A mixture of vinegar and lemon juice

The “classic” rust remover is a solution of vinegar and lemon juice, which are mixed in equal proportions.

- The resulting mixture is applied to the damaged areas of the instrument using a sponge or soft swab.

- After treatment, the tool is left for a couple of hours so that the product has time to remove the rust. It is important to ensure that the applied solution does not dry out, and to do this, periodically apply the product to previously treated areas.

- After a couple of hours, the remaining mixture should be rinsed off under running water and then the instrument should be dried.

Note! When using this method, it is important to follow safety rules, use gloves, and protect mucous and wound surfaces!

Folk remedies

You can quickly and safely deal with rust using available tools. The most unexpected and inexpensive compounds come to the rescue, including acetic acid, hydrogen peroxide and even carbonated drinks like Coca-Cola, but for these products to work, they must be used according to the instructions.

How to remove with acetic acid?

For cleaning, it is recommended to use an essence with a concentration of 70%.

Mode of application:

- Place the instrument that needs cleaning into a suitable container.

- Fill it completely with acetic acid.

- Cover the container with a lid and leave for several days. The more rust, the longer it will take.

- After cleaning, rinse the tool in a baking soda solution. It neutralizes acid.

After this treatment, you can continue to use the devices. The effectiveness of cleaning with essence is very high. It allows you to cope even with a thick layer of rust. If it is small, then you can use table vinegar or lemon juice.

It is not recommended to use vinegar to clean aluminum tools as it will dissolve the epoxy layer and damage the metal structure.

If rust has stuck to the tool in pieces, then the areas can be cleaned with ordinary food foil. It is used as a scraper.

Citric acid and hydrogen peroxide

You can get rid of rust using citric acid and pharmacy hydrogen peroxide. To prepare the solution you will need:

- citric acid – 20 g;

- peroxide – 15 ml;

- water – 100 ml.

Instructions for use:

- All components are mixed with each other.

- Place the instrument in a suitable container and fill it with solution.

- Leave them for a day under a closed lid.

- After the specified time, the solution is drained. The instrument is washed with clean water, dried and used for its intended purpose.

During the cleaning process, the solution will become dark in color. This is normal and indicates the effectiveness of the composition. With its help you can cope with a small layer of rust.

If the instrument is severely damaged, the concentration of the solution must be increased. In advanced cases, they refuse to add water altogether, dissolving citric acid in peroxide .

The video will tell you how to remove rust using citric acid and peroxide:

How to remove Coca-Cola?

Coca-Cola is a popular carbonated drink that can be used to remove rust. The effect is achieved due to the content of orthophosphoric acid, which corrodes oxides.

Mode of application:

- pour Coca-Cola into a suitable container;

- place rusted objects in it;

- cover the container with a lid;

- leave for a day.

The next day, the part is removed, rinsed with clean water and dried.

Coca-Cola is one of the budget and effective rust removers. Sprite and Fanta have a similar effect.

Soda

You can deal with rust using baking soda. An alkaline solution will help get rid of a small layer of corrosion without harming the metal. The effectiveness of the method is explained by the active action of sodium.

Mode of application:

Prepare the required amount of soda slurry by mixing the powder with water. It should be moderately thick, reminiscent of a paste in consistency.- Using a sponge, apply the paste to the instrument.

- Leave the mixture to act for an hour.

- Rinse the product and wipe it with a dry soft cloth.

- If necessary, the procedure can be repeated.

Baking soda is not a highly effective way to combat rust, but a small layer can be removed this way.

Zinc chloride

You can use zinc chloride to remove rust. Apply it as follows:

- 20 g of zinc chloride are dissolved in 200 ml of water, the product is prepared in the quantity required;

- pour the solution into a suitable container, lower the tool into it;

- leave to act for an hour;

- Rinse the instrument with clean water and wipe with a dry cloth.

Zinc chloride contains free hydrochloric acid, which has the ability to dissolve rust. The main thing is not to overexpose the composition so that the metal itself does not turn black.

