Do-it-yourself UAZ dumps (drawings)

An SUV for the owner of a suburban area, taking into account the quality of the roads, is an excellent help, and sometimes even a necessity.

Under the hood of such a unit there are almost a hundred, and sometimes more, workhorses, which, coupled with the impressive weight and driving characteristics, becomes a serious argument in the fight against off-road conditions. Why not use this power to improve the traffic situation in your local area during the winter? Manufacturers have long been concerned with suitable attachments, producing snow plows for UAZ and other SUV models popular in our country. Why not save money and make your own model of the blade, given that homemade versions turn out no worse, and sometimes even better than factory ones?

Car modification options

Alterations (tuning) of the GAZ 66 car could be minimal, for example, original drawings were applied to the cabin and body using airbrushing or a film with the selected picture was pasted. More serious changes are also possible, involving replacement of the cabin and body. And the most demanding owners make almost complete replacement of units; all that remains from the original car is the frame and axles with wheels, and sometimes they are modified too.

The choice of GAZ-66 for modernization is primarily due to its high cross-country ability. You can turn a car into an SUV, in comparison with which even the best foreign analogues no longer seem so wonderful. On the Internet you can find many photos and videos of various homemade products that are not inferior in exterior and driving performance to foreign models.

There are even proposals to put such craftsmen at the head of domestic factories or even the entire automotive industry. In addition to SUVs, tractors, loaders, all-terrain vehicles and other special equipment are manufactured on the GAZ-66 basis. Of course, wheeled vehicles cannot compete with tracked vehicles in cross-country ability, but they are quite suitable for farming work. With such alterations, the gear ratios of the gearbox and rear axles are often changed,

and various devices for hanging replacement equipment.

Factory option

There is no need to reinvent the wheel; it is much easier to find out how to make a dump for a UAZ from the manufacturers. It will most likely not be possible to completely copy factory suspended plows, but it is quite possible to take some models as a basis. In addition, a detailed study of proven options will allow you to avoid many mistakes when designing and manufacturing your own snow shovel.

- Blade dimensions. The minimum blade width on sale is 1900 mm, this is understandable; the wheels are located at a distance of up to 1.8 m on the outside of different models. The blade should cover this distance with a margin even in an inclined position; a width of 2-2.1 m would be ideal.

- Rotary mechanism. Different models provide finger fixation in the center or the use of additional rods. With such a blade size, it is better to use additional reinforcement.

- Fastening to the car. This unit provides the ability to lift the shovel vertically and sometimes protect the steering rods.

- Lifting mechanism. From the simplest leg for lifting the blade when moving backwards to winch mechanisms with manual or electrical control.

- To cushion the UAZ blades when colliding with serious obstacles, you can make it movable and equip it with springs.

Step-by-step assembly process

During the work:

- The springs are lighter. To do this, the sheets are removed from the front and back.

- Brakes are being replaced.

- The housing from Niva is being installed.

- The transfer case is installed. The original model is not more reliable than the base model, so a different layout option is selected. This unit, removed from the ZIL 157, is excellent. But now it is quite difficult to get one that is working and in good condition.

- The cardan shaft is shortened, the RK66 traverse is shifted by 20 cm. This is necessary because The spare part taken from Nissan does not fit in length.

- The engine is installed on special brackets.

- It is best to take the steering from the ZIL, but in this case you will have to shorten the bipod.

When creating the car, the original thrust from the GAZ-66 is also shortened.

Mounting the cab from the Niva does not create any problems. It is carried out at three points using M12 bolts.

All all-terrain vehicles created on the basis of the GAZ-66 cope with the functions assigned to them and can be used in many areas of the national economy.

Read news about the new Niva

- Studded tires for Lada Niva (2121) 4X4 1700 i 4×4, 2015. Buy studded tires for Lada, prices, photos.

- Engine crankcase ventilation system, EGR valve, device, operating principle of PCV, diagram, how to check, cleaning -

- Snow and swamp-going vehicles on ultra-low pressure wheels - review of models

- The history of the famous Soviet SUV UAZ-469

- Towing device (towbar) with a removable ball and a platform for a winch for Chevrolet Niva (VAZ 2123) - buy with delivery throughout Russia

- Buy a Renault dump truck in Moscow! Current prices for dump trucks. Photo

- New Niva: what AvtoVAZ will produce in 2022 :: Autonews

- Error P0441 on Lada Kalina: what to do and how to fix it?

