DIY gasoline burner

Gasoline burners quite often help out fishermen. They can be divided into 3 main types:

- Gasoline or running on other types of liquid fuel.

- Gas powered.

- Multi-fuel.

The latter type of burners is designed to operate on various types of fuel. It just so happened that gasoline devices appeared a little earlier than gas ones. Despite the fact that quite a lot of time has passed since the advent of gas burners, gasoline burners are still used in our time.

Moreover, they are not just used, but used more and more intensively. The thing is that each type of burner has a number of advantages and disadvantages. Under certain conditions, gasoline burners show better results and high efficiency. This article is aimed at introducing readers to the advantages of gasoline burners.

A budget alternative to traditional heating: making a gas heater with your own hands

From the author: Hello, dear readers! Finding a budget alternative to traditional heating is a task for many business owners. Popular electric heaters do not solve the task of saving the family budget, so gas and solid fuel heaters come first.

The operation of such structures is much more profitable and easier to learn. We invite you to familiarize yourself with several technologies for making a gas heater with your own hands, taking into account safety requirements and ease of use at home and in the utility area.

Advantages and disadvantages

Whatever type of home heating heater you choose to implement with your own hands, regardless of the complexity of the design and layout, you must ensure that the following requirements are met:

- ease of assembly and transportation, ergonomics;

- safety and reliability during operation;

- efficiency in the process of consuming energy, gas or solid fuel;

- high efficiency and productivity;

- availability of structural elements and materials for do-it-yourself assembly;

- durability.

Depending on the functional requirements, you can choose the right type of heater.

Advice: infrared, quartz heaters and electric convectors are considered the most effective, safe for home use and most common among homeowners.

The main advantages of homemade heating devices for different types of premises, residential and non-residential, are:

- use of inexpensive and accessible materials for construction;

- individual calculation of operating needs and high efficiency;

- quality and ease of assembly.

When purchasing a model of a factory heater, it is not always possible to obtain exactly the characteristics that will satisfy your need for heating the room. Basic requirements for a gas-type heater

You can safely use a gas-type heating device if you adhere to the following requirements:

- all operating elements responsible for gas supply must be factory-made and carefully checked for integrity;

- the design provides and implements simple and understandable methods for activating/deactivating the unit;

- The design and layout of a gas heater must be carefully thought out.

With rare exceptions, gas heaters are very mobile, take up little space and are easy to assemble. Let's talk about the advantages of gas heating structures:

- ease of operation and assembly;

- high efficiency and efficiency;

- minimal damage to nature and households, the products of complete combustion are practically harmless, the main thing is not to forget about the importance of installing ventilation;

- quick heating of the room;

- natural gas, liquefied or network gas, is considered the most affordable of all energy carriers;

- Some factory and home-made models also combine electronic components necessary for the operation of control units and ventilation, but the costs will not affect the family budget.

Operating rules

Any heating design requires attention to detail, first of all, your personal safety. This is especially true for gas equipment, where it is necessary to take into account the chemical properties of the gas and the technical nuances of the design. What should you pay attention to first of all when operating a gas heater and what safety rules should you follow?

To avoid fire hazards, gas explosions, and poisoning, it is worth remembering the following rules:

- the absence of well-thought-out supply and exhaust ventilation or disruption of their operation can lead to the accumulation of unburned natural gas. Its toxicity is dangerous, it can cause poisoning and suffocation, and if the temperature changes and a flammable source appears, it can lead to an explosion and fire;

- during operation of the structure, you must not touch it, as it heats up to very high temperatures;

- Gas cylinders, according to safety regulations, should be stored strictly vertically and in a well-ventilated area;

- large cylinders are recommended to be installed in a separate room with the least traffic and a well-thought-out ventilation system;

- cylinders that are not in use must be stored in non-residential premises. It doesn't matter whether they are empty or full;

- When replacing a cylinder, you should always carry out a visual inspection for the integrity of parts and the tightness of joints. The best option is to apply a soap solution at the joints.

Burner classification

The design features of the burners depend on what type of fuel is used. For example:

- There are burners that operate exclusively on gasoline and no other fuel.

- There are designs that, in addition to gasoline, also use kerosene.

- The operation of any type of burner requires a special device capable of maintaining pressure on a constant basis. Due to this factor, these devices are classified according to this method.

- There are designs in which there is no pump, while other devices are equipped with a pump.

- Burners are also classified according to the method of fastening the fuel container.

- Some types of burners are designed so that the fuel container is located separately from the burner and the fuel is supplied to the burner through a hose. There are burners where the fuel container and the burner form a single structure.

Popular models of factory gas heat guns

If it is not possible to make a gas heater yourself, you can study the modern market of heating appliances and choose the best option.

Some of the most popular companies producing gas heaters include companies such as:

- Ballu;

- Fubag;

- Neoclima;

- Master;

- Resanta;

- Interskol.

According to a survey conducted among users of specialized forums, the top included the following models: MASTER BLP 17M, Neoclima IPG 15, Interskol TPG-15.

All gas heating appliances from the famous American company MASTER are distinguished by high-quality assembly, reliability, efficient operation, and excellent design.

MASTER BLP 17M. The unit has an adjustable power of 10-16 kW, making it possible to maintain a comfortable temperature in a room with a volume of up to 655 m3.

