The process of smoking at home has always been a rather labor-intensive undertaking, especially when it comes to the most delicious form - cold smoke processing. It was necessary to monitor the temperature and quality of the process for long hours, maintain the proper operation of the smoke generator and, most importantly, control how accurately the flow of smoke was directed towards the meat or fish filling. The process can be seriously simplified if you make your own electrostatic smokehouse. The quality of processing will remain virtually unchanged, and worries and problems will noticeably decrease.

The secret of live smoking

It’s worth making a reservation right away - making an electric smokehouse with your own hands only makes sense for cold smoking. Despite the fact that enthusiasts are actively experimenting with hot smoking and even trying to cook kebabs using electrostatic devices, the best quality indicators are still obtained with smoke with a smokehouse temperature of no more than 45-50°C.

In this case, the electrostatic amplifier provides two additional factors that are practically useless when processing food in a hot smokehouse:

- The electrostatic field accelerates both predominantly charged water molecules and existing polar organic compounds into smoke, including acids and lower alcohols. Thanks to this, the process of saturation of products occurs many times faster than in the absence of an electrostatic field;

- When a cold electrostatic smokehouse operates, there is no degradation or destruction of animal protein and fats, those basic building blocks that make up meat, lard or fish. In this sense, the process of smoking in an electrostatic field is very similar to drying, but with a higher processing speed.

- In hot smoking, moisture is intensively removed from the surface of the product, and even if the electrostatic field “throws” water vapor and acids from the smoke, all this is swept away by streams of hot air. Essentially, it is the process of frying meat or lard in hot air with the addition of smoke.

There are more than enough fans of both smoking methods, cold and hot, so every year more and more new methods and designs of electrostatic smokehouses appear. There are even schemes for smokehouses with a built-in unit for monitoring the temperature of the meat surface using a remote infrared thermometer and with an adjustable electrostatic field voltage. It is clear that such smokehouses are made mainly for processing large volumes of products; for yourself, you can make a small electric smokehouse with your own hands (photo).

Unlike large chambers with powerful electrostatic units, which require a barn, garage or at least a summer house, small-sized electric smokehouses can be used even in a city apartment. Naturally, the productivity of an electrostatic smokehouse is less, but the taste and quality of the product is noticeably higher.

Electric smokehouse device

The circuit diagram of the apparatus for electrostatic smoking is very simple and quite easy to assemble with your own hands. The design of the smokehouse consists of the following parts:

- Housings made of dielectric material, possibly wood, plastic or even paper;

- Electrostatic “radiating” mesh suspension made of steel, copper or brass wire;

- Smoke generating unit of a smokehouse or smoke generator;

- Flue flow cooling systems.

The main module on which the quality and performance of the smokehouse depends is the electrostatic field generator. There are a huge number of designs and different circuits of the electrostatic unit, but not all of them work equally successfully and provide a high quality product.

A removable wire hanger is mounted in the center of the body, onto which the products are directly attached. The radiating mesh is installed on the walls of the electrostatic smokehouse, and a smoke generator is installed in the lower part of the body. In powerful smokehouses, the smoke generating unit is removed together with the cooler as a separate structure outside the housing.

Drawings and models

Below we provide drawings and models for making smokers (smokers) with your own hands. You can also contact companies that will manufacture the product to order. You just need to provide the drawing (model) file.

Drawing of a large grill-smoker-smoker in PDF and SLDPRT format

Drawing of a smokehouse with a lid-house and a water seal in DXF and CDR format

Drawing of an octagonal smoker-smoker in STP, IPT formats

Drawing of a simple smokehouse with a water seal in PDF format

Drawing of smokehouse No. 1 with a water seal in DXF, PDF, KOMPAS formats

All drawings of smokehouses

Electronic generator using spare parts from a TV

Most cold smoking enthusiasts believe that the easiest way to make an electrostatic smoker with your own hands is from a TV scanner. Indeed, old transistor televisions used a frame scanning board. In modern TVs, its functions are performed by several chips and keys, so getting hold of such a board will not be easy, and the device will cost a lot.

In fact, the use of a board is not very suitable for such utilitarian purposes; it is important not only to obtain an electrostatic field for the smokehouse, but also to control its power. Otherwise, the smokehouse will work like a Russian stove, so most often a separate circuit is made, which uses only a high-voltage transformer.

You can assemble an electrostatic smokehouse with your own hands from an ignition coil from an internal combustion engine of a car. There is not much difference, but if in the previous case the maximum potential of the electrostatic field in the smokehouse is only 20 kV, then in a system with an ignition coil the total is 40 kV.

The currents are very small; if the insulation is broken, the trans from the TV can noticeably hit your hands, while the impact of a high-voltage generator on a coil from a Lada car will be equal in strength to the discharge of a powerful stun gun, as in the video

Therefore, if you plan to build a small smokehouse, then it is best to make its electronic part using a TDS17 transformer.

Smoking cabinet with smoke generator

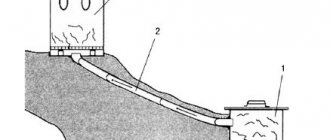

In cold smoking devices, smoke is not produced in the chamber, but separately, in a smoke generator. It is placed below the smoking cabinet and the smoke, passing through the chimney, is cooled.

Advice! To improve the quality of smoke, the chimney is equipped with a condensate collector, filter, refrigerator and other accessories.

Diagram of a smoking cabinet with a smoke generator

Electrostatic smokehouse for yourself, the simplest option

You can smoke lard and meat quite simply even in a city apartment, where there is no way to install and run a smoke generator, and even more so there is no way to get rid of the combustion products of wood chips. Therefore, home models of electrostatic smokers are made compact and low-power.

The main advantages of the electric smoking chamber option below are as follows:

- Very simple design;

- The minimum amount of materials and parts required for the manufacture of a smokehouse;

- Easy maintenance.

For your information!

To obtain high-quality processing of products with smoke in a smokehouse, it is necessary to use an adjustable electrostatic field. The basic provisions and operating principle of a smokehouse with a controlled electrostatic field are outlined in the video

Camera design

The smokehouse is a body with a diameter of 300-350 mm and a height of 600-700 mm; you can use a plastic or cardboard pipe of the appropriate diameter. At the bottom of the body, a metal base is made - a sleeve, preferably from an aluminum or steel container.

This design does not have a separate remote smoke generator; instead, a built-in model is used. Essentially, this is a tray with a built-in electric heater. Since the volume of the electrostatic chamber is small, no more than 70 ml of fine sawdust from beech or alder is used for one session. As a heater, you can use a Chinese soldering iron with the handle removed; instead of a tip, a copper wire bent in a spiral is laid.

The main amount of smoke in the smokehouse is formed due to the sublimation of dry chips upon contact with a heater coil heated to 350-400°C. As a result, the smoke produced for electrostatic smoking is colder, more humid and richer than that produced by thermal decomposition of wood. Most of the smoke is cooled on a cone plate at the bottom of the smoker.

In order to avoid smoke leakage, a tee pipe is installed in the upper part of the lid, onto which a container for collecting condensate and a miniature fan are placed. Some of the air and smoke from the electrostatic chamber is pumped out through a PVC tube in order to create a vacuum and prevent the leakage of odors and smoke.

Electrostatic unit design

The electrical part of the smokehouse consists of three parts:

- Electrostatic high voltage generator;

- Pendants for meat and fish;

- Grid guide.

In the upper part of the smokehouse, a grate is installed on ceramic insulators, on which a pendant with products is placed. The negative electrode of the electrostatic generator is connected to the grid. Whatman paper with glued wire is placed along the walls of the smokehouse; this is a positive electrode. Sharpened pieces of the same wire are soldered onto the wire; they direct the flow of charged molecules towards the products.

Generator circuit

The most complex part of an electrostatic smokehouse is the electronic circuit of the high-voltage constant voltage generator. The electrostatic generator circuit is shown below.

The circuit is based on a TDS17 high-voltage transformer. To form rectangular pulses, a circuit assembled on NE555 from a powerful field-effect transistor IRF3205 is used; the operating frequency of the driving circuits is about 10 kHz, but it can be adjusted using a variable resistor R5. As a result, the potential of the electrostatic field on the smokehouse grid can vary within 10%. To power the circuit, an EN 8 142 series assembly is used.

A stranded copper wire with a diameter of 1 mm is used as the primary winding; ten turns are wound directly onto the magnetic core. When setting up a high-voltage field generator, you may have to swap the connections so that the output produces the polarity required for the smokehouse.

How to build a wooden smokehouse in the form of a house with a pitched roof with your own hands

If you have woodworking skills and carpentry tools, such a smokehouse can be built in one working day from hardwood boards or 8 mm thick plywood.

