Types of homemade generators

The circuits of homemade smoke generators may differ slightly, but they are all united by a common device. They include a chamber in which the pyrolysis process occurs, a heating source, a smoke pipeline and a smoke cooling system. The device can be made using available materials.

You can make a smoke generator from a fire extinguisher, an electric stove, or an aquarium compressor.

Let's look at these and other ideas in more detail.

Electric stove smoke generator

If the idea of homemade smoked sausage has just struck you, and you haven’t prepared for it in advance, you can find a simple and quick way: make it from an electric stove. All other parts can be found in a barn or garage: a barrel without a bottom or a piece of tin pipe, a piece of wire mesh, a sheet of plywood and wood chips.

It is better to set up an impromptu smokehouse outside, then at home it will be difficult to get rid of the aromas that will permeate all things.

- Install the tiles in a place that the extension cord can reach.

- A barrel is placed on the electric stove and wood chips are poured into it.

- At 2/3 of the height, the barrel is pierced with two reinforcing pins crosswise, and a mesh is laid on them.

- This is where your products will be hung.

- The top of the barrel is covered with a sheet of plywood or iron. The smokehouse is ready.

All that remains is to adjust the tile to the minimum temperature so that the wood chips smolder, and from time to time add fresh material for pyrolysis into the barrel.

The smoking process with such a device is not very convenient because you need to constantly monitor the situation, raise the barrel to adjust the temperature, and remove food to add wood chips.

Such a device cannot be called a proper smoke generator for cold smoking, but for temporary use the idea is quite suitable.

Generator for smokehouse from fire extinguisher

A great idea for a homemade smoke generator is to use an old fire extinguisher. You need to cut off the top of it, it will then be used as a lid. You don’t even have to remove the lever; it will become a handle. Below the cut, two holes are drilled in the body for air access and smoke exit.

Thus, you will get a generator with a top ejector. The advantage of using a fire extinguisher is that it is sealed and durable, and is the right size.

This home-made cold-smoked smokehouse with a smoke generator can work continuously for 10-12 hours.

Advice! To prevent the added sawdust from being compressed into a dense mass, a spring is suspended inside the container.

How to use an aquarium compressor for a smoke generator

We have already said that you can use a low-power aquarium compressor to operate a small smoke generator. For this purpose, you will need an active compressor, that is, one that is installed outside the aquarium. Submersible aquarium filters are not suitable for smoke generators.

Such a device can easily serve a small smokehouse with a volume of 15-20 liters.

This will ensure a sufficient supply of smoke. It is better if the device is equipped with air supply power adjustment. It is not difficult to connect a compressor for a smoke generator with your own hands: if it has two air outlets, you need to combine the supply into one channel and insert the hose into the air supply fitting in the ejector.

Such a system can operate around the clock; the pump consumes little electricity.

You can go another way: use a fan for a smoke generator. A computer cooler is suitable for this purpose; it will provide the necessary air injection.

Smoke generator stove for smokehouse

For a large-volume smokehouse, you will need a full-fledged oven. It’s easy to make a smoke generator stove for a cold smokehouse with your own hands: it’s a basic potbelly stove with two levels for fuel: the bottom? for firewood and the top one for wood chips. Pellets, firewood are placed in the lower part, or a portable gas stove is placed, which will heat the upper part with sawdust.

From the top part there is a pipe - a smoke duct, from the bottom - a regular hood, like for a stove.

To lower the smoke temperature, the pipeline is cooled by burying it in the ground or making a water “jacket”. To ensure that smoke enters the smokehouse, the pipe is tilted towards the stove.

Advice! Professionals recommend making the chimney pipe not from galvanized steel, but from stainless or black steel.

Assembly sequence of a homemade structure

Let's take a closer look at the assembly sequence of a smoke generator for cold smoking based on a profile pipe (for home use, dimensions of 100x100 mm are considered sufficient). No one forbids using round pipes, but working with them is a little more difficult.

The production of a smoke generator is carried out in several successive stages:

- 2 cm are retreated from the lower edge of the rectangular pipe and a cut is made with a grinder. They do the same on the opposite side. You get two through slits.

- A rectangular blank is cut out of a metal mesh, which along the long side should be 10-20 mm larger than the cross-section of the pipe. It is carefully inserted into the cuts. It turns out to be a grate on which you will pour wood chips. (This is just one way to make such an ash pan; in the photo below you can see just a grate hammered into the pipe.)

