All owners of personal plots are faced with the problem of mowing grass, which grows literally before our eyes, and during the season it is necessary to improve their plot several times. The usual hand scythe has long been replaced by gas trimmers and electric trimmers. But the price for them does not decrease and is quite significant for many owners of dachas and private houses. Craftsmen nevertheless found a way out of this situation and learned to make trimmers with their own hands literally from improvised means, using gas and electric tools not intended for these purposes.

How does a trimmer work?

To make a trimmer at home, you should first understand the principle of its operation and design. In general, all manual mowers are classified into gasoline and electric. The first option is more convenient, because the user is not tied to an outlet, but to make a homemade device, electric motors from household appliances or tools are often used .

The design of both types of manual lawn mowers includes:

- engine (electric or gasoline) - suitable for household tools (screwdriver, drill, grinder), washing machine, and chainsaw;

- tank - for a gasoline engine;

- starter - it is best to use a simple button with a return mechanism;

- the rod is made of solid wood or a metal pipe (aluminum pipe is perfect, since it is lighter), you can also make a sectional design that will allow you to adjust the holder to the height of different people;

- a handle for ease of use, on which a button is placed - it should have a comfortable grip and be made of non-slip material;

- knife or fishing line - it is better to use knives, as the fishing line breaks faster;

- protective casing - powerfully weld from thin metal, cut from a large plastic bottle, or use an old frying pan.

Advice! It is better to make a knife from tool steel, an old circular saw blade or a hacksaw. It can be solid or with a replaceable blade. The second option is more convenient, since if damaged, it will be enough to simply change the edge.

However, it is worth understanding that factory designs are more complex than homemade devices. And you won’t be able to get a complete analogue of a store-bought trimmer. Below are recommendations for assembling a functional hand mower from various equipment.

Motorbike

Here you need to start by strengthening the engine from the brush cutter on the trunk of the bicycle. Three strips of metal will help, two long for side mounting, and one short, slightly longer than the length of the trimmer motor. It is better to fasten the entire system with bolts.

Then the engine rotation transmission is mounted to the rear wheel of the bicycle. To do this, there is a large circle for a pulley on the wheel sprocket, and a small one on the motor spindle. The transmission belt must be selected without sagging, but the tension should not be excessive. The design resembles the mover of a foot-operated sewing machine.

Making your own trimmer from a drill

One of the easiest ways to make a trimmer is to use an old drill or cordless screwdriver. The second option is a little worse, since the battery will significantly limit the operating time. But you can increase autonomy by installing a 12-volt car battery into the design. However, given the large size of this battery, you will either have to take care of long wires, or make the entire device wheeled.

So, to make a trimmer from a drill, you will need a durable holder, a power tool itself and a homemade knife . The process includes several stages.

- Making the holder. It can be wood or metal, but many recommend finding an aluminum pipe that is lightweight and yet highly durable. In addition, it can be easily drilled if the trimmer will not be disassembled in the future, and the drill will be firmly fixed.

- Attachment to drill (or screwdriver) holder. This is done using metal brackets or clamps. Some home craftsmen claim that you can secure the instrument with ordinary tape, but there are several nuances here. First of all, it's not safe. Secondly, it is impossible to use tape to create the required angle between the holder and the working mechanism, which means using such an assembly will be extremely inconvenient.

- Attachment to power cable holder. This is done with tape so that the wire does not hang and interfere with work.

- Another important design point is the knife. It can be made from steel. For ease of use it should be thin. And if the trimmer is assembled using a battery-powered screwdriver, then the material should be chosen to be light - this will allow you to “squeeze” the maximum operating time out of the battery. Next, the selected metal strip, sharpened on both sides, is drilled in the middle and tightly fixed on both edges to the bolt, which in turn will be fixed in the drill chuck.

- For safety during work, you should take care of the protective casing, which can be made of plastic. A great option is to use the top of a 19 liter plastic bottle.

Principles of operation of an electric motor

Such a motor can be either single-phase, which operates from a regular network, or three-phase, which requires additional electricity. When connecting an electric motor, you must always remember personal safety. For a motor operating on one phase, RCD protection must be installed, and a three-phase motor must have appropriate capacitors.

For a home lawn mower, you can also use a drill with speeds of up to three thousand. When assembling the structure, it is necessary to correctly select the power of the mower for its swathing. A cordless or electric drill mounted on a base or platform will perform its tasks efficiently, and the grass will be mowed.

Grinder trimmer

Another simple and convenient option is to make an electric garden trimmer from an angle grinder. In general, the assembly scheme is similar to the previous method, but with the difference that attaching the power tool to the holder is even easier. If you remove the included protective casing from the grinder, you can screw a U-shaped fastener, welded yourself, into this thread. You can secure it to the holder using bolts or welding, if you do not plan to disassemble the homemade trimmer in the future. Some craftsmen immediately weld a protective casing to the fastener.