Design

Much depends on the availability of materials and technical skills. It is more reliable and easier to make a blade without a rotating mechanism, thus saving a little on materials and significantly reducing the production time, but this will reduce its scope. On the other hand, the rotating mechanism can become the most vulnerable point of the structure; its design requires a certain margin of safety to be provided at the fixation points. The working surface of the blade also requires reinforcement; it is important to monitor the weight of individual parts. It is desirable that the blade can be mounted and dismounted by one person.

To protect the surface being cleaned, a rubber strip should be used, the fastening of which should be detachable so that the rubber can be replaced as it wears out. Where the blade is attached to the vehicle, it is worth considering a possible sharp collision of the blade with an obstacle. Mounting points should not be located in front of important parts of the vehicle.

Material selection

At this stage, the choice always remains with the performer; you can only advise or suggest where it is easiest to find suitable parts. Two-hundred-liter barrels have proven themselves well as material for a dump shovel, but given the planned dimensions, 2 barrels or additional reinforcement of the structure will be required. Square or rectangular pipes can be used as guides and reinforcing ribs; it is also possible to use a rolled angle, thin channel or I-beams.

For jumpers that regulate the angle of the blade, you can use lanyards or pipes of different diameters with holes for fixing fingers. When using a winch to control the lifting of the blade, additional material will be required to arrange a platform for the winch itself and a block system if necessary.

Ears for attaching the blade to the car

This is the eye for attaching the blade to the Niva in the end; I was able to bend it, so I left it as is.

- (1) - this is the factory eye

- (2) and (3) - I drilled for the bolt

- (4) - welded additional eye

- (5) - the bolt that holds the eyes is screwed into the Niva spar

After fitting the shovel to the machine, I added a few more jibs from a tube with a diameter of 20 mm, you can make them from the same profile pipe, I had the tube in stock. Blue arrows indicate the jibs, red arrows indicate where they are welded. It should be noted that I tried to attach them to the spring, because it is a shock absorber and shock absorber. Only the farthest one in the photo is attached to the rod itself, there was no possibility of attaching it to a spring, and the load is maximum there. without it, the right corner would have been turned over by a snowdrift.

Main stages and nodes

Where to start working in order to implement the planned dump on the UAZ with your own hands? The drawings must be made taking into account the model of the SUV, and there should always be some margin in size so that possible shortcomings can be corrected on the spot. The first step is to equip the place where the structure is attached to the car. These can be either simple fixed brackets or a whole platform like a “kenguryatnik” to accommodate not only a blade, but also a winch with a block system. The platform can be made either permanently or as a removable structure, which is preferable since it does not spoil the appearance of the car.

Homemade all-terrain vehicle assembled from GAZ-66 and UAZ spare parts: photo and description

A homemade all-terrain vehicle based on the GAZ-66, which was put into small-scale production: photo and description of the design of the all-terrain vehicle.

A whole team of homemade workers worked on the creation of this all-terrain vehicle. Through trial and error, they went towards their goal: to make a car that would combine ease of maintenance, reliability, practicality, cross-country ability, maneuverability, good speed, large capacity and carrying capacity.

Well, since the all-terrain vehicle is intended for operation in hard-to-reach places and remote from civilization, it must pave the road itself: drive over logs and fallen trees, wade through bushes and young growth, overcome ditches and swamps.

To realize their plans, they took the GAZ-66 car as the base of the all-terrain vehicle. The rear suspension remained leaf spring, but the front suspension was converted to a spring suspension, and double springs were installed. This gave significantly more suspension travel and made it softer. Now the springs do not limit the angle of rotation of the wheels, as a result maneuverability has increased.

The axles have self-locking cross-axle differentials.

The wheels are used from the MAZ-537 (Hurricane) military tractor with herringbone-type lugs. The tires were “lightened” - some of the lamellas were removed, as a result their pattern became more “evil”.

The V-shaped engine, with a power of 120 hp, pulls well at the bottom and at the same time allows the all-terrain vehicle to reach a speed of 95 km/h. Gas tank with a capacity of 105 liters.

Also interesting: Kuban gardener calendar 2022 lunar, sowing and planting, garden table, Krasnodar Territory

The interior of the all-terrain vehicle is simple and ascetic; it can accommodate 12-14 people. But for hunters it’s the best! Often the car serves as a “shift vehicle” - in order to transport people and fuel to the right place. Overall a workhorse!

In the photo: the design team.

Dimensions of the all-terrain vehicle: Length 5600 mm; Width 2500 mm; Height 2600 mm. The vehicle weight is about 3000 kg.

