Do-it-yourself cultivator for walk-behind tractor, drawings and dimensions. How to make a cultivator for a walk-behind tractor

Before making a cultivator for a walk-behind tractor with your own hands, it is necessary to treat all metal elements with a special anti-corrosion compound to prevent the premature appearance of rust after frequent contact with the ground.

Simple models can be made without drawings. To make and correctly assemble more complex devices, it is necessary to plan the work, calculate the dimensions of the module and parts.

A homemade cultivator made from a pitchfork is a simple way to reprocess (remake) products. To do this, the teeth of the mechanism are bent with a hammer like a corkscrew and placed on the handle. A shovel handle is used as a handle. Electrical tape is used for fastening.

Some craftsmen manage to make a cultivator with their own hands from a bicycle frame with a wheel. A steel rod is welded or bolted between the 2 base blocks. The head is mounted to the crossbar. For this design, it is recommended to take a medium-sized wheel.

In order to correctly assemble a disc cultivator and work correctly with cutters, it is necessary to design diagrams of components and individual parts. Taking into account the deformation of the discs, special adjusting nuts are used. The discs are welded to bushings located on a rotating axis with brackets. It is necessary to provide a protrusion on the bracket where the pipe will pass. The cultivator handle is attached to the pipe surface.

Do-it-yourself cultivator for a walk-behind tractor, drawings. DIY hand cultivator

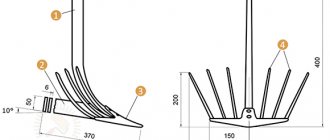

The simplest option for making a cultivator at home. This is a small design, the capabilities of which are enough to grip a strip 20 cm wide. The basis of the device will be a handle in the form of a metal pipe with a diameter of 2.4 cm. The length of the element is selected specifically for the height of the user. A strong wooden axle must be installed on the bottom of the pipe. The processing organs will be attached to it. Despite the simplicity of the design, homemade hand cultivators can be equipped with wheels. They can be cut from a metal sheet 0.3 cm thick and secured with nuts.

There is another design option, which involves a base in the form of a strip of springy metal. In this case, the parameters of the workpiece should be as follows: length - 5 cm, width - 2 cm, and thickness - approximately 2 mm. A wooden handle is attached to this part, through which processing will be carried out. The tape is folded, so it can be shaped into a loop, and then the edges can be turned on both sides with a file. The diameter of the loop can be any; this parameter is calculated based on the area of the garden.

Operating principle of the “ELECTRIC BED” device.

The operating principle of the “ELECTRIC BED” device is very simple. The “ELECTRIC BED” device is created in the likeness of a large tree. An aluminum tube filled with (U-Y...) composition is the crown of a tree, where, when interacting with air, a negative charge is formed (cathode - 0.6 volts). A spiral-shaped wire is stretched into the soil of the bed, which acts as a tree root. Bed soil + anode.

The electric bed works on the principle of a heat pipe and a constant pulse current generator, where the frequency of the pulses is created by the earth and air. Wire in the ground + anode. Wire (stretch wires) - cathode. When interacting with air humidity (electrolyte), pulsed electrical discharges occur, which attract water from the depths of the earth, ozone the air and fertilize the soil of the beds. In the early morning and evening you can smell ozone, like after a thunderstorm.

Lightning began to flash in the atmosphere billions of years ago, long before the appearance of nitrogen-fixing bacteria. So they played a prominent role in fixing atmospheric nitrogen. For example, over the last two millennia alone, lightning has converted 2 trillion tons of nitrogen into fertilizer - approximately 0.1% of the total amount in the air!

Do an experiment. Insert a nail into the tree and a copper wire into the ground to a depth of 20 cm, connect the voltmeter and you will see that the voltmeter needle shows approximately 0.3 volts. Tree roots, like pumps, use osmosis to lift water from the depths of the earth and ozonate the soil.

Homemade cultivator for a walk-behind tractor with your own hands. For mini tractor

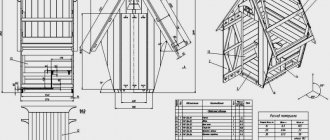

To make a homemade cultivator for a mini tractor or for a walk-behind tractor with your own hands, you will need metal plates, square, 15*15 centimeters in size, rectangular - 25*4 centimeters and a steel pipe. You need to start making a cultivator with cutters.

In order for the cutters to be reliable and suitable for processing all types of soil, and not just loose black soil, they must be assembled using bolts - holes must be drilled in the workpieces, the number of which depends on the size of the metal strips that will serve as blades.

For mini tractor

The longer they are, the more holes are needed to secure them securely. Next, the strips are fixed to the workpieces, overlapping each other in a circle, and clamped with bolts.

