Overture

Three years ago, under the influence of friends, I became interested in carp fishing.

They taught me how to catch and told me all the secrets. The first carp have arrived. And then, one day while fishing, with an envious eye I saw a fisherman with a carp boat. I really liked this ship. I asked how much it cost - I really didn’t like it ($1000 “for a minute”). The first decision was made: to make a boat for delivering bait with your own hands. I looked through the forums on RC modeling, estimated the estimate - scratched my turnip. It came out to about $150 for components. Yes, and the task seemed too easy to me (woe to me, naive one).

https://www.youtube.com/watch?v=wgsQfYQ8zac

The second decision was made: to make the most budget boat possible with your own hands, and ideally for free. Honestly, friends, not out of greed, but out of sporting interest.

So, a concept was developed: I decided to make a boat with DTMF control. This is when you call from one mobile phone (transmitter) to another (receiver), and when you press the keys, a “beep” of a different tone is heard. On the second phone (receiver), all that remains is to program the transformation of this “beeping” into different control commands depending on the received tone (one signal starts the motor, another stops it, the third turns it).

See how simple it is? I decided to convert the signal using the Arduino Uno board. We will consider this issue in detail in the Electronics section. Let's start with the body.

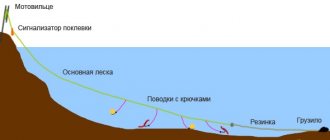

Tackle for fishing on a boat

To fish using a boat, you should use the following gear:

Spinning. It should be quite powerful and have a test of at least two hundred grams.

Coil. It is recommended to use an open reel inertia reel, since inertialess reels are not suitable due to their insufficient power.

Fishing line. It must be very strong and withstand heavy loads. The diameter of the fishing line must be at least 0.9 mm.

Hooks No. 5-8.

Leashes with a line diameter of 0.20 mm and a length of twenty centimeters.

The boat is attached in this way:

- One end of the main line is attached to the boat using a large carabiner.

- The other end of the fishing line is attached to the boat's reel. The main line along with the leashes is wound around it. The length of the reel should be fifty centimeters, the width – seven centimeters.

- The leashes are attached to the main line in this way: the closer the leash is to the boat, the shorter the length of the leash should be and vice versa, the closer the leash is to the angler, the longer the leashes should be.

Frame

Initially, I planned to use the body from an old toy. The son (he had his share, so to speak) easily presented an old pirate frigate on wheels. But upon preliminary weighing of the proposed equipment (battery, motor, electronics, etc.), it turned out that the frigate did not have enough carrying capacity.

Unfortunately, I could not find a toy of a suitable shape at an adequate price in stores. And I decided to make the hull for my fishing boat myself. Again, after looking through many forums and articles, I decided that the material would be fiberglass and epoxy resin.

I started making the hull for the boat by building a blank, onto which I then planned to apply materials. I made the blank like this: I made a frame from fiberboard and cardboard. I simply attached it with hot glue to a sheet of fiberboard.

Then the compartments of the frame began to be filled with plaster (alabaster). A little life hack: add a little vinegar to the alabaster, and it will harden more slowly, but at the same time there will be intense release of gases, so do not forget to ventilate the room.

When the blank was dry, I corrected it a little and covered it with paper sketch, so that later it would be easier to separate it from the body.

The fiberglass I used is also called glass mat. The seller said that for curved shapes it is better to use it. Epoxy is the simplest.

And again a minute TB: You need to work in WELL ventilated areas. I'm not kidding. It’s not for you to mix a couple of drops in a matchbox. I bent over the hull of a fishing boat a couple of times while applying a layer of epoxy, and then for three days I couldn’t catch my breath and my head hurt.

I applied 2-3-4 layers of these. Previously, I was surprised by home-made workers: is it really impossible to count the two or three layers you applied. It turns out that while working, sometimes you have to overlap the layers, and sometimes you have to apply patches. Therefore, it is better to simply focus on the thickness of the case walls. On average, the hull walls of my fishing boat are about 3 mm thick. At this stage, the boat for delivering bait to the fishing point was called the “Pasta Monster”, because fiberglass fibers stuck out in all directions.

See about copters: Do-it-yourself radio-controlled fishing boat - Do it yourself

Next is the most tedious task - putty. I used this universal putty with fiberglass.