The method is quite effective; zinc chloride can cope with even large areas of corrosion.

Potato

It may seem strange, but even ordinary new potatoes are suitable for removing rust. To do this, the potato tuber is cut in half, and one of the halves, which will be used in the work, is sprinkled with salt. The latter is necessary in order to draw moisture to the cut, as well as to give the potato surface abrasive properties.

After cooking, the damaged area is generously rubbed with potatoes and left in this form for 15-20 minutes. At the end of the period, the instrument is wiped and dried. This method is suitable for removing surface rust that has not yet penetrated deep into the metal.

Potatoes and dishwashing liquid

Method: Sounds crazy, but it works! Cut the potato in half and pour dishwashing liquid onto the cut side. Use potatoes like a dish sponge and watch the rust disappear.

This method is best used on smaller, less stubborn rust stains on easily accessible surfaces.

Pros: a simple and relatively quick way to remove rust. Works great with kitchen appliances. Uses ingredients you most likely already have.

Cons: This is probably the dirtiest method for removing rust. Be sure to work over a sink or somewhere outdoors.

Soda

I think many of you still remember the horror story about how a carbonated drink can allegedly eat away at the esophagus. The “proof” of this claim was the fact that soda can remove rust from a spoon, coin, or other metal item if left in the drink for several hours.

The interesting thing about this story is that half of it is true. Although soda is unlikely to corrode the esophagus, it can indeed be used to clean rust from an instrument. By analogy with removing corrosion from cutlery and other small items, the tool must be soaked in a drink for several hours or even overnight.

This method is good for removing small damaged areas, but is not suitable for deep rust. In addition, its use is difficult when restoring large instruments, since in this case a fairly large container and a lot of soda are needed.

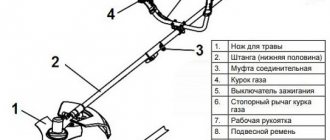

Mechanical cleaning and straightening of the ax

To remove the outer layer of rust and small edge defects, you may need the following tool:

- hand brush with metal bristles;

- coarse and fine sandpaper;

- electric grinding wheel.

Using a metal brush, remove the top layer of rust. If you have a power tool, it can be replaced with a drill with a grinding wire attachment. In hard-to-reach bends and in the interior, you will have to work hard with coarse sandpaper. Next, you should remove defects in the blade using a sharpening stone and polish the entire ax with fine sandpaper.

In some cases, you can be satisfied with the work already done, but to make the ax look like new, you need to clean it of rust at the molecular level.

Baking soda

Regular baking soda is equally good for removing rust from tools. To do this, add a small amount of water to the soda, necessary to obtain a thick “porridge”. Then the product is applied to the damaged areas.

Depending on how deep the corrosion has penetrated, you will need to wait from half an hour to an hour and a half. If at the end of the procedure the rust is not completely gone, the treatment should be repeated.

What causes rust

In order to effectively deal with a problem, you need to know the source of its occurrence. Rust can appear for the following reasons:

- Low quality, “hard” water. The impurities that make up it create favorable conditions for the development and spread of rust. Also, most often a poor water communication system leads to a house or apartment. The liquid passes through already rusty pipes and spreads to other places. In this case, cleaning alone will not be enough: the problem will reappear.

- Worn things out. Over time, the protective enamel breaks down and disappears. Because of this, the surface becomes more susceptible to external influences.

- Untimely cleaning and care of household items. If you neglect the situation, rust will definitely appear on the surface. The best solution to the problem is to monitor the condition of things and carry out treatment in a timely manner.

For other types of metal corrosion, see the following video below:

Sandblasting

An alternative mechanical way to remove corrosion is a sandblasting machine, which can easily remove even stubborn rust. The necessary equipment is quite expensive, so purchasing it only makes sense for processing a large number of damaged tools.

