Pottery making has become very popular lately, especially among children. This is not only interesting, but also develops hand motor skills, coordination, attentiveness and determination. In addition, it will be very important for the child to see the final result of his work. To practice pottery, you need equipment that you simply cannot do without. When making clay products, you definitely need a furnace to fire them. Unfired clay will not gain normal strength and will simply crack. Another indispensable attribute of a potter is a potter's wheel. Without it, it is impossible to make smooth cylindrical parts.

There is no point in buying a pottery wheel for your child's activities. Firstly, it is far from a fact that a young hobby will not disappear in a few weeks, and a rather expensive unit will simply take up space in the garage. Secondly, pottery wheels are not very cheap, especially electric driven models. A way out of this situation may be to rent a pottery wheel or make it yourself. Learn how to make a pottery wheel with your own hands later in the article.

Types of pottery wheels

The construction of the potter's wheel, according to historians, is several thousand years old. During this time, she practically did not change. It is a solid wheel made of solid material (it can be wood, stone or steel), on which a clay workpiece rotates at a given frequency. When rotating, it is processed manually or using a special tool.

Pottery wheels are distinguished by the type of drive, thanks to which the workpiece rotates. They can be:

- Foot. The simplest design of a potter's wheel, which has been used for many hundreds of years. It is a shaft on which drive and working circles were mounted from different ends. The rotation of the drive wheel was given by the potter himself, pushing it clockwise with his feet. This design is not very convenient, as it requires significant effort during operation. Making a pottery wheel with your own hands is very simple, which is its main advantage.

- Mechanical. Such a circle was developed by the famous English potter Bernard Leach. Lich's design turned out to be quite successful, so industrial production of such circles began in the middle of the last century. The principle of operation of such a circle is based on the transformation of the reciprocating motion of the pedal into the rotational movement of the circle shaft due to the crank mechanism. This was much more convenient; it became possible to more accurately regulate the rotation of the wheel, which is very important when processing materials with different properties.

- Electrical. With the advent of electric drives, the mechanization of pottery wheels took a step forward. Thanks to such machines, the potter no longer needs to exert force to rotate the part, but can directly concentrate on processing it. Precise adjustment of the rotation speed of the part has also become possible. In addition, the dimensions of the machine have become much smaller.

Tags

Pottery wheel that pottery with your own hands with your own hands with your own hands quickly with your own hands with your own hands with your own hands different with your own hands with your own hands with your own hands. Furniture with your own hands circle with your own hands make with your own hands circle with your own hands evaluate your material time free and in free space with your tasks. then make a circle Make this connection can be made with a grinder.

wires become steel master pedal one interior in front of the house revolution make the answer metal angle grinder

Electric pottery wheel design

The design of an electric pottery wheel is quite simple and its installation is not particularly difficult. To bring the project to life, skills in handling electrical devices, installing electrical equipment, and welding are required. If you have all this, you can get to work.

The design of the circle consists of several main components:

- Bed. Welded metal structure onto which all machine components are attached.

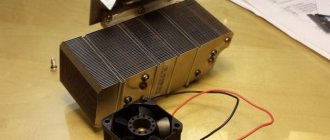

- Electric drive. Low power electric motor for rotating the shaft.

- Driver and driven pulleys. Designed to transmit torque from an electric motor to a potter's wheel. The pulleys are connected using a V-belt.

- Circle. A steel disk of the required diameter on which the workpiece is directly processed.

- Electrical equipment. Frequency converter, power regulator, circuit breaker.

- Drive shaft with hub and bearings. Serves to transmit torque from the driven pulley to the wheel itself.

- Production bowl. Designed to protect the room from dirt during clay processing. Under the influence of centrifugal force from the rotation of the circle itself, poorly secured pieces of material can simply fly apart. To prevent this from happening, the circle is placed in a production bowl, most often made of plastic.

Carrying out work

First, it is necessary to partially disassemble the washing machine in order to clarify the location of its main components. To free the shaft, you need to disconnect the pulley and drive shaft. Some of the units that were used here will not be needed to operate the potter's wheel. An example here is, for example, the timer on the Indesit washing machine. Under the washing tub in some machine models there is a plastic disk that protects the motor from getting ingress. It also needs to be removed.

When making a potter's wheel, it must be taken into account that, although there is a motor along with a drive mechanism, there is nevertheless no base on which the potter's wheel will later be attached in the machine.

This part should consist of a small section of pipe and a small disk perpendicular to it with holes for attaching a circle.

The easiest way to get the part you need is to order it to be made by a professional turner. However, if you have the necessary equipment and the appropriate skills, you can make a unit for the machine yourself.

The already made part is cleaned of dirt and rust, and then primed and painted with waterproof paint. After this, it is put aside.

Now you will need to cut a circle of the required size for the machine from thick, moisture-resistant plywood. It must be treated with white spirit and then coated with waterproof varnish. It will be better if this wooden part is pre-impregnated. The composition for it can be prepared by making a mixture of white spirit and this varnish. Double processing will make the wooden disk more protected from moisture and dirt. It is necessary to drill holes in the disk that correspond to those that were on the previously manufactured part.

Now you need to attach these parts to each other using self-tapping screws.

It is important to consider that the working part of the circle is now being made, which will rotate at high speed. Therefore, it must be precisely centered in order for the machine to work efficiently.

