Having thought about installing neon lighting as a decorative element, many feel the desire to do everything themselves. But, there are several factors that must be taken into account. And above all, the need to manufacture special lamps. Due to the fact that they can only be made using specialized equipment, neon ceiling lighting is usually not done with your own hands, although there is such a possibility.

Necessary materials for DIY creation

Today the market offers everything you need to create a neon sign yourself. The required materials and tools are listed below:

- aluminum pipe (preferably rectangular);

- aluminum profile;

- liquid welding;

- primer;

- sandpaper;

- dye;

- hacksaw for metal;

- side cutters;

- connectors for flexible neon;

- flexible neon.

In fact, everything is not as complicated as it might seem at first glance. Initially, you need to decide what the sign will look like. That is, create its layout. The best way to do this is to assemble a model from thick wire, which is secured with strong wire to hold its shape.

In the future, for the convenience of creating a neon sign in practice, the layout can be transferred to paper. The most difficult task in the process of organizing a sign is to bend the profile pipe so that it does not break or become wrinkled.

However, even if there are no obvious flaws in the bending of the pipe, it is still recommended to perform spot welding where the pipe intersects. This provides the sign with an additional level of durability. It is quite acceptable to use chemical welding (cold).

Making a suspended ceiling yourself is not so difficult

In order to get high-quality and beautiful work, at a minimum, it must be a two-level ceiling. The two-layer technique has the most advantages:

Simplicity. It is easier to screw one sheet to another than to screw it to the ceilings. Stylish and fantasy. A single-level ceiling will not provide as many ideas for implementation as a multi-level ceiling. Easier to cut curves.

Required material

Repair is always a painstaking and also costly task. It is impossible not to spend a penny and still get a beautiful, modern design. Even the simplest designs require costs. Approximate list of required materials:

- Plasterboard sheet - 1 sheet is required per 1 m2.

- Ceiling profile.

- Guide profile (PPN).

- Connector for profiles: single-level, if necessary, two-level.

- The suspension is straight.

- Screw for fastening direct suspension.

- Spring suspension.

- Rod with loop for spring suspension.

- Dowels. If the ceiling is made of reinforced concrete, then anchors will be required.

- Profile extension.

- Drywall screw.

- Screw for metal.

- The dowel is plastic.

- Putty.

- Ribbon.

- Primer.

Safety precautions

Do not forget about such an important aspect as safety precautions when working with chemicals. Although the recipes offered to you in this article will not contain caustic or toxic substances, it is still worth taking some protective measures:

- The container in which you will mix substances should be such that you won’t mind disposing of it later.

- Protect your body by wearing gloves, safety glasses, and a gown or other non-synthetic clothing.

- The workplace must be well ventilated.

- Keep children away from work.

Related article: Crochet summer jumpsuit for girls

Correct connection and installation

In order for the backlight to turn out without flaws and shortcomings, you should take into account some rules.

Rules:

The tape is sold in five-meter reels, and, if necessary, it is cut and soldered to the required size; The tape is carefully cut exclusively according to the markings; Pieces of tape are soldered according to the diagram; To secure the LED strip, use double-sided tape or self-adhesive tape. Before gluing, the surfaces are degreased, the protective layer is removed, and the tape itself is pressed to the required area. Installing the tape on a baseboard is different from installing the tape on a wall

Both options are used by the consumer

Installing the tape on a baseboard is different from installing the tape on a wall. Both options are used by the consumer.

It happens that the power supply is sold without a power cord. Then you need to buy a cord.

How to solder correctly:

- Plus and minus when the tape is the same color;

- If the tape is colored (RGB), then contacts V+, R, G and B should be soldered.

After the tape is of the desired size, you need to connect the transformer and controller.

At all stages of work, the main principle is accuracy, caution and thoroughness. Bending radius – at least 2 cm

Paths cannot be bent more than 90°.

Neon selection

In reality, real neon sign lights are quite expensive. A neon lamp is a gas-discharge lamp and consists of a figuratively curved glass tube filled with gas under low pressure. The color of the lamp depends on what gas is in the tube. For example, neon produces a red-orange color, helium produces a white-orange color, and argon produces a lilac color. However, regardless of gas, such lamps are still called neon. To light such a lamp, you need a special low-current and high-voltage transformer of several kilovolts, capable of “knocking out” electrons from gas molecules. The amount of voltage and current also affects the shade of the lamp. Neon transformers are expensive, and making them yourself will require serious calculations and electronic components. Well, blowing shaped glass tubes is a real art that requires remarkable knowledge, training and tools. Thus, making neon lamps at home is almost impossible.

Instead of using real neon lights, an excellent replacement is LED flexible neon. In essence, flexible LED neon is a regular or addressable LED strip in a transparent silicone shell. LED neon is cheap, its glow is as effective as a real neon lamp, and working with LEDs does not require any special skills.

