern in the form of crosses, imitation of barbed wire or mesh are popular. To manufacture the first, uniform drilling of metal is used across the entire width of the workpiece.

Turkish Damascus steel

Refers to the traditional type of patterned steel. The manufacturing method involves forging a bundle of intertwined steel rods. The composition of the rods varies. A complex pattern is formed on the surface - many smooth wavy lines. The size of the lines depends on the chemical composition of the metal of the rods, their diameter, and the method of twisting.

Japanese

It stands out for its fine layered steel structure. The surface is etched. The structure of the alloy appears thanks to unusual polishing. Hardening also has its own characteristics. The handle of the blade is covered with a protective layer of clay mixture. Only the blade itself is hardened. The result is reflected in the properties of the Japanese sword. The blade becomes hard, sharp and brittle. The handle remains elastic.

Mosaic

A modern version of Damascus. It got its name because of the specific manufacturing method. The layered structure gives a beautiful decorative effect. There are two most popular manufacturing methods:

Shell

A metal pipe or container is used to connect mosaic elements. Contrasting steel is placed inside. The container is filled with inert gas or oil. When heated, oxygen binds. A neutral environment is formed inside the shell. The pipe is completely welded. In this state, the shell is sent to the forge. Heats up to welding temperature. Forging often occurs using a hydraulic press. After the formation of a single mass of metal, the shell is removed. A mechanical method is used for removal. The resulting workpiece undergoes further processing.

Technological

Holes are cut in the steel bar in accordance with the specified pattern. Metal inserts of a different chemical composition of equal diameter are placed in the holes. Holes and liners are cut with a plasma cutter. The package is welded using the diffusion method.

The advantage of this method is the ability to create the necessary drawings and various images. Unlike surface engraving, the pattern covers the entire thickness of the blade.

Fibrous

This method is used to make high-quality Japanese knives. The layers of steel are not positioned to the length of the future blade. The rods are finely chopped and laid out at right angles. In this form, the package is forged.

Combined

Combines classical and traditional manufacturing methods. Both methods are applied simultaneously, hence the name. A stamp pattern is applied to the block assembled using the mosaic method. The surface is forged and polished. In the case of applying relief by drilling or milling, the prepared alloy is forged and etched. Grinding is not used in this case.

It is also possible to combine the technique of forging wild Damascus and inserting a metal alloy with contrasting properties. Nickel is used as an alloy that differs in composition. It has a white color, which allows it to stand out against the background of the overall black and gray pattern of the blade.

Industrial

Produced on industrial equipment of metallurgical enterprises. The quality of the blades does not differ from the handmade work of blacksmiths. The scale of production is much larger. The type of patterns can differ into wild, mosaic, combined.

Modern Damascus Steel

A pattern snakes across the metal surface. In it you can guess the ancient Arabic script, and the hot waves of sand, and the light ripples of the surf, and the foggy streaks of storm foam... Each blade is unique, and not only experts understand this. After all, the drawing on it is like handwriting - and there is no other like it. The handwriting of a master blacksmith.

Igor Yurievich Pampukha is a third generation blacksmith. His grandfather was a military gunsmith in one of the units of the Red Army, his father worked as a blacksmith for a long time, and now he has his own forge in the Nizhny Novgorod region. Igor Yuryevich was born in Dushanbe, where he first stood up to the hammer. Now he is a famous blacksmith, a member of the creative union “guild of gunsmiths”, a regular participant and winner of international exhibitions “blade”, “weapons and hunting”, “hunting and fishing in Rus'”.

...Through the light weather of the coming autumn, the rays of the still hot summer sun break through. We enter a modern forge: the metal of tools and workpieces gleams coldly everywhere. “Now it will be hot here,” the blacksmith assures, smiling through his mustache. – I’ll show you how to make the simplest one – stamp damask.

Of course, not from “scratch”, but from the moment the multilayer package is already welded, otherwise you would have to spend the whole day in the forge.” With a confident hand, the master pours coke. And now he is already in the oven... Soon heat begins to emanate from the reddened mass. The piece of metal doesn't seem like anything special. We are trying to guess what will happen...

Damascus? Bulat? That is the question!

Damascus and damask steel are often confused. In ancient times, Indian steel was highly valued, which could be bought in Damascus, which became the center of the arms trade in the era of Alexander the Great. However, the origin of steel in the Damascus bazaar was often difficult to find out, so almost all weapons purchased there were called “Damascus.”

Metallurgical historians distinguish between “pure Damascus” - old Indian cast patterned steel, and “welded Damascus” or new “Damascus steel”. “Pure Damascus”, which is better known by the Russian name “bulat”, is an elastic and very hard material. The sharpened blade of a damask blade can remain sharp for a long time.