On a note! The convenience of using a grinder as a basis for a trimmer is that the knife is attached to it very easily onto an existing mechanism. The cutting element itself can be made from an old circular saw blade. If this is not available, you can use fishing line or wire.

Pros and cons of homemade design

To create a lawn mower yourself, you need to have minimal skills in construction, and also understand something about assembling mechanisms. A homemade lawn mower has many ready-made schemes, so in this case you definitely won’t have to improvise. The main advantage of a DIY lawn mower will be its low cost. The owner takes all the necessary parts from old and faulty devices.

The quality of the lawn mower will directly depend on the engine power rating, as well as the sharpness of the blades . You should not use cheap steel to create a homemade lawn mower model, as it can ruin the whole job. Craftsmen advise using high-quality steel for this. It should be sharpened unevenly: sharp towards the ends, and left blunt at the attachment point. This way, vegetation will not wrap around the propeller and the engine will not become clogged.

In terms of ease of use and functionality, a ready-made lawn mower from a store will be better than a do-it-yourself mower. The factory model has several speeds at once, you can independently adjust the height of the knives, and it produces less noise.

You can improve a finished homemade design. Experienced mechanics advise creating lawn mowers with an adjustable long handle, a grass catcher, safety bumpers, the ability to control the cutting height, in some cases this model is even combined with a bicycle.

Having decided to create a lawn mower on your own, you need to consider all the main advantages and disadvantages of the design, because not everyone can create such a product on their own.

Making a manual mower from a vacuum cleaner

It is quite possible to make a trimmer from an old vacuum cleaner. In this case, the engine will have to be removed from the housing and, in this form, attached to the holder in one of two possible ways. The first option is described in the previous paragraph - fasteners are welded from metal according to the size of the motor. The protective casing can again be made from a plastic bottle.

But there is a second way to mount the motor. Due to the fact that the engine is larger and heavier, it is convenient to place it on a structure with wheels, for example, from an old stroller . As practice shows, holding a trimmer made from a vacuum cleaner suspended using muscle power is extremely tiring and inconvenient. In this case, a homemade head for attaching the knife is not needed. The motor in the vacuum cleaner is equipped with a fan, removing which frees up space for installing the cutting element. The latter is done by analogy with the description for a drill trimmer.

Attention! When making a lawnmower from a vacuum cleaner, you should not use wire as a knife. In reviews, many craftsmen write that high speeds developed by the engine lead to rapid wear (tearing off) and, accordingly, frequent line replacements. It is easier to immediately make a knife from a rectangular piece of metal.

Other options

There are many other units that can be used to make a grass trimmer. A vacuum cleaner, drill or chainsaw is used as a base.

From a vacuum cleaner

When making a homemade trimmer from a vacuum cleaner engine, the latter is mounted on a rod. The knives are installed on the motor shaft and covered with a protective casing. Instead of knives, you can use a metal disk with fishing line. The engine is also covered with a casing, this will protect it from dust and dirt. To create additional cooling, you need to install a cooling device. It is made from a disk with curved blades (fan) and mounted under a washer through which the trimmer line passes. Air enters from above through a hose and cools the engine.

From a drill

If you need to quickly make a trimmer, then a drill will help. To do this, a knife is made from a metal plate and sharpened. Then a hole is made in the center, a bolt is inserted and secured with a nut. The finished knife is inserted into the drill chuck and carefully clamped.

This design is dangerous for the user, so a protective casing is attached to the drill. It is made from a plastic pipe and placed on the body of the instrument.

From a chainsaw

Since the chainsaw engine is heavy, it cannot be used to make a bottom-drive trimmer, but it can be used to make a riding lawn mower. Manufacturing process:

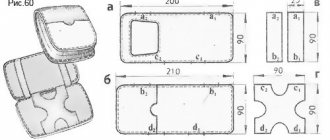

- First, a cart is made from a 25x25 mm corner. Its dimensions are 500×600 mm.

- Wheels are installed at the corners of the structure.

- The gas cable and fuel hose are extended.

- The tire and steering wheel are unscrewed. A handle is made from a water pipe on which the steering wheel is mounted.

- When installing the engine on the frame, the shaft must be located at the bottom of the structure. In this case, the gearbox is rotated at 90°C.

- Then the cutting unit is mounted on the tool shaft.

The tool is ready. To make it easier to work with, you can purchase a shoulder or backpack strap for the trimmer in the store.

Share your homemade ideas. What power tools did you use and whose inventions were you inspired by?

Chainsaw-based lawnmower

A chainsaw is a popular tool. A huge number of removable units were created for it - from a cultivator attachment to a drill. There are other options for using it. One of them could be a trimmer, or more precisely, a lawn mower on wheels, since the heavy weight will not allow you to hold such an assembly in your hands.

