Toys

You can make children's crafts from radio components with your own hands.

What can be made from radio components. It is possible to make a tank, but this is a very complex and painstaking work, because we will need a lot of parts, namely, microcircuits will form the basis.

Making a model of a railway with a train will be no less difficult. You will have to spend a lot of time soldering numerous transistors. The railroad itself can be made from matches.

Manufacturing aircraft is another complex task that requires many chips and circuit boards to complete.

An airplane is an airplane, or you can make a helicopter. The screws can be made from transistors; be sure to use LEDs for effectiveness.

Make a boat or motorcycle from radio parts.

If you don’t want to bother with small details, then make a toy, for example, a Cheburashka.

Wireless microphone

To make a microphone at home, you need the following parts:

- microphone head;

- battery (12 V);

- capacitor (1 µF);

- resistor (47 kOhm and 100 Ohm).

- enameled wire (0.5 mm);

- quartz self-oscillator (10 MHz).

For the work of the master, electronic circuits are used.

Resistor R2 is intended to power the head, and R1 is intended for the microcircuit. An antenna consisting of thirty turns is connected to the input of pin 3. Then assembly can begin. This scheme provides for hanging installation.

Execution order:

- The 100 Ohm resistor must be soldered to pin 4 on the chip. Next, you should insulate the contact with a cambric and solder a 47 kOhm resistor.

- The next step is to solder the capacitor while maintaining polarity. After this, you can solder the microphone to the capacitor and resistor and make a common contact using jumpers.

- Next, the battery is soldered through the connector (it will be used as a switch).

- When the circuit is ready, you can start making the antenna: the wire is wound around a drill (it will be used as a frame) and the antenna is soldered according to the circuit.

- The connector is closed with a jumper (this turns on the microphone).

Homemade radio electronics must be tuned to the short radio wave range (10 MHz).

Watch the video:

Wire crafts

While I was looking for photos of crafts made from old radio components, I came across another way of creativity - from colored wire and wires.

These figures of soldiers and horses can be made from twisted wire in a colored braid. Such crafts are good for young radio amateur clubs and creative workshops. Agree that such crafts will be easy for both girls and children to solder.

Send the best crafts made from old radio components that you think deserve to be in this rating.

Master Soldering tried his best for you.

Electronic circuits

Radio amateurs offer electrical circuit diagrams of various home automation devices with a description and list of parts. They are simple and reliable. The radio components that are used in them can be purchased at any specialized store. Before manufacturing devices, you should prepare and think through design features. A simple algorithm that all radio amateurs use will help with this:

- make a list of necessary radioelements;

- become familiar with the operating principle of the device;

- find an electrical circuit diagram of home automation;

- think over the design features of the device;

- prepare tools: soldering iron, tin, solder, pliers, side cutters, etc.;

- the presence of a measuring device is mandatory;

- the workplace should be comfortable;

- buy the necessary radioelements and parts for the structure.

A list of necessary radio elements is necessary for comfortable work, since it is not very pleasant to constantly run to the store for radio components that have not been purchased. To manufacture a device, you should find its electrical circuit, familiarize yourself in detail and understand its principle of operation, since this will greatly facilitate further diagnostics of the operation of the product. Construction features and design are also important. This issue should be approached very seriously.

The quality of work is determined not only by the internal “filling” of the product, but also by the design features. The latter plays an important role in its trouble-free operation. For example, if the device gets hot, then you should consider a cooling system. Besides, it’s not very pleasant to watch an ordinary rusty box. Appearance is also of great importance, as it shows the accuracy of the craftsman.

The presentable appearance of the product can contribute to additional income. Preparation of the workplace and tools is one of the reasons for the high productivity of the craftsman, since he is not distracted by the search for the latter.

The presence of the device is very important, since after purchasing the radio components they should be checked again. A faulty radio component can damage other elements of the circuit. The device must measure resistance, voltage and perform continuity testing of semiconductor elements. A simple multimeter is suitable for these purposes. It is very important to calculate the cost of the device, since this is a very interesting activity. For example, a radio amateur decided to make an electronic alarm. He will be interested in knowing the cost of parts and labor in order to compare with store-bought counterparts.

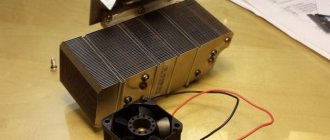

Thermostat in everyday life

The device is designed to maintain and regulate temperature . It is simple to implement and not sensitive to frost. The product must be used in heating systems, incubators, greenhouses, to maintain the temperature in the room, etc. In addition, it makes sense to use the device in overheating protection and fire alarm systems.

The device is connected to a load, the role of which can be played by a heating element, a three-phase relay or any heating element. It can be connected to the GSAV15R series 0.5 inch (1/2") gas electric valve, and perform automatic control in the cellar, greenhouse, garage or room.

