Home / Devices

Back

Reading time: 3 min

0

1732

Equipment for welding work of inverter or transformer type is necessarily present among the home equipment of specialists in this profile. Welding units have long been no longer an attribute of the pros.

Anyone interested can purchase it and do small home welding tasks. Welding equipment is easy to use.

There is no need to study welding for a long time in order to weld what is required at home. Turning on the welding machine is generally easier than ever. Find a suitable electrical outlet. Turn on the welding cord.

- Introductory information

- Is it possible to cook using a car battery?

- Own experience of cooking from a car battery

- Is it worth welding from a machine battery?

- Safety regulations

- Summary

general information

Many welding inverters, whether domestic or professional, can be equipped with a built-in start-up charging function. A typical example of such a device is Caliber SVIZ 200AP.

This and similar devices are considered start-charging devices, since you can connect any battery to it and charge and/or start it. An inverter with a starting-charging function is a welding machine, a starting device for a car, and a battery charger in one housing. Comfortable? Still would!

Using such a device, you can start a car engine in cold weather, recharge a car battery and other types of batteries. In any difficult situation, you can solve many everyday problems with your own hands.

Therefore, we answer the most popular question: “Is it possible to charge a battery with an inverter welding machine?” Answer: yes! But only if the device is equipped with this function.

Is it worth cooking from a battery?

Welding from car batteries is possible, but we do not recommend using this method on an ongoing basis. The only advantage of this method is the possibility of welding in the field. But there are several times more disadvantages.

The most important drawback is the almost uncontrollable current with which welding is carried out from the battery. The batteries themselves tend to increase the initial current value, and you will never know the exact values. This is inconvenient and leads to frequent defects that you cannot even prevent.

Also, due to uncontrolled current, the device may simply burn out. Our inverter survived, but if you use it ineptly, you will lose both three batteries and a welding machine. At the same time, be prepared for a large overconsumption of electrodes. When welding from batteries, you can waste a whole pack of rods when manual arc welding.

In addition, it is better not to install the battery used in this case in the car. The likelihood of problems is small, but it still exists.

Is it all worth it? Yes, if you have no way to power the device at all, but it is very necessary. But in other situations, it is better to simply buy a fuel-powered generator and use it to power the welder. In addition, you can also power other power tools, which is very convenient.

Peculiarities

Charging any battery with an inverter welding machine requires compliance with certain rules and knowledge of the features. We will list the main nuances that you should pay attention to.

First, about the batteries themselves, in particular car batteries, since they are most often charged using such inverters. During operation, the battery loses its properties, as a result, the capacitive characteristics decrease. And if you add subzero temperatures to this, the battery will “sit down” at a catastrophic rate. Because of this, you simply will not be able to start your car normally. What are the ways to solve this problem? The battery can be connected to the battery of another car or started “from a pusher”.

But these methods are ineffective and often do not work when “revitalizing” a modern foreign car. In such situations, an inverter with a built-in charger start-up function comes to the rescue. Of course, you can buy a separate unit designed exclusively for charging. But the inverter is more functional in everyday life. They can both recharge the battery and perform welding.

Application

Please note that for these purposes you need to use only a special welding inverter with a start-charging function. An ordinary inverter machine is not suitable for these purposes. It is simply not designed for this. A device with a start-charging function is capable of reducing the output voltage to the required 12 or 24 Volt battery. But a regular inverter will simply output 50 Volts and your battery will burn out.

A welding inverter with a charging function must be switched to this mode before carrying out work. By default, it does not perform the charging function. Set the voltage you need (12 or 24 Volts, depending on the battery). Also setting Amps. We recommend using a ratio of 1 to 20 relative to the power of the battery itself. So, when setting 3 Amps, you can charge a battery with a capacity of 60 Amps.

The battery needs to be charged for no more than an hour, ideally no more than 40 minutes. This is usually more than enough to start any internal combustion engine. But if you need to fully charge the battery from scratch, then charge for 2.5-3 hours, while reducing the current. If your battery is 60 Amp, then set no more than 1.5-2 Amp on the device.

How to make a starting charger for a car with your own hands? Reasonable savings

How to make a starting charger for a car with your own hands

It will be useful for all drivers to know, since it does not contain scarce parts. It is quite easy to assemble it yourself if you have the necessary parts and experience in repairing electronic equipment. Such a device is also useful because, in addition to helping to start the engine, it can be used to recharge a dead battery.

What is the difference between a charger and a jump starter?

Today, several types of such devices are produced, among them the following products can be distinguished:

- Devices for battery charging only;

- Engine starting devices;

- Combined products for charging and starting the engine.

