Lathe - what is it, and is it possible to make it yourself?

This device allows you to make various products and blanks at home - sticks, barrels, cylinders. They can be used in repair or construction. Often such elements are used to create decorative products. They can also be used in modeling.

Purchasing a large lathe is not always necessary. It has a high price and large sizes. Making a wood lathe with your own hands from a drill is simple and accessible.

The principle of operation of such a device is simple. To begin with, the workpiece is cut into the headstock chuck. In this case, the tailstock fixes the product along its length. Then you need to install the tool rest, turn on the drill and start turning the part.

Choosing an Electric Motor for Woodworking Operations

An equally important element of the machine is the engine. The main characteristic that needs to be given enough attention is power. Regardless of the type of motor - single-phase or three-phase, the power can range from 1200 to 2000 W.

Perfectly suited engines:

From a washing machine, if a lathe is needed for small-volume work and the size of the workpiece will not exceed 30–40 cm, in this case the exact maximum length is selected experimentally. Such engines can help in processing small items, dishes, small knobs for stairs and similar interior elements.

Some models of washing machines are equipped with an asynchronous electric motor, in which, by changing the winding, you can step by step change the shaft rotation speed. Similar motors are also installed in floor fans, only there they have a lower power of about 40–100 W. This motor is enough for a mini-machine for small household products.

The motor from a washing machine produces about 300–500 W, which is more than enough for the average needs of a wood turner. Motors in washing machines are much better suited for turning operations, since the bearing assemblies in the drive itself are designed to withstand high shaft fracture loads. This will make it possible to process trunks with a slight deviation from the cylindrical shape.

Device

Any lathe includes a certain set of components that should be in a home device.

bed

This node represents the base. It ensures reliable fixation of the elements and their correct placement. The stand also makes the device stable.

Headstock

This part of the device fixes and rotates the workpiece secured in the chuck.

For reference! On small homemade devices it moves along the guide elements of the frame.

Tailstock

It is a moving part that fixes and presses the workpiece to the chuck. This is carried out during processing in centers. This element must have perfect alignment with the spindle assembly.

Caliper

On small machines, the support function should be performed by a tool rest. It is important that it moves along the guides of the frame and is well secured in the working position. On small machines, this fragment serves as a stop for the cutters.

When manufacturing a device, it is important to consider its design

Additional equipment of the machine

Additional attachments will allow you to use the machine for drilling holes at an angle and perform simple turning and milling technological operations.

To perform milling work on this equipment, it is necessary to ensure horizontal movement of the workpiece, for which a movable horizontal table with a vice is used to fix the workpiece. The best drive for this table will be a screw gear, which is driven by a handle.

Using a homemade drilling machine, where the role of the working head is played by a hand drill, holes are drilled at an angle if the machine is equipped with a rotating plate with holes in an arc. On this plate, capable of rotating on an axis, which is fixed to the machine stand, there is a carriage and a drill. The holes on the rotary plate are made at angles of 30°, 45° and 60°. The procedure for manufacturing the mechanism:

- A hole for the axis is drilled in the center of the machine stand and the rotating plate.

- Using a protractor, the axes of the holes located at the most common angles are marked on the rotary plate, and the holes are drilled.

- Using the axial holes on the post and plate, these two elements are combined and secured with bolts.

- Three holes are drilled on the stand to secure the rotating plate with pins.

The rotating plate is rotated to the desired angle with the tool attached to it and is fixed with three pins connecting the fixed and rotating parts of the stand.

Machines with a rotary plate can also be used to perform simple turning work. For these operations, the drill is positioned horizontally using a rotary plate.

Selecting materials to create a device

To make the device you will need:

- Electric drill - performs drive functions. It must be fixed to the wall of the front support.

- The support should preferably be made from boards and beams. The best option would be a product in the shape of the letter T.

- Supports - they are made of metal corners or beams. The materials used affect the strength and reliability of the machine.

- Bed - can be made of steel. This will make the tool more reliable.