- A hole is drilled from the opposite end of the pipe at a distance of 2-3 centimeters from the end and a metal pipe with a diameter of 2 centimeters and a length of 10-15 centimeters is welded onto it from the outside. Let's call it an outlet pipe - smoke will go out through it.

- In the opposite wall, exactly opposite the outlet pipe, a hole is drilled for the compressor fitting. The fitting is secured with a weld or a nut.

- You need to secure a thin tube in the fitting so that it fits 3-4 centimeters inside the outlet pipe. It turns out to be an ejector: if air from the compressor is supplied to the fitting, an internal draft arises, which is sufficient to pull smoke out of the generator.

- Two square covers are cut out of a metal sheet, slightly larger in size than the body (that is, the cross-section of our square profile). Despite the fact that we are talking about cold smoking technology, the product is powered by smoldering wood in the lower part, which means that the structure will heat up (at least in the part where the sawdust burns). A strip of heat-resistant metal is welded along the contour of the lid so that it fits tightly on the pipe.

- At the bottom of the unit (where the mesh is welded) legs made of reinforcement are attached.

- A plastic sleeve is put on the outlet pipe, through which the smoke will flow into the smoking chamber.

The device is ready! You can start cold smoking. For convenient carrying, handles can be welded on the sides of the body. It is better to install the structure on a non-combustible platform. Cleaning the smoke generator must be thorough and regular, since ash constantly accumulates in it during operation.

Homemade smokehouse from a pipe: how to make

A pipe smokehouse is one of the simplest options that you can easily make yourself.

To do this, just follow the instructions and prepare in advance everything you need for work.

Materials and tools that will be required

For a homemade design you need to prepare:

- steel pipe with a diameter of 10 centimeters;

- plastic corrugation - the length should not exceed three meters, or you can use a metal sleeve;

- a piece of metal tube - up to 40 cm with a diameter of 2.5-4 cm;

- a small compressor - an aquarium compressor will do;

- fitting connection, which will have the same diameter as the smoke duct;

- switch and electrical wires;

- thermometer.

The tools you need to prepare are a welding machine and a grinder. It is advisable to have at least minimal experience working with these tools in order to avoid injury during the generator assembly process and do everything correctly and accurately.

Drawing of a smoke generator from a pipe

To make the assembly process easier, it is worth studying the drawings of a pipe smoke generator.

Below is the simplest and most detailed option.

Drawing of a smoke generator made of a pipe with a lower and upper ejector.

Step by step assembly

You need to use all previously prepared materials to assemble a smoke generator, which will be used for cold smoking, with your own hands from a pipe.

- First of all, the camera is made. As a rule, the average height of a smoke generator is 70-80 centimeters. There should be a lid at the top that can be removed. This is necessary so that you can easily pour fuel inside the device. A small container is made at the bottom where the ash will fall.

- In the simplest versions of the generator, wood chips are poured onto the bottom of the device, which is welded tightly to the edge of the pipe. In this case, the structure is turned over to clean it. There is no ash pan in such a homemade smoke generator.

- There is also another design option. The wood chips are poured onto a grate, which is pre-attached at a certain distance from the bottom of the device. The ash that remains after the fuel burns out will fall through the grate. Typically, the bottom of such devices is removable. You can also add a flapper to clean out the ash pan. This option is considered the most labor-intensive.

- Regardless of the chosen option, a small hole is drilled in the lower part of the homemade generator, the diameter of which will be 5-6 millimeters. A minimum amount of air will enter the device through it so that the sawdust slowly smolders.

- If the hole is larger, it may cause a fire.

- In the upper part of the structure, approximately 7-9 centimeters below the upper edge of the pipe used, another hole is made. With its help, the smoke exhaust pipe will be attached to the smoke generator.

- Next the ejector is assembled. This device is used to suck smoke from the smoke generator and direct it into the chimney. A small diameter tube into which pressure will be supplied from the compressor fits a couple of centimeters into the chimney pipe, which has a larger diameter.

Due to the fact that the air moves slowly, a slight vacuum occurs and smoke from the chamber begins to flow into the chimney.

- After all the most important parts have been connected and secured, you only need to finally assemble the homemade smoke generator and check how efficiently it works.

- Chips must be placed inside the structure. It is enough to use 700-800 grams of fuel. It is best to use sawdust from deciduous or fruit trees, which will make the finished smoked product not only tasty, but also quite aromatic.