The main advantage of sandblasting compared to metal brushes is the ability to process even hard-to-reach areas. However, sandblasting is not recommended for use on sheet surfaces. The fact is that sand released under high pressure can leave a serious dent or even a hole in thin metal.

Vinegar

Method: Submerge the item in vinegar and leave overnight. Remove the item and scrub with a wire brush or steel wool. If your tool cannot be completely immersed in vinegar, soak rags in vinegar and wrap the rusty area.

It is best to use this method on heavily rusted objects made entirely of steel, which can be immersed in vinegar without the risk of damaging other surfaces.

Pros: Super-simple “set it and forget it” method. It won't take too much effort to remove the rust once you remove the item from the vinegar container.

Cons: The product needs to be soaked overnight, so it takes time to achieve results.

By the way, in this video you can see what happened to a rusty tool that was accidentally left in a container with vinegar for 19 months!

Laser processing

As a more technologically advanced means of fighting rust, it is worth considering a laser, which can be used to remove corrosion quickly and effectively. Laser processing has only one disadvantage - the cost of the equipment, which starts from several hundred thousand rubles. Therefore, its purchase makes sense only for commercial use. However, nothing prevents you from contacting workshops that have the necessary equipment.

Lemon acid

Method: You may not have citric acid on hand, but it is easy to find in most stores in the deli section. Add a few glasses of hot water to a bowl and add 2-3 tablespoons of citric acid. Submerge the item in water and leave it overnight, remove it in the morning and brush off any remaining rust stains, rinse and dry.

Best used on heavily rusted objects and tools that can be immersed in liquid without damaging the integrity of other surfaces and coatings (citric acid removes paint!).

Pros: works great! Another “set it and forget it” method.

Cons: as we already wrote, you may not have citric acid on hand, but it can be easily purchased at your local store.

Rust removers

The most affordable professional way to remove corrosion from tools is through various solvents, cleaners and rust converters. They are present in huge quantities on the domestic market, and prices for such products start from several tens of rubles.

Unfortunately, among them there are quite a lot of low-quality items that can only remove surface corrosion. Therefore, before purchasing a specific product, I strongly recommend that you study reviews and reviews of it.

To summarize, I would like to note that it is much easier to prevent corrosion than to later solve the problems caused by its occurrence. To do this, do not forget to dry the tool after use (especially important for gardening tools) and store it in suitable places.

Why vinegar eats away rust well: chemical reactions

The structure of vinegar (that is, its acidic environment) effectively dissolves all unwanted deposits and damage on metal objects. At the same time, it does not damage the things themselves. The main thing is to use only soft cloths and brushes during the processing process so as not to damage the surfaces.

Author's note

Kirilova Olga

Treatment with vinegar will only be effective if the cause of rust is eliminated.

Do you cook often and are tired of cleaning the stove? Find out a quick way to clean the inside of your oven, get organized and save your time.

Rust converters for tools

ASTROhim Antiruster is one of the most effective rust converters.

There are products on sale that allow you to stop the oxidation process - these are rust converters, which are available in the form of an aerosol. They are usually used as a primer for painting. Such compositions are made on the basis of orthophosphoric acid. The most common: Fenom, Permatex, ABRO, ASTROhim Antiruster .

These preparations are recommended for use when you plan to coat metal products with paint. They do not remove rust, but only stop the corrosion process.

The advantage of converters is that after they are applied, a special film appears on the surface, protecting against further spread of plaque.

Vinegar as a way to get rid of rust in a car gas tank

Vinegar is also actively used to remove rust from a gas tank. However, there is one significant drawback - a large amount of acid will be required, because the tank must be filled completely

Processing sequence:

- Fill the tank to the brim with 9% or 10% vinegar. Close the lid.

- Leave to steep for one night.

- Then pour off half of the acid. Shake the tank and release the remaining liquid.

- Pour soda in there. It will react, removing all the small particles of corrosion.

- Rinse the inside several times with clean, warm water to remove any remaining vinegar, baking soda, or residue.

