What you need to do to make a homemade anemometer

1. Using a needle, make two tiny holes in the tennis ball, one opposite the other. The easiest way to do this is to heat the tip of the needle over a fire.

2. Thread a sewing thread or fishing line through the ball, leaving about forty-five centimeters on one side. Tie it tightly and cut off any excess length.

3. Tie the other end of the fishing line to the stick and wrap it with thread until the distance between the stick and the top of the ball reaches thirty centimeters.

4. Using duct tape, attach the stick to the protractor. The thread should hang from the outside of it from a central point.

5. To measure wind speed, place the protractor in the direction of the wind. Keep it by the corners as far away from you as possible. The thread should not touch the protractor. At zero wind speed the string will hang straight down along the ninety degree mark.

We conducted another experiment and this time we measured the wind speed, which is constant in the region where you live. Conducting various experiments and experiences is very interesting, exciting and educational. Especially for inquisitive boys and girls like you.

To make a device that measures air flow speed, you will need available tools. For example, you can use halves of plastic Easter eggs as anemometer blades. You will also definitely need a compact brushless permanent magnet motor.

The main thing is that the resistance of the bearings on the motor shaft is minimal. This requirement is due to the fact that the wind can be very weak, and then the engine shaft simply will not turn. To create an anemometer, a motor from an old hard drive will do.

The main difficulty in assembling an anemometer is making a balanced rotor. The engine will need to be installed on a massive base, and a thick plastic disk will be mounted on its rotor. Then you need to carefully cut out three identical hemispheres from plastic eggs.

It is recommended to carry out balancing in a room where there is absolutely no wind movement. The anemometer axis must be in a horizontal position. Weight adjustment is usually done using needle files. The idea is for the rotor to stop in any position, and not in the same one.

Main types and uses of an anemometer

The most common anemometer models are:

- A manual model with an impeller, or the so-called paddle anemometer. Its operating principle is reminiscent of the operation of a fan, which gave the device another name - a ventilation anemometer. When the air mass hits a wide surface area of the blades, it changes the intensity of their rotation and makes it easy to calculate the wind speed. A counting mechanism is launched from the impeller using a toothed wheel device, which records the number of revolutions of the blades per unit of time. All that remains is to calculate the speed, which will be equal to the product of the circumference of the blade path and the number of revolutions. The main advantage of this model is the ability to determine not only the speed, but also the direction of the wind. The scope of application of a blade anemometer is measuring the parameters of air flows in ventilation systems and pipelines.

- Cup anemometer. The first model constructed by man to measure wind speed. The blades of the device resemble small cups, sequentially placed at the ends of a metal structure and directed in one direction. The operating principle of a cup anemometer is similar to that of a blade model. The counter, “hardwired” into a plastic case, accurately determines the number of full revolutions of the blades per unit of time. You can easily make such an anemometer with your own hands.

- Thermal anemometer - performs two functions at once: determines the speed and temperature of air masses. The principle of operation is based on the laws of acoustics: the device detects sound, determines its speed and calculates the wind speed, while simultaneously noting its temperature. The electronic “filling” guarantees the accuracy of measurements and prompt correction of data as the intensity of movement of air masses changes. The hot-wire anemometer is widely used in laboratory research and control measurements of microclimatic conditions at the workplace in large industrial workshops.

The operating principle of anemometers of all listed models is almost the same. The device, mounted on a high pole, is raised as high as possible and installed in a direction that allows the movement of air masses to be accurately captured. Mechanical anemometers are controlled using a verification device included in the delivery set. On induction models, readings expressed in meters per second are displayed on the built-in dial.

Anemometer installation

It is better to install the anemometer on a long pole away from buildings or on the roof of a house. During installation, we think through all the steps, prepare tools and fastening materials. It is useful to install the pole without an anemometer, make mounting holes and holes for cable penetration. We fix the anemometer on the pole and carefully mount the structure. We pass the cable inside the building and connect the cycling computer.

Each simple cycling computer has options for measuring maximum speed, average speed for the entire mileage, and average speed for a given period.

Using these options will allow you to measure the maximum wind speed at the location of the anemometer, the average wind speed for the period and for the entire time of its operation. A fragment of the operation of a homemade anemometer is shown in the video. DIY anemometer sekret-mastera.ru

"sensitive" anemometer

Technical characteristics: Measuring range from 0.5 m/s to 3.5 m/s. Accuracy 0.5 m/s. Update interval 2-5 seconds.

Cut a 3 x 2 inch (7.6 x 5.1 cm) rectangle.

Mark into three 1-inch (2.53 cm) wide rectangles.