- Next, you need to tightly close the lid of the device and install the constructed structure in a certain place next to the wall of the smokehouse. If the smoke generator is free-standing, then you need to attach a hose to the chimney, which will be directed directly into the smokehouse.

- Then the fuel is ignited through a small side hole and the compressor is turned on.

- Now all that remains is to ensure that the sawdust smolders evenly and does not die out from time to time, so that you get tasty and aromatic home-made smoked meats.

The simplest smoke generator made from cans

Of course, this device is far from a professional gas generator, but the idea has the right to life. We will need the following materials and tools:

- Three empty vertical tin cans of the same diameter.

- Tee.

- The squeegee is extended by ½ inch.

- ½ inch locknut.

- Hose fitting.

- Four clamps long enough to wrap around a can.

- Copper tube.

- Minimum set of tools.

- Compressor from an aquarium.

Remove the bottom of one of the cans. On the second we drill a hole with a diameter of 11 millimeters. This hole is intended for air supply. We connect two jars together. For this purpose, galvanized strips are used. They are wrapped around the cans and secured with a clamp. The third jar also needs to be connected to the others, but bottom up.

Drill a hole on the top can. You will need to screw a ½ inch thread into it. We attach a tee into this drilled slot. To one end of which we install a pipe 14 centimeters long, and to the other end - a fitting. We also install a copper pipe. A compressor is needed to supply air. We connect the compressor tube with the ejector tube. We put sawdust into the generator. The cans must be placed on a fireproof base; an asbestos blanket will do. We put the generator into operation. For ignition we use a hand torch. We direct the burner flame into the ignition hole.

If we have assembled everything correctly, then after a short period of time dense smoke should pour out of the pipe. This is a signal that the generator is working. An ordinary cardboard box serves as a smokehouse. The device is assembled, but has many shortcomings. Suitable as a trial version of the smokehouse. But it's not serious. This smoke generator does not have a condensate collection tank and does not have a cooling system. The idea is worthy of attention, but with further modifications.

Rules for using a smoke generator

Equipment in this category is suitable for cooking fish, various types of meat, mushrooms, and vegetables. The smoking chamber should be regularly cleaned of dirt. Deciduous wood is suitable for backfilling. Spruce, pine and other conifers are not used to prevent clogging with resins.

At the end of processing, fragrant herbs and a couple of juniper branches are added to obtain special aromatic parameters. It is necessary to clarify the features of smoking of different types of initial food products.

When working with a smoke generator for cold smoking, you must follow the general rules of fire and electrical safety. Do not place the combustion chamber near flammable objects. Check the integrity of the wiring.

If the design has a powerful electric heater, it is connected to the network through a circuit breaker according to a grounded circuit.

What is a smokehouse smoke generator: basic definitions and problem statement

Cold smoking technology involves long-term exposure of the original products to the smoke of smoldering wood. This process destroys bacteria and blocks decomposition processes. At the same time, this treatment imparts a specific taste and smell.

The limited temperature range (+16°C to +36°C) allows moisture to be removed slowly.

Using a gentle regimen helps preserve structure, healthy vitamins, and fat. Depending on the size of the pieces and other factors, the process may take several days. The information provided will be useful in creating a list of requirements for suitable equipment:

- It is necessary to create a sufficiently large amount of smoke to ensure rapid smoking.

- To maintain optimal temperature conditions, you need to consider a cooling system.

- The duration of the procedure forces the use of autonomous equipment that performs its functions without careful control.

- To reduce costs, consider creating a cold-smoked smokehouse with a smoke generator with your own hands.

A simple rustic way of smoking

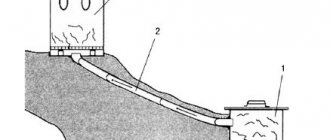

This design consists of two chambers connected to each other by a chimney. The smokehouse is located on one side, on the other side there is a stove or hearth, which is the smoke generator.

The smokehouse is made from boards - it must be completely sealed. You can use a barrel. The chamber is placed on a hill, always above the stove for good smoke movement

The chimney must be 3 to 4 meters long so that the smoke intended for smoking is cooled to a suitable temperature.

Depending on how the smokehouse will be used, there are 2 types of chimney lining:

- If the smokehouse is stationary, then the chimney is made in the form of a brick channel or a metal pipe buried in the ground.

- If the structure is assembled “in haste,” then a trench dug on a slope is perfect.

Connect the chimney to the smokehouse from below to fill it with more smoke. A filter must be placed at the connection point so that the soot is blocked and does not settle on the smoked products.