Let's take a quick look at their design features. Products of the first type can be transformer or pulse. Charging is possible with constant or pulsed currents. Launch-only devices have large overall dimensions and weight.

For the most part, they are made on the basis of welding machines, by isolating an additional output that provides 15-16 volts. And finally, combined devices that can recharge the battery and, if necessary, start the engine.

How to choose a circuit for such a device?

To assemble such a device, you need to have at least a little experience in handling measuring instruments and a soldering iron. Be able to understand radio circuits and setup of radio-electronic products. If all this is available, you can begin to select a circuit diagram and complete the necessary radio components. There are few of them and they do not belong to the category of scarce ones.

If such work is being done for the first time, you should choose a not very complex circuit for the starting charger, and in the future, as you gain experience, you can move on to the manufacture of more complex and reliable devices. You can choose a suitable scheme on the Internet, as well as in many printed publications. You just need to take into account the fact that the starter consumes a current of approximately 200 Amps, so if the device has an ammeter, it is necessary to ensure that it is turned off when trying to start the engine.

Features of its manufacture

Before starting work, you need to prepare tools and components. You may need the following components:

- An electric soldering iron with a power of approximately 100 watts;

- Soldering acid and solder;

- PCB plate for mounting the device;

- Transformer with a power of 1500 Watt;

- Cooling fan, suitable for computer;

- Powerful diodes with current from 100 Amperes;

- Electric drill and set of drills;

- Wire for connecting to a 220 Volt network;

- Cable for connecting to the battery, its cross-section must be at least 10 mm2;

- Cable products for windings;

- Clamps for this cable, preferably quick-release;

- A set of bolts and nuts for fastening mounted parts.

How to weld using a battery

It should be within 200 - 280 mA. If necessary, it is adjusted by selecting turns. The transformer should be run for a while to check how hot it is. If heating does not occur, wind the secondary winding. Before this, the core is also carefully insulated.

For the secondary winding, you need a wire with a cross-section of 10 mm2, the number of turns is from approximately 15 to 20, it is selected experimentally so that the output voltage is approximately 16 Volts. Power diodes must be installed on radiators to cool them. All parts are mounted on a PCB plate. A fan for cooling, as well as measuring instruments, are installed in the finished case.

We tried to answer your question about how to make a starting charger for a car with your own hands. The simplest circuit of such a device is considered, however, when using it, certain rules must be followed so as not to prematurely damage the battery or radio-electronic products installed in the car.

Safety regulations

In appearance, the car battery is absolutely safe. All its parts are inside a strong case. This impression is deceptive.

You should not be negligent about the safety rules when using car batteries. Moreover, when ensuring the operation of the welding inverter.

If you want to remove the battery from the car, move it or perform any actions, use special gloves. The most correct and safe option is also special clothing for these purposes.

But if this is an unplanned event, you are unlikely to follow her. Therefore, we will limit ourselves to thick gloves.

If electrolyte has dripped onto an open area of your body, you should immediately rinse the area. This area can be treated with a solution of soda or ammonia diluted with water.

Remove gloves and wash your hands well with soap. Don't eat near batteries, don't smoke, and generally be careful. If you are tired and need to take a break, place the car batteries in an isolated room and you should go out.

If your car batteries become dusty, they need to be cleaned. This is done using ammonia diluted with water. Use a clean, dry cloth.

If you have removed the batteries from your car, clean the plugs to ensure there is no dirt left behind. To prevent the formation of excessive gas pressure.

Remember that car batteries can become a threat to your health. When working with your car's battery, take good care of your body and mucous membranes from damage by acid.

You may get a serious burn. You should definitely have a fire extinguisher in your garage. If handled incorrectly, problems can also occur with welding equipment.

These are absolutely simple safety rules. But not all masters remember this when they start working with devices. Remember that it is better to prevent problems from arising than to eliminate the consequences later.

Welding with battery electrodes

I have heard about welding from car batteries for a long time, and there are also videos on YouTube confirming this. And in principle, I had no doubt about this because the characteristics of the batteries allow this to be done. Firstly, there is a large current, up to 600A from a 55Ah battery, and with a battery of larger capacity there is an even greater maximum current, so even a large excess of current is obtained rather than a lack of it. But in general, a year ago I needed to weld a motorcycle frame and a side trailer for it, but there was nowhere to connect a welding inverter at the dacha.

At my dacha I have my own electricity, a small solar power plant is installed, and there is a 12-220 volt converter installed there with a maximum power of only 1 kW, and naturally it will not handle welding. But at that time I had four batteries in my power station, two of 65Ah each, and two more of 90Ah each, so I decided to see for myself that it was possible to cook from a battery. In general, I brought two batteries to the welding site and connected the battery in series at 24 volts. The electrodes were 2.5 mm in diameter.