And also a lot of coarse sandpaper. Then the process is clear: rub, putty, rub, putty. And so on until you understand that this is the best thing you can do with your own hands.

When I removed the body from the blank, its weight was 1 kg 200 g. Which is pretty good for such rigidity and such load capacity.

I painted it when the water cannon was already in place (described in the next section). Painting was carried out in three stages: primer and two layers of “Yacht enamel PF-167” paint.

Useful tips

As you can see, a DIY fishing boat can be made quickly.

In addition, there are other useful recommendations that will help not only design the product yourself, but also make it durable:

- it is better to choose fiberglass rather than plywood, because it is much lighter and does not require additional protection from moisture, since it is not susceptible to its negative effects (this material is also highly durable);

- the selected battery must have sufficient capacity so that the boat does not stall in the middle of the pond, but it is also important to pay attention to the weight of the component (it should not weigh down the structure too much);

- the boat can be additionally equipped with lighting and a navigator - this will make it possible to carry out night fishing;

- In order for the product not to go under water, it is necessary to correctly calculate the displacement, which ranges from 2.5-12 liters (this is affected by the distance the ship floats, the amount of feeding, and the weight of the necessary equipment).

Motor. Clutch. Deadwood. Screw

In this chapter, I’ll talk about what is most intimidating in boatbuilding for beginners - about the homemade deadwood (waterproofed shaft) and what is located on both sides of it: the propeller and the motor. Well, how to connect all this with your own hands so that it works reliably and flawlessly on a bait boat.

A homemade deadwood for a boat consists of the following components:

- The body is a thin-walled tube from an old refrigerator. External diameter 5mm, internal – 4.5mm. The edges had to be rolled out manually so that bearings with an outer diameter of 6 mm would fit on both sides.

- The shaft is a stainless steel rod with a diameter of 3 mm. On one side I cut an M3 thread for attaching the propeller.

- Bearings 3*6*2 mm. I ordered the bearings from the Chinese. In the photo there were bearings with boots, but upon arrival it turned out that instead of a boot there was only some kind of wire. The Chinese returned the money, but I decided to bet what I had.

- Oil seals. Their role is played by TO-220 insulating bushings (radio components, if anything).

The photo above and the video below show how the deadwood is assembled.

During operation, the oil near the bearings can heat up and become more liquid, so I decided to add more seals from simple 3/5 mm rubber rings. They are inserted directly in front of the bearing.

I used LITOL-24 as a thick lubricant. There are several nuances in filling the deadwood. You need to fill the deadwood housing with grease so that there is only grease inside, and not half grease, half water. To do this, the tip of the syringe is cut off to create a straight tube. The piston is removed. And such a tube is simply inserted into the barrel (or whatever you have) with lubricant to the very edge. Then the piston is inserted into the syringe, and only then do we remove the syringe completely filled with lubricant without air.

As for the clutch, I consider it my duty to inform you that you need to use the factory clutch. I checked many homemade rubber and metal options, but until I bought a normal coupling and aligned the motor in a plumb line, there were constant problems with reliability and runout.

When choosing a motor, I was dumbfounded by the prices, so I started looking for alternatives. I found the most powerful of the cheap ones - this is the 540-4065 electric motor.

I think that it was even possible to use a slightly weaker motor, but I can’t say so, since I haven’t tested my bait boat with weaker motors yet. Perhaps someday it will come to this, in order to increase the power reserve from a single battery charge.

I made the propeller myself from 1 mm thick brass. I cut out three identical blades in the shape of a pig's ear. And I soldered them to a bronze stand with an M3 thread. It turned out well, but I advise you to buy it, or you will have to make a device for proportional soldering of the blades.

After the first tests, it became clear that everything works well, but under one condition: if the sternwood has a fulcrum not far from the propeller. In my case, the screw is located at a considerable distance from the deadwood exit from the body. I decided to fix it relative to the body of the water cannon by soldering three MZ nuts to the deadwood and connecting the water cannon and the deadwood with screws.

Watch about copters: How to fly a radio-controlled helicopter: step-by-step guide

Comparison of homemade and store-bought boats. Characteristics and cost

It is hardly worth giving details of the models sold and their prices. It is better to give average information. The copies offered for sale have a range of 500-1000 meters and a speed of 1-3 m/s. The weight of the loaded bait is from 1.5 to 8 kg.