The device of a smoke generator for cold smoking, which you can make yourself

- The figure shows a chamber (1), in which products are placed on hangers for subsequent processing.

- Sawdust (3) is poured into a firebox of a suitable size, made of a sufficiently strong, heat-resistant material.

- The draft adjustment here is organized using a blower (7).

- The compressor (6) supplies fresh air through a flexible hose (5) and pipe (4).

- The container is closed on top with a lid.

- Therefore, the smoke is directed through the connecting tube (2) into the smoking chamber.

Ejector

Experts recommend using the first option. When placing the ejector at the top, you can enjoy the following advantages:

- the volume of the combustion area increases. The likelihood of solid fuel fading is reduced;

- In this option it is easier to ensure slow smoldering. Consequently, you will have to replenish your firewood supply less often;

- The upper location of the ejector with forced air supply creates sufficient thrust. Additional smoke filtration with a backfill layer will be useful;

- lower - contributes to the entry of large particles into the chimney, forcing it to increase its length to reduce the operating temperature in the smoking chamber;

- proximity to a heated area reduces the service life of the pipe and increases the risk of damage to welded joints.

Compressor for smoke generator

This connection of the compressor minimizes the thermal impact on the ejector, which extends the service life of the unit. At the same time, sufficient air flow is ensured to supply smoke to the food processing area.

Smoking chamber

The figure shows an example of a factory smoking chamber. It’s easy to guess that an old refrigerator is quite capable of performing such functions. While maintaining optimal temperature conditions, the components of its structure will not be damaged.

Typical rubber seals will perform their direct functions. Built-in guides and grids are useful for placing food items.

Modernization

The design described above is fully functional. But it has many disadvantages and is not very convenient. Based on the results of its use, modifications and improvements were made.

Adjustable traction

One of the main disadvantages of the described design is poor regulation of combustion intensity. It can be slightly changed by adjusting the compressor performance. An adjustable blower can be added to the design. It can be made according to the gate principle:

- In the lower part of the body (above the place where the stack is attached), weld a piece of round pipe 10-15 cm long.

- Drill two holes that are located exactly opposite one another.

- Take a rod that fits into these holes. Its length is 20 cm greater than the diameter of the pipe.

- Cut a circle from a sheet of metal (2-3 mm thick). Its diameter is slightly smaller than the internal diameter of the pipe.

- Make a “handle” from the rod (bend it).

- Insert a handle into the holes and weld the cut circle.

That's it, the adjustable damper is ready. Turn it, adjust the intensity of air flow, adjusting the intensity of combustion.

Ash pan

Another drawback is that ash spills through the mesh. You can place the smoke generator on a metal plate, but you can make an ash pan. By the way, the gate can be made in an ash pan. This will be more correct, since the air leak can be almost blocked, which cannot be achieved with a damper in the housing - the air enters through the mesh.

The ash pan is made from a piece of pipe with a slightly larger cross-section than the pipe on the body. If you don't have one, you'll have to cook it. The bottom is welded to a piece of pipe, and a thin strip of metal is welded to the body around the perimeter. The body is inserted into the ash pan (the legs are also welded to it).

Condensate collection

When a smoke generator for cold smoking operates, condensation occurs. This makes life difficult, especially if the temperature outside is low. You can solve the problem by making a condensate collector. For this:

- lower the exhaust pipe of the smoke generator downwards,

- at the lowest point we install a container for condensate, welding two pipes to it - one opposite the other;

- on the opposite side the pipe rises again and enters the smoking cabinet.

With this device, a significant part of the condensate ends up in the container. The problem is not so acute.

Design features of the device

In its simplest form, the design includes several parts, each of which performs its own function in the finished unit:

- Capacious tank with sawdust. There may also be a door necessary for loading fuel. Small smoke generators often do without it, and sawdust is simply loaded into them by pouring it on top. The lower part is complemented by small holes for burning sawdust.

- Duct – A small hose used to direct air inside. Traditionally, it is located in the upper part of the unit body.

- The outlet pipe is located on the opposite side of the housing. Its purpose is to direct cold smoke into the smoking chamber.

- An air blower is, in other words, a compressor.

The design with a lower ejector location is convenient primarily because it allows you to quickly replenish the supply of spent sawdust. Thanks to this, smoke can easily penetrate into the container with the food being cooked.

The solution with top ejection is notable for the fact that the product producing smoke is located at a significant distance from the area where sawdust smolders. In this design, the smoke generator for smoking is not subject to large thermal loads. The smoke is purified in the backfill, and as it passes through the main path it also cools.