Let me say that I managed to brew it, and quite well.

, but most likely there was not enough voltage because

the arc ignited very poorly

and good penetration was not achieved, since the arc barely burned and often simply went out. But what surprised me was that if the electrode gets stuck, it heats up to red in a second and melts. I haven’t observed this with conventional welding, but here you have to be more careful, the electrodes burn out in one fell swoop when they stick.

Just recently, at the beginning of February (2016), I needed welding again, but I already had three 90Ah batteries. I was making a frame for a wind generator. With three batteries connected in series

The welding turned out to be excellent and with a lot of current.

Introductory information

In theory, everything seems much simpler. But in application, certain conditions must be met. The current in the electrical network must remain uninterrupted and not fall below 180 Volts.

Or your welding unit must cope with low voltage work. Such equipment is not cheap.

It is not even discussed that you must have access to electricity. But some country houses and dachas, garages located far from the urban area are not connected to electricity.

What to do in this case. Our opinion comes down to buying a fuel generator for welding. But not everyone wants to spend extra money, especially if you rarely use welding.

The correct option under such circumstances is to use a 12-volt car battery. Some specialists manage to connect the battery to a welding inverter.

Even to carry out non-long-term welding. In our review we will write whether it is possible to carry out welding tasks using a 12 Volt battery. Is it really necessary to take such risks?

How to make a welding machine from a car battery

I started welding with 2 mm electrodes, and at first I even burned a few holes in the metal because the current was too high. Then I welded with 2.5 mm electrodes, but the current was still too high and I had to cook very carefully so as not to burn through the thin 3 mm metal. I even cut such metal freely with electrodes. Then I didn’t have any other electrodes, but I think 4 mm electrodes would have gone freely under such a current. Overall it cooks great

except that the current is too high, which there is nothing to limit. But you get used to it, and it’s quite normal to brew something even serious.

But it’s better not to deeply discharge the batteries, otherwise they will deteriorate quickly, but the high current will do them no good. I will say that from three 90Ah batteries you can easily burn 15-20 electrodes each and the batteries do not discharge much, and such a number of electrodes is already decent.

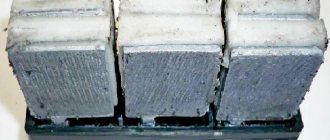

Below are some photos of batteries and welding

This is what the batteries themselves look like when they are connected in series; my welding wires are 35 kW.

These are actually 2 mm electrodes

Electrodes 2.5 mm

In this photo you can see the penetration from the back side, I didn’t specifically photograph the welding process itself, so I didn’t capture the welding quality specifically, but overall it cooks well.

And here is the result of the welding, the frame for the wind generator is welded.

If anyone is interested in the wind generator itself and welding, I wrote an article about making a wind generator and there is a video there where you can see what I did and how I welded it. That's all, if there is anything new I will write in the following articles.

E-VETEROK.RU wind and solar energy - 2013 Email: [email protected] Google+

Pure Sinus Perm:

Nice channel, just beautiful.

Pure Sinus Perm:

Well done, make more videos like this about three-phase power supply. Make a video about chickens and how many eggs they lay.

isak nyton:

Well, what did you film, you didn’t even show the trans

Anatoly Anatolyevich:

Well done

Types of memory

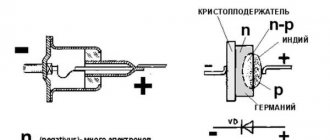

The most common types of batteries:

Most cars use WET batteries . These are lead-acid containers filled with liquid electrolyte. They require an aqueous solution of H2SO4 to function. The properties of the battery allow it to be used with any charger, regardless of its technical characteristics.

In AGM, GEL, sulfuric acid is used as an electrolyte in different states. These car batteries are more sensitive to changes in current levels and overcharging. To restore capacity, you will need to purchase specialized memory devices.

When choosing a charger, it is important to study the technical capabilities and battery parameters . One of the indicators you need to pay attention to is voltage. Passenger cars typically use batteries with a nominal voltage of 12 V. For trucks, the figure can reach 24 V.

Classification of memory

- Chargers. When charging the battery, do not turn on the engine.

- Launchers. Used to start engines up to 7 liters in volume. They are lightweight, can operate at low temperatures, and can be charged from a cigarette lighter.

Assembling a 12 volt welding machine

As an electrode for welding, we use a graphite rod from a AA battery, having previously disassembled it. Be careful not to cut your hands on the edges of the battery case. Also try to keep the rod intact.

DIY electronics in a Chinese store.