Author's note

Kirilova Olga

Do not carry out the procedure at low temperatures. This may negatively affect the condition of the tank.

Acetic acid and rust react immediately upon contact

Pros and cons of deletion

Using vinegar to combat rust stains, you can appreciate a number of positive aspects:

- The versatility of the product (vinegar solution perfectly removes red stains from metal, plastic and ceramics).

- Availability (low cost, vinegar solution is available in any kitchen).

- Efficiency (at a pH of 2.5 pH, the vinegar solution dissolves stubborn stains of rust, grease and lime in a matter of minutes).

The downside to using a vinegar solution to remove rust stains is that it has a pungent odor.

An open window in the room and a few drops of your favorite essential oil, previously added to the cleaning solution, will help solve the problem of unpleasant odor.

How to care so that the knife does not rust

How to prevent a knife from rusting is a completely natural question. And there is only one answer - proper care and timely prevention.

- It doesn’t matter what kind of knife you have - kitchen, hunting, decorative or homemade, it is necessary to periodically apply a layer of special wax to it. Collectible instruments that are not used at all are especially susceptible to corrosion.

- If the knife is intended for personal purposes, then try to use it as often as possible - this way the tool will be processed naturally.

- After routine cleaning, be sure to wipe the knives dry and treat them with acetone or alcohol.

If a knife rusts in your house, what to do and how we described it in the article. With the help of our tips, you can restore the original shine and beauty of your cutlery quickly and easily. But it’s better not to allow corrosion into your kitchen, but to take care of household items in a timely manner. Follow preventive measures and you will never see destructive rust in your home.

Features of removal from various tissues

Removing traces of corrosion from fabric must be carried out not only taking into account the degree of contamination, but also taking into account the quality and color of the material. In order not to damage the structure of the fibers and maintain the shade, you should choose the right cleaner:

Black fabrics

The presence of dark pigment requires careful use of potent agents. Such things are treated with glycerin compounds, toothpaste, diluted vinegar

The use of bleach and strong acids is unacceptable.

Colored products. Clothing with a pattern belongs to the “complex” group. Many bleaches can worsen the color, so choose only those products that are gentle. Recipes with vinegar, glycerin, and toothpaste are suitable for colored ones. Colored items should not be left in the sun and treated with whiteness.

White linen. If the light-colored fabric is of natural origin (cotton, linen, viscose), then chlorine-containing or acid bleaches can be used to clean it. Citric and oxalic acids are allowed as home remedies.

Jeans. The thick fabric from which jeans are made is difficult to clean. To remove rust marks, use products with good penetrating ability. Vinegar, citric acid, and household chemicals are suitable.

Synthetics. Thin fabrics made from artificial fibers are sensitive to strong reagents. It is recommended to clean them using universal liquids or mixtures based on glycerin, vinegar, and citric acid.

Cotton, linen. Natural fabrics withstand organic acids (citric, oxalic, acetic). Household chemicals intended for these fabrics are also suitable.

Silk, satin. Delicate tissues do not tolerate aggressive substances and strong mechanical stress in the form of friction. To clean them, neutral, mild-acting compounds are used.

FAQ

In the process of processing things, devices and tools, questions may arise that will take you by surprise. To avoid this situation, check out the answers to the most frequently encountered ones.

Which vinegar, 70 or 9 percent, is better to use to remove rust from metal?

You can use either 9% vinegar or 70%. Only in the second case is it not used in its pure form: it must be diluted with clean water.

Precautions when cleaning with acetic or citric acid

To avoid harming yourself and your health during processing, adhere to the following precautions:

- Handle acid only with gloves. Otherwise, it may cause burns or irritation to the skin.

- Wear a mask to prevent vinegar vapor from entering your respiratory tract.

- Do not bring your head too close to the treatment solution.

- Make sure that the liquid does not spill on other objects. Especially for food and dishes. It is best to remove such kitchen utensils from reach.