For a design made according to the latter scheme, it is undesirable to use fine-grained raw materials, because it is possible to reduce the efficiency of the unit as a whole - if you use large chips, then smoke passes through it more easily.

Smoke generator stove for cold smoking

If you need to install higher productivity, cook a simple stove. It can be made from the same large-diameter pipe or a rectangular body can be welded from metal. Weld the door and make a chimney fixed at an angle. That's all the difficulties. It is also necessary to divide the internal space into two parts using a horizontally fixed metal sheet.

The lower part is larger, the upper part is smaller. A fire is lit below and sawdust is poured onto the sheet. The rest of the process is known.

A pipe is laid from the stove chimney to the smoking cabinet. It should have an upward slope, albeit a small one. In this case, the entrance to the cabinet should be located in the lower part so that the smoke envelops all the products. Therefore, the cabinet is installed on a platform, legs, or pedestal.

To save space, you can install a smoke generator stove under a cabinet by welding a structure from a metal corner.

But with this design, the smoke can be too hot. Additional measures are needed to cool it. An alternative is to find a larger diameter pipe and put it on the main chimney. Install the cooler so that the air flow is directed into the gap between the pipes.

Another option is to make something like a water jacket, receiving hot water while smoking. But where to put it is the question. Although, warm water is always useful in the household.

A smoke generator for cold smoking of this type requires more costs - metal or a thick-walled pipe, plus a chimney. Moreover, it is better not to make a chimney from galvanized steel - zinc is not a metal that is good for health. Asbestos should not be used either. Firstly, it does not remove heat well, and secondly, it is even more harmful than zinc.

Therefore, the choice in this regard is small - order pipes made of black steel or buy stainless steel. Here everyone decides for himself.

Traditional cold smoke smokehouse setup

Regardless of the type of smoking, the source of smoke is the fire. When cold smoking, the main thing is that the smoke is cold or warm, but not hot. The maximum temperature is about +40°C. To do this, the fire is lit several meters from the smoking cabinet, and a chimney pipe is laid between them. Passing along this path, the smoke cools to acceptable temperatures.

Construction of various types of smokehouses

Installing a chimney is a long process. The smoke path must ensure normal heat removal and must be sealed. To create a chimney, you can use a standard metal chimney (but not galvanized steel), but in order for the smoke to cool better, it is advisable to bury the pipe in the ground. All in all, not an easy task. This is why they prefer to make a hot smoked smokehouse - there are fewer problems - you place a barrel over the fire and smoke...

But there is a simple smoke generator for cold smoking, which will cost literally several thousand. But to work you will need a welding machine and the ability to handle it. Everything else can be bought at the market or at a hardware store. If you have all the components, you can assemble a smoke generator for smoking with your own hands in an hour or two.

Choosing the right one

In addition to understanding how a smoke generator for cold smoking works, it is important to know what technical characteristics it must meet. Here are some measures of proper quality:

- smoke generator performance;

- intensity;

- maximum automation of the smoke generator;

- simplicity;

- transportability of the smoke generator.

The first point in the characteristics of a smoke generator for smoking indicates how much raw material can be processed in the shortest period of time. The higher the performance of the smoke generator, the larger the smoke supply module and the food chamber should be.

Intensity describes how fast and how much smoke can be delivered. A certain line is important here, because with a large amount of it, it may not have time to cool to 25-30°.

The process must take place around the clock without interruption. This means that wood chips will have to be placed in the smoke generator at night. Not everyone wants to get up specifically for this, so it’s worth thinking about whether it’s possible to implement an automatic feeding system based on a timer or volume.

Installers and designers always try to achieve maximum strength and reliability of the structure while keeping it simple. It is simplicity that allows you to reduce repair and production costs. Also, such products usually last longer. This principle should be based on a smoke generator for a smokehouse. Making the device stationary is a personal decision for everyone. But there is no guarantee that the site where the smoke generator is now located will not be in demand for an economic building tomorrow.

The best smoke generator for cold smoking is considered to be one that is easy to move and install in a new location.

Deciding on materials

Wood chips and sawdust produce a lot of smoke when smoldering in the generator housing. The main task of the device is to ensure uniform combustion for a long time and direct the smoke into the cabinet with the food being prepared. At home, making a smoke generator for a smokehouse for cold smoking is not as difficult as it might seem at first glance.