Attach a piece of welding cable to the battery terminals. On batteries with low capacity, it is better to use short wires to reduce resistance. It is optimal to use lengths of 40-60 cm. On batteries 60, 75 Ah, you can use a long cable. A terminal is placed on the other end of the positive cable. A graphite rod from a battery is attached to it. It needs to be held tightly to make reliable contact.

The negative wire must be attached to the part for welding. In the absence of special welding compound, it can simply be pressed down. You need to press with pliers or another insulating tool.

When the graphite rod touches the parts, it will begin to heat up and melt the metal. This will cause them to weld together. At first, the lead burns until the remaining acid from the battery is removed from it, and then it cooks better.

This welding method is accompanied by a short circuit on the battery, which causes the battery to heat up. If it boils, it may explode. In this regard, it is impossible to keep the circuit closed for a long time. You need to pause and periodically check the battery temperature. Ideally, cover it so that in the event of an explosion, acid splashes do not splash onto the body. The likelihood of this happening is very low, but reinsurance won't hurt. Welding takes a lot of energy, so one charge will only last for a couple of minutes.

Welding electrodes can be used instead of a graphite rod. In this case, you will get a truly reliable connection that can hold the load. You can also use battery rods for regular welding if you don’t have electrodes on hand.

Battery welding

Starting current indicator up to 600 A.

- Starting chargers. Combines the functions of the other two types. These are portable devices with a control panel and charge level regulator. They can gradually reduce the supplied current as capacity is restored; when the battery is fully charged, they can automatically turn off.

Battery chargers can be pulse and transformer . The first ones are small in size and consist of an inverter and a protective element that prevents short circuits. The latter are equipped with a voltage rectifier and transformer. This makes them more bulky. In terms of ease of use and technical parameters, pulse charging is better suited for modern cars of domestic and foreign production.

Characteristic

Main parameters of recharging equipment:

Rating of chargers 2018

- Caliber. A domestic enterprise that produces memory devices at an average price of 3–4 thousand rubles. The devices can charge batteries with a capacity of up to 100 A/h, rated up to 24 V. Models with increased current are suitable for restoring batteries with a capacity of up to 250 A/h.

- Bosch. The chargers are easy to use. The instructions for use indicate that the battery begins to charge after pressing just one button. All models are protected from dust and splashes. There is a function to save the specified settings and automatically turn off. The cost is more than 5-6 thousand rubles.

- Resanta. Latvian company. Automatic chargers are equipped with mini-batteries that start the engine even when not connected to the mains. The mobile model PU-2 additionally has a compressor, a USB input, and a flashlight.

- Orion. Devices from this manufacturer operate only in automatic mode and can smoothly reduce the current level at the end of the charging cycle. Voltage control prevents intense heating even during long-term operation and reduces the load on the battery.

- Cedar. Chargers from a domestic manufacturer are designed for 12-volt lead-acid batteries. Restoring capacity with a stabilized current supply, cyclic mode allows you to avoid short circuits and accidental polarity reversal. Even with a long-term connection, the device does not lead to overcharging or overheating. Price from 2 thousand rubles.

- Telwin. Italian manufacturer of car accessories. The most popular model is Nevatronic 12. It is suitable for all types of batteries with a nominal voltage of 12 V.

- Aiken. This brand produces many chargers suitable for cars, trucks, and motorcycles. The relatively low price (1-1.5 thousand) is explained by the fact that the devices function only when connected to the mains. Therefore, they cannot be used on the road.

A good charger may cost more than a new battery, but the cost is quickly recouped.

Power supply assembly

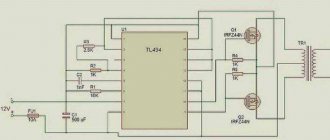

I assembled a homemade powerful power supply from a welding inverter using the following parts:

- A surge filter consisting of a choke and a high-voltage capacitor.

Source imgur.com

- Diode bridge. For this purpose I used the KBPC 5010 bridge, but you can use 4 separate elements of suitable power. After the rectifier, I installed a 1000 µF capacitor to smooth the pulses.

- High voltage field switches (IRF740/IRF840).

- Short circuit protection (on 2 field-effect transistors (you can use any with a load of up to 100 A)).

- PWM regulator (on timer 555 and key IRFZ44).

Source pressadv.ru

After assembling all the elements, it was decided to check the functionality of the circuit without installing it in the power supply case. As it turned out, this was not done in vain, because when measuring the output voltage, it was possible to establish that it was significantly higher than the required nominal value (more than 3 times). This drawback was eliminated experimentally by reducing the number of turns on the secondary winding of the transformer.

About the power supply from the welding inverter in the video: