If you regularly encounter problems with high shelves, if you have to use chairs and stands that are not always reliable to remove necessary items or wipe dust in hard-to-reach places, then it’s probably time for you to think about how to get a step-stool or a compact folding ladder. Because getting a full metal stepladder out of the closet every time is not always a convenient option. Moreover, you can start making a step-stool yourself, rather than buying this design in a hardware store, hardware department or supermarket. This item will fit optimally into the interior, take up minimal space, and serve as a constant helper in the household. All you have to do is choose the model you like, purchase the necessary materials, stock up on tools, and be patient – start making a practical and beautiful thing.

Transformable step stool

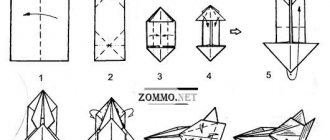

Stages of assembling transformer parts with your own hands

Before attaching all the elements, it is advisable to carry out preliminary assembly to make sure that all parts of the product fit perfectly together. Next you need to do the final assembly using wood glue, dowels, screws, screws and dowels. Each type of transformer has its own installation features. Let's take a closer look at them.

Elements of a classic steppe chair.

The transforming chair is assembled in the following order:

- The finished and carefully polished parts of the back and high sides of the chair are fixed with self-tapping screws.

- The seat and steps are attached to the grooves of the small side walls. The joints are additionally fixed with glue and self-tapping screws.

- The resulting parts of the chair are held together with a piano ring.

Assembly diagram of a transformable chair.

Steps to assemble a step stool with your own hands:

- For greater stability, the ends of the stool legs should be sawn with a slope of 10 degrees.

- Using dowels, you need to connect the middle legs and ends of the drawers. The steps are cut at an angle of 80 degrees.

- The high chair legs are attached to the top drawers with self-tapping screws.

- Secure the drawers to the top step with self-tapping screws.

- Reinforce the middle legs with a dowel and dowel and attach to the front and back sides.

- Using screws, attach the small legs to the crossbar, then to the front side beam and install the step.

Assembly diagram for a stair stool.

DIY transformer scales:

- The side ends of the chair are attached in pairs to the crossbars using self-tapping screws.

- The steps are attached to the stool using a piano ring.

Stages of assembling a stair stool with a screw module:

- Align the inside corners of the middle and bottom steps. Drill 38mm holes in opposite corners. Secure your leg.

- Using self-tapping screws and wood glue, assemble the remaining pieces of the product.

Step-by-step assembly of a stair stool with a screw module.

High step stool

Another design variation

- We cut out blanks for the chair and steps according to the patterns. The design consists of several elements: four legs; two crossbars at the bottom; two crossbars at the top. And also - drawers (connecting strips between the legs): two upper, lower. And also: two plywood overlays located on the sides; top step.

- For the steps you should prepare blanks: four middle legs;

two crossbars; two small legs; three front and one rear tsars; two steps. Dimensions in millimeters

- For a high stepladder in the form of a stool, we cut out and prepare the parts according to the drawing. We carefully sand each of the workpieces until smooth. And in order for the stool to gain stability, its legs will be positioned in a parallel manner and at a slope of 10 degrees.

- We will also make sure that the ends of the plywood overlay and crossbars do not move away. If you chose dowels to fasten the middle legs, drill grooves for them (dowels need to be placed in the holes).

- We cut the end of the drawer at 80 degrees. When cutting out the step from below, we make two cutouts so that it coincides with the legs of smaller dimensions. We connect the large legs with the upper crossbars with screws. We do the same procedure with the drawers and the top step.

- We install the stool with steps in the way they will look when assembled, and screw the structure guide. If no shortcomings are observed, we disassemble the stepladder-stool again, and then reconnect the parts, but using gluing. And when they are noticeable, there will be an opportunity to correct them. We use clamps to compress the workpieces and securely glue them.

In the same way, according to the drawing, you can assemble a ladder chair

Watch the video on the topic:

The benefits of making it yourself

Making a wooden staircase with your own hands gives the master a number of advantages, the main of which are:

- Assembling a chair yourself will cost much less than buying a ready-made one at a furniture store;

- the ability to select exactly the optimal design option for the stated purposes under specific conditions of use;

- saving space by simultaneously combining two functions in one sample;

- satisfaction from a product assembled independently, the operation of which also brings quite tangible benefits.