Welding can also be used for these connections, but in this case they will not be strong enough, and repairing and replacing knives will be a complex process. Welding is used here to connect the cutters together. To do this, holes are made in the blanks, the diameter of which must correspond to the outer diameter of the pipe.

The cutters are put on top of it and secured with tacks or short seams. This product can now be put on the shaft of a mini tractor and used for its intended purpose.

How to sharpen a homemade cutter correctly?

Manufacturers of motorized cultivators sell equipment with already sharpened standard cutters. However, what should a person who has made cutters for an existing cultivator do on their own? In this case, you will need to sharpen the cutting knives of the device yourself.

To sharpen the equipment, you will need a grinder equipped with a diamond wheel with a diameter of 12.5 cm. Otherwise, you can use a sharpening machine, but it will be difficult to use due to the dimensions and direction of bending of the knives. If the manufactured cutters are equipped with small-sized knives, then you can use fine-grained sandpaper to quickly sharpen them.

It is necessary to sharpen the knives of a homemade cutter for a cultivator strictly at an angle of 45 °. In this case, it is necessary to independently determine the side that goes deeper into the soil. There is no need to remove too much metal from the knife; 1-2 sharpenings per season are sufficient. In some cases, the frequency of sharpening the cutter knives may vary - it all depends on the intensity of use and the type of soil being processed.

If you work intensively with the cultivator in wet weather, you will need to monitor the condition of the cutters. To prevent the formation of corrosion, they should be treated with a special anti-corrosion compound, which can be found in almost any auto parts store.

It is also very important to try to prevent the cutter from getting on stones and other hard objects - this will help extend the service life and reduce the need to sharpen the cutting knives of the device

Cultivator for walk-behind tractor

Cultivator for Motor Sich walk-behind tractor photo

Attachment for walk-behind tractor, cultivator for walk-behind tractor.

A cultivator for a walk-behind tractor is an attachment for cultivating land.

Cultivators are used for continuous tillage of the soil before sowing and for cultivating crops, loosening, weed control, moisture conservation, and hilling are carried out.

The difference between a cultivator and a plow is that a cultivator performs loosening without turning over the soil layer.

Cultivators consist of a cultivator stand and a cultivator arrow photo.

From left to right:

- Flat-cutting pointed cultivator share

- universal cultivator share

- loosening rigid cultivator share

- loosening spring cultivator share

The arrows of the cultivator paws are made of steel grade 65G; when sharpening the cultivator arrows, the metal must not be overheated.

It is also possible and necessary to harden and heat treat the cultivator pointer. For hardening, the paw is heated to 820° (light cherry-red color of heat), after which the pointer is cooled by immersing it in an oil bath. After cooling, the cultivator needle is released, that is, it is again heated to 400° (gray tarnish) and slowly cooled in air.

After such operations, the file does not leave any mark on the cultivator arrows and the cultivator tines normally perform their job of cultivating the soil.

Device with a motor from an electric saw

In this electric cultivator, the function of the power unit is performed by an electric chain saw of the Parma brand. It is attached using clamps to the cultivator frame. If necessary, the saw can be quickly dismantled and used for its intended purpose.

The frame is welded from steel pipes Ø24 mm. Working cutters are made from a Ø30 mm pipe, and steel teeth are welded to them - 6 pieces at an angle of 30 degrees to each other. The rotation of the cutters is transmitted by a two-stage chain transmission. In the first stage, the drive sprocket is used from the saw, and the driven one is installed from the bicycle. The second stage consists of a motor sprocket and chain.

The cutter shaft is made of a round metal profile and is mounted in the frame fork using rolling bearings. The cutters and sprockets are secured with dowels. This device requires protective covers to be installed on the drive chains.

DIY cultivator for walk-behind tractor. DIY flat cutter for walk-behind tractor

In recent years, many land owners are increasingly using new technical developments that can make life much easier and spend much less time on certain tasks. Walk-behind tractors, cultivators, mini-tractors and other devices have a tangible impact on the life of an agronomist.

If traditional hoes were previously popular, which forced them to cultivate heavy soil in a half-bent state for several hours, today they have been replaced by innovative flat cutters designed for operation together with a walk-behind tractor.

Flat cutters for a walk-behind tractor: advantages and disadvantages of using the device

Flat cutters can be safely called a kind of hybrid of a harrow and a knife. They are mounted parallel to the ground or at a slight angle. As a result, the device sinks into the soil to a shallow depth and cuts off the roots of weeds, thereby turning the soil itself, promoting better preservation of moisture and nutrients.