Designing a smokehouse

Before starting work, a drawing of a cold-smoked wooden smokehouse is drawn up. The following points must be taken into account:

- installation location;

- desired sizes;

- roof type - single-pitch or gable;

- type of smoking - cold or hot;

- for cold smoking, the type of smoke generator is free-standing or in the ground.

Before starting work, it is necessary to prepare the installation site, and if you choose a chimney laid in the ground, dig a ditch for it.

You can also make such a device from a wooden barrel. A self-made barrel smokehouse has all the advantages of a smokehouse in the form of a house.

Necessary materials

To make a building measuring 90*60*120 cm with a pitched roof you need:

- bars with a cross section of 50x50mm for the frame;

- boards, lining or plywood for cladding walls and roofs;

- fat collection tray 40x70 cm;

- slats for gratings measuring 80x50 cm;

- chimney made of asbestos-cement or galvanized pipe ∅80-120 mm, 30-50 cm long;

- sheet of slate or corrugated roofing.

Important! There should be no through knots in the bars and boards. When the boards heat up and dry, knots will fall out and holes will form, breaking the seal of the chamber.

Manufacturing process

To assemble the case you need:

- Take 4 bars with a cross section of 50x50 mm, 2 front ones 150 cm long, 2 rear ones 140 cm long. From one of the ends mark 30 cm for the legs.

- On the inside of the side walls, slats or metal corners are screwed for grates with food. In the hot smoked smokehouse, a mount for a tray for collecting fat is additionally mounted. It can also be installed on a stand with legs.

- Vertical posts are connected by horizontal transverse bars 50x50 mm. You need 8 such bars - 4 60 cm long, 4 90 cm long. The bars are connected with self-tapping screws, and metal corners are used for strength.

- After assembling the frame, the back side, side walls and bottom are sheathed with boards or plywood. A door is hung on hinges on the front wall.

- Holes for the inlet and outlet chimneys are cut in the bottom and top of one of the walls. This can be done in the boards intended for sheathing before attaching them to the frame. If there is a free-standing smoke generator, the hole for the inlet chimney is cut in the opposite direction from the outlet above the floor.

- The top of the body is covered with a sheet of slate or corrugated board. It is allowed to use tongue-and-groove boards or lining.

- All cracks are sealed with polyurethane foam or felt. This is done to maintain the temperature and density of the smoke.

- The chimney is being installed. To adjust the draft, it is recommended to install a damper in it.

- The required number of gratings is manufactured. They are made from wooden slats or metal rods or stainless steel tubes. A stainless steel grate is the best option. It is easy to clean and does not absorb odors. With the recommended dimensions of the smokehouse and slats, the grid size is 80x50 cm.

- If there is no ready-made container for the pallet, then it is made of sheet metal. To do this, take a rectangular piece of metal 50x80 cm, cut out 5x5 cm corners, bend the edges and weld the joints using electric welding. The blank can be cut from the tank of an old Soviet washing machine.

After assembly, the device is placed at the place of use.

Scheme of a wooden smokehouse

Manufacturing a gable roof

This smokehouse looks more beautiful, but is more difficult to assemble than with a pitched roof:

- all vertical posts are taken the same length;

- two equilateral triangles are assembled from the bars above the front and back walls;

- the vertices of the triangles are connected by a block;

- when installing a roof made of metal sheet, it is bent in the middle at an angle of 60-90°.

Gable roof diagram

Operation of an electrostatic mini smokehouse

Before starting, the products are hung on the smokehouse suspension for a relatively short time, 5-7 minutes. turn on the blower fan. To avoid breakdown of the electric field, the meat and lard must be dried, and even the excess moisture must be blotted with a napkin.

Sawdust is loaded into the smoke generator box, a “soldering iron” is inserted and the electrostatic system terminals are secured. Next, the smokehouse is closed with a lid and the heating is turned on; after the lower part of the body is filled with smoke, the power generating system is turned on. In order for the smoke to concentrate on meat products, it is necessary to adjust the level of the electric field potential, otherwise most of the decomposition products will settle on the walls of the smokehouse.

Fire source for smoldering wood chips

A common quality of fire sources for mini smokehouses is the ability to adjust the heat. The following heat sources are used to heat wood chips:

- bonfire;

- Primus or blowtorch;

- portable gas burner;

- electric stove with regulator;

- in a summer kitchen or other well-ventilated room, a stationary gas stove can be used.

Important! If overheated, the food will not be smoked, but will become fried or dry out.