Note! From many everyday examples, it is known that hand-made furniture is always treated with much more care than purchased samples.

Because of this, they usually last much longer than store-bought items.

What to make a wooden ladder chair from: choosing the material

The easiest way to make a step-stool with your own hands is from wood - wood is affordable, it is easy to process, it has the necessary strength, and the products acquire an attractive appearance. However, there are a huge variety of types of wood, and not every species is suitable for making a folding stepladder chair. Let's find out what kind of wood to make a step stool from.

Softness of wood

To make a step stool from wood, it is important to choose the right wood for its softness. Material that is too loose and fibrous will “fluff” and peel off when trying to process the surface. The product will turn out to be sloppy and will only be suitable as a country ladder, stepladder, or stool.

If you take hardwood, you may encounter another problem - the complexity of processing. In this case, without the use of specialized equipment, it will also be difficult to properly process the surface of the folding ladder-stool. Therefore, if you do not have sufficient carpentry skills, it is better to choose medium-soft wood - it will be easiest to make a stool-ladder from such wood with your own hands at home.

So, according to hardness, wood can be divided into:

- hard – oak, beech, walnut, acacia, yew;

- soft - pine, juniper, linden, alder, aspen.

The most popular type of wood when making a DIY step stool is pine. When choosing lumber, pay attention to the region of growth: wood growing in the South has a looser and more fibrous structure, while northern trees have a denser texture.

Types of wood

What type of wood should you use to make your own staircase chair? To make the product truly durable and stable, you should not skimp on wood. To make a children's ladder stool with your own hands, choose selected or premium wood. The same types of lumber are also suitable for interior wooden stairs, transformable chairs.

Selected and first-class wood has no or only a small amount of small knots and cracks. They are completely free of rot, through cracks or traces of knots; this wood has not been damaged by bark beetles. In addition, these types of wood have a beautiful appearance with a beautiful wood grain that is uniform and uniform. This type of wood will make a transformable stepladder chair not only durable, but also attractive.

Folding ladder chairs are best made from selected or first-grade wood - they have no through defects, and the surface has a beautiful wood pattern

But what if you need to make a step-stool with your own hands from wood at minimal cost? If the aesthetic component does not play a special role for you (for example, if you plan to paint the furniture with matte paint), then you can choose second-grade wood. Its appearance is not so attractive - the presence of knots, cracks and other defects is allowed, but their number is insignificant. Second-grade wood does not have through holes, traces of bark beetles, rottenness or mold. And small loose knots and cracks can easily be filled with wood putty, which will then be covered with paint.

Matte paint will help hide any defects on the surface of the ladder, stepladder, or stool.

Is grade 3 wood suitable for a wooden folding ladder stool? If you need to put together a country stool for one or two seasons, then you can take this too. But such a tree may already have bark beetle damage and may have mold and mildew. Third-grade wood, as a rule, is loose, with large and long fibers, so the surface of a product made from it cannot be carefully processed. The strength of a hand-made ladder stool made from third-grade wood will also suffer: due to the looseness of the wood, the fastenings may become loose over time.

Wood type

What type of wood can you use to make a wooden transforming step stool with your own hands? Let's understand the characteristics of different types of wood and find a middle ground.

- Pine and spruce

If you want to make a wooden step-stool with your own hands, then you will most likely choose pine - after all, it is the most popular and widespread lumber from which furniture is made. Pine is a soft wood, so it is easy to process - you can cope with the task even without professional tools. In addition, pine has a light shade of wood, which means that a wooden step-stool with your own hands can then be painted or tinted in any color.

Pine wood is rich in resins, so tree parasites do not like it. But the product will have to be protected from water, since loose fibers actively absorb moisture. If you need to make your own transformable stepladder chair for use in a damp room, then pine will not be the best choice. The same is true for outdoor use - at a minimum, products should be stored under a roof. But for an interior wooden folding stepladder-chair, pine is perfect.

- Birch

Birch is harder than pine, but not as hard as beech or oak, so it is probably the second most popular type of wood among those who make their own staircase chairs. Birch has a very beautiful, unique wood pattern, so such wood is rarely covered with matte paints - it is mainly tinted and varnished. Therefore, making a transforming staircase chair from birch with your own hands will not work out very cheaply - you will have to not skimp on the type of wood. Otherwise, this is an excellent choice.