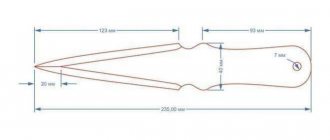

For this project we used Arlight ARL flexible LED neon, which operates on 12V DC, with a cross-section of 8x16mm and a cutting ratio of 10mm. The standard size of flexible neon 8x16 mm is one of the most common, and it is not difficult to find.

In total, we purchased several neon coils of different lengths with different glow colors:

- Yellow, 5 meters.

- Warm white 3000K, 10 meters.

- Blue, 5 meters.

- Cool white 5000K, 5 meters.

- Red, 5 meters.

- Amber, 5 meters.

- Green, 5 meters.

How it works

Neon lighting is based on a gas-discharge tube. It is a glass flask sealed on both sides, with electrodes attached at the ends that are not interconnected. A special substance, a phosphor, is applied to its inner surface. Discharged neon is pumped inside it - a gas that does not interact with the materials of the device in its normal state.

As soon as a high voltage current is applied to the electrodes, the atoms of the gaseous substance lose electrons and form ions - active elements. The latter, interacting with the substance sprayed onto the bulb, cause a glow - which is perceived as neon lighting. Moreover, its color is completely determined by the composition of the phosphor.

Please note! To initiate a neon lamp, a voltage of about 15 kV is required! Therefore, the circuit of such a lighting system must have a step-up transformer.

Where can flexible neon be used?

The most common areas include:

- decoration of building facades, architectural monuments;

- design of advertising signs, banners and billboards;

- decoration of parks with illumination of trees and bushes;

- car design (body, interior);

- design of interior spaces of clubs, bars and other establishments.

Using flexible neon.

The switch is working. Video

You can learn about the joint operation of an LED lamp and an illuminated switch in this video.

All calculations made in the article are valid for the normal glow mode; when using them for switches, the resistor values can be adjusted to increase by 2-3 times. This will reduce the brightness of the LED, neon and the power dissipation of the resistors, and therefore their dimensions.

If a capacitor is used as a damping resistance, then its value must be adjusted downwards to reduce brightness, as well as dimensions, but the operating voltage of the capacitor cannot be reduced.

Reducing the current through the backlight reduces the likelihood of energy-saving lamps flickering in the dark, since the charge level of the input capacitor in the pulse converter of these lamps does not reach the start threshold.

Our comfort comes from little things. Such a small detail - the backlight of the switch - but there are many advantages from it. How to connect a backlit switch so that everything works without problems, how to “make friends” with LED and energy-saving lamps, how to make sure that this small improvement does not “draw” a lot of electricity. All this is in the article.

In electrical switches, the backlight is an LED or neon bulb. Outwardly, they are little distinguishable, but neon lights consume less electricity, but create a larger voltage drop. For LEDs, the minimum glow current is 2 mA and the voltage drop is 2 V, for neon bulbs in the backlight - 0.1 mA and 70 V, respectively. And this should be taken into account when choosing.

Another important point: the switch backlight may not work correctly with all types of lamps. The backlit switch works with incandescent and halogen lamps without any problems. But with energy-saving and LED ones, it is better not to install them or take special measures. If you just connect it, there may be problems. The most common ones are that the backlight will not light up or the light will blink when turned off.

If we talk about the number of keys, then the backlight can be on a switch with any number of keys: one, two, three or even four (if you find them). In addition, they can be both on regular models and on walk-through models. The location of the luminous point is also different: on the key or on the body. On the key it can be at the top or in the middle, on the body - at the center at the top or bottom.

Neon lighting installation

Before starting installation work, it is necessary to draw up a plan for the placement of lamps, transformers, wiring, switches and interior elements. Then perform electrical equipment calculations. For neon lighting, it is better to use special components and wires with silicone insulation.

The neon tubes themselves are attached to lamp holders, which are pre-installed with screws or dowels on the surface of the wall, ceiling, floor, furniture and other interior elements in accordance with the diagram and plan. After they are installed, you need to install convectors - already calculated based on the power and length of the lamps (approximately 10 W per working meter of device length, so one converter is used for 7-8 m).

What is

Traditional neon lighting is based on glass lamp tubes, closed from the outside environment, filled with an inert gas. A special feature of this lamp is its wide color variety. This is precisely what explains its widespread use. The natural shade of light emanating from such a source is red and pink. However, the use of a special surface substance on the bulb allows the radiation to be directed to any part of the spectrum.

In addition to high aesthetic values, neon lighting is valued by consumers due to the following series of advantages:

- Uniformity of lighting.

- Wide variety of colors.

- Durability (at least 10-15 years).

- Fire safety (the lamp does not heat up above forty degrees).

- Safety for others.

- Quiet operation.

- Comfortable visual perception.