"Welded Damascus" ( modern Damascus steel

) or, as it is also called, “welded damask steel” is inferior to real cast damask steel in hardness, but the quality of blades from Damascus is higher than from ordinary steel. The method for producing Damascus steel was most likely invented by accident. Previously, the remaining cut-offs, trimmings (metal was in short supply, nothing was thrown away) - everyone collected together and welded steel for knives and tools. One day, someone saw that a beautiful pattern was being created, and the quality of the metal was becoming noticeably better, and they began to specially fold the pieces.

It is known that iron itself does not have sufficient hardness; it appears in its alloys with carbon and alloying additives. In those days there was no carbon steel as such, but depending on the ore at the molecular level, the original metal contained some amount of chromium, molybdenum or other elements. As a result of forging, the steel turned out better or worse, but the carbon content still remained insufficient. To improve the properties of the metal, the layers were repeatedly rearranged, heated over a fire, and hardened, due to which the steel acquired the necessary strength and hardness.

Today, blacksmiths work with finished metal. In modern steel grades, the content of carbon and alloying elements is determined (in the thickness of our package there is approximately 0.8% carbon, and there are also molybdenum, chromium and nickel, which give a good structure). Therefore, there is no need for some labor-intensive operations. But still, if we compare the ancient technology and ours, the principle remains the same, only the materials are different.

Damask steel recipe

only at first glance it is simple: they coat the crucible with clay, put pieces of different metal inside, close it with a lid with a slightly larger diameter, and coat it with clay again. Then another heat-resistant coating is applied on top. The crucible is placed in the furnace for 5.5 hours (it takes four hours to reach the desired temperature and about two hours for melting). The result is an ingot - this is a crystal of a superhard structure. Then they cut off the “head” and the lower part of the ingot and unforge it. In fact, everything is much more complicated. You can cast for a long time, and then it turns out that it comes out with a crack, and all your efforts are in vain.

The production of Damascus steel has its own secrets. When making a stamped Damascus, it takes 1-1.5 hours for forging and about the same amount for the workpiece. In complex Damascus - only 3-4 days to assemble and weld the package. Mosaic Damascus is made from layers of different structures - twisted, layered, laid out in a certain order. Twist in a regular vice while hot. The layers must be carefully stacked. In terms of cutting properties, mosaic and stamp Damascus are practically the same, although their prices are different.

Are there “formulas” for damask steel and Damascus? Knowing them is one thing, but learning to put them into practice is quite another. You must be able to make metal so that it has high cutting properties - it is a working material. And for it to work, it must be forged correctly, cut correctly, hardened correctly, tempered correctly, sharpened correctly. Here, for example, is medical steel: an error of 10°C during heat treatment results in a completely different material - the entire technological process must be strictly followed. And this is difficult to do if you have no experience.

To determine the quality of a blade, you need to put it to work. If you cut something hard all day, a blade from Damascus will shrink around lunchtime, and from damask steel - somewhere in the evening. And it will also have to be sharpened. The sharpening technique has its own secrets: you can sharpen it so that the blade will cut hair on the fly.

Flaws

The main disadvantage is the low resistance to metal corrosion due to the high carbon content in the composition. Finished products require careful care and storage.

The absence of alloying elements - the necessary components to impart certain physical properties to the metal - leads to the formation of rust on the surface of the blade. As a result, the blade can quickly become unusable.

It is recommended to store Damascus steel products in an oil composition.

High cost of products. Intricate manufacturing, unique patterns, and the metal's superior strength characteristics contribute to the high price tag.

Calculation of average carbon content in Damascus steel

There are a lot of articles written about Damascus steel, but since you're about to make it, it's worth repeating some of the theoretical points. Damascus steel consists of alternating layers of high and low carbon steel.

The average carbon content of Damascus

plays an important role .

It can be calculated as follows:

Suppose you welded a package of 30 grams of St3 and 70 grams of U8. So your Damascus is 30% steel with 0.3% carbon and 70% steel with 0.8% carbon. Using a simple proportion, we calculate that (0.3 x 0.003 + 0.7 x 0.008) x 100 = 0.65. Therefore, the average carbon content in the bag is 0.65%. Not enough. It is also necessary to take into account that when the package is first heated to welding temperature, about 0.3% of the carbon burns out, and with each subsequent heating, about another 0.03%. This means that it is necessary to use higher-carbon steel grades, or to increase the relative content of U8 in the package. Using this formula, you can calculate the average amount of carbon in the package and, accordingly, select the appropriate hardening mode. An operation called carburization can increase the carbon content. It should also be remembered that a contrasting pattern is obtained when using steels whose difference in carbon is equal to or greater than 0.4%. The finished product is etched in one of the above reagents. In this case, the product must already be hardened (hardening increases the contrast of the pattern) and polished. The entire defatted product is placed in the etching solution, and the operation is continued until the pattern is clearly and completely visible.

Cooking Damascus

When they see a knife or blade, rarely does anyone imagine what and who is behind this product. At best, they represent a hefty blacksmith with a pair of biscuits the size of a cow’s leg.