DIY lifehack 1: Polisher tube

Along our tube we make a longitudinal cut on one of its sides.

After the longitudinal slot, leave four centimeters untouched, cut it off and carefully remove burrs from the resulting workpiece. As a result, we get this:

We tear off the tape from the sandpaper sheet, insert its edge into the slot so that when twisted to the left, the sandpaper is directed upward.

Twist the sandpaper around the tube and secure its edges with masking tape.

We install one of the ends of the resulting homemade tool into the cam of the drill.

Using the resulting product, you can quickly process the edges of parts.

They can also process any holes. For convenience, the free end of the manufactured device can be placed in the hole of a large washer.

Moonshine still refrigerator

The refrigerator consists of two parts. This is a coil through which alcohol vapor passes, and a reservoir for cooling the coil. The parameters of each node are important for obtaining a quality product. Do not neglect the recommendations and try to invent a “bicycle”. It is possible that after a few years and a lot of experimentation, you will be able to reproduce the effective work with other parameters, but is such a result worth the time spent?

Coil parameters

There are certain nuances in the manufacture of a coil. First of all, take a closer look at the material. Copper, aluminum, and stainless steel are used for manufacturing. In rare cases, glass is used. Of course, the operation of a glass refrigerator and coil can be fascinating, but one wrong move and you can lose such a wonderful accessory.

Copper coils are common. They have good thermal conductivity, are easy to process, and soldering can be used if necessary. But there is one peculiarity. After each distillation, it is necessary to clean the copper coil with vinegar or citric acid.

The next most common are aluminum options. Although they have lower thermal conductivity, they are popular due to their availability, ease of processing and low price.

Well, the last category is stainless steel coils. Thermal conductivity is even lower and is 3-4 times less than copper. The material does not oxidize and does not react with alcohol. This applies to food materials. But the complexity of processing can prevent you from producing a high-quality coil.

The next parameter is the size and thickness of the tube. The optimal length is 1.5-2 m. There is an opinion that the longer the coil, the larger the contact area with the coolant in the refrigerator. On the one hand, this is true. But if the length is excessive, there is a risk of extreme hydraulic resistance. The inner diameter of the tube is recommended to be 8-12 mm.

The last parameter is the location of the coil. The correct position would be vertical. The horizontal option is not recommended. If it is not possible to install the coil vertically, then position it at least at 45 degrees.

Refrigerator tank parameters

In most cases, tank dimensions depend on the coil used. Running water is used for cooling. Airborne options are not effective enough and are rarely used. In winter, you can use snow or ice for cooling.

When using water, there are open and closed options. The open method uses running water; the closed method does not circulate water. For the closed version, use an ordinary bucket or other container where the coil is placed. Of course, the closed version is more economical, but you often have to replace the heated water.

The next parameter can be considered the direction of water supply when using a flow-through system. It would be correct to supply water from below, and remove the heated liquid from above. With this option, cold water moves towards the steam, creating a countercurrent.

Manufacturing refrigerator cooler

To make a refrigerator, you will need a tube with a diameter of 8-12 mm, a wall thickness of 0.9-1.1 mm, and a length of one and a half to two meters and a metal or plastic pipe with a diameter of 75-80 mm.

Before making the coil, it is necessary to fill the tube with sand or other bulk material. This will help prevent the tube from flattening when winding. Wooden choppers are hammered into the ends of the tube. If you have extra length, you can clamp the ends or solder them.

After this, you should wind the tube onto a cylinder of suitable diameter. The pitch between turns should be 12 mm.

After winding, the ends are released and the sand is poured out. The finished coil should be rinsed under running water to clean the inner surface. The coil is placed in the refrigerator pipe, conclusions are drawn and the refrigerator is sealed.

DIY lifehack 2: Twister tube

This time we make a very small longitudinal slot, no more than 1 cm.

Having cut off the tube and removed the burrs from it, insert its uncut end into the drill, and place the tip of the wire into the cut.

By turning the drill on at low speed, we get a very neat spring.

To provide the resulting product with the necessary functionality, its outer turns should be carefully bent. This is how it turns into a full-fledged spring, which can be used for its intended purpose.