How to check the quality of sharpening

There are five ways to determine the sharpening quality of a device:

- Finger check. Carefully run your finger across the blade and feel the tip of the blade.

- Slicing a tomato. Place the tomato on a cutting board and cut into slices. Use a sharp knife to thinly slice the vegetable.

- Using the nail. Place the blade on the nail plate and draw it across the direction of growth. Do not press, but use the weight of the product. The nail apparatus is a sensitive organ. Irregularities and errors are determined accurately. A dull blade will slip off the surface.

- Shave your hair. With a sharp knife you can cleanly shave your beard and remove stubble. The worse the result, the duller the knife. A similar test is to try cutting the hair. It is difficult to do this with an insufficiently sharpened tool.

- Paper test. Cut a sheet of writing paper into strips. Keep the sheet suspended. A well-sharpened knife will cut off the border near the very edge.

Options for homemade machines

To make a lathe, it is recommended to perform a number of actions:

- Attach elements that will regulate the interval from the table to the chuck. You can use boards for this.

- Make a back support from wooden beams. In their design, it is important to provide a screw that can be adjusted.

- Make a tool rest from wooden blocks. You need to attach a rail to it. Its length must coincide with the interval between the supports.

- Provide a button that will put the device into operation. To do this, you need to transfer the contacts to a new button or block the regular press. In the second case, the device will start when the plug is plugged into the socket.

There are also various types of device modifications:

- The base can be a beam or a metal structure.

- To secure the drill, you can use 3 pieces of plywood in the shape of the letter P.

- If you have a welding machine, you can make the tailstock yourself. This will require several nuts, bolts, and bearings. You also need to take sheet steel and short pipe fragments.

Sharpening knives with a drill

Craftsmen have adapted to using an electric drill to care for cutting tools. To solve the problem, use the following as an attachment for a drill for sharpening knives:

- circle - Velcro;

- sandpaper.

These are budget options. Every owner keeps electric drills in the house. For work you need to buy only abrasive material.

Circle - Velcro

The material of the nozzle is super-hard, durable, wear-resistant mineral corundum. The name used is “electrocorundum” - “emery” stone.

An inexpensive attachment for a drill makes the tool universal. In addition to drilling and screwing screws, it will be possible to grind, polish and, of course, put the knives in order.

Sequence of work:

- insert the nozzle into the drill,

- place the tool between the circles,

- turn on the drill at minimum speed.

Special attachment for drill for sharpening knives.

Sandpaper

Glue a strip of sandpaper with double-sided tape around the circumference of the cartridge. For sharpening, 3 cm of abrasive with an average grain size of 80-120 is suitable. We sharpen the knife at an angle to the rotating work surface.

The main thing is that the direction of rotation is towards the pointed edge.

Safety precautions

To get the desired result, you need to:

- keep the sharpening angle constant;

- Follow the drill manufacturer's recommendations.

The steel softens due to heat upon contact with the grinding surface. This degrades the quality of the blade. Therefore, water is periodically used for cooling.

When dry sharpening, the following rules apply:

- They removed the layer of metal and raised the knife.

- The side to be sharpened is directed along the circle.

- Do not allow the blade to heat up above the sensitivity threshold of the skin of the fingers.

Additional materials

When using a drill as a sharpening tool, it is advisable to prepare auxiliary items in advance.

- To secure the drill to the table while working, you will need a vice or clamp.

- To glue the sandpaper to the cartridge, use a glue gun and glue sticks.

Practical examples of a homemade lathe

To make a simple machine, it is important to ensure the alignment of the drill shaft with the support tip. It can be placed on a frame made of durable plywood. It is not necessary to use a spindle. It is quite acceptable to clamp thin workpieces in a drill chuck. For larger items, you can make a special washer plan. The drill itself is supported by a special bracket. This helps prevent vibrations.

The stop for the incisors must be movable horizontally and vertically. The tailstock is not vertically adjustable. In this case, horizontal fine adjustment is carried out using a screw.