Birch wood is easy to process with both hand and power tools. The structure of the tree is denser than pine, so the folding stool-ladder can be decorated with carved ornaments - even with fine detail, the design on the birch will be clearly legible.

An important advantage of birch is its price. It is slightly higher than that of pine, but again does not reach oak and beech. You can make a transforming stepladder chair from such wood with your own hands quite inexpensively, so we can safely recommend birch to home craftsmen.

A wooden step stool made from expensive species will fit even into a rich and luxurious interior

- Nut

Walnut cannot be called a banal choice for furniture production, but such a stool-ladder will look great in the interior. Walnut wood has a deep and unobtrusive pattern, against which the carved elements of furniture are perfectly revealed. Walnut will be appropriate in a rich, classic interior.

Making a wooden folding stool-ladder from walnut is not a task for a novice carpenter, since the wood is dense and hard, its processing requires powerful specialized equipment and, of course, appropriate skills. On the other hand, due to such durability, the kitchen ladder stool will last for many years without damage, scratches or chips.

- Beech

If you are planning to make a transforming stepladder chair with your own hands that will last forever, then pay attention to beech. This wood is strong and dense, comparable in these indicators to oak. Beech perfectly reveals carved patterns and holds fastenings securely, so furniture with transformation mechanisms will last a long time. You can also make a stepladder-chair with wide steps from beech: durable wood can easily withstand heavy loads.

The main disadvantage of beech, besides the price, is the property of wood to actively absorb moisture. A beech children's step stool may not survive spilled paint and subsequent washing. You should not use furniture in rooms with high humidity. This option is also not suitable for open air.

- Oak

Those who are looking for how to make a step stool as durable as possible often choose oak. This is a fairly valuable and beautiful type of wood that has excellent performance characteristics: it does not rot, is not afraid of water, and holds fastenings securely. By making a one-time investment in making a do-it-yourself ladder stool from oak, you will receive a product that you will be happy to use for decades.

Oak wood has a beautiful and rich pattern, so stain or tinting varnish is most often chosen as a finishing method. A children's step-stool made of oak can be painted, carved patterns can be made on it - in any design it will look perfect. An oak ladder stool will fit into any interior style, and numerous photos confirm this.

Step stool – transformable made of plywood

You can make a folding step-stool not only from solid wood, but also from plywood. Moreover, the structure can be either entirely plywood or combined. The second option is preferable, since according to the drawing of the staircase chair, frame, load-bearing elements will be made of timber, and the front planes will be made of plywood.

Assembling a chair-staircase-transformer in a combined version according to the drawing is no more difficult than from solid wood, and in some cases even easier.

To make a transformable stepladder chair, you need special plywood - furniture plywood. It is made from natural raw materials, which are glued and compressed under pressure. Furniture plywood has a multi-layer structure that resembles a sandwich. In each layer, the fibers are located in different directions, due to which sufficient strength, resistance to moisture and load resistance are achieved.

Photo of a plywood ladder stool. Simple but reliable and affordable design

When choosing plywood for a staircase chair, you need to pay attention to the quality of the glue used in production. In cheap handicraft sheets, gluing can be done with toxic adhesives containing phenol and its compounds. Products made from such plywood are not suitable for indoor use, and in general it is better to choose reliable material from a trusted manufacturer.

To make a wooden step stool with your own hands, you can take plywood made from different types of wood:

- Softwood plywood

Choosing softwood plywood for a ladder stool is an excellent solution. The material is perfect for making furniture; it has a light shade, so it can be painted any color without any problems. Coniferous plywood is not the most durable, but due to its high resin content it is not susceptible to rotting and parasites. But it is better not to place plywood furniture made from coniferous wood near heat sources - uneven heating can cause the material to crack and delaminate.

- Hardwood Plywood

The production technology for this material is the same, only hardwood chips are used as filler. You can find sheets of larch, birch, aspen, poplar and other types of wood. For making a transformable staircase chair with your own hands, hardwood plywood is better suited, since, all other things being equal, the material has higher strength. But such plywood is not moisture resistant - so that the product does not warp during operation, it must be coated with protective compounds and use antiseptic impregnations.

- Combined plywood

If you are going to make a transformable stepladder chair with your own hands, then consider the option with combined plywood. In its production, both coniferous and deciduous wood was used. Typically, coniferous layers are placed in the middle, and the outer layers are made from more attractive and aesthetically pleasing hardwood.

Plywood, like other lumber, comes in different grades: the quality and appearance depend on the grade. Choose from the highest or first grade for a convertible step stool.

When choosing plywood for making a step-stool with your own hands, pay attention to the thickness and number of layers: the more layers, the thicker and therefore stronger the plywood.

When choosing plywood for a stepladder chair design, rely on the dimensions in mm, and not on the number of layers - all manufacturers have different thicknesses

The thickness of plywood sheets does not directly depend on the number of layers. Different manufacturers may change the thickness of one layer, which affects the final dimensions of the material. When choosing, base your choice on the thickness in mm, and not on the number of layers.

Tools and consumables

We will need the following tools:

- hacksaw for metal (optional - circular);

- jigsaw (preferably electric);

- screwdriver;

- grinding wheel and rim for cleaning wood;

- hammer;

- Bulgarian;

- self-tapping screws;

- brushes and paint (optionally, paint, stain) for final finishing.

Experts recommend using multilayer plywood (at least twelve millimeters thick) as the main material. If the base is thicker, then, undoubtedly, the product will become stronger, but its “weight category” will increase. And we are for a compact and not too bulky design. A small clarification: when you plan to work not only indoors, but also outdoors, you need to choose a moisture-resistant version of the plywood sheet.

You can sit down and relax

Building a classic version of a step stool

In order to make a transformable stepladder chair with your own hands exactly according to the drawings, you will need a minimum set of power tools:

- Jigsaw with a set of saws for wood;

- Manual electric router with 25 mm and 30 mm end mills;

- Drilling machine or drill with a device for precise vertical drilling;

- Polishing machine with wood attachment;

- Screwdriver;

- Set of carpentry clamps.

Since this design, in addition to the functions of a staircase, will also be used as a piece of furniture, it is best to choose a design with elements of carving and decor.

For the most part, a step stool will be used as a piece of furniture, so it makes sense to make it as beautiful and attractive as possible. In this case, decorative elements are practically not used; windows are made on the sidewalls in order to make the structure lighter and give it a more elegant look.

Structurally, each part of the step-chair consists of two sidewalls, between which four transverse steps are glued. One of the steps serves as a seat, the rest are used only for climbing stairs.

Initially, you will need to transfer the contours of the side posts of the stepladder chair to the boards. This can be done in two ways. In the first case, the contours are transferred by drawing lines using carbon paper. The second method allows you to do the work much faster - you can simply print out the outlines of the parts of the future step-chair and stick the paper on a wooden blank.

At the first stage, you need to make longitudinal grooves or cuts on each side of the large and small parts of the step stool, as in the photo. The grooves must be made for two reasons: firstly, they will be necessary for further processing of the workpieces. Secondly, the step boards will be inserted into the grooves. If you fasten the steps only with self-tapping screws, the rigidity of the step-chair will be very small, and the entire structure will quickly fall apart under the weight of a person.

Next, you need to make several through holes with a drill and cutter, preferably at the corner points of the internal contours. This must be done in order to be able to cut out selections along the openwork thread with a jigsaw.

Following the inner contours, we cut out the outer lines of the sidewalls in the same way. After all four sidewalls have been cut out, two for the larger part of the stepladder chair and two blanks for the smaller one, you will need to calibrate the dimensions, as in the video

To do this, two side blanks are folded in pairs and cut on a router. This allows you to make both elements of the step-chair absolutely identical in shape and size. At the same time, we remove chamfers and burrs, and treat the surface with a grinding and polishing attachment.

The steps for a stepladder chair are best made from oak boards, 15-20 mm thick. For the large swivel part of the chair, you will need to make three steps, all three of different sizes. For the smaller stationary part, you will need to cut two steps, also of different sizes. The step blanks, cut to size, are carefully glued to the sidewalls. To do this, you need to coat the gluing areas with wood glue or epoxy glue and insert the blanks into the grooves. To maintain the geometry of the step-chair, gluing is best done with fixation in carpentry clamps.