In addition to the above positive aspects, flat cutters:

- improve soil condition;

- destroy crusts and lumps formed after heavy rain;

- repel pests;

- prepare the soil for long-distance planting;

- perform inter-row cultivation of crops;

- saturate the top layer with oxygen.

Naturally, in some cases, owners purchase flat-cutters with a ripper for a walk-behind tractor, which not only perform the mentioned tasks, but also remove excess load from a person, are easy to operate, do not require lifting, and are characterized by excellent productivity. Such devices often have a fairly affordable price, but some craftsmen manage to create flat-cutting rippers for walk-behind tractors with their own hands.

Do-it-yourself flat cutter for a walk-behind tractor: a simple manufacturing method

If the walk-behind tractor has quite impressive characteristics, it is advisable to make several flat cutters and place them on the device. Thus, you will get an even more productive unit that will not only save time, but also energy.

For excellent maneuverability of the created flat cutter, you need to take care of the appropriate wheels. Almost any materials are suitable for them. An iron tube would be an excellent choice for an axle.

Then, it is advisable to weld two circles on both sides of the concrete cutting. According to the diameter, you need to attach several wires (using a welding machine), the diameter of which does not exceed 8 mm.

On the inside of the axle, it is necessary to leave space for placing the bearing and further installation of a homemade plane cutter. Since the walk-behind tractor body is not always made of very durable material, the main emphasis is on the axle. After the bearing is attached, a plate should be welded to it.

Flat cutter blades can be created from separated mower parts. Their lightness and compactness make them ideal cutting element components. It is important to make sure that they are securely fastened, otherwise the structure will move from side to side and will not perform its task efficiently.

To limit the depth of immersion, small wheels are often used. A standard children's car can be an excellent “donor”.

The wheels themselves can be supplemented with iron parts so that the plastic does not deteriorate while driving. The immersion depth must be at least 5 cm.

To increase the weight on the flat cutter for the cultivator and increase the pressure for entering the soil, you can weld a weighting agent in the form of any part. If the necessary components are missing, you can use a basket of bricks, but such a solution is not convenient.

For a better understanding of the design features, it is suggested that you familiarize yourself with the drawings. Featured videos

can also become a guide, because on these materials many craftsmen share their experience with users and reveal the secrets of creating truly durable and reliable attachments for walk-behind tractors.

It is worth noting that the created flat cutter is suitable for both Neva walk-behind tractors and equipment from the brands Centaur, Salyut and others. The versatility of the product allows you to create a truly excellent assistant at home and without any special financial costs!

Cultivator for MTZ walk-behind tractor. Description

The active growth and development of small farming in the 90s provoked industrial enterprises to produce compact units to facilitate agricultural work. These machines were significantly superior to tractors, which the average farmer could not afford to maintain. They were not only compact in size, but also highly maneuverable and productive.

However, by this time the Minsk Tractor Plant (MTZ) had already introduced small-sized models Belarus-05, MTZ 082 and MTZ 112 to the agricultural market, which immediately gained popularity due to their reliable design and ease of maintenance. Serial production increased and it was decided to move further production to the Smorgon Aggregate Plant, which was a branch.

The MTZ model range was expanded with walk-behind tractors with different characteristics and, accordingly, they had different indices in the name 05, 06, 07, 08, 09, 10 and 12. But only some 05, 06, 08, 09 and 12 gained popularity thanks to a successful combination functionality and reliability. Today, the main focus at MTZ enterprises is on the production of models 06 and 09.

Advantages of MTZ models

- Versatility, thanks to which you can connect any attachments to the walk-behind tractor to facilitate agricultural work. The design provides not only for the use of plows, cutters, harrows, and other things, but also brushes, blades and snow blowers for cleaning the area.

- Small dimensions allowing the walk-behind tractor not to take up much space when stored.

- Maneuverability, which is achieved through a well-thought-out design despite the significant weight of the unit.

- Easy to maintain.

- Possibility to repair without resorting to service centers.

- Low requirements for the quality of fuel and lubricants.

- Availability of spare parts.

Disadvantages of MTZ walk-behind tractors

- High cost compared to analogues from other manufacturers;

- Unclear gear fixation (as noted by owners);

- The need to apply effort to switch the differential;

- Mandatory running-in before use.

- Weight. It can be considered as advantages and disadvantages at the same time, because such walk-behind tractors are quite difficult to control on wet soil.

Cultivator for the Neva walk-behind tractor. Equipment for plowing land

Most often, a motor unit is purchased to be used as a motor cultivator to perform the hardest work on earth: autumn plowing and cultivation of the fertile layer. Thanks to the very large torque output from the gearbox, the power is 7-10 hp. enough to process even loamy or saline soils in several passes.