Note! The main advantage of this design is the ability to use the drill for its intended purpose. To do this, it needs to be dismantled.

Recommendations for making your own case

When creating home machine tools, the main emphasis is on creating a solid foundation - a housing or stand. For these purposes, an ordinary board or sheet of thick plywood is often used. It is necessary to drill a round slot in the rack to install the body of the electric drill.

The hole size must exactly match the size of the power tool.

It is necessary to provide for the installation of a tightening bolt on the machine body. After making the slot, a small recess is sawed in the form of a 2 mm groove.

The housing stand is secured to the fixed frame with a metal angle. The drill is placed in the finished slot and secured with a clamping screw.

A metal reinforcing bar with a cone-shaped part on one side serves as a blank for the central part of the headstock. At the end of the rod, before the beginning of the tapering part, a thread is cut for an M8 nut.

Tailstock design

The wooden blank of the tailstock part must match the contour of the front stock in shape. And to secure the middle, a steel blank with a sleeve is used, which has an internal thread M 14 x 1.5. You also need to remember to install the M 8 locking bolt. Along the edges of the bushing, you need to cut an M 24 x 3 thread to screw in the nut holding the bushing.

The components of the cutting stop are assembled from rolled steel. The bracket is made from a metal sheet strip measuring 6 x 10 mm. The size of the cylindrical mandrel in diameter is 15 mm; the edges of the bracket are welded to the pipe using electric arc welding. A stop is attached to the stand, like a corner. The assembled mechanism is connected to the workbench with a bolted connection. To install the bolt, a special nut with a wide side is provided, which is attached to the bottom cover of the workbench with screws.

Installing a work piece

Before you begin processing the parts, the wooden workpiece should be thoroughly dried and ground 3 mm on one side for better processing. Two recesses are made at both ends of the workpiece to install the nut. The workpiece is placed between the middle parts of the headstocks and firmly fixed with a stopper.

After installing the workpiece, the cutting stop is moved to a distance of no more than 20 mm from the installed part.

The working plane of the cutter is located at the height mark of the central part of the workpiece.

Is it possible to make this on metal?

To make such a device, you need to take into account that the power of the electric drill will be small. In addition, the lathe is made exclusively of metal. In any case, it can only be used on soft materials such as copper, aluminum or bronze.

Important! Instead of a drill, you need to use a powerful and professional tool. Household devices break down too quickly.

The metal cutting machine must be more powerful

Other sharpening methods

There are many ways to sharpen a knife. A sharpening stone, a metal rod and all kinds of electrical means are used.

Special devices

An electric sharpener is not cheap. But even a housewife can use the device. Sharpening is quick and effortless. The developers have provided various nuances. Therefore, operating the device does not require much experience and knowledge.

An electric sharpener will do the job like a professional. By changing special abrasive belts during processing, a sharpened, polished blade surface is obtained.

Sharpening with a drill.

Manual method

For the manual method use:

- whetstone;

- sandpaper;

- Musat.

The blade is moved along the surface of the sharpening stone, alternately changing sides. This is a labor-intensive process. To achieve the desired result, it will take 30 minutes of work. After finishing the work, the stone is washed with a soapy solution and sand.

Musat is a corrugated round metal rod. The tool is used for straightening or finishing the cutting surface.

Sharpening stones.

Rules of care and use

In order for the device to serve as long as possible, it is necessary to provide it with high-quality care. To do this you need to do the following:

- promptly remove waste that gets on the device during operation;

- keep the machine in a dry place, since wooden elements may be damaged by moisture, and metal elements may become rusty;

- promptly change parts when they fail - this must be done before starting the next work.

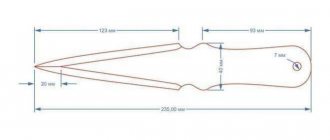

Making a lathe from a drill is not difficult. To get a high-quality and reliable design, you need to think through all its components and prepare drawings indicating dimensions.