What is an asynchronous motor

An induction motor (IM) is an electrical machine used to convert electrical energy into mechanical energy. This engine got its name due to the fact that the rotational speeds of the moving part of the engine and the magnetic field (MF) do not coincide.

- The basis of the IM is the stator and rotor. The stator is a cylinder made of electrical steel sheets.

- Its core contains special windings that must be shifted 120 degrees from each other.

- A rotor is a rotating part of an electrical machine driven by a drive or drive shaft.

The rotor is made of steel sheets. It can be of two types, phase or short-circuited, and is made in the form of a drum, disk or wheel

The operating principle of the IM is that when voltage is applied from an external source to the stationary stator windings, a mutual induction emf is induced in the rotating part of the motor and induces eddy currents. Due to eddy currents, its own EMF is generated, which forms the rotor MF.

Types of asynchronous motors

Induction motors can vary in the number of phases used.

There are single-phase, two-phase and three-phase electric motors.

- Single-phase electric motors have one operating winding and use single-phase current. Such an engine can operate from a standard network and is the most common in its category. The disadvantage of a single-phase motor is the need for an additional winding, which provides additional rotation to start the rotor moving.

- A two-phase asynchronous motor is a little more complicated than a single-phase one; it has a phase-shifting capacitor and two windings that are opposite each other. Two-phase devices operate on alternating current.

- A three-phase IM has three working windings shifted relative to each other by 120 degrees. Stable operation in such an engine is achieved due to the MP being shifted in space. The main advantage of such a motor is its resistance to overloads, but three-phase motors have a complex system for adjusting the shaft rotation speed.

Also, asynchronous motors may differ in the type of rotor installed in them. More common in industry are induction motors with a squirrel-cage rotor (induction motor with a squirrel-cage rotor); among the advantages of such an engine are the following:

- Cheapness;

- Strength;

- High performance;

- Easy to maintain.

Asynchronous motors with a phase-type rotor are less popular, due to a number of disadvantages:

- Need for regular maintenance;

- High copper consumption;

- Complexity of design.

Operating tips: what difficulties may arise

A common problem with generator operation is power overload. This causes intense heating of the winding and breakdown of the insulation. As a result, the generator breaks down. Occurs due to:

We have already discussed the rules for selecting containers and calculations above. And regarding the problem of power overload in a three-phase generator, it is necessary to note some more nuances when connecting single-phase consumers:

- Consumers with a voltage of 220 Volts can only be connected to one third of the total power (for example, if a generator produces 6 kW, then this is only for 380 Volt devices, and for single-phase devices it will be only 2 kW, no more). Otherwise, there will be an overload.

- If your generator has two single-phase lines, then together the power through them will be 2/3 of the total power. That is, 6 kW is 4 kW for single-phase, 2 kW for each phase. Moreover, when using phases at the same time, make sure that the load does not differ from the power by up to 10%, otherwise the phenomenon of “phase imbalance” will occur and no current will flow.

When working, it is important to monitor the AC frequency indicator. If you have not built a frequency meter into the common electrical panel, then at idle the output voltage is 4–6 percent higher than 380 Volts (or 220 when connecting single-phase ones).

What is an asynchronous generator

An asynchronous generator (AG) is an asynchronous machine operating in generator mode.

The design of an asynchronous generator is very similar to an asynchronous motor, but energy conversion occurs in the opposite direction. AG converts mechanical energy (this can be wind, hydraulic, or others) into electrical energy.

The operating principle of asynchronous generators is that magnetic lines of force formed as a result of rotor rotation cross the stator windings. When a load is connected, the EMF generated in the coils leads to the appearance of current in the circuit. Below are photos of asynchronous generators:

Advantages and disadvantages of asynchronous generators

Among all the advantages of an asynchronous generator, it is worth highlighting:

- Ease of maintenance;

- Low cost;

- Low sensitivity to short circuit (short circuit);

Despite this, asynchronous generators are not very popular, the reason for this is a number of disadvantages:

- Unreliable operation under high load;

- Dependence on electrical network parameters;

- Dependence on the active-inductive nature of the load.

Do-it-yourself solar power plant for home

The design of a homemade solar power station, built with your own hands, is a combination of a homemade solar panel and a system for storing and consuming electricity. In such a power plant, the most expensive part is the set of solar cells, which must be placed in a protective tray. After connecting the solar panel to the storage system, all that remains is to correctly install and orient the photo panels.

In some designs of solar panels, special racks are provided for this purpose, allowing you to adjust the angle of inclination of the panel and fix its azimuthal orientation. This allows you to ensure the maximum amount of electricity received depending on the position of the sun.

Asynchronous generator from an asynchronous motor

If necessary, absolutely any blood pressure can be converted into an AH with your own hands. In order to assemble such a generator, you will need any AD that can be removed from an old washing machine or other equipment, neodymium magnets and epoxy resin.