But the price of a boat for baiting fish with minimal characteristics is 20-30 thousand rubles. And models with a large load and range already cost over 50 thousand rubles.

As the experience of homemade designers shows, a do-it-yourself bait boat is superior in capabilities to budget purchased models. And the price is much cheaper. The cost calculations given show that you can make a homemade product by spending only 3-5 thousand rubles.

In addition, the quality of a homemade delivery vehicle is often superior to cheap purchased options.

Operating procedure

- having made the markings, cut along the red lines; - bend along thin lines and fold angles: 1 - tilt of the bow of the boat; 2 — raising the bow of the boat; 3 – lifting the stern; 4 – slope of the stern part;— fasten the bent parts with paper clips;— glue the paper with any glue, after which the shape of the boat will be ready;— measure the displacement of the boat;

2. Installation of rails for mounting the propulsion motor, antenna, gearbox, deck, electronics.

- slats for mounting the engine (1) - at the stern of the boat; - the engine is placed with a slight tilt, while a hole is drilled in the stern in order to install the propeller shaft casing, for which the syringe body will be used; in this case, the thin end of the syringe is installed outward (7);

a) two welding electrodes are ground with fine sandpaper; b) holes are drilled in the boat hulls at a distance of about 10 mm from the bow and stern; c) rods are inserted into the holes and tightened with nuts, and the joints are filled with epoxy;

- deck slats, after which a deck is cut out of a piece of plastic, holes are drilled along its contour, holes for the antenna, switches for the type of work and power supply, as well as for a tube with wires.

3. Production and installation of the propeller shaft and the propeller itself.

- the screw shaft is made of stainless steel with a diameter of 2.5 mm, it must be threaded to install the screw and polished; - a four-bladed screw is made from a piece of stainless steel with a thickness of at least 0.5 mm, then it is installed on the shaft and tightened with two keys using screws; - installed The screw at the fastening points is filled with sealant.

4. Installation of electronic equipment and decks.

Connection diagram of the left case

- the electronics are checked and configured;

- decks are installed using sealant and screws.

5. Making a transmitter (can be made from the control panel housing of an old TV or calculator):

- a connector for the antenna is made in the center of the body;

- on the side you need to install a power switch from a children's toy;

- a modulator board with a supply voltage LED is installed at the top of the case;

- a transmitter and a Krona battery are installed in the lower part of the case;

- The transmitter is connected with a wire about 15 m long to the car battery.

The boat is ready for operational testing and operation.

Operating principle of a fishing boat

In order for the tackle to have buoyancy, lightweight and waterproof materials should be used for its manufacture.

In addition, in order for the river flow to have a directional effect on the structure, it needs to be given special geometric parameters. The meaning of the action of the boat is a copy of the flight of a “kite”. Only in this case is the windage of the transport boat moving across the pond applied. Thanks to this, the hooks with bait fall into the required place.

When using such a kite, it is important that there is a current in the reservoir or a wave formed by a strong wind. The boat can only be sent on a long voyage if there is intense water movement.

Water jet and turning mechanism

When designing my bait boat, I simultaneously correlated the size of the propeller, water jet cylinder and turning mechanism. After searching through many options, I decided on a deodorant bottle. The outer diameter of the balloon is about 42 mm, which is 4 mm larger than the circumference of the screw, and 3 mm. less than the diameter of the rotating mechanism, which will be described below.

After 153 measurements, with trembling hands, I cut a hole in the newly completed hull of my boat.

The water cannon was glued with hot glue. I made a hole to collect water. I decided to add a piece of aluminum perforation for additional rigidity of the cylinder, since the metal in it was very thin and easily bent with little effort.

Next, I attached the motor mount to the body of the bait boat. I did it this way: I attached a screw and a rigid coupling to the deadwood. To the coupling there is a motor fixed in the mount. After that, I set the boat in such a position that the sternwood took the most vertical position, while the motor was in free suspension.

It remains to apply a little glue to fix the correct position of the fastening, and after it cools, apply the amount of glue necessary for reliable fixation.