To restore the soil structure, the manufacturer offers the following tool options for work:

- A plow for a Neva walk-behind tractor with a coupling device is most often equipped with a standard or universal design of a coupling device with a frame. The walk-behind tractor allows you to plow medium-heavy soil, roots and young growth of trees;

- Cultivators and cutters for the Neva MB 2 walk-behind tractor allow you to more deeply and thoroughly fluff up the soil, chop the roots of weeds, turn vegetation debris into mulch, and use the walk-behind tractor as a multi-cultivator.

In addition to the single design, there are paired plows that allow processing with a pair of cutting edges with soil dumping in two rows, as in the photo. But it is recommended to work with such serious devices on the Neva MB 23 or Neva MB23SD motor units.

You should not expect to plow virgin soils with a walk-behind tractor; medium-heavy soil with a lot of roots and weeds is usually too tough for even the heavy MB 23 walk-behind tractors. The Neva was created to work on already plowed soil. In this case, cutters, cultivators, and plows work great.

On salt marshes and clayey soils, the rotational power of the lugs and their weight are not always enough to plow the compacted layer of soil. Often, the hooks are welded with additional weights, for example, flywheels from trucks, which lowers the center of gravity of the walk-behind tractor, makes it more stable and makes it heavier by 20-25 kg. The width of one lug wheel is 210 mm with a diameter of 460 mm.

Using the attachment on the hiller's motorized unit, you can quite successfully loosen the soil, both before planting and to remove weeds in the rows between plants. But working with such a device is quite difficult; knowledge of the specifics of setting up the tool is required.

Cultivator: concept, scope of application

An electric cultivator is a device equipped with an electric drive and designed for cultivating land. Thus, it can be a full-fledged analogue of manual labor and will cope perfectly with the task of loosening the soil, applying fertilizers, creating beds and weeding them. In simple words, an electric cultivator is a mechanized chopper.

Attention! The device in question is not at all intended for cultivating large agricultural areas. But it is perfect for caring for a small flower garden, vegetable plot, etc.

The main task of the cultivator is to give the soil the necessary structure (it removes a layer of earth no more than 30 cm deep), thus preparing it for fertilizing, watering and other manipulations with the area planted with crops.

Among the main advantages of an electric cultivator are the following:

- Ecological cleanliness. Since the cultivator runs on electricity, it is completely safe for the environment and humans. That is why it can be safely used even in closed areas (in greenhouses, for example).

- Light weight of the device. Thanks to its lightness, even people who do not have significant physical abilities (for example, old people) can handle the device.

- Compactness. The cultivator can be easily moved around the site and, if necessary, can be easily transported by car.

- Easy to operate and maintain. To work with a cultivator and maintain its working condition, it is not necessary to have special skills.

- Low manufacturing costs. It is quite possible to make a cultivator from parts that everyone has on hand, so it is accessible to a wide range of gardeners and gardeners.

The cultivator up to the walk-behind tractor is self-propelled. What is a walk-behind tractor

A walk-behind tractor, or motor-cultivator, is a self-propelled two-wheeled unit that is equipped with an internal combustion engine. The device moves freely forward, and the summer resident walks behind it, holding handles with various components and controls. Many available models have multiple forward and reverse gears. In order for the operation of such an invention to be as productive as possible, it is equipped with additional tools, including a plow, which allows plowing and cultivating the land.

The average weight of a walk-behind tractor reaches 100 kg, and the engine power often exceeds 8 horsepower. Due to such features, such a tool can become indispensable for plowing a garden area.

You should pay attention to the fact that all walk-behind tractors are equipped with a special drive for attachments, which allows you to transfer part of the engine power to a suspended mower. Basically, such a universal mechanism allows you to cope with various agricultural work, including:

- plowing the land;

- cultivation;

- transportation of the crop (in this case, you need to get a small trailer);

- cutting the grass.

With the help of such miniature trucks, residents of our regions transport firewood, fertilizers and crops. In winter, it can be used as a snow removal tool. Even the weakest model can easily pull a load weighing up to 400 kg.

Hand plow

Although such a device is called a plow, its intended purpose is contradicted. It does not have the classic properties of a plow. Even two people are not enough to work with such a tool. He is more of a classic cultivator. The device resembles a flat cutter, but an additional traction handle is installed.

Such a structure is handled by one person from the front, who acts as a traction force. And the second, the operator, controls the process of cultivating the land. It is impossible to use such a device without a co-pilot.

It is important to note that such a tool is not suitable for plowing soil for two reasons. The first is that a normal plow turns over layers of soil, but the device only loosens it. In addition, human power alone is not enough for normal plowing of the land.