Manufacturing technology

IMPORTANT: for this purpose, the most optimal thickness option is the lid of plastic drink bottles.

Note! When covering the crack, it is advisable to use a minimal amount of glue. Then it will dry faster. Glue only from the outside, carefully fixing the junction of the syringe with the cap.

All. The oiler is ready for use and transportation. The oil will not spill.

Operating principle

Once the wooden oil press (or metal) is assembled and equipped with replaceable attachments, you can begin to use it for its intended purpose. To extract oil using such a unit (for example, from sunflower seeds), you must perform the following steps:

- Raw materials are poured into the loading ladle of the device.

- The rollers, the surface of which is covered with a grater cloth, are driven into rotation by means of a handle.

- Due to the rotation of the rolls, the raw material is drawn into the gap between them, where the peeling occurs.

- After peeling, the sunflower kernels and the husk from which they are freed end up in the lower bucket.

- The mixture consisting of sunflower kernels and husks is winnowed.

- Rollers with a grater cloth are replaced with rollers with a smooth surface, with the help of which vegetable oil will be squeezed out.

- The cleaned seed kernels are placed in the upper bucket and sent to rolling.

- To reduce the size of the gap between the rollers, which is necessary so that the seed kernels passing between them are compressed with the required force, a special lever of the hand press, which is moved to the second position, allows.

- The result of rolling is a mushy mass, which must be pressed to extract the vegetable oil from it.

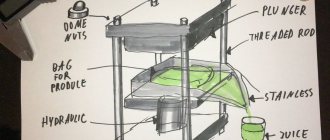

Manual type wooden hydraulic oil press for squeezing oil from seeds and nuts

Since a manual squeezing press is not able to provide the high pressure exerted on the raw materials used, the percentage of oil yield is lower than when using specialized equipment. If you use an electric motor or a hydraulic press to drive such equipment, you can correct this shortcoming.

A manual oil press has a number of advantages. We present the most significant of them.

- Due to the simplicity of the design, such a press can be made by hand.

- The finished product has excellent taste and high nutritional value.

Manual screw press for home oil extraction

At home or in a small production workshop, you can use both a wooden and a screw press to produce vegetable oil, which are highly efficient. It should be kept in mind: if you do not make such devices for extracting oil yourself, but purchase ready-made models, then a wooden press based on a hydraulic mechanism will cost much more than a screw press. If you take such a unit to organize a small business producing and selling environmentally friendly vegetable oil, it will pay for itself quickly enough. Such equipment will pay for itself even faster if you use it to produce not only sunflower, but also olive or even cedar oil.

Communities › DIY › Blog › Oil can

I think many people use this type of oil can, but I got it with a minor flaw.

Obviously, I couldn’t leave this thing like that, so I decided to give it a second life. To begin with, I cut off the damaged bottom and selected a suitable diameter; a coffee can was used.

Afterwards the paint was removed from the surfaces and prepared for soldering.

I tinned the outside of the oil can.

Well, I soldered it with a big hoop.

The final stage is painting.

A couple of hours of work and now the oil can is back in service.

Thank you for your attention

PS You can watch the whole process with interest in my video.

Comments 43

Cool. You watch how people waste time on all sorts of nonsense, and then you remember yourself, when it seems easier to throw it away, but you spend a certain amount of time and are thrilled that you were able to fix it.

no matter what anyone says... BUT a thing that was repaired with your own hands radiates positive emotions))

I bought a new one with a flaw... it didn’t pump oil at all. I had to disassemble and repair the pump... now it’s also in service...

I don’t remember... three years ago there was an issue... There was something wrong with the pump... I picked a ball under the hole... I ground it... honestly, I don’t remember... it was a long time ago... it was a shame that the new one didn’t work...

familiar oiler, from chipmaker.com.ua?

I saw it there, thought about buying it, and then I googled it, you can buy a new one for not much more. and in general, as at any flea markets, first of all I Google the prices. for example, files from VK8 cost 450 UAH there, but on the Internet it’s 150