- When processing, open windows or otherwise provide ventilation to the room.

An antiseptic compress will help get rid of a burn.

First aid if vinegar gets into your eyes

If vinegar gets into your eye, follow these instructions:

- Rinse your eye under cold water. Allow 20 to 30 minutes for this process. It is during this period that all toxic fumes will be washed out of the eye.

- Brew strong tea (black or green). Cool to room temperature and rinse your eyes with the solution. This can relieve swelling and disinfect the surface.

- To reduce pain, apply a compress of cold tea to the eyelid.

For any form of burn, consult an ophthalmologist. Only he will be able to determine the area of damage and eliminate all consequences without harm to health.

Adviсe

Simple tips will speed up the process of removing red stains:

- Traditionally, a 9% acetic acid solution is used for cleaning. If you don’t have one at hand, you can use 70%, provided that it is diluted with water (1:1 ratio).

- Surfaces treated with vinegar should not be actively rubbed with metal brushes and hard sponges (there is a high risk of color loss, scuffs and scratches).

- When choosing between white table vinegar and apple cider vinegar, it is better to give preference to the second option to combat rust stains. It will quickly deal with the problem of yellow stains.

Working with vinegar solution requires compliance with certain precautions. Removal of stains is carried out only in a well-ventilated area, wearing a respirator and protective gloves.

Ignoring recommendations may cause skin burns and respiratory tract irritation.

Removal of stains is carried out only in a well-ventilated area, wearing a respirator and protective gloves. Ignoring recommendations may cause skin burns and respiratory tract irritation.

How to select and prepare wood

An ax handle is the handle of a working tool. Labor productivity completely depends on how easy it is to work with it. Therefore, a regular straight stick will not work in this case. A real ax handle is a curved beam with an oval cross-section and straight sections. The tail part should be widened and bent downwards. Only with this option the hand of the person performing the work will be able to reliably hold the tool without experiencing fatigue for a long time.

The following types of wood are best suited for making an ax:

Wood should be harvested in the fall. Birch is perfect for carpentry tools, while maple is more often used for camping tools. Its impact strength is less than that of birch. The ideal option is considered to be very durable and rarely changes shape. It is better to make an ax handle from a section of wood located near the root, and the workpiece should be 15 cm wider and longer than the future product.

Attention! Before the prepared beams are used to make an ax handle, they must dry for at least a year in a dry, dark place, for example, in the attic. This is necessary so that when finished, the handle does not shrink and start to dangle in the eyelet.

Fresh wood can only be used if the ax handle breaks, as a temporary option that needs to be replaced quickly.

Source

How to remove rust from metal at home. Causes of rust

Rust is the outward manifestation of metal corrosion as a result of the chemical process of oxidation. Outwardly it looks like a brown-red formation. Of all the metals, iron and its alloys are the most susceptible to corrosion. Even stainless steel, despite its name, can also rust.

Corrosion spots can cover the metal surface completely, or form locally in individual areas. It is not easy to remove rust from metal; it is much better to prevent its occurrence. If measures are not taken in time, over time the plaque can completely destroy the product.

When choosing tools made of stainless steel, remember that this material is also susceptible to corrosion and you need to monitor the products no less carefully than items made from other metals

At home, the main reasons for the appearance of traces of corrosion are constant exposure to water and high air humidity. The most susceptible to the formation of oxides are those objects that are located on the street: window grilles, iron door visors, padlocks, chains, pipes, etc.

At home, rust is most often found in areas with direct access to water, such as the bathroom and kitchen. Often, corrosion stains can be found on water faucets, chains or places of their attachment, on pipes.

Plumbing pipes are most susceptible to corrosion due to constant contact with water

Rust can be one of the reasons for annoying squeaking door hinges in your home. It is important to understand that in addition to external discomfort, a coating of corrosion on hinges significantly increases their wear.