The all-terrain vehicle was built not in a single copy, but in a whole series. It is registered with Gostekhnadzor as an all-terrain vehicle and can be driven on public roads (included in the dimensions).

PSM issued to the all-terrain vehicle. To drive an all-terrain vehicle you need a tractor license.

Author of the photo: Sergey Stulov.

Lifting mechanisms

You can see options where a manual drum winch is used as a lifting mechanism, and it is controlled by a person located on the front platform. This is not very safe; it would be better to raise and lower such dumps on the UAZ after the vehicle has completely stopped.

Using electric winches is much more convenient and safer, but not everyone is willing to spend money on such equipment. The most budget-friendly option would be a special stand that is activated when the car is reversed, and to constantly hold the blade in the upper position during transportation, you can use a lanyard.

Improvement of the Shishigi salon

The goal of upgrading the interior should be to eliminate all kinds of problems and shortcomings. As for the GAZ 66, the weak points here can rightfully be considered noise insulation and quite a lot of dust inside the cabin. Eliminating these issues is of paramount importance.

Using special insulating materials, we carry out thorough sound insulation and eliminate all cracks. After sound insulation is well done, the cabin will become relatively quieter, and dust will practically be eliminated from entering the cabin.

Now it's time to trim the interior. To make the interior of the car more modern, it is necessary to reupholster the seats or completely replace them with softer and more comfortable ones. Next, we replace the door trim, ceiling trim, and floor trim. Don't forget about a modern sound system - not a single modern car can do without it. It is worth installing a modern subwoofer and powerful speakers. Then a trip on such transport will become even more exciting.

These are the main transformations that need to be carried out in the salon. Everything else is a matter of fantasy. Here you can be as sophisticated as you like - add all sorts of bells and whistles if necessary. This could be all sorts of additional storage space, cup holders, armrests, window curtains, LCD monitors and DVD players and much more - there’s a lot to choose from here.

Modernization of the dashboard. Adding brightness.

You can add modernity to the dashboard using the notorious LED backlight. It will look quite stylish, and the readability of the panel will noticeably improve. The backlight color can be selected as desired. A panel with white light will look especially bright. Blue or green color will add unusualness to the interior of the cabin. In any case, this will bring an additional effect and make the salon attractive.

In addition to the dashboard lighting, all fixed light bulbs in the cabin can be replaced with LEDs. If desired, you can lay an additional LED strip along the bottom of the cabin, under the seats, or vice versa in the upper part of the cabin. This technique will delight passengers during night trips. If you are not well versed in electrical engineering, then it is better to use the help of people who are professionals in this field to equip the machine with additional lighting.

This is how, with the help of simple transformations, a good SUV turned into just an excellent supercar with improved technical characteristics, an attractive appearance and a fairly comfortable interior.

In general, tuning a GAZ 66 with your own hands is a rather painstaking task and does not tolerate haste or negligence. This requires a measured creative approach, perseverance and a great desire to make your dream come true. The above options for modifying the famous SUV are just a small part of the ocean of possibilities in the field of transforming an ordinary truck. With a responsible approach, you can do something different. Therefore, you should not be afraid of difficulties - if you have a desire, boldly take action. And the result will definitely exceed all expectations. Good luck with your remodeling!

Next is a video with GAZ 66 tuning, there are various interesting options:

You can also read on this topic:

Bugatti Veyron - the legendary dream-car

Mitsubishi Pajero technical specifications

Test drive of the Gili Emgrand x7 SUV

Do-it-yourself tuning Dodge Caravan

The Japanese have announced prices for the American version of the new generation Nissan Armada

Share on social networks

Alexander Stepanoff March 4, 2015

Published in: Russian cars

Tags: SUVs, Cool, Our cars

How to make a snow plow for a UAZ with your own hands

A homemade blade for an UAZ is an excellent alternative to similar industrially produced products. The domestic SUV is distinguished by high cross-country ability and engine power, and is heavy, providing reliable traction with the ground. Equipping the machine with attachments expands its capabilities and eliminates the need to buy and maintain expensive garden equipment.

Homemade super-jeep based on GAZ-66 (13 photos)

At the end of May 2011 in Irkutsk at the central stadium "Trud" the 7th regional festival of auto tuning BaikalMotorShow (BMSH-2011) will take place. We present to you one of the participants.

LEGEND OF THE STEPPE The moment of truth came when, after a voyage through the dusty hills, we stood next to the sparkling Land Cruiser 100. The iconic Japanese SUV looked like an innocent toy next to the creation of Vyacheslav Zolotukhin from the once closed city of Krasnokamensk.

That’s when we fully realized the scale of this super SUV, 5.8 meters long, 2.3 meters wide and the same height. After all, judging by the ease with which the car just literally fluttered over the slopes and rocks, it is difficult to imagine that it is based on the chassis of the well-known GAZ-66 military truck. Vyacheslav has known good cars for a long time; back in the 90s he was involved in transporting them from the Far East. I had more than one Japanese SUV at my disposal; I drove a lot of things on them. And over time, I wanted much more than standard factory solutions could offer, even in the class of heavy jeeps. Tuning? No, it didn't suit me. I wanted, so to speak, a conceptually different level, something like a Mega Cruiser, but with my own ideas about comfort, capacity, reliability, maneuverability, and so on. So it came to the need to build your own car, freely using the achievements of the domestic and Japanese automobile industry. The foundation of the project was the GAZ-66. Of course, not by accident, but very consciously. This Soviet “blockbuster”, of course, has its own miscalculations: a useless engine and gearbox, and the very layout of the car with a heavy cabin and an engine above the front axle is an extremely poor solution in terms of weight distribution. But the “shishiga” also has its own wonderful sides, especially in military models produced before 1975, when the car was made only for the defense industry and really to the conscience. In addition, the light army truck was designed with the expectation of being dropped from the air. The main advantages are a strong but “flexible” frame made of 6 mm steel and strong axles with free axle shafts and effective self-locking differentials. One of the disadvantages for “civilian” use is the constant engagement of the front wheels, the axle is switched off only in the transfer case. But this problem turned out to be removable with skill. In general, the bare chassis of the GAZ-66, with the engine, gearbox and cabin removed, became an inspiring start for the design. So to speak, the skeleton is ready in the rough, and with the full preservation of the wheelbase. But the heart and body of the future “King Kong” were parts... also from trucks, but now Japanese, and medium-duty ones at that. The engine from the five-ton Hino is a 6-cylinder diesel engine with a volume of 7.5 liters. Atmospheric, completely cast iron, with in-line mechanical equipment, with a timing gear drive - a beauty! The 6-speed gearbox is from him, but the transfer case remains original from the 66th, but Vyacheslav went over it and replaced our “square” bearings with imported analogues, after which the noise noticeably decreased.

A huge hood on gas struts opens up the vast engine compartment. The only thing that is not native to the 7.5-liter Hino diesel engine is the air cleaning system - it was borrowed from KamAZ. And the cone adapter to the engine air pipe is made from a tank shell casing!

The bifurcated exhaust tract is not for showmanship - it was necessary to use two compact “cans” of mufflers instead of one bulky one.

In front of the rear axle, a 180-liter tank from the ZIL-130 is completely inconspicuously placed and additionally protected . Do I need to clarify that adjusting the power unit required other fastenings and alteration of the frame cross members? In addition, the frame was “trimmed” at the edges. But it is important to note that the heavy diesel engine, for reasons of proper load distribution, was shifted as far back as possible. In turn, this had a positive effect on the design of the body itself, which, according to all the canons of classic jeeps, turned out to have a forward axle and a short overhang. At the same time, the relatively bulky engine does not “stick out” high - to reduce the center of gravity, it is located as low as possible, for which it was necessary to modify the sump. And the diesel engine did not “climb” into the cabin at all, like in the same Hummer.

In the park of Vyacheslav Zolotukhin from Krasnokamensk there is a Toyota Land Cruiser 100, but for off-road trips he created his own version - Mega Cruiser Russia

KNOTAL CHANGE Why is there some kind of “Hummer”, here the interior is not a Spartan booth, but spacious and cozy, one might say cruise cabin with magnificent views.

It is based on a double and “wide-body” cabin from the Isuzu Elf truck, respectively, with “its” interior, although largely modified. But the rear part, that is, the luggage part, is borrowed from the Noah minivan! To connect it with the Elf cabin, it was necessary to expand the dimensions with inserts, and make the rear window original. The front ensemble is no less interesting. The wings are made using those from GAZ-3307, the hood is original production, the radiator grille is a composite of two grilles from Prado, and the headlights are from Delica. The steering wheel is adapted from a Honda passenger car - with the steering mechanism from a 5-ton Hino, its smaller diameter did not affect the efforts, but the steering with it is sharper and faster than that of trucks.

The “cabin” comfortably accommodates 3 people in the back, not very cramped for four, in front there is a double passenger seat from HiAce, which “spins” and folds into a table.