Cart

Based on the size of the tool, a trolley is made. It may look like a metal frame with wheels at the corners and a handle for moving it. The most convenient number of wheels, according to experts, is 4. This improves maneuverability. A chainsaw is mounted inside with the steering wheel and tire removed so that the shaft is facing down. A steering wheel is attached to the handle of the future trimmer and the cable is extended to make it possible to start the device without bending over.

Mowing mechanism

The greatest difficulty in making a lawnmower from a chainsaw lies in the mowing mechanism. To make it, you will need to weld a special nozzle. To do this, you need to take two metal pipes 40 cm long and 50 and 58 mm in diameter. A tube of smaller diameter is welded to the engine sprocket. After this, it is inserted inside a larger diameter pipe and secured with bolts and locknuts. This is done so that it is possible to adjust the height of the knives. If this option is not required, you can get by with one pipe.

A knife is welded to the second part of the pipe. Due to the high performance of the engine, it is possible to make a cutting disc from metal with a thickness of 4 mm and a diameter of up to 180 mm. Knives 120 mm long and 30 mm wide are bolted to the disk. An excellent material for making them is an old two-handed hacksaw. Such a cutting unit is suitable for tall and thick grass - the engine power is enough to cope with it, and the knives will not quickly become dull and become unusable.

Reinforced dual blade design

To increase the width of the treated area in one pass, you can make a design with two knives . In this case, a pulley or sprocket is attached to the crankshaft. Using a backpack belt or bicycle chain, torque is transmitted to the knife shaft. In this case, the cutting parts are spread from the front to the sides. And in this case the frame is made so that the cutting elements do not reach the front wheels. They are attached using bearings and also have a pulley or sprocket.

The sprocket and pulley are selected in such a way that the knives rotate at a speed of 500 rpm - this ensures an even cut. It is optimal to sharpen the knife at a sharpening angle of 60 degrees, otherwise it will need to be sharpened again often. The length of the knives is selected based on the width of the supporting structure, so that when rotating there is a minimum gap between them. The part opposite the tip is bent at a slight angle, which makes it a kind of blade. This provides airflow - the grass will not stick. The knife should not be tightly secured so that when stones hit it, it changes its position, since it is easier to return it to its place than to repair the engine or shaft.

Advice! To properly assemble a mower from a chainsaw, it is recommended to watch thematic videos, since the design here is more complex than that of previous models.

Operational safety

A homemade lawn mower requires careful safety practices. This is due both to the fact that the tool is electric and to the presence of knives. The first thing you need to do before turning on the lawn mower is starting work. check its functionality, the sharpness of the knives, the reliability of all bolts, and the free movement of the wheel. It is highly advisable to collect debris locally as rocks or wooden blocks can cause injury to your mower or mower. Children or pets must leave the work area.

Proper use of a lawnmower. push him away from you. If there is a need to stop using the lawn mower for a while and then return to it. then you should always disconnect the mechanism from the power source, not the button next to the motor, and remove the plug from the socket. And the most important thing. Operating the electric lawnmower is strictly prohibited in the rain or on wet grass. Cleaning or repairs may only be carried out with the engine switched off and cooled. will enjoy DIY lawn mower for many years to come.

Making an electric scythe from a washing machine with your own hands

You can also make an electric scythe using the motor from a washing machine. It is asynchronous and is activated via a button. The winder can be made from a return button, for example, from measuring instruments. The fairly compact dimensions of the motor make it possible not to make a large cart, as in the previous version.

On a note! The convenience of using such an engine lies in the fact that it already has a pulley, and replacing the piston pulley with a more convenient one is not necessary. The belt and second pulley are located right there - in the washing machine.

Knives are made by analogy with the descriptions above. But there is one important point - in order to prepare the motor from a washing machine to work as a trimmer, you should not forget to make a protective casing for it. It will protect the drive from the grass. But at the same time, it is necessary to take care of protection from overheating, that is, the casing should be larger in size and have holes for ventilation. An old bucket or large plastic bottle will do for this purpose. Don’t forget to take breaks - such a motor is not designed for long-term operation .

Assembling the lawn mower

To assemble a lawn mower, we need a hacksaw for metal, not a machine.

The first thing you need to do is create a frame for the engine. For this purpose, you need to take a metal sheet with a thickness of two to three millimeters. The size of the frame is chosen based on the length of the knife, but the maximum width of the lawn mower rarely exceeds sixty centimeters. Thus, it is necessary to cut a square of metal with a side of 50 or 60 centimeters. In the center of the area you need to make a hole for the engine. The flange motor is attached to the frame with the shaft down. If the engine has ears, then additional fasteners need to be welded to the frame.