See about copters: How to make a radio-controlled plane

For the “rudder” in my fishing boat, I used a plastic jar of aquarium fish food. This jar, by the way, turned out to be divided into four parts by jumpers. All I have to do is carefully cut and mark everything for connection to the water cannon cylinder.

The turning lever is made of fiberglass 3 mm thick. I cut out an approximate shape, and then used a file and sandpaper to cut out a recess in the shape of a food can.

I took a knitting needle from an umbrella (2 mm thick) and threaded it into a waterproof boot for rods (33x12mm).

The end of the spoke was bent at an angle of 90 degrees and inserted into the SG-90 servo drive.

Reversible model

Trying to improve the ancient gear, craftsmen began to change the design features of the boat, adding new elements and developments. As a result, they invented something more functional, powerful and efficient. The modern modernized version includes:

- Lead board.

- Main float.

- Plastic springs.

- A special mechanism for switching and limiting speed.

- Towing line.

- Front sights.

The presence of springs provides a kind of shock absorption, smoothing out strong jerks of aggressive prey during intense bites. The role of the float is to notify the fisherman about a bite that has occurred, as well as to improve the stability of the product. The safety bracket is used to prevent frequent tangling of the fishing line with the control elements. Changing the course of movement of the tackle is carried out by a special switching element.

A modernized boat is being created using the following technology:

- Well-dried wood is used as the main raw material, which is given the appropriate shape. A redan is fixed at the lower end of the product, which prevents the gear from floating to the surface.

- Then the workpiece is carefully treated with drying oil and waterproof oil-based paint. The part that is under water should have a blue tint, and the part that is above water should have a white tint.

- To fix the lead weights, 8 mm holes are made in the middle of the board, and a cork strip is fixed in the upper end part between the springs.

- Stainless steel strips can be used to make springs.

- A foam blank is used as a float. The element itself is placed on a wooden base near the switches and springs.

- The safety bracket is created on the basis of copper wire. Its thickness is 2 mm.

Homemade springs must be bent in such a way that during operation the direction switch rises above the waterline to the height of the underwater part of the float.

This option can move both from the shore and in the opposite direction, which makes it more functional. In turn, simple models move only to one point without changing course.

Electrical diagram

Everyone stays where they are and no one runs away. There is nothing to be afraid of. Below is a complete wiring diagram for a fishing boat. The diagram is large because it is detailed, but now everything will become clear.

Dotted lines highlight individual blocks. You may not use some of them at all, or replace some with an inexpensive purchased analogue. Just one circuit may seem complicated to you, but you don’t even need to understand it, and if you want, you can solder even what you don’t understand.

How to make a bait boat at home

Stories about such homemade products are not fiction. You can make a controlled delivery vehicle with knowledge of technology and electronics. For those who have made a model of a toy yacht, it will be easier to make a radio-controlled boat for fishing with your own hands. Help can be obtained from the Internet - on fishing forums.

Homemade drawing

Before starting work, it is useful to make a schematic drawing of the future delivery vehicle. When drawing a drawing you need to determine:

- The hull shape is a simple hull or catamaran.

- The shape of the bottom is flat or with a keel.

- The size of the entire ship and its compartments.

- The number of compartments with bait, their locations.

- Location of the engine and electronic filling.

It is better to make the drawing in full size, then it can be used as a basis for making the case. The compartments for loading feed should not be narrow, otherwise there will be difficulties with placing finished boilies.

Case manufacturing

You can use the hull from a finished model or toy boat, but then you will have to somehow place bait compartments and additional equipment in it. It is better to choose flexible plastic as the material for making the case. You can make a housing template from cardboard, cover it with fiberglass and epoxy resin in several layers, and then putty and paint it.

Motor-propeller group

Advice on homemade production is of little relevance here. You will have to buy the drive motor and batteries for it. You can make the shaft, propeller and deadwood yourself out of sporting interest, but their total cost does not exceed 500 rubles. Hardly worth saving. You can make a jet rudder yourself, but you will also have to buy a servo to control it.

But it is necessary to install a screw in the protective tube and provide a grille in the water supply channel. Then the algae will not wrap around the propeller, and small knots will not damage it.

A bait boat with a catamaran hull can be equipped with two engines and two propellers. When one of the engines is reversed, the turn will occur literally on the spot.