Both bumpers are made in-house, made of metal. In general, Vyacheslav does not like to work with plastic, he trusts only metal, and makes things from it as it should be, carefully and accurately. Using our own know-how in technology. The fit of the parts is excellent, and all the joints with the necessary welding of the elements are invisible. For example, the front doors in their original version had cutouts for the wheel arches, but now they are solid, as if they were stamped that way by a Japanese assembly line. The original wheels were remade as if “inside out”; as a result, the offset of each wheel increased by 10 cm, that is, the track was widened by 20 cm, which, given the height of the car, added the necessary stability. I installed tires from the Tiger, they are smaller and lighter than the original ones from ’66. The front hubs are made detachable, and not with the help of fast, but low-resource “switches”. Here Vyacheslav used a much more timeless design similar to the closed threaded clutches on the GAZ-69 and UAZ. It requires two special keys and five minutes of time, but everything is extremely reliable.

For reliability, the body is mounted on the frame on 12 supports; according to the Japanese experience, each support is made of three rubber pads.

Test drives revealed “raw” areas in the structure. Thus, powerful torque and power were roughly applied to axles with a large gear ratio, “tailored” for a frail gasoline engine. The car drove jerkily, with a “catapulting” effect. In jeep tuning they usually raise the number, but here it was necessary to lower it. In addition, the car shook and tossed quite a bit due to the rigid suspension - the curb weight was only about 3.5 tons, which the GAZ-66 chassis hardly noticed. Oddly enough, the solution to the first problem was found with the help of GAZ - in the plant’s arsenal they found faster main pairs that were used on buses. The second question turned out to be more tricky. At first we experimented with the selection of springs, but somehow we could not achieve a good result. Then the highlight of the program was found - shock absorbers. In addition to everything else, the truck is also a “parachutist”! Its so-called double-action shock absorbers were designed for a hard landing, the likes of which do not exist in the Dakar. Instead of the original “jumpers”, Vyacheslav installed converted shock absorbers from KamAZ. In addition, the shortest and stiffest sheets from the spring packages were removed.

The wheels of the 66th are barely recognizable: the wheels are “riveted” to widen the track, the bolts are made of stainless steel, and the tires are off-road KI-115A in size 12.00 R18, used on Tigers.

And the front hubs have been independently redesigned with the ability to “turn off” the wheels. TRIUMPH OF THE UNFORMAT That's when the "Mega-Shishiga" drove as we wanted: smoothly, softly and at the same time very confidently - the traction reserve allowed us not to resort to downshifting in most cases, even in meter-long snow on the slopes. But there is a lot of snow here, and in the conditions of the hills it is formed in a specific way: somewhere the wind blows it away, and somewhere it sweeps up entire dunes. Unfortunately, our meeting with Vyacheslav took place in conditions of melted snow, but even without that we managed to taste the delights of a truly extraordinary SUV in every sense. So huge and empty, it rides surprisingly easily and softly both on broken asphalt and across the steppe, dotted with furrows and rocks. He waddles over ditches and stones like a bear, with a calm gait, energy-intensive and without any “concussion”. The owner says that if the car is loaded, then it actually floats like an executive sedan. The landscape here is, in principle, flat and hard, but 40 km from here the forest begins, with holes and ruts. Due to lack of time, we did not go there, but Vyacheslav had already visited a lot of places. Of course, the dimensions will not allow maneuvering among dense tree trunks, but in this case there is no such need - the operating conditions are not the same.

The wheel weighs 80 kg, which forced us to strengthen the spare tire bracket more than once.

It folds down, which makes access to the trunk difficult, but its solid door is planned to be converted into a more convenient double door in the future. What’s more important is that in winter you can easily go skiing and snowboarding: there are no organized trails in the vicinity of Krasnokamensk, but there are as many wild slopes as you want - choose to suit every taste, and “Mega-Shishiga” will take you to the starting point without any lift. No noise or vibration bothers us, although no serious additional insulation was done. Supplying heat to a large salon is also no problem. Yes, at the same GAZ there are examples of small-scale construction of hooded all-terrain vehicles with all-metal bodies on the Sadko chassis, but those cars are very heavy, with problematic engines - they cannot drive off-road without a downshift and huge fuel consumption. The notorious “Tiger” on an armored personnel carrier with 7 tons of live weight and an electronically controlled diesel engine is also not a competitor. And Vyacheslav’s brainchild drives everywhere effortlessly and economically - on the highway at 80 km/h it consumes only about 13.5 liters. It took a year and a half to build the car, but three years have already passed since then! And the surprising thing is that the car is still almost unknown not only in the region, but even in Krasnokamensk itself - Vyacheslav does not advertise it, he almost never comes into the city. So the BMS should become an all-Russian premiere for this Transbaikal legend. Among those rare people who know, there were those who wanted to buy this off-road cruiser for good money and even offered a Lexus LX in exchange. Vyacheslav refuses, but is ready to consider an order for the construction of similar or other interesting machines. One such new project is already maturing and promises another exclusive, but the author has not yet talked about it.