Instructions on how to make an asynchronous generator:

- First you need to make small holes in the core structure and remove a thin layer of 2 millimeters. The depth of the holes is 5 millimeters.

- Measure the rotor and make metal strips in accordance with the dimensions of the device.

- Purchase and install neodymium magnets. Each pole will require 8 magnets.

- Secure the magnets. It is worth considering that when you bring the magnets to the rotor they will begin to move, so they should be held well until they are finally fixed.

- Take paper or tape and wrap the rotor.

- The end part of the rotor must be sealed with plasticine or other similar material to seal the device.

- Fill the free space between the magnets. This must be done using epoxy resin.

- When the resin has completely hardened, remove the previously used paper or tape.

- Sand the rotor surface.

- Determine the condition of the device, replace the bearings if necessary.

- For the generator, you need to assemble a rectifier and purchase a controller for charging.

If you have completed all of the above steps, then the work can be considered complete. Thus, after spending a little time and money, you get a working generator.

Build process

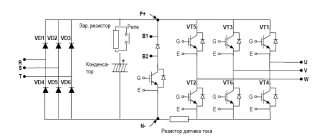

Everything is simple here! Capacitors are connected to the electric motor in a delta configuration. During operation, you need to periodically check the temperature of the case. Its heating may occur due to incorrectly selected capacitor capacitors.

A homemade generator that does not have automation must be constantly monitored. Heating that occurs over time will reduce efficiency. Then the device needs to be given time to cool down. From time to time you should measure the voltage, speed, and current.

Incorrectly calculated characteristics are not able to give the equipment the necessary power. Therefore, before starting assembly, you should carry out drawing work and stock up on diagrams.

It is quite possible that a homemade device will experience frequent breakdowns. This should not be surprising, since it is practically impossible to achieve a hermetically sealed installation of all elements of an electric generator at home.

So, I hope it’s now clear how to make a generator from an electric motor. If you want to design a device whose power should be enough to simultaneously operate household appliances and lighting lamps, or construction tools, then you need to add up their power and select the desired engine. It is desirable that it has a small power reserve.

- Generator for home - purpose of the device, power selection and tips for repairing the main types of generators

- Wind power plants for the home: selection of modern models and calculation of their efficiency + instructions on how to do it yourself

Gasoline generator - selection, connection and installation of modern devices. Rating of the best generators for the home in 2022!

If you fail when manually assembling an electric generator, do not despair. There are many modern models on the market that do not require constant supervision. They can be of different power, and are quite economical. There are photos of generators on the Internet; they will help you estimate the dimensions of the device. The only negative is their high cost.

Where are asynchronous generators used?

Different types of asynchronous generators can be used in domestic conditions when it is necessary to obtain a small amount of electrical energy from mechanical energy.

In addition, AGs are used as the main elements of electric power plants.

For example, they can be used for:

- Power supply for AD, household appliances, lighting, etc. in areas remote from power lines.

- Power supply for low power radios.

- Heating and melting materials with heat.

- Electric welding.

- Obtaining constant voltage in autonomous electrical installations.

Thus, it turns out that by performing a number of simple operations with IM, you can obtain a low-cost generator device for autonomous power generation.

Most popular models

Currently, the most popular generators are models from, U-Polemag, Vega, and Verano-Co. They occupy a large part of the device market.

Vega produces devices that operate on the principle of magnetic induction. This idea was realized by the famous physicist Adams. The price often depends on the power and size of the device. The minimum cost is 45 thousand rubles. This manufacturer has a number of advantages:

- Products from are very environmentally friendly.

- The generators are completely silent, which allows them to be installed anywhere.

- The devices are relatively compact.

- The manufacturer has quite a few models, the power of which starts from 1.5 kW and reaches up to 10 kW.

The minimum service life is 20 years. Batteries must be replaced every 3-4 years.

"Verano-Co" is a Ukrainian manufacturer that uses only high-quality components for its products. It produces generators for both domestic and industrial purposes. The operating principle of the alternative energy source is the same as that of other magnetic units. The cheapest model costs 50 thousand rubles. Prices for devices reach 200 thousand rubles.

You may be interested in this All about resistivity

U-Polemag is a Chinese manufacturer. Represents the largest variety of generator models. The standard efficiency of the devices is 93%. Maximum energy loss is 1%. Often purchased for household use. It has compact dimensions, low noise level and light weight. The package includes cooling systems. The maximum duration of use reaches 15 years. Prices for the model range start from 30 thousand rubles. and reach 90 thousand rubles.

Energizistem produces vertical devices. Consumers do not have a clear opinion about the quality and power of devices. Prices for generators are a little high and start at 50 thousand rubles.

Photo of a generator made from an asynchronous motor

Share with friends