Operating procedure

The first step is to create a sketch of the pendant.

Then it must be molded from the prepared mass. To do this, you can use a mold and make an impression. You can also mold it by hand.

The workpiece is dried in the oven according to the recommendations for working with this type of material.

The fastening is secured using universal glue.

After drying, the decoration can be painted and varnished.

There are many design options for such pendants. Photos of a homemade pendant made of polymer clay can be found on thematic websites.

DIY lifehack 3: Curler tube

This time the tube will be useful without longitudinal cuts. Using pliers, just flatten it at some distance from the edge.

We insert the long end of the tube into the cam of the drill, and into the short flattened end - the ends of the wire stripped of insulation, which must be twisted when performing electrical wiring.

We turn on the drill at low speed and end up with tightly twisted ends.

Each life hack that we have listed above is very easy to implement. However, the homemade product obtained with its help will be very useful for you when performing a fairly large number of operations. And in addition to this, the metal tube, which we had lying around idle and which we really wanted to throw away, found a completely worthy use for itself.

Homemade products from a washing machine engine:

1. How to connect a motor from an old washing machine through a capacitor or without it 2. Homemade emery from a washing machine engine 3. Homemade generator from a washing machine engine 4. Connecting and adjusting the speed of a commutator motor from an automatic washing machine 5. Potter's wheel from a washing machine machines 6. Lathe from an automatic washing machine 7. Wood splitter with an engine from a washing machine 8. Homemade concrete mixer

30 ideas for homemade pipes (bright photo selection)

PVC and aluminum pipes can be used not only for their intended purpose. They can be used to make furniture, garage shelving, closets or rooms, decorative items and even jewelry. See a selection of things made from PVC and aluminum pipes, choose what your home is missing, and try to make it yourself.

Is it possible to make a moonshine still from copper?

Making a moonshine still completely out of copper is a difficult task, if only because of the high cost of the material. But, as we have already found out, even individual parts made of this metal can improve the future product.

Therefore, we will consider the option of making a copper coil with our own hands, if only for the reason that getting a copper tube is an easier task than a cube or a relatively large-diameter vessel for a column.

DIY copper coil

A coil made of copper will do an excellent job of producing fairly high-quality aromatic moonshine, which is especially important if you set yourself the task of preserving the taste and pleasant aftertaste of the additional component present in the brew

The coil (also an integral part of the refrigerator) is an essential part of any moonshine still

It is designed to ensure that the alcohol vapor coming from the mash heated in the cube is cooled by the cold water surrounding the coil. Here they condensed and flowed into a substituted vessel in the form of a high-proof intoxicating liquid.

The coil (also a component of the refrigerator) is an essential part of any moonshine still. It is designed to ensure that the alcohol vapor coming from the mash heated in the cube is cooled by the cold water surrounding the coil. Here they condensed and flowed into a substituted vessel in the form of a high-proof intoxicating liquid.

To make it you will need:

- at least 1.5, or even 2 meters of copper tube with an internal diameter of at least 8, but not more than 12 mm. The thickness of the tube also plays an important role. The thin-walled one is too fragile for the load that, on the one hand, comes from alcohol vapor, and on the other, from cold water. Therefore, it is better if the thickness is close to 1 mm;

- cooler housing. A good option for this purpose is a plastic sewer pipe with a cross-section of about 80 mm. You need to weld two pipes to it for supplying and draining water.

The best option is if the refrigerator is mounted on the device in a vertical or inclined position and operates from the water supply. Moreover, alcohol vapor should enter the coil from top to bottom, and water should be supplied from bottom to top (the lower pipe is for inlet, the upper pipe is for draining water). Then the cooling will be the most effective.

https://www.youtube.com/embed/hU62Qr3eRzEWinding the spiral is the most important stage. To do this (so that the tube does not flatten during the winding process), it must be filled with sand or filled with water and frozen, closing the ends in any suitable way. They can, for example, be filled with wooden plugs, flattened or even soldered.

The prepared tube is sequentially placed on any object with a circular cross-section of approximately 35 mm in diameter (pipe, smooth log, etc.). The pitch between the turns must be maintained at approximately 12 mm so that water can circulate freely between them, ensuring reliable cooling.