To assemble the structure you will need:

- steel pipe with a rectangular or round cross-section with a diameter of 100 to 120 mm and a length of 800 to 1000 mm;

- metal pipe with a diameter of 20 to 40 mm and a length of 300 to 400 mm;

- a sleeve (can be made of pipe or plastic) 2.5 m long and with a diameter corresponding to the size of the chimney;

- small pump;

- profiled tube (with a side of about 80 mm);

- pipe fittings;

- fine metal mesh;

- thermometer for monitoring the regime inside the unit.

Obviously, the larger the smoke generator for cold smoking in terms of dimensions, the more spacious its firebox. But a large unit is difficult to refuel due to its bulkiness and heaviness. To install the finished structure, you will need legs made of metal reinforcement. They will ensure the product stability and reliability during operation.

Additionally, you will have to acquire an aquarium compressor with a rated power of up to 2 l/min. It is advisable to purchase a model with an air flow regulator.

Why do you need a smoke generator?

Cold smoking is a long process, which requires not only equipment, but also a decent supply of firewood and time to maintain. It often lasts from 2 to 7 days, and during this entire period the fire must be constantly maintained in the firebox. it just makes this job easier.

Some factory-made models can work autonomously for days without requiring any attention.

A smoke generator for smoking produces and supplies smoke to the smoking cabinet where the products are located. Pickled meat, poultry or fish come into contact with smoke, after which a whole chain of chemical reactions is activated. Thanks to them, aromatic and very tasty food is obtained.

A smoke generator for a smokehouse is an effective and at the same time structurally simple device. To make it, you can use available materials.

In the cabinet where food is smoked, nothing burns, since the temperature inside is not very high (ranging from +20 to +40 °C). This temperature is precisely a characteristic feature of cold smoking. With the hot method, the smoke temperature is much higher - about 100 degrees.

A smoke generator is a device that produces smoke cooled to room temperature for a long time, often without any supervision from the owner.

Let's look at the main mistakes

Beginners are often not satisfied with the smoking result. This is because they make a number of common mistakes:

- Incorrect salting. To prevent food from spoiling, they must be thoroughly salted. For high-quality salting, take 2-3% salt for every kilogram of meat or fish. It is better to take nitrite salt or a mixture of nitrite and table salt. This way, moisture is better removed from the products.

- Pre-drying. Salted meat contains a lot of moisture, so it should be dried before placing it in the smokehouse. Prolonged drying will result in a dry product. It is enough to keep the meat ventilated for 6-10 hours.

- Using the wrong wood chips. Using wet fuel will result in a bitter taste in smoked meats. The same effect is possible if the smoke generator operates too intensively, so its performance must be monitored.

Use without ventilation. After smoking, meat and fish should be ventilated, which will help remove the pungent odor and improve the taste. During your time in the fresh air, not only the taste will change, but also the color.

Considering these simple tips, everyone will be able to prepare stunning masterpieces that will delight even demanding gourmets with their taste, and the cost will be several times cheaper than store-bought dishes.

What can you cook with a smoke generator: Fish Pork Beef Goat meat Chicken Goose Vegetables Mutton Duck Game Eggs Salo

Hiking option

- Take an electric stove, turn it on at full power, place a metal container with fruit wood shavings on the stove.

- You will also need a metal barrel.

- The bottom of the barrel is removed (it has no bottom or lid).

- This barrel is placed above the electric stove (the electric stove stands in the place where the bottom of the container was).

- Holes are drilled in the middle of the barrel (4-6 at one level), a grate is lowered into it (the products for smoking are laid out on it), rods are inserted into the holes, they will hold the grate.

- When the tile heats up, the chips begin to smolder and smoke, and the smoking process begins.

- The barrel is not completely covered tightly with a sheet of plywood or something else.

This is a quick fix option. Such smoking will not be beneficial either for a container for wood chips or for an electric stove. But if you use this method not every day, but once or twice a season, then it is quite a worthy country option.

Industrial smoke generator for cold smoking

The figure shows the operating principle of an industrial smoke generator for cold smoking

An industrial smoke generator is more complex than a household one and is designed for continuous operation.

It consists of a wood hopper, a feeding mechanism, a heating element and other parts.

Industrial units allow you to adjust a large number of parameters:

- temperature in the smokehouse;

- humidity;

- smoke density;

- cooking time.