Radio control circuit

This is also a purchased part of water transport, which cannot be made with your own hands. Craftsmen versed in radio engineering can remake and reprogram radio control boards based on mobile phones or electronic device control panels. But by purchasing a ready-made transmitter and receiver with control functions, you will not waste time on alterations.

It is also necessary to take into account the range of action, as well as the fact that a signal is required to open and close the loading compartments with bait.

Bait unloading unit

Not the last detail of the entire device. After all, a boat is being made to bring in and unload bait. It will be a shame if, having arrived at the desired point, he cannot pour the food into the water. The aft compartments may be located inside the hull. Then there should be opening flaps at the bottom of the compartment. The container with bait can be on the “deck” and, tipping over, unloads its contents. There are options for installing stern compartments on brackets outside the dimensions of the boat itself. The feed is unloaded by releasing the latch that holds the bottom of the compartment, fixed on a rotating hinge.

In any case, you will need a reliable servo drive to control the operation of the unloading mechanism.

Additional details

It is better to paint finished vehicles in bright colors. Especially if you plan to work with it at distances of several hundred meters.

It is useful to provide handles on the body for easy portability.

Echo sounder equipment

Small wireless echo sounders that can be installed on a boat will not be able to provide complete information about what is happening in the water column. As a rule, this is information about the depth at the location of the echo sounder and the presence of schools of fish. But even such data can be useful. Information is displayed on a small screen.

When designing the ship's hull, you need to provide a compartment for installing the device itself and a separate echo sounder battery.

Navigator equipment

Advanced craftsmen are already installing GPS navigators on their boats with memorization of several coordinate points. This is convenient if fishing takes place in the same body of water. Having found a promising place and entered its coordinates into memory, you can deliver bait next time, guided by the navigator.

Programming Arduino microcontrollers

Arduino, if anyone doesn’t know, is a microcontroller for the general public. Very accessible and simple. Roughly speaking: I connected it to the computer via USB, loaded it with a sketch (a program that says what the microcontroller will do) and everything is ready. I will not describe the process of installing drivers and downloading programs. Everything can be found on the Arduino website.

If you have any questions, the network is full of detailed descriptions of this process.

My bait boat uses two Arduino boards: one UNO and one NANO.

For Uno, in addition to the sketch, you will need libraries.

How it works?

For an inquisitive mind, it is always important to know not only how a mechanism works, but also why it happens.

In the case of a boat, everything can be explained using the example of the oldest such gear. Imagine a piece of log about 40 centimeters long and 10 centimeters in diameter. The ends of this stake were sharpened, and two ropes were attached to them, one 20 centimeters long and the other 40 .

The rope was tied at this point, often on a ring, and a working cord with a garland of two or three thin leashes was tied to them. A certain angle of attack was obtained: the current pressed on the log, and the fisherman, loosening or tightening the main line, maneuvered with the distance from the ship to the shore.

Cover (deck) of the boat and controls on it

The material for the cover was fiberglass laminate 2 mm thick. I attached the hull of the fishing boat to a sheet of fiberglass laminate, traced the outline with a marker, and cut out the desired shape with a jigsaw.

The weight of the lid was 590 grams. For such rigidity this is quite a normal result.

Next, I placed the main power switch on the lid (it comes complete with a rubber cap),

I placed the power regulators and the toggle switch for the flashlight in a powder container, which I attached with “liquid nails” glue for complete waterproofing.

For the receiver phone and voltmeters, I used an external junction box. It also houses the battery contacts for charging the battery. On the back side there is a connector for unloading.

Making a paper boat

This trick is familiar to every one of our compatriots whose childhood and youth occurred during the Soviet years. Having reached the present day, a paper boat can push its creator to new, more complex experiments.

In the meantime, it’s worth practicing on paper:

- An A4 sheet is folded in half twice;

- The resulting segment is unfolded once to bend 2 corners towards the center to form a pyramid with a rectangular protrusion;

- The outer side of the protrusion is turned outward so that its corners can be bent into a triangle;

- The inner side of the protrusion is also wrapped, and the corners are bent;

- The resulting triangle needs to be pushed inward to get a flat square;

- Both sides of one half of the square are folded over the other to form an accordion triangle;

- The previous action must be repeated, and then take the ends and unfold the finished ship.

Knowing how to make a ship out of paper, you can move on to more interesting designs.