It is very important to use a Pozidriv (PZ) slotted screw. Because in such a slot the needle does not touch the side walls. The length of the screw should be as short as possible so that the magnet is as low as possible. The photo shows a 2x6mm screw.

After tightening the screw, the “wings” are carefully separated and the impeller is given the desired shape.

In order for the magnet to hold well on the screw, you need to screw on another nut. But don't twist it.

Due to the attachment of a neodymium magnet (size 4x4x4 mm), the center of gravity of the impeller rises and it becomes unstable on the needle. To lower the center of gravity, weights need to be glued to the INNER part of the “wings” (washers for a 4 mm screw are used).

The impeller can rotate not only on an awl, but also on VERY WELL sharpened pencils or on a sewing needle attached to a pencil. The impeller spins best on a sewing needle, but this option requires great caution and is categorically NOT SUITABLE FOR CHILDREN.

About anemometers: Samsung b2100 xplorer buy in the online store

Dependence of rotation frequency on wind speed (on a mechanical pencil 0.5 mm): 1.5 Hz - 1.4 m/s 4 Hz - 2.85 m/s 6 Hz - 3.4 m/s

DIY anemometer: the simplest diagram

Anemometer is a device for measuring wind speed. The classic cup anemometer is a purely mechanical device capable of measuring wind speed in the range from 2 to 20 m/s. An anemometer simply counts the number of revolutions of the impeller.

To determine the wind speed, you need to measure the number of revolutions over a certain period of time, for example 30 s, and then calculate the number of divisions that the anemometer needle passes in 1 s. After this, you should use the graph to determine the wind speed.

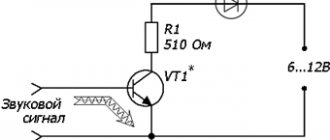

The easiest way to construct its analogue is on the basis of a low-power electric motor, for example DM-03-3AM 3 91, which acts as a generator. The four-bladed anemometer impeller was taken ready-made and purchased on Aliexpress for about $1.

The impeller diameter is 10 cm and the height is 6 cm.

The electric motor is located in a housing made of a cold welding container, in the lid of which a hole is cut for the electric motor shaft and wires leading from the motor.

A VD1 diode bridge assembled using 1N5817 Schottky diodes is connected to the electric motor. An electrolytic capacitor C1 1000 μF x 16 V is connected to the output of the diode bridge.

Cup device

An instrument called a hand-held cup anemometer appeared earlier than other types of these instruments. The device is simple. It got its name from the appearance of the impeller blades, which resemble tea cups. The speed of air flow is determined by the speed of their rotation.

The impeller (Figure “b” No. 1) consists of four blades facing one direction. The counter (Figure “b” No. 2) is hidden in a plastic case.

The impeller is held by a metal axis connected at the lower end to the counter. Arms made of strong wire (Figure “b” No. 3) protect the impeller from mechanical deformation.

Video of work

Winter work results

s-st — hours for winter 0 m/s — 511.0 1 m/s — 475.0 2 m/s — 386.5 3 m/s — 321.2 4 m/s — 219.0 5 m/ s — 131.5 6 m/s — 63.3 7 m/s — 32.5 8 m/s — 15.4 9 m/s — 9.1 10 m/s — 5.0 11 m/s — 3.5 12 m/s — 2.2 13 m/s — 1.3 14 m/s — 0.8 15 m/s — 0.5 16 m/s — 0.5 17 m/s — 0, 2 18 m/s - 0.0 19 m/s - 0.1

Based on the results of two winters, I saw that my winds were not strong and the windmill would not be effective, so I made a small one with 50cm blades. peak power 150 W. I just made sure that at least one economical light bulb would shine when the light went out.

Now a little about Arduino.

I found a diagram of how the mouse works on the Internet; it clearly illustrates how my system works.

Based on the mouse diagram, I made the following diagram.

The pulses come from the phototransistor to the Arduino, and it perceives them as button presses.

The algorithm of the program is as follows: We count how many button presses occurred in one second, and here we have the rotation frequency. In order to convert this frequency to m/s. Even when I was doing it on Atmel, I made an algorithm for calculating the frequency in m / s. He looked like this:

int ob_per_sec=0; // Variable that contains the revolutions per second.

int speed_wind=0; // The value will go here after converting the frequency to m/s.

int speed_wind_max=0; // The maximum value of wind readings m/s falls here.

int speed_wind_2=0; // Number of seconds from the start of the program with a wind speed of 2 m/s.

int speed_wind_3=0; // Number of seconds from the start of the program with a wind speed of 3 m/s.

int speed_wind_4=0; // Number of seconds from the start of the program with a wind speed of 4 m/s.

int speed_wind_5=0; // Number of seconds from the start of the program with a wind speed of 5 m/s.