How it works

A smokehouse with a smoke generator, built with your own hands, is very mobile and compact. When not in use, it can be stored in a garage, basement, or even a closet. This depends on what is used as a smokehouse. You can use any metal box of suitable size for the camera. If there is no ready-made one, then you can make it yourself without any problems.

The box sizes vary, depending on the volume of product you will be smoking.

For home smoking, the optimal dimensions are 1.0 / 0.6 / 0.6 m (H / W / D). The top of the box is closed with a lid with a built-in thermometer and several small (0.3 -0.5 mm) holes to create traction. The upper part of the smokehouse in working condition should be above the smoke generator - this creates additional natural draft, and even when the fan stops, smoke will enter the chamber without delay.

Now you need to assemble everything:

- We install the generator on a fireproof base - a metal table, a concrete slab or floor, ceramic tiles. This must be done for fire safety reasons. In addition to the fact that the smoke generator gets quite hot, pieces of burning wood chips may fall out of it.

- We load approximately 0.5 - 1 liter of dry wood chips, sawdust, shavings of deciduous trees into the smoke generator (coniferous trees are not used for smoking) and close it tightly with a lid.

- We connect the compressor pipe and connect the chimney to the smoking chamber.

- We ignite the fuel through the side hole.

- Turn on the fan.

- The smoking process has begun. The tee with the fan acts as an injector. A vacuum is created in the chimney pipe, which causes smoke to be drawn in from the generator, and a rather noticeable air-smoke flow is directed towards the smoking cabinet. At the same time, an influx of air into the firebox from the outside is formed, through the side openings in the smoke generator. The combustion is self-sustaining and no human intervention is required.

Let's move on to the insides

By and large, the cold smoked smokehouse is ready. All that remains is to equip it from the inside. Depending on what types of products you are going to smoke, you should make grates to place pieces of meat or lard, and hooks to hang fish or sausages.

It would also be a good idea to make a removable tray where excess fat will drain. It will be much more convenient and easier to wash it.

If all this is done, the products are prepared, the fire starts in the firebox, and shavings or sticks from fruit trees are ready, then the cold smoked smokehouse is ready for use. All that remains is to wait for the coals to appear, add specially prepared shavings or branches to them and close them so that they smolder.

Wood burning

This smokehouse is generally constructed in the same way as the one previously described. The only difference is that a hole is cut in the bottom of the refrigerator for the pipe to enter. The latter is laid at an angle in a ditch dug in the ground to create normal traction. The soil will allow you to thoroughly cool the smoke coming out of the firebox, which is completely hidden in the pit. Its walls are constructed from refractory bricks or the previously mentioned metal containers. The distance between the hearth and the smoking chamber should be at least 2 meters.

The smoking process looks like this:

- light a fire in the firebox;

- wait for coals to form;

- a steel sheet with sawdust is placed on them;

- the firebox is closed with a lid;

- The refrigerator is filled with prepared foods.

Design Features

In order not to make mistakes in the process of making a smokehouse with your own hands from a refrigerator, you need to decide what technology you plan to use to smoke products with its help: cold or hot smoking, since the difference in technology makes some differences in the design of the device.

Also, when making a smokehouse from a refrigerator with your own hands, you need to decide: it will be used indoors or outdoors, which also makes certain differences in the design.

Connection of the smokehouse with the firebox

Having installed the smoking unit, they dig a groove to the future firebox. The combustion container is buried in the ground, and a pipe is laid along the groove to it, which is connected to the smokehouse. There should be a 15-20 cm layer of earth above the chimney to naturally cool the smoke.

Reference! Cold smoked products are safer for the body. Nutritionists do not prohibit their use, since the white smoke that is formed at a low temperature does not emit carcinogens.

Hot smoking device

There are two ways to enjoy homemade smokehouse food from the refrigerator, one of which can even be used indoors.

Smoking outdoors will require you, in addition to a refrigerator, to have a smoke generator, which can also be made from improvised materials. We recommend using an old thick-walled frying pan with a lid for this. It is necessary to make several holes in the bottom of the frying pan, and insert an armored hose from half a meter to a meter long into the lid, which, through a flange, cuts into the refrigerator chamber in the place where the compressor was previously located.

We recommend: Features of waterproofing work

At the bottom of the refrigerator, processed in exactly the same way as for preparing cold-type smoked meats, electric heaters with a power of 1000 to 1200 W (can be from an unnecessary heater) are installed, capable of maintaining a temperature of about 60-80 degrees inside a closed refrigerator.

Instead of a heating element, you can take a burner from an electric stove.