The thermostat device is very simple and does not require programming skills. The block diagram of the product connection is shown in Figure 1.

Picture 1 . Block diagram of connection.

The thermostat consists of the following structural blocks: thermal diode, main thermostat cascade, relay and power supply. The latter consists of an ordinary RC filter. It is designed for the correct operation of all elements of the circuit. The resistor included in the power supply also functions as a regulator for setting the hysteresis of the thermostat operational amplifier.

The main cascade performs regulatory functions in automatic mode. It also includes a control element - a variable resistor. The thermal diode is an element that controls the operation of the main stage. The output stage is a relay controlled by an operational amplifier. The operating temperature range is adjustable from 15 to 97 ° C.

Scheme 1 . A simple DIY thermostat.

It is recommended to place the board with the relay in a separate housing. The thermal diode is attached to the surface where it is necessary to control the temperature. The list of radio components is as follows:

- operational amplifier: AD822;

- power supply: 12 V 0.5 A;

- electrolytic capacitors: 1 µF at 16 V;

- resistors: R1 (5 Ohm 0.5 W), R2 (variable at 10 kOhm), R3 (10 kOhm), R4 (500 kOhm) and R5 (39 kOhm);

- diode D1: D226 series (with any letter index);

- transistor: IRFZ44n;

- DC relay: any for supply voltage up to 12 V and switching over 220 V.

The transistor switch is made on an N-channel field-effect MOSFET transistor. It has good technical characteristics and is suitable for controlling powerful loads. Its power reaches 110 W, but the radio component should be placed on a radiator to remove thermal energy.

The thermostat circuit can be upgraded by installing 2 LEDs (preferably in different colors). The first is placed at the output of the power supply. It signals that the device has power. The second one needs to be connected in parallel to the load (heating element). It must be taken into account that the LED must be connected in series with a resistor. For power indication, a resistance value of 0.8 to 1.2 kOhm is suitable. In the second case, for 220 V you should select a resistor with a resistance of 150 to 200 kOhm.

Security system

Modern security alarms are very complex devices. They perform many functions. However, it does not make sense to buy systems to perform one function. For example, if you need to protect a garage door, there is no point in using electronics with a variety of functionality. Manufacturers are constantly making equipment more complex, and this affects its cost.

Radio amateurs offer a simplified model with a minimum number of radio components. A block diagram describing the principle of operation of the device is shown below (Fig. 2).

Figure 2 . Signaling block diagram.

The device consists of the following components: power supply, sensor(s) for perimeter control, relay and alarm device. The power source is an ordinary 12 V battery. Instead, you can use a bridge rectifier circuit powered from a transformer (220/14 V). An electrolytic capacitor should be installed at the output of the diode bridge. In this case, polarity must be observed. A sensor is an ordinary reed switch or a group of elements that are connected in series. The relay closes the electrical circuit and activates the alarm device when the reed switch is activated.

If the perimeter is violated, one of the reed switches is activated. As a result, the electrical circuit opens. One of the relay contacts opens and the other closes. Power is supplied to the alarm device and it is activated. The circuit diagram of the device is quite simple (Scheme 2).

Scheme 2 . Simple sound alarm.

The circuit can use from one to several reed sensors. List of radio alarm components:

- DC relay P1: any with an operating voltage of 12 V and a current of 1 A (one pair is activated and the other is opened);

- signaling device: any 12 V;

- reed switch: 100 mA and 12 V.

Reed switches are recommended to be installed in places where the probability of penetration into the object is quite high (doors, windows, etc.). All alarm elements are masked.

Radio amateurs recommend using up to 10 reed switches. Exceeding their number makes it difficult to diagnose alarm faults.

Rocker for crib

There are times when it is necessary to put a child to sleep, and it is necessary to constantly rock the crib so that the baby falls asleep. This takes a lot of time, but sometimes you want to relax. In this case, electronics in everyday life will come to the rescue. The schematic diagram of the “assistant” is not very complicated. The product can be divided into several parts: power supply, generator, actuator and children's bed.

The power supply consists of a transformer (220/15), a diode bridge, a capacitor and a zener diode. The output voltage must be stabilized. Its value should not exceed 12 V, and the current strength should not exceed 4 A. The generator and actuator are assembled on microcircuits (scheme 3).

Scheme 3 . Electronic "nanny".

The bridge driver (actuator) is assembled on the L298 chip. When a logical one appears at the “IN1” input, and a logical zero appears at the “IN2” input, the driver moves in different directions. The actuator speed must be controlled using the “ENA” input. The ATmega16 microcontroller controls the driver. However, to do this, you need to download “firmware” to it, which you can write yourself or download a ready-made file from the Internet.