…………………………………………………………..

int speed_wind_22=0; // Number of seconds from the start of the program with a wind speed of 22 m/s.

if (ob_per_sec >0 && ob_per_sec<4) { speed_wind=2; speed_wind_2 ;}

if (ob_per_sec >4 && ob_per_sec<7) { speed_wind=3; speed_wind_3 ; }

if (ob_per_sec >7 && ob_per_sec<11) { speed_wind=4; speed_wind_4 ; }

if (ob_per_sec >11 && ob_per_sec<15) { speed_wind=5; speed_wind_5 ; }

if (ob_per_sec >15 && ob_per_sec<18) { speed_wind=6; speed_wind_6 ; }

if (ob_per_sec >18 && ob_per_sec<23) { speed_wind=7; speed_wind_7 ; }

if (ob_per_sec >23 && ob_per_sec<27) { speed_wind=8; speed_wind_8 ; }

if (ob_per_sec >27 && ob_per_sec<30) { speed_wind=9; speed_wind_9 ; }

…………………………………………………………..

if (ob_per_sec >60 && ob_per_sec<67) { speed_wind=22; speed_wind_22 ; }

if (speed_wind> speed_wind_max){ speed_wind_max = speed_wind ;} // check and rewrite if the maximum value is greater than the previous recorded one.

And display the value on the screen.

speed_wind

speed_wind_max

If necessary, you can then view how many minutes the wind blew at a certain speed; to do this, you need to display the variable (with the necessary speed index) speed_wind_№ (but divide it by 60 to get minutes.).

In my program I did this: when you press a certain button, all the variables are displayed one by one, from speed_wind_1 to speed_wind_22.

First version

No sooner said than done, and thoroughly.

I welded a cross from scraps of polypropylene pipes. I unsoldered all the sensors and extended them with wires that I laid inside the pipes. The distance between the sensors was 70 cm.

The program code is like this.

The last two numbers give the desired horizontal wind speed and direction. The direction is calculated as an azimuth to the north direction and is given in degrees. Rotate clockwise.

Alas, the results disappointed me.

When averaging 25 measurements, readings in calm air jump to an average of 1.5 m/s, with measurements being given approximately once every second. If you average 10 times more readings, the situation improves, but does not fundamentally solve the problem. In addition, judging by the graph of speeds in two axes, one pair of sensors produces significantly more radiation than the other. Most likely the problem is in the wires with which I extended the sensors. We'll have to redo it.

Addition

The anemometer screw, which is not loaded with anything, reacts sharply to every gust and change in wind speed. But the loaded propeller of this wind generator still lags in reactions, and because of this, the data in the readings is not synchronous. Today the wind is 3-7 m/s, the anemometer actually caught a couple of gusts up to 10 m/s, but they lasted less than a second and the wind generator simply did not have time to react to them.

After some time of observation, some average current values from the wind generator were drawn at a certain wind. The propeller starts at 3.5-4 m/s, charging 0.5A at 4m/s, 1A at 5m/s, 2.5A at 6m/s, 4A at 7m/s, 5A at 8m/s. These data are averaged, since the ammeter is an analog ammeter, and I can make an error of up to 0.5A in the current readings from the wind generator.

Source

How to make an anemometer using arduino

The author of this homemade product once faced the question of how one can determine whether there is wind in the place where he lives. This question arose because he wanted to install a wind turbine to generate electricity. Using this ingenious device, you can take measurements of how often the wind blows, at what average speed it blows, and so on. The basis for collecting and processing information is the Arduino board.

Materials and tools for making an anemometer: - a piece of square pipe; - Bulgarian; — welding; — bearing; - scan; - nails; - dye; — LED-phototransistor sensor (can be removed from the printer); — Arduino circuit; - minimum set of tools.

About anemometers: Magnetic measurements

Manufacturing process:

Step one. Making an anemometer sensor

To make a sensor, you need to take a piece of a square pipe and then cut a window in it, through which the filling will then be installed. A metal plate needs to be welded inside this pipe; it will act as a bearing holder. Then another plate is welded to fix the lower bearing.

The author decided to make the top in the form of a pitched roof. To do this, take four triangles, first tack them by welding, and then boil them well.

Next, the workpiece is clamped in a vice and the diameter of the drill is 0.5 mm less than the diameter of the bearing in the bottom cover and a hole is drilled in the middle. Both are needed for bearings. To ensure that the bearings fit into place with tension, the size of the holes is adjusted using a reamer. Once the bearings were installed, a 100-gauge nail was inserted into them. In the middle of the window, a plastic washer with four slots is placed on it. A thread was cut from the bottom of the nail and then the impeller was screwed onto this axis.