After the glue has dried, the steps of the step stool must be reinforced with carpentry screws. At this stage we have two small structures, one looks like a short chair, the second looks like a stool. To make a full-fledged folding stepladder out of them, you need to connect the two parts with a furniture or piano hinge.

Attention! To ensure that during use the vertical load on the step-chair does not deform or tear off the hinge fastening, special stop pins are used in the design.

The last element of the chair is the back. It must be made and a stepladder installed on the chair without fail. Otherwise, the front supports of the ladder will be unstable and will quickly fail.

The step-chair is almost ready for use; you need to finish the exterior with stain or varnish.

The result is a nice design that can not be hidden, but rather installed in the kitchen or hallway, where there is always work for such devices.

Pros and cons of homemade design

It is necessary to highlight the pros and cons of assembling the structure with your own hands.

The advantages are as follows:

- designing a staircase chair at home will be much cheaper than buying it in a store;

- you can save time, because you can’t always find a suitable chair in the store;

- everyone will be happy to make a design for themselves that will be useful;

- common advantages of all models: compactness, ergonomics, versatility, ease of use.

Disadvantages: you need to calculate all the indicators very well, otherwise the step may break.

How to make a successful step stool

The process of making a chair or stepladder with your own hands may seem overly complicated and confusing, but this is a deceptive impression. In practice, construction requires only three conditions:

- Choose your own drawings for a chair or stepladder of a suitable design and size;

- Choose high-quality material, preferably oak or beech boards;

- Rent carpentry power tools.

Advice! Making a step stool manually, using a saw and a plane, is quite difficult even for an experienced carpenter, so you need to start work by selecting the necessary tool.

If desired, the simplest version of the chair can be made according to the drawing below.

Types of structures

Different types of products differ mainly in their design, according to which they can have the following designs:

- chair-ladder with steps smoothly rising outward (without backrest);

- modular block in the form of a stool;

- a chair with a ladder, but with a backrest for sitting;

- a high stool equipped with retractable steps.

Additional Information. All types of prefabricated products can also differ in the material from which they are made (they can be metal, plastic or wood).

The main requirement for the models is high structural strength, reliable fastening of individual components and good stability of the platform itself. All samples can be fixed or collapsible depending on how they are stored in non-functional form.

Stationary

A fixed or non-removable ladder is made so that the product does not shrink to a compact shape, but remains in its original state. The most popular types of stationary chairs that can be turned into a comfortable and fairly high staircase are:

- after simple manipulations, the transformable chair turns into a three-step staircase;

- a stool, which is a structure with a retractable part that moves along special guides;

- staircase in the form of a chair with a small back;

- a small stool with steps that spiral out from under the base (seat).

Non-folding products are inconvenient because they take up too much space in the room, but they are more functional than folding ladders.

Folding

The seats can, if desired, be quickly converted into a fairly compact form and then converted back into a stool or a comfortable ladder. When folded, the chair takes up minimal space and is used only when necessary.

The most famous examples of folding seats that can be converted into a step design are:

- a transforming stool that easily folds and turns into a compact whole;

- bar counter with steps, which when folded turns into a small structure.

Important! The hinge mechanism used in folding models must include a reliable latch with a safety lock, eliminating the possibility of its spontaneous return to its original state.

In a situation where it is planned to manufacture a prefabricated staircase with a folding back, a special hinge mechanism (piano ring) will be required to fix it. With its help, you can easily lower the top of the folding chair, creating additional support.

What is this

Beautiful wooden step stool assembled and disassembled

First, let's figure out what it is. From the name it is clear that the product includes the functions of two items: a chair and a stepladder. Accordingly, it has their characteristic features.

So, a stepladder chair consists of steps, legs and a seat. Depending on the type of construction, the seat can be used as a step or reclined while performing the functions of a stepladder. It is worth noting that this product has greater weight and dimensions than a regular chair. Still, this design is a success with many owners.

Step stool - a little helper for your home

Drawing of transformers and dimensions of parts

When making a transforming ladder with your own hands, you can use standard dimensions (indicated in millimeters) of blanks:

Drawing of a transformable chair.

1. To assemble the transformable chair we will need:

- two front sides, 20 * 270 * 400;

- two back sides, 20*325*850;

- three slats for the back of the chair, 20 * 50 * 400;

- rear seat, 20 * 165 * 400;

- front seat, 20 * 90 * 400;

- three passes, 20 * 120 * 360;

- six strips, 20 * 20 * 95.