Making delicacies using the hot method is simple and quick: place the products on old shelves or hang them inside the refrigerator, pour fruit sawdust into an improvised smoke generator and place it on a constant heat source (fire, gas or electric stove), turn on the heating elements. After a few hours (depending on the product being prepared), the hot smoked delicacies are ready.

Those who often make smoked fish with their own hands recommend drying it first. For this purpose, a hole is made in the upper part of the refrigerator, onto which an old kitchen hood is installed, and a fan is placed in the chamber itself. It is recommended to dry the fish until the crust dries. If you do not plan to smoke the fish or do not consider it necessary to pre-dry it, you can skip this step.

Hot smoking

- Heating devices or devices (for example, an electric oven with various types of heating elements).

- A special container with a thick bottom and a lid for heating wood.

- Lattices and hooks for laying out and hanging edible ingredients.

- Pipe for chimney.

- Fasteners that will fix the door in the closed position.

- Tray for collecting fat.

In both cases, you cannot do without a working tool. Here we will provide a small list, based on which you can prepare for the upcoming processing. So, to successfully complete the task, you may need: screwdrivers, an angle grinder, a pry bar, a drill, metal scissors, self-tapping screws, bolts, nuts, and, of course, garbage bags.

Cold smoking

To ensure the technology of preparing dishes using this method requires:

- refrigerator (preference is given to Soviet models without plastic filling inside);

- refractory bricks for fireboxes;

- pipe 4 - 5 meters long, 100 -150 mm in diameter;

- iron firebox cover;

- grates and hooks for laying out or hanging processed products;

- corner pipe element for comfortable connection of a structure located at a slope to the surface;

- tray for collecting fat;

- exhaust fan.

To make a smokehouse from a refrigerator yourself for use in the yard, you need to decide on the installation location. The design feature depends on this. If the terrain allows, the structure is installed on a slope without additional manipulations. It is important that the refrigerator converted into a smokehouse is installed above the smoke generator (furnace). If the place is flat, then a hole is dug under the firebox, or the smoking cabinet is installed on a stand.

Contents of the refrigerator compartment

The refrigerator compartment should have racks and hanging hooks used for arranging and hanging food.

There should be a tray at the bottom into which the fat will drain. In this case, you need to make sure that it does not interfere with the flow of smoke into the chamber.

Let's consider all the components:

- Firebox. The fire pit should be in a depression. Thanks to this, the pipe will be cooled naturally by the earth, which will protect it from excessive heating and will quickly cool the smoke moving through the pipe.

Please note: the firebox does not require pouring a foundation. It will be enough to lay bricks or a sheet of steel on the bottom.

For hot smoking, the firebox must be placed as close to the chamber as possible.

Good to know: during hot smoking, sawdust is placed on the bottom of the chamber, preferably fruit sawdust, which provides a pleasant aroma of the product.

- Chimney pipe. The pipe is removed from the pit and must be connected to the chamber. The connection point is where the compressor used to be, the location of which depends on the model of the refrigerator. The chimney can be secured with fittings or cut into the lower part of the refrigerator body. The second case is more effective, since the smoke comes from below and saturates all the products as much as possible.

- Location. It is recommended to install a smokehouse from a refrigerator, regardless of the type of smoking, at a difference of 0.5 m, i.e. the chamber should be higher and the firebox slightly lower. This will ensure that smoke quickly rises and enters the chamber from the fireplace.

Some tips for use

If you need to smoke a small amount of food, it is better to place it on the bottom shelf of the refrigerator. In this case, a reflector (any piece of tin) is attached to the top, speeding up the cooking process, which can significantly save wood chips.

To give the smokehouse an aesthetic appearance, you can remove the back wall of the refrigerator and replace it with heat-resistant glass. Through it you can observe the process. You can also run a wire with a thermocouple into the rear compartment, covered with a shield, which will allow you to regulate the temperature during smoking.

Our step-by-step instructions, drawings and recommendations will help you make a smokehouse with a smoke generator. This cabinet made from a walk-in refrigerator looks very stylish and original.

To summarize, it is obvious that making a captilla for personal use is very simple. It is not necessary to spend large sums of money on a ready-made device - just apply a little imagination to the old units at hand.

Homemade products are always the most delicious. And preparing smoked delicacies is an excellent reason to get together with a group and get out of town at any time of the year. An undeniable advantage is also that during the assembly of the smokehouse it will be possible to free up space from unnecessary old equipment, giving it a second chance at life.