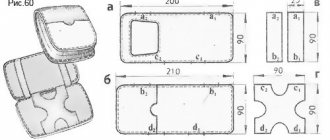

For a detailed manufacturing diagram, see the figure below.

To summarize, we can say that the all-copper moonshine still you purchased can serve as an excellent gift for lovers of home-made strong alcohol from fruits, compotes, jam, malt, wheat, barley and other components to preserve the taste of these products in the finished moonshine.

We recommend reading: How to choose the right moonshine still for your home?

Of course, no one argues that everyone is pleased to have such a wonderful device as an alambrik in their arsenal.

However, it can be perfectly replaced by a do-it-yourself moonshine still, equipped with homemade or purchased and fitted individual copper parts, which is no worse than a copper moonshine still

And if it’s important for you to get just a clean product, an ordinary stainless steel one is enough

Copper as a material for making pipes

Copper is the optimal material that ensures the performance of systems at high pressures and temperatures. Therefore, copper pipe is used not only for the installation of hot water supply pipes or heating system lines, but also for other purposes.

For comparison, you can take polypropylene pipes and copper ones. The former are able to withstand temperatures only up to + 95ºС at pressures of no more than 25 ATI. The latter are capable of operating at T=250ºС and pressures up to 300 MPa.

Copper is the main material from which the French, British, Australians, and Swedes prefer to install water supply and heating systems. High mechanical strength, ease of machining - these properties have made seamless copper pipes popular in the construction of various types of communications.

Modern production of such products involves applying a protective polymer layer to the surface of the pipes, which eliminates the appearance of stray currents in magnetic field zones.

Glitter pendant

An unusual and easy-to-manufacture pendant can be made using practically available materials.

To work you need to prepare:

- base of a metal product,

- glitter,

- glue for decoupage.

Operating procedure.

- Apply a layer of glue to the prepared base and carefully place glitter on it.

- Then the workpiece is again covered with glue, on which another layer of glitter is placed.

- The number of layers depends on the base of the decoration.

This method can give a second life to a pendant with lost decorative elements or a boring old pendant.

Nuances of installing copper lines

Plumbers, who have a set of tools and experience working with copper, perform a number of actions during the installation of copper pipelines:

- cleaning, calibrating, cutting;

- giving the desired shape;

- crimping, soldering, connection.

Each owner of an apartment or private house can perform the same actions with their own hands.

The main thing is to learn the nuances of technology and the secrets of producing such work. Each action requires an appropriate tool.

As a rule, a mechanic's tool kit includes:

- copper pipe cutter or hacksaw;

- files, sandpaper, rags;

- locksmith wrenches;

- gas key No. 1;

- manual calibrator, pipe bender;

- gas burner, flux, solder, fum tape.

The start of installation work is always preceded by activities aimed at calculating and drawing up a layout of the water supply or heating system.

Based on their diagram, the required number of copper pipes, their length, diameter, and the number of additional installation parts are calculated.

Soldering copper with a gas torch - solder.

To solder copper, you can use copper-phosphorus solder. The melting point of copper-phosphorus solder is low. Copper-phosphorus solder has such a feature that it does not require additional flux to work, since it contains phosphorus, which performs all the necessary functions. The solder is very hard, it is almost impossible to bite off a piece for soldering. I use side cutters to break off pieces from the rod. The process is not simple - the pieces fly in different directions.

Before soldering, it is best to bleach copper in lemon juice. Dilute ordinary citric acid in warm water and throw in copper blanks.

Copper can also be soldered with silver solder in places where the soldering point is not visible. There are also special copper and silver pastes for soldering.

Methods for connecting copper pipes

In practice, one of two methods is used to assemble copper pipelines - by soldering or mechanical crimping.

Secrets of soldering with a gas torch

When choosing a soldering method for installing the system, you must consider the following: all connections made in this way are permanent. Soldering provides a high percentage of density guarantee, but imposes some restrictions on maintenance. It is often impossible to upgrade a system without adding complexity.

Patination of copper with ammonia at home.