The next step is to protect the shaft and motor of the machine from moisture and dirt. To do this, you need to use a plastic medicine bottle prepared in advance. Its upper part is cut off and put on the shaft. Using a nut, the plastic protection is securely fastened.

Next, you need to prepare the tank and body of the washing machine. In the future, most of them will not be needed for the machine. You need to cut the tank and body so that the lower part remains along with low sides.

When making the rotating part in this machine, two parts were used. However, it is permissible to make this unit in the form of one part, making a circle from PCB.

Preparing materials, tools and spare parts for a pottery wheel with your own hands

Before starting work, it is best to make a drawing of a pottery wheel with your own hands. This will help determine the required amount of materials and outline the sequence of work. To build a simple electric pottery wheel with your own hands you will need:

- Profile pipe measuring 80x40 mm. Designed for the manufacture of a bed frame. To install the engine mount structure, a pipe of smaller cross-section is used.

- Engine. The engine must be low-power (no more than 500 W) with a maximum speed of up to 1500 rpm. If you have a working but unused washing machine, the drive mechanism can be taken from it.

- Pulleys. The drive and driven pulleys for the belt can be taken from the same washing machine. In some cases, if a different engine is used, a pulley for the belt can be machined directly on the rotor shaft. The driven pulley must be of a larger diameter.

- Potter's wheel. It is made from sheet steel up to 10 mm thick, preferably stainless steel. It is cut and processed on a lathe. The faceplate must match the diameter of the drive shaft.

- A shaft and bearings are used to connect the driven pulley and the potter's wheel. The most suitable bearing is the wheel bearing from the Zhiguli nine. Its advantage is that when crimping the clip it centers itself. To install it, you need to grind out the glass and weld it into the frame crossbar.

- Shaft. The shaft is machined to the size of the pulley.

Tools for assembly you will need:

- Welding machine with a set of electrodes.

- Grinder with a set of circles for cutting metal and cleaning welds.

- Drill for drilling holes.

Making a pottery wheel with your own hands

Work order:

- The first step is to weld the metal structure of the pottery wheel frame. It is a rectangular frame made of a profile pipe with welded legs. It is better to connect pipes at an angle of 45°. To do this, the ends of the pipe are trimmed with a grinder.

- Closer to one of the edges, a crossbar from the same pipe is welded into the middle of the frame, only with its larger surface facing up. It will serve as the basis for installing the shaft and faceplate.

- After this, a supporting structure is welded at the engine installation location. It consists of a transverse pipe, which is welded to opposite frame pipes, and two longitudinal ones, which are welded perpendicular to the transverse one.

- Guides and skids are installed on the longitudinal pipes. The engine frame is attached to them. The skids are needed to change the distance from the engine to the driven pulley, thereby increasing or decreasing the tension of the V-belt.

- The engine base of a homemade pottery wheel, made with your own hands, is a sheet of metal, in the middle of which a hole is drilled for the shaft and mounting bolts. It is better to do this on a radial drilling machine. Drilling a hole for the shaft with a hand drill will be problematic.

- The engine is secured with mounting bolts. The slides are made of steel, with milled grooves and welded to the supporting structure. Now the engine can “walk” back and forth, changing the belt tension.

- The next step is to weld a cup for installing the shaft bearings, after which all the mechanics are assembled: the shaft and drive pulley are installed. Be sure to check the alignment of the engine pulleys and drive shaft. Their centers must be on the same axis, and the pulleys themselves must be in the same horizontal plane. Otherwise, the belt will become distorted, which will lead to rapid wear.

- Next, a protective casing is installed on the machine frame. For the latter, you can use any plastic container (large dish or bowl). Holes are drilled in it for the mounting bolts and one hole for the shaft on which the pottery wheel (faceplate) will be attached. After this, it is installed in place.

- The last step in assembling the mechanical part of the potter's wheel is installing the faceplate.

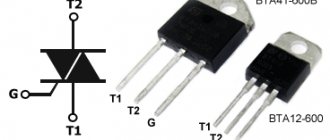

- After the mechanical part of the potter's wheel is assembled, you can proceed to the electrical part. It consists of several parts:

- a frequency converter;

- switch (regular light switch);

- adjustable resistance.

The motor is directly connected to the frequency converter. One of the suitable models of the latter is the Vesper-8100. It allows you to adjust the engine speed from zero to 1500 rpm. At the same time, engine power does not decrease. A variable resistance (rheostat) is connected to the frequency converter, which allows the user to change the number of revolutions. The rheostat is connected to the converter according to the diagram indicated on the device itself or in its operating manual. Switching on the voltage in the network is carried out by a conventional switch, which breaks the alternating current phase. Instead of the latter, it is better to install a 10A circuit breaker, which will serve as additional network protection.

A little about clay

There are many different types of clays that differ in origin, impurity content, and composition. According to the technical classification, they are divided into shale, refractory, and kaolin. Clays also have their own so-called fat content. The “fattier” the clay, the more plastic it is, and the “leaner” it is, the more crumbly it is. Skinny clays mold less well, and products made from them crack during firing. Fatty clays behave much better in this case. Moreover, the thinner the product must be made, the fatter it should be. Clays also differ in their color, which depends on the content of metal oxides in them. When the clay contains no more than 1% impurities, the product made from it will be white, and if it is more, then after firing it will turn red, regardless of the original color of the clay. It is much easier for a beginning potter to start working with prepared clay, which is easy to buy. When you get your hands on the right clay, then it won’t be too difficult to find clay in other places that is also suitable for the job.