Of course, neon lighting has no disadvantages:

- It is impossible to create a specific shape for the tubes to match the interior elements with your own hands.

- The need to install a step-up transformer.

- The increased fragility of neon lamp bulbs requires special care during their maintenance and cleaning of the room.

In general, neon lighting, with the right choice of components and proper installation, is a good, durable and maintenance-free way to decorate a room with lighting.

This is interesting: Repairing the VAZ 2110 gearbox on your own

A little about the lamp

A fluorescent lamp is a product in which a fluorescent lamp acts as a light source. The operating principle of such a light source is based on the transmission of voltage using mercury vapor. Under the influence of an electric charge, this substance produces a bright glow, due to which the lamp has excellent light output.

Note! Such lamps are produced by manufacturers with different emission spectrums. This allows you to install lighting of the most comfortable spectrum.

This lamp is considered one of the most common models in office, municipal and public institutions. But besides this, it is also quite widely used in private houses and apartments. The fluorescent light source has gained popularity due to its efficiency and bright glow. At the same time, the principle of organizing a lighting device is quite simple. Therefore, many today carry out repairs and assembly with their own hands.

Second option

In the second case, we will use a base for the lamp made of electronic ballasts (electronic ballasts). This DIY product is perfect for technical or utility rooms. In this situation you will need:

- frame. It can be made from scrap materials (just do not take flammable products);

- electronic throttle or electronic ballast. It's better to use the second option;

- G13 cartridges. They are taken at the rate of two sockets per lamp;

- stranded copper wires with a cross section of 0.2-0.5 sq. mm. Flexible (multi-wire) ones with tinned ends are also suitable;

- screws and nuts for installing all parts on the body.

We make the lamp as follows:

- install the cartridges at the required distance from each other;

- attach electronic ballasts. Since this element will heat up during operation, we position it in such a way that it is affected by a minimum of third-party heating;

- we connect the cartridges with electronic ballasts using wires according to the diagram;

- To connect the cartridge, you need to remove the insulation from its wire. It is necessary to remove approximately 1 cm;

- after this, the wire free of insulation must be inserted into the hole until it stops;

Note! According to the specifics of the selected cartridge, it is necessary to select the wire cross-section. It is better to use solid wires.

- the wires just need to be inserted into the sockets, and they are clamped by the leaf spring holders inside;

- We insulate all contacts between the wires well;

- We place all the elements inside the case and cover it with a protective cover on top. Despite the fact that this is not a mandatory procedure for low pressure lamps, protection of the device and its contents is still necessary. Otherwise, the lamps may be damaged by mechanical shock and mercury vapor may escape, which is very toxic to the human body;

- For better sealing, you can apply additional sealant along the entire length of the body. But this will complicate the process of repairing and replacing failed lamp parts in the future.

Connecting such a lighting device will go to a 220V power supply. This design allows you to place the lamps on the wall or ceiling. However, repairs for such products will be somewhat difficult due to the method of mounting the device. As practice shows, self-assembled fluorescent lamps using this scheme work well and for a long time. But for this it is necessary that the ambient temperature be in the range from -10 to +30°C. To summarize, we can conclude that the process of self-assembling a luminescent model lighting fixture is not that complicated. The main thing here is to follow the connection diagram for all components of the electrical circuit and clearly follow the sequence of manipulations.

How to make angel eyes for a vase yourself? Support structures for outdoor lighting: what you need to know

Handmade items fill the home with special warmth and comfort. In addition, they turn out to be exclusive. We offer an overview of lamps that will completely change the atmosphere in the room, turning into the envy of friends and relatives. Moreover, they are made from everyday items that are usually thrown away.

Cardboard bags for juices or other drinks are a fairly common thing in most homes. Most often it is thrown away. But Malayan designer Edward Chu spent a lot of time cutting them into hundreds of strips and making amazing lamps from them without a drop of glue, a simple origami principle.

Yaroslav Olenev proposed making lamps from disposable plastic spoons and became the winner in the Ecology and Design category from the Future Now magazine.

Natalie Simpson also found an equally original use for ordinary wooden hangers. But they look amazing in the form of a chandelier.

Kevin Champeny must be given his due; not everyone has the strength and patience to string 14 thousand bears to get a chandelier.

Tira Hilden and Pio Diaz have their own vision of the problem of housing lighting. Their lamps make the room look like a forest. All the walls come to life and turn into trees.

A talented welder, Matt Ludwig also turned out to be an excellent designer. For JJ's Red Hots restaurant, he made an incredibly original chandelier from an old drum set.

Texas artists Joe O'Connell and Blessing Hancock used parts from old bicycles to create stunning lamps and hang them in a tunnel under the highway.

It will probably be difficult to find a more original chandelier than one made from a pumpkin by a Polish artist. He carves stunning patterns into the peel that never repeat.