2. Assembling the transformer ladder:

Transformable chair step by step

- First, as mentioned above, we draw patterns for the blanks.

- We prepare plywood parts according to the patterns: a pair of front side panels, a pair of rear side panels, three slats for the back; rear and front seat; three steps and six slats.

Approximate drawing and assembly diagram - All this must be carefully cut out using the appropriate tools. And then we carefully sand the parts for the folding stepladder, and process the sharp ends using a router.

- We make the back of the chair from planks. We attach it to the sidewalls with self-tapping screws. We connect the steps with the seat in this part to the sidewalls using grooves made with a chisel.

- We assemble the structure: we lubricate the joints with glue, reinforce them with screws, and screw them into the pre-drilled holes.

Manufacturing process

A do-it-yourself wooden ladder stool, assembled according to a pre-drawn sketch, can become an indispensable seat in the house and comfortable for home use. To manufacture it, you will need to stock up on all the necessary components (including special models). Most often, the material chosen is wood or plywood, which is easy not only for conventional processing, but also for finishing.

Tools and materials

To work you will need a set of tools:

- Universal jigsaw.

- Drill with a set of drills.

- Lumberjack and carpenter's plane.

- Clamps, chisel and hacksaw.

You should prepare consumables, which should include dowels, dowels for fastening, wood glue, as well as self-tapping screws. You can use boards, plywood or MDF blanks as the main working material. Before preparing drawings of a wooden folding ladder, you need to decide on the configuration of the future product.

The thickness of the material used is selected so that the finished product can withstand the weight of a person (at least 20 mm).

Useful tips for making your own stepladders

Assembling a stepladder according to a ready-made drawing with dimensions is not difficult - even a novice master can do it. But, there are nuances that it is better to find out in advance so as not to encounter problems during the work process:

- When marking the “legs” of the stepladder to determine the location of the steps, you also need to mark the points for their attachment.

- On the side parts of the stairs, closer to the top step, it would be a good idea to attach two or three hooks. They are useful for hanging a bucket of paint, a bag of tools, or a harvesting basket. You can also attach a hollow piece of plastic or iron pipe at the top, inside which you can put a screwdriver, pencils and other small things that are inconvenient to hold in your hands, but also difficult to go down to get them every time.

- To prevent the legs of the stepladder from moving apart when a person is at the top, a stopper needs to be attached approximately in the middle of the sides. It can be used as a belt, thick rope or chain, which will not allow the stepladder to open further than its length.

You need to take care of your own safety!

Table No. 2. Options for stepladders

| View, illustration | Description |

| Mini chair | A variant of a miniature stepladder, the height of which is usually 70-90 centimeters. You can work on this design both standing and sitting. A stepladder-chair can have two, three or five steps, at the top there is a working platform, which is also a seat. |

| Rack platform | This stepladder has a fixed platform at the top, which is quite spacious for a person to work from above for a long time. Typically, such stepladders are about 1.3 meters high and are used during finishing renovation work. It is not advisable to store such a ladder at home, since it is not compact. |

| One-sided split | This stepladder has steps on one side only, with a support bar on the other for added rigidity. This is a fairly light, compact ladder that is convenient to use at home. But, it is worth considering that the design is not very stable. |

| Double sided | This is a more stable and convenient option due to the fact that the steps are located on both sides of the structure. The advantage of a double-sided stepladder is that two people can be on it at the same time. Also, the second side with steps can be used to place tools or hang necessary items (for example, when hanging wallpaper). |

| Rolling stepladder | This is a more massive structure, with locking wheels installed on the legs to facilitate movement. This model resembles an extendable one-sided staircase, but usually the rolling one has a greater height. To move the ladder, you need to raise the wheel clamps, and when the structure is installed in the right place, the clamps are lowered again to make the ladder immobile. |

The indicated options and recommendations should be enough to understand the manufacturing technology of a simple wooden stepladder, as well as to determine its dimensions and other operating parameters. Then you can proceed directly to assembling the stairs.

Video - Do-it-yourself folding stepladder

This is interesting: Potbelly stoves for the home, for the dacha, do-it-yourself potbelly stove, economical potbelly stove - we’ll tell you in detail