Perhaps, even among American SUVs one cannot find such “humiliations” for the Toyota LC100.

Why might a blade be useful?

An all-wheel drive vehicle can be used for more than just cross-country travel. Its performance characteristics are on par with those of tractors used by public utilities.

The snow blade on the UAZ is used for the following purposes:

- Planning of the local area, construction site, field and vegetable garden. The wheeled all-terrain vehicle generates enough torque to cut off the top layer of dense soil and move it over long distances. A machine equipped with a knife levels out bumps, fills holes, and makes the area even and smooth.

- Landscape design. Equipment equipped with a blade is used to dig out pools and ponds. The depth of the reservoir can reach several meters depending on its area. A homemade bulldozer is used to build alpine slides, embankments and artificial hills.

- Clearing the area of snowdrifts. A car with a shovel effectively clears snow up to 50 cm high. In a short time, passable equipment with a blade can tidy up a garden plot and driveways to a house. The entire area is cleared, or work is limited to areas, paths and paths. Snow moves to the fence or is removed from the site.

- Construction and repair of roads. In holiday villages this problem arises constantly. A UAZ with all-wheel drive can level the road surface, fill potholes, and clear ditches of debris. When moving forward, most of the work is done. When shifting to reverse gear, the final leveling occurs.

The mounted knife is also useful for field work. It is used to move cut trees and bushes, fertilizers and tops.

Popular manufacturing options

The UAZ-3303 truck has a two-seater solid metal cabin with two side single-leaf doors. In the front part of the structure, under the removable hood cover, the engine is located. Behind the cabin there is a cargo platform with folding sides. Depending on the model, it is made of wood or metal. The body can transport cargo weighing up to 1200 kg.

Dimensions of UAZ –3303

The technical characteristics of the car are designed for operation in different conditions, including in rural areas. Many people working in the agricultural sector note that despite all the advantages of the truck, it does not have equipment for unloading materials using a dump truck. However, it is possible to solve this problem if you construct a dump truck from an UAZ with your own hands.

Re-equipping a vehicle with a lifting mechanism will increase its functionality and save time on unloading the body. At the same time, the carrying capacity of the vehicle remains at the same level.

There are two options for making a dump truck convenient for use from a UAZ-3303.

Option

The easiest way is to lay a square beam under the front side of the body and attach a long cable to it, laid along the entire length of the platform. In this case, the truck will be unloaded as follows:

- When opening the side of the machine, the cable is pulled out and attached to some stable support, for example, a tree or pole.

- As the car moves forward, the beam moves along the body and pulls the load.

This method, although simple, is far from perfect, since the load may end up in an unstable position.

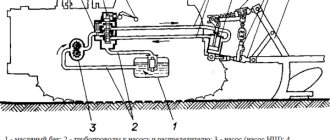

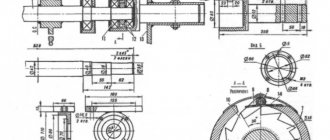

Device for installing springs - drawing

Option

When constructing a dump truck yourself, a more reliable way is to install the hydraulic system on the platform frame. Despite the fact that some companies offer ready-made kits for lifting the body, you can make such a device yourself.

How to make it yourself

To make a blade, you need tools and equipment that are available in every home workshop.

To work you will need:

- welding machine;

- Bulgarian;

- electric drill;

- roulette;

- square;

- durable knife;

- adjustable wrench;

- core;

- sandpaper;

- paint brush.

- steel barrel 200 l;

- 2 springs from UAZ or GAZ;

- profile pipe 20x40 mm;

- iron corners 30x30 mm;

- hardware (bolts, washers, nuts);

- car tire;

- acrylic paint.

To make a blade for an UAZ with your own hands, drawings should be prepared for 4 components of this product: an installation device, a subframe, a knife and a lifting mechanism.

Tools and materials

You can install a snow blade on the frame of any motorized cultivator that has a power of more than 4 hp. and weight not less than 50 kg. The heavier the unit, the better it will cope with the consequences of a snow storm.

It is best to equip the domestic Neva walk-behind tractor with a shovel. This equipment has high performance characteristics and is adapted to work in the most severe weather conditions with maximum load.

A shovel for a walk-behind tractor is made with your own hands using the following devices:

- roulette;

- welding machine;

- grinder with discs for cutting and grinding metal;

- electric drill;

- set of wrenches;

- screwdriver;

- paint, paint brush.

After preparing the tool for work, it is necessary to decide on the material from which the shovel blade for the Neva walk-behind tractor will be made. You can make a shovel from various metal products that have a sufficient margin of safety.

The blade for the Neva walk-behind tractor can be assembled from the following materials:

How to secure

The fastening device is the most complex and critical part of the entire blade design. The shovel is mounted on the frame using brackets made from straightened springs or profile pipes. It should be borne in mind that such a factory-made mechanism can cost 10,000 rubles or more. Therefore, it is advisable to do it yourself and spend the saved money on purchasing components.

A simple option is the central holder, which is assembled in the following sequence:

- Welding a profile pipe to the back of the shovel.

- Fastening a semicircle made of steel sheet to a stiffener rib.

- Drilling holes in a semicircle.

- Making an L-shaped holder.

- Attaching the holder to the semicircular base with a central swivel bolt.

- Attaching the device to the car frame.

Adjusting the angle of the bucket is done by removing the locking bolt, turning the blade in the desired direction until the holes line up, and re-tightening the bolt and nut. To reduce the impact force on hard objects and bumps on the ground, an adapter with a short and stiff spring is inserted into the holder.

Source

Making a blade for Niva

The device consists of 5 main elements. First

— factory-made “kenguryatnik”, the only purchased part. We install it on the “nose” of the car. In principle, you can weld your own if you find pipes of the required cross-section. Second element

— cross member with mounting axles

(Fig. 1)

.

Important Universal excavators EK Kranex and Tveks

Cross member assembly. We press the axles into the pipe (ST-3;5) with a hammer to a length of 100 mm. On the axle, close to the pipe, we put washers on both sides, which we then weld to it. The axles must have 6 2.5 mm holes for pinning the nuts after they are installed.

We weld the finished crossbar to the “kenguryatnik”, additionally strengthening it with 4 corners 30×30 mm, 40 mm long.

How to make a UAZ blade for snow removal with your own hands on an UAZ?

In the modern world, with the current level of technical development, removing snow with a hand shovel is becoming quite rare. It is not advisable to spend time and your own energy cleaning the territory of the house, the surrounding area or the street, if you have a strong SUV, in particular, even such as a UAZ. In this article we will look at the types of blades for snow removal, as well as options for making a blade for an UAZ with your own hands.

Video of the blade operation

Well, a video of working with the blade, as you can see, the blade shovels quite a lot of snow, and is limited only by the Niva’s cross-country ability, so far the tires are ordinary, studded road tires, the Niva is not very passable on it, but this is enough to clear snow from the road.

Further operation of the dump on Niva

In general, it performs its functions 100%, the height of the shovel itself is satisfactory, it is not necessary to lower it, because it will throw snow onto the car, the angle from the car is also normal, but you can increase it a little, they also installed an additional PTF on the roof, because the blade blocks the headlights, and they become useless.

They cost 100 watt halogens, there is a separate topic about how they shine, they shine over the blade onto the road, one closer, the other further away.

What not to do

Now about why the blade had to be repaired, this nuance should be taken into account by absolutely everyone who wants to make a blade for the Niva with their own hands, the fact is that with short rods of the blade to the Niva, you risk getting this kind of embarrassment

The car is fine, the skirt is a little wrinkled. but the blade got it and broke off the long rod. Acceleration was in third gear. on a reduction gear, I wanted to break through a packed pile of snow, in general I suffered from garbage. It turned out this way because the shorter rod (the right one) was slightly shortened after a minor repair (on the same day).

The blade successfully served faithfully for several months, then during an impact this left link was broken off and welded literally 5 centimeters closer to the car, resulting in a short arm, and as a result, the blade went under the car.

In the photo above this is the minimum shoulder, its size is 60 cm, but it is better to make it larger to be sure that the blade will not turn down under the car in case of a strong impact.

Design stage

A lot in this work depends on the available materials, as well as skills in working with equipment. To save materials and time on manufacturing a snow removal blade for UAZ, you can make a permanent blade. It is more reliable and simple, but also less effective at clearing snow.