The product is equipped with a microphone that picks up the baby's cry. In this case, the signal is converted into an electrical pulse supplied to the microcontroller. After this, a discrete signal is sent to the actuator. It makes 15 swings (it all depends on the firmware file). The speed and frequency of swings are controlled using resistors R1 and R2, respectively. The microphone must be placed near the child. Parts list:

- microcontroller: ATmega16;

- pulse generator: LM78 (can be replaced with L05C, T092);

- actuator (driver): L298;

- variable resistors: R1 (10 kOhm) and R2 (10 kOhm);

- resistors: R3 (1 Ohm) and R4 (2 kOhm);

- capacitors: C1 (1 nF) and C2 (1 nF);

- diode bridge: any diodes designed for a reverse voltage of 20 V;

- electrolytic capacitor: 2200 µF;

- transformer: 220/15 V;

- electric motor;

- microphone: any 12 V.

In addition, you should consider the installation diagram and design. It must be reliable and durable. The microphone is isolated, and the product itself is located in a place safe from children.

Street automatic lighting

Situations arise when it is necessary to turn on the light in the yard. If the owner is at home, then this is easier to do. When a person returns from work and it is dark outside, he has to turn on the flashlight on his mobile phone or use another source of light energy. Radio amateurs offer a simple scheme for automating the switching on of lighting. It consists of widely available radio components (Scheme 4). The main element of the product is a microcircuit.

Scheme 4 . A device for automating the switching on of lighting.

DA1 chip is an operational amplifier that is used as a comparator. If the voltage at the non-inverting input “3” is higher than at the input “2” (inverting), then the signal level is set high at output “6”. The divider, assembled on resistors R2 and R3, sets the voltage at input “2”. It is 5 V. At output “3” the magnitude of the potential difference depends on the value of R1, as well as on the state of the phototransistor VT1.

At night, the resistance of VT1 is high, since it is in a closed state. At input “3” the voltage value is less than the supply voltage of the product. At input “6” a high level of the signal is set, supplied through R4 to the base of transistor VT2. As a result of this, it opens. Power is supplied to the relay coil. Its contacts close the power circuit of the incandescent lamp.

In situations where the illumination of the phototransistor is high, it is in the open state. In this case, the voltage value is “3” lower than “2”. It follows from this that the signal level at “6” tends to zero. The voltage and current are insufficient to power the DC relay and its contacts are open (the lamp does not light). List of radio components:

- operational amplifier D1: KR544UD1B (you can use KR544UD1 with any letter index);

- phototransistor VT1: MP26B;

- transistor VT2: KT815 or KT817 (any letter index);

- resistors: R1 = R4 = 2.4 kOhm, R2 = 9.1 kOhm and R3 = 6.2 kOhm;

- capacitor C1: 4700 pF (ceramic);

- electrolytic capacitor C2: 20 µF at 16 V;

- diode VD1: KD522B;

- DC relay K1: any 12 V and contact switching of at least 220 V.

The power source can be of any type at 12 V. Voltage regulation does not need to be done, since the circuit is not sensitive to its fluctuations. The response threshold is achieved by resistor R1.

Thus, automation plays an important role not only in production, but also in everyday life. It ensures comfortable work and life because it allows you to perform tasks automatically without human intervention.

Garland auto switch

The switch is made using simple DIY instructions. To create homemade products with your own hands, you will need the following materials:

- aluminum cylinder;

- wide tape;

- tin;

- electric motor with gearbox;

- Super glue;

- PVC sheets;

- switch;

- battery (3.7 V).

Master Class:

- First, a cylindrical contact is assembled (a casing from a capacitor will do): it is sanded to completely clean the surface and wrapped with adhesive tape (5 mm left at the edge).

- After this, a template should be cut out of paper, and an insulated cylinder should be placed on it. Tracks are cut out on its surface for connecting electrical garlands: in these places you need to expose the surface of the capacitor.

- Next, the motor pulley is glued to the cylinder. The next step is to glue the body of PVC fins in the shape of the letter “P”. In each rack you need to drill holes for the motor and drum shaft.

- A screw is screwed into the central part of the cylinder opposite the pulley. Here it is necessary to achieve alignment. Afterwards, the drum and engine are secured to the frame.

- The next stage is cutting the sheet metal into narrow strips for rubbing contacts and closing the circuit. Then they are bent and attached to the frame using a plastic jumper. One of the contacts is located on a non-insulated section of the drum.

- Electricians recommend soldering terminals to the contacts. The battery is connected to the motor via a switch. Then the wiring coming from the power cable is connected to the extreme contact, which is constantly in contact with the drum. After this, the remaining contacts are connected. The wires that remain are twisted together.

This way you can make an auto switch yourself. The result will be an interesting alternating flickering of the light bulbs.