Step two. Impeller manufacturing process

To make an impeller you need to take a nut and weld three nails to it with a 2mm electrode. The ends of the nails are trimmed and threaded. Then the halves of the ball are put on the ends.

A hexagonal stainless steel rod was welded to the body as a holder. And to prevent the body from rusting, it was covered with white enamel.

In order for the sensor to read information, you need a washer with slots. The author took it out of an old ball-point computer mouse. When the slot passes in front of the LED phototransistor sensor, it sends a signal to the electronics.

As for the impeller blades, they were first made from tennis balls. With this size of blades, the impeller starts in winds of 5 m/s. To make the impeller more sensitive, balls with a diameter of 55 mm were purchased; in this case, the impeller begins to rotate already at m/s. In this case, measurements are carried out up to 22 m/s.

Step three. Electronic part

As an electronic circuit, the author first used a homemade LUT circuit with the addition of a green maxi from China. But the system could not show wind speed in meters/second. It only displayed the number of revolutions.

At the moment the circuit is being assembled on Arduino. The operating principle of the author's anemometer is exactly the same as that of a computer mouse. Now you just need to connect the two circuits.

It was decided to transmit pulses from the phototransistor to Arduino, and the circuit began to perceive such signals as button presses. To get the wind speed, you just need to count how many button presses there are during a certain time, say, per second.

That's all, now the anemometer can be considered ready. If necessary, you can add a function to the code that would count how long the wind blew at a certain speed. This homemade product will be an excellent addition for those who are planning to install a windmill or closely monitor the weather.

anemometr.rar [9.54 Kb] (downloads: 1118)

How to make a homemade anemometer (wind speed meter)

How to make a homemade anemometer (wind speed meter)

The task arose to assemble an anemometer for one project so that data could be taken on a computer via a USB interface. This article will focus more on the anemometer itself than on the system for processing data from it:

1. Components So, the following components were needed to make the product: Mitsumi ball mouse - 1 pc. Ping-pong ball - 2 pcs. A piece of plexiglass of a suitable size Copper wire with a cross-section of 2.5 mm2 - 3 cm Ballpoint pen refill - 1 pc. Chupa Chups candy stick - 1 pc. Cable clip - 1 pc. Hollow brass barrel 1 pc.

2. Impeller manufacturing

3 pieces of copper wire, each 1 cm long, were soldered to the brass barrel at an angle of 120 degrees. In the hole of the barrel I soldered a stand from a Chinese player with a thread at the end. I cut the candy tube into 3 parts about 2 cm long. I cut 2 balls in half and, using small screws from the same player and polystyrene glue (with a glue gun), attached the halves of the ball to the lollipop tubes. I placed the tubes with the ball halves on soldered pieces of wire and secured everything on top with glue.

3. Manufacturing of the main part

The supporting element of the anemometer is a metal rod from a ballpoint pen. I inserted a mouse disk (encoder) into the lower part of the rod (where the plug was inserted). In the design of the mouse itself, the lower part of the encoder rested against the mouse body to form a point bearing; there was lubricant there, so the encoder rotated easily. But it was necessary to fix the upper part of the rod, for this I selected a suitable piece of plastic with a hole exactly the diameter of the rod (such a piece was cut from the CD-ROMa carriage ejection system). It remained to solve the problem of ensuring that the rod with the encoder did not fall out of the point bearing, so I soldered a few drops of solder on the rod directly in front of the holding element. Thus, the rod rotated freely in the holding structure, but did not fall out of the bearing. The reason why a circuit with an encoder was chosen is as follows: all the articles about homemade anemometers on the Internet described their manufacture based on a DC motor from a player, CD-ROM, or some other product. The problem with such devices is, firstly, their calibration and low accuracy at low wind speeds, and secondly, the nonlinear characteristic of wind speed in relation to the output voltage, i.e. There are certain problems in transferring information to a computer; you need to calculate the law of changes in voltage or current depending on wind speed. When using an encoder, there is no such problem, since the dependence is linear. The accuracy is the highest, since the encoder gives about 50 pulses per revolution of the anemometer axis, but the converter circuit is somewhat more complicated, which contains a microcontroller that counts the number of pulses per second on one of the ports and outputs this value to the USB port.

4. Testing and calibration A laboratory anemometer was used for calibration:

The whole process is clearly visible on the videos:

Thank you for your attention.

Testing and Calibration

A laboratory anemometer was used for calibration

The whole process is clearly visible on the videos:

Thank you for your attention

Z.Y. in the first video there is something incomprehensible with the sound, the hairdryer was making a lot of noise, why did YouTube convert it like that - I don’t know, if anything - it’s not a techno sound