At the same time, if you make a blade for an UAZ with a rotating mechanism, this will entail a heavier structure and you will have to calculate the strength of the components to fix the future blade. When designing a blade for your SUV, it would be nice to take into account the possibility of its installation and dismantling by one person. Also, when designing a snow plow for an UAZ, it is necessary to place a rubber seal, which will help protect it. Particular attention should be paid to the places where the blade is fixed. First, they should not be placed opposite important units, and second, the possibility of a sharp impact on an obstacle must be taken into account.

ATV plows

High maneuverability, combined with high traction force and powerful lugs, make a regular ATV an excellent base for installing a snow shovel.

Photo source unikar.rf

The blade selection process includes four stages. First you need to decide on the installation kit - a structure that is attached to the frame and depends on the ATV model. Then a subframe is selected, after which all that remains is to select a suitable blade for it and a mechanism for lifting it.

There are two types of installation kits - front and central. The first ones are designed to be connected to the front base of an ATV and are intended for vehicles with low ground clearance. The advantage of the second type is to increase the rigidity of the tractor frame and improve the stability of its movement when clearing snow.

Front installation kit

Central installation kit

The blade mount is designed in such a way that it does not reduce ground clearance or reduce the vehicle's maneuverability.

The width of a snow shovel for an ATV depends on the engine power, the weight of the machine and ranges from 125 to 150 cm.

Inexpensive snow shovels that do not have a lifting mechanism are equipped with “skis” - a special sliding device that maintains a safe gap between the shovel blade and the surface of the coating.

The highest quality, but also the most expensive, blade systems for mounting on ATVs are produced by the American company Warn. A set consisting of a straight shovel, an installation kit and a frontal base along with lifting and turning mechanisms will cost the buyer 59,000 rubles. For comparison, prices for similar equipment from the Russian company Atvstar, but not equipped with a shovel drive, range from 15 to 20 thousand rubles.

An ATV with a mounted shovel can only be used effectively on loose snow no more than 50 cm high and not compacted into dense layers.

Blade design

A snow plow includes a shovel (working surface), a mechanism for adjusting angles (when turning) and a fastening unit.

For example, modern dump models are equipped with a special mechanism that reduces vibration and protects the collapse and vehicle suspension from deformation as a result of collisions with obstacles.

Selection of materials for the blade

When making a snow blade, you can use metal barrels (200 liters in volume).

They have proven themselves long ago, and it is recommended to use at least two barrels to strengthen the structure. To guide and strengthen the shovel, it is better to use square or rectangular pipes, as well as a thin channel and I-beams. Remember that your blade needs to be strengthened, but taking into account possible overload.

The mechanism for adjusting the angles of inclination of the snow plow can be made from pipes of different diameters. In order to control the blade from the cabin, you will need a winch and a system of fixing units, which also requires additional costs for materials.

Tips for choosing

When choosing between specific models, you should pay attention to the main characteristics of the blade

- Mass – it is the mass of the element that mainly determines which machine it can be used with. Heavy blades cannot be installed on walk-behind tractors, and light options are useless on SUVs and can quickly break.

- Mounting unit - you definitely need to find out whether the selected model can be installed on your existing equipment. On snowmobiles and cars, plows are mounted on a subframe, so you should choose this element for your equipment in advance.

- Dimensions, especially width - wide blades are well suited for quickly cleaning large areas and clearing roads, but they should only be used with fairly powerful vehicles. Narrow blades are better at clearing narrow passages (for example, in personal plots) and require less equipment power.

- The installed system of protection against solid obstacles - under a layer of snow it is difficult to see curbs, stones and metal structures, and running over them at speed can lead to damage to both the blade and the walk-behind tractor or snow blower. Most often, rubber scrapers are used for this; more expensive models are additionally equipped with return springs. If you purchase a model with springs, you should make sure that the design is equipped with rebound shock absorbers.

- Rubber used - the choice of rubber is very important both for the safety of the road surface being cleaned and from the point of view of the blade's resistance to wear. The previously popular rubber with metal wire reinforcement has recently been replaced by newer materials reinforced with polyamide or nylon fibers. The use of ordinary rubber without hardeners may result in the need for frequent replacement of scrapers.

- Control system - for low-power equipment such as snowmobiles, walk-behind tractors and snowplows, a blade without adjustment or with the ability to set the angle of attack is sufficient.

When choosing a spare or replacement blade for a snow thrower or walk-behind tractor, try first of all to consider the options included in the standard configuration of your equipment - you will definitely not have compatibility problems with them.

To learn how to make a snow plow with your own hands, see below.