How to prevent rust

Controlling humidity and keeping your tools away from water is key to preventing rust. To prevent tools from rusting over time, store them in a dry place. If any of your instruments get wet (rain, snow, etc.), dry them as thoroughly as possible and as soon as possible . It's also best to store all your tools (including power tools) off the ground, especially if they're stored in a workshop or garage, so there's no risk of moisture seeping through the floor.

Sealing the metal parts that are most susceptible to moisture is also a reliable rust protection tactic. Most manufacturers provide a layer of chrome or paint, but older tools often do not have a protective coating. Paint, rubber sealant or wax coating are cost-effective ways to prevent rust and extend the life of your tools.

Follow us on Pinterest for more interesting articles.

Useful short videos from Make-Self.net

Rules for using an ax

There are few such rules, but they emerged from the practical use of the tool:

- The ax is used for its intended purpose. They cut branches, make wood chips, and work on wood. If you use it to chop metal or other hard material, the ax will quickly become dull and the edge of the blade will be damaged.

- You cannot use an ax with an old ax handle. It may break off upon impact and cause injury.

- The ax needs to be sharpened periodically.

- You should not use an ax with a dangling head. During operation, it can come off and injure a person standing nearby.

- If the ax handle has dried out but is still strong, soak it in water for at least 10-15 minutes before use. The swollen wood will hold the head well.

- For long-term storage, the head of the ax is greased with oil, it is removed from the sun, it is better to put it in a case.

Why does rust form on an ax?

Everyone knows the electrochemical process known as corrosion. Electrons pass from the anode to the cathode through the electrolyte. The iron content provokes destruction, as the physical properties of the metal deteriorate from exposure to:

- water;

- humid air;

- stray currents.

Corrosion happens:

- local – covers several areas;

- uniform - over the entire surface area;

- intercrystalline - destruction occurs within the boundaries of metal grains.

There are 4 types of rust:

- yellow - a humid and undersaturated oxygen environment contributes to it. She can be found underwater;

- brown - water is not involved in the appearance. This is the rarest type;

- black - provokes low oxygen content. This is a stable and slow process that occurs without water;

- red is the most common type. Covers the entire area. Oxygen and water destroy the metal completely. It is also used for smelting cast iron and as a dye.

Increasing the temperature speeds up the process. It is worth noting that several types of corrosion can develop simultaneously. Only precious metals are resistant to it.

Rust solvents for metal products

Treatment with rust solvents allows you to return the instrument to its original appearance.

Various types of chemicals are used to clean iron objects. Rust solvents are made from acid, zinc oxide or plant components. To get your tools in order, you can try Syntilor Ruggine, Sonax, Liqui, Wurth, etc.

Such products are harmful to the skin, so work should be carried out with protective gloves.

When using chemical compounds, you should adhere to safety precautions:

- Strictly follow the manufacturer's instructions for using the substance.

- Wait the right time for the product to react with the corrosion, and then clean the product.

- Make sure that the drug does not come into contact with the skin and mucous membranes.

- Use solvents only for small items.

Products based on tannins and additives are considered safe, since they do not contain toxic compounds.

Preventing rust

High humidity, temperature changes, and aggressive environmental influences always lead to the formation of corrosion on metal products. For prevention, you must adhere to several rules:

- The instrument should be wiped down after each use. Shovels, rakes and other gardening tools should be cleaned with solvent or kerosene to completely remove residues and plant juices.

- Regularly treat metal objects with special compounds that prevent corrosion.

- Periodically carefully inspect all instruments for damage. Replace damaged parts immediately. At the first sign of rusting, take action immediately.

Particular attention should be paid to those places that are located near the fasteners or blades. They must be cleaned with a stiff wire brush and plain water.

There is no need to throw away an old tool that is covered in rust. There are special products on sale that can restore it to its original appearance and eliminate signs of corrosion. For this purpose, you can also use substances that are always at hand. Getting rid of rust will not take much time, and the service life of the tools will be significantly extended.