At home, copper wire can be patinated (aged) and polished. To do this, you need to buy ammonia at the nearest pharmacy and pour it into a jar with a lid. Then hang the product OVER THE AMMONIA SOLUTION!!! After the copper darkens, take out the pendant, rinse and dry. You can also purchase special universal solutions for blackening.

Tools for mounting elements

It is not always possible to cut a pipe without damaging the wall structure. The wall thickness of copper pipes up to a diameter of 28 mm is only 1 mm. Even the use of a disc pipe cutter for copper pipes does not fully guarantee an even cut. If wall disturbances are observed, a calibrator is used. This tool is used to calibrate (align) the pipe and socket.

Pipe cutters are available in manual, electric, pneumatic, and hydraulic types. Structurally, the pipe cutter is a mechanical clamp, where two rollers act as supporting elements. One of the rollers has a cutting edge.

The cutting process is carried out by sequentially pressing and rotating the pipe cutter around the pipe axis. The smoother and more often the pressing is performed, the better the quality of the pipe cut.

Installation work is often accompanied by bending of copper pipes. A high-quality, even bend of any radius helps create a tool called a pipe bender. There are two types of copper pipe benders - spring and mechanical.

The first tool has a simple but effective design. Designed for bending small diameter pipes. The second type includes several design varieties.

A spring pipe bender is made in the form of a long casing that fits onto a copper pipe. One end of such a casing is slightly widened for greater ease of use. The copper pipe placed in such a springy shell is bent by hand without the risk of jamming at the bend.

Disadvantages - the bending radius has to be checked by eye; for a specific pipe diameter you need your own spring pipe bender.

Mechanical pipe benders (lever, segment, crossbow, hydraulic) allow you to bend pipes of different diameters (from 10 to 125 mm). Copper pipes of large diameters are usually bent using a segment bender or a hydraulic pipe bender. The bending angle when working with such devices can be 180°.

Bead pendant

There are many ways to make a beaded pendant with your own hands. You can use wire, fishing line or thread as a base.

In the first case, the material itself will provide the desired shape, which allows you to create simple but original jewelry.

So, you can string beads onto a wire so that you get a line of the required length. You can use it to make a flower or another pattern depending on your taste preferences. All that remains is to carefully secure the end of the wire at the intersection of two or more lines.

Characteristics of copper water supply

The durability of copper water pipes is to some extent due to the fact that the chlorine contained in the water, in reaction with copper, contributes to the formation of a thin oxide film on the inner surface. This film additionally protects the pipe wall from the negative influence of the pumped medium.

Copper is also considered the optimal material according to the results of sanitary and bacteriological studies. This metal has a bacteriological effect, for example, against the staphylococcus virus.

Copper has a high thermal conductivity coefficient. This point forces us to take measures aimed at isolating pipes from the external environment.

An uninsulated cold water supply system in the summer can create a serious problem with the collection and disposal of condensate. Uninsulated hot water pipes experience significant heat loss. When installing copper pipe networks with your own hands, you should take these points into account.

Wire pendant with stone

This DIY pendant is made from gold, copper wire and stone. It is better to take the last element with a hole to make it easier to attach it to the decoration.

For the braid, 2 equal pieces of copper wire, one millimeter thick, are taken as the base. It will have to be wrapped with gold wire, which is twice as thin as the base.

The copper pieces are folded parallel to each other. After this, they begin to connect them with gold wire in a spiral according to the principle: 4 turns around one base, 2 turns around both bases.

The length of the workpiece should be such as to cover the perimeter of the stone, make a curl and fasten for the chain.

Having made the decorative braid of the required length, you need to thread one of the free ends into the hole in the stone. After this, place the wire around the perimeter of the center of the decoration. After this, the remaining ends of the copper wire are masked under a decorative curl at the top of the pendant.

A loop is formed from the other end through which the chain will pass, and after making a spiral, the ends are fixed in the center on the inside of the product. In a similar way, you can make other models of stone pendants with your own hands.

Conclusions and useful video on the topic

You can learn how to install a copper water supply from the following video:

Quality, reliability, durability – plumbing and heating systems endowed with these properties often delight apartment and house owners if copper is used for installation work.

Indeed, when there is confidence that there are no leaks and are not expected in the future, that there are no gusts even in severe winter, this means that a system of copper pipes is installed in the house.

Do you have anything to add or have questions about the technology for installing copper pipes? Please leave comments and participate in discussions about the post. The contact form is located in the lower block.

Glass bead pendant

Using glass balls, you can create simple but original jewelry, including pendants in the form of a bracelet for your hand. To do this, first place the balls in an oven preheated to 260 degrees for 20 minutes, and then immediately place them in water with ice. The result will be workpieces with internal cracks, but a smooth surface.

To make a fastening for such a bead, you will need a cap and a pin, the hook of which is inserted with the loop up, and another loop is formed from the remaining end for the chain.

All that remains is to smear the inside of the cap with a sufficient amount of glue and fix the bead. Based on the length of the chain or cord, you can turn the product into a pendant or bracelet.

First steps

Wire-based products amaze with their beauty. I would like to join this art and also create something beautiful. However, in order not to encounter the beginner's disappointment syndrome, you need to start with simple crafts, gradually complicating them.

The first steps in weaving can be simple contours of animals, fantasy people, and various objects. For example, to make a simple Christmas tree, it is enough to bend the wire, why bend its halves symmetrically.

If you make blank rings, and then connect them in groups of three to five pieces with another ring, you will get a simple bracelet. A garland of rings will decorate a child's room. Children from preschool age and older are gladly involved in the work of creating wire products.

Preparation of electrolyte for electroplating

The content of copper sulfate in the solution is 150-180 g/l. Copper sulfate powder is dissolved in hot water and, after cooling and filtering, sulfuric acid is carefully poured into it in small portions at a rate of 30-35 g/l. If the content of copper sulfate in the solution is exceeded, copper sulfate begins to crystallize on the walls of the galvanic container and on the anode, in this case it is necessary to analyze the electrolyte (see “Analysis and adjustment of copper plating electrolyte”) and, according to the results, add water or acid.

An excess of sulfuric acid in the electrolyte can lead to copper deposits that are brittle and fragile. Lack of acid causes the deposition of a loose and porous layer.

To improve the quality of the resulting copper deposits, experts advise adding alcohol to the electrolyte in an amount of 8-10 g/l. Alcohol in a small amount improves the structure of the coating, making the copper finely crystalline, harder and more elastic.

The quality of the electrolyte and the resulting copper deposit may be negatively affected by the possible presence of organic impurities in the solution. To eliminate them, add 2-3 g/l of potassium permanganate or the same amount of crushed activated carbon to the heated solution. After cooling to 18-200C and filtering, the solution can be used.

When used intensively, the electrolyte must be filtered to remove sludge - powdered copper, graphite and dust. Sludge gradually accumulates in the solution, settles on the bottom and walls of the container, fine particles form a suspension that can contaminate the resulting copper deposits. The amount of sludge is influenced by the quality of copper used in the manufacture of the anodes, as well as the increased current density in the process.

The article Analysis and adjustment of copper plating electrolyte discusses the method for determining the content of copper sulfate and sulfuric acid in the electrolyte solution, and also provides a calculation of the number of components.

Christmas tree

To make a Christmas tree you need to take a shaggy green wire and twist it into a cone, in the direction of the spiral. It is necessary to gradually reduce the size of the circle.

Using a similar pattern (in the form of a spiral), you can also make a caterpillar, snake, snail and other animals.

This is an excellent option, for example, for crafts for kindergarten, since it does not require special skills and time for busy mothers.

Types of wire

Wire surprises with its plasticity and great potential for use in the design of jewelry and decorative souvenirs. It is widely used to create costume jewelry. In rare cases, material is taken from noble metals. Basically, simple, inexpensive wire is used:

- copper;

- aluminum;

- costume jewelry, sold in creative goods departments.

Jewelry wire is created specifically for creative works. Its alloy contains metals that have valuable artistic properties - softness, strength, ductility, beautiful appearance. The cross-section has a round, semicircular or square shape. On sale you can find copper wire with a silver coating with a flat section, aluminum with a shiny coating. Aluminum creative material resists corrosion and negative environmental influences.

They also work with technical materials consisting of pure copper and stainless steel, but the process is complicated by the need to clean it of insulation.