Power is supplied by connecting to a gas cylinder through a reducer and connecting to a household electrical outlet. Mechanical ignition causes some inconvenience.

Neoclima IPG 15. A device with a power of 18 kW is capable of heating a room measuring 400 m3, while the fuel consumption is 1.4 kg/h. The model also includes a hose and a gas reducer.

The Fubag Brise 15 model has a power of 18 kW. It features minimal fuel consumption. Heating a room with a volume of 500 cubic meters will require only 1-1.2 kilograms of fuel per hour. The heat gun has a flame control device, as well as a high-quality protection system

Interskol TPG-15. The unit has a capacity of 300 m3 per hour, the power of which can be changed within 3-15 kW, while fuel consumption will vary from 0.73 to 1.3 kg/h. Such a device can operate on both propane and butane.

Important Beautiful and funny birthday greetings to the commercial director in your own words

Do you need a gasoline torch when fishing?

- A very interesting question, since a gasoline burner has a certain weight and takes up some useful space. When you go fishing, every kilogram of excess weight is counted. Many people, when going fishing in the summer, do without gasoline burners, since they can light a fire without any problems. But not everyone is always lucky and there are situations when it is impossible to light a fire, especially in bad weather conditions. If wooden branches are very wet, they will not catch fire without additional effort and equipment. Having a gasoline burner will help you light a fire without much difficulty, even if the branches are wet. In addition, you can heat a kettle of water or cook food on a gasoline burner.

- There is another situation when fishing is carried out before dark and no one wants to light a fire because of fatigue. In this case, it’s easier to use a burner to quickly cook dinner, even if it’s late.

- When cold and wet weather has set in for a long time, a gasoline burner will always help out and you won’t have to think about what to cook tea or food with.

Conclusions and useful video on the topic

We offer a selection of videos that will help you better understand the issues of heating and insulation of the garage.

Instructions for assembling a super-economical water heating system:

Mini-review of an economical gas stove that consumes 0.5 liters of gas per hour:

Tips for self-assembling an oil heater from a used cast iron radiator:

Video instructions for rational organization of heating in the garage:

Recommendations for reducing heat loss in the garage:

The issue of heating a garage is not difficult to solve. It is enough to understand the main advantages of each heating system and possible limitations in its use. You should choose based on your own needs.

The main thing is not to forget about fire safety rules. No amount of savings is worth putting your car and your own health at risk.

Buy or make a gasoline burner yourself

The easiest option is to purchase the device in a store, especially since the manufacturer offers various models. It is very difficult to determine which of the developments is most suitable due to the design features.

Some models are too heavy to be taken with you, especially if there is no transport. If transport is available, this factor is not of fundamental importance.

Industrial designs are expensive, and for their normal operation only high-quality gasoline is required.

As for homemade gas burners, there are also several options for their manufacture. For self-production, you can use used parts from gasoline burners. After assembly, you get a high-quality, efficient, and most importantly functional device. This approach can be done by anyone, even an inexperienced fisherman. A gasoline burner operates on the principle of mixing gasoline vapor and air flow. The burner is designed in such a way that this combustible mixture is constantly supplied to the combustion area, which maintains the combustion process. At the same time, for some reason, lower grades of gasoline burn in homemade burners, compared to industrial developments.

Source

How to cheaply, efficiently and safely heat a garage or summer cottage in Sochi?

A potbelly stove will help you effectively and safely heat a garage or summer cottage in Sochi. It is quite warm in the south of the country, but in damp, chilly weather you want to be in comfortable conditions. Electric heaters are the most convenient and easiest way, but at the same time the most expensive. Solid fuel stoves are a cheap option, but also labor intensive. Approximately in the middle of the above indicators, gas heating is located. But you need to spend a lot of money on organizing this heating system. How to heat a garage or summer cottage in Sochi cheaply, efficiently and safely? A good option would be to use several different methods to heat a garage or summer cottage.

- Both a regular potbelly stove and an infrared heater , which has the function of maintaining a set temperature, will help.

- Modern models of potbelly stoves are compact and convenient. Their main advantage is high energy efficiency. One stack of firewood is enough for 8-10 hours .

- A fireplace stove is perfect for heating a summer cottage in Sochi . This device combines the characteristics of a stove and a fireplace. It's nice to watch the flames burn in the firebox and enjoy the warmth.

- You can also create comfortable conditions by using an electric mattress or sheet .

A very economical and convenient heating option is an infrared film heater, which is placed directly under the carpet or linoleum. This device perfectly heats large surfaces. Unlike other systems, the infrared heating system is not afraid of drafts and does not dry out the air.

Tip: Before you start heating the room, you need to open the garage door or windows in the country house, creating a draft for 5 minutes. Fresh air will warm up faster.

PETROL ROAD

The Record kerosene stove lay idle in my garden house for a long time. At first I wanted to throw it away, because nowadays you rarely find kerosene even in the countryside, but then I changed my mind and decided to switch to a more affordable fuel - gasoline.

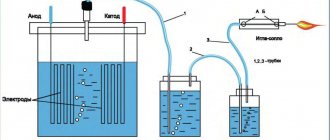

However, you cannot simply replace kerosene with gasoline. The first one has a high vaporization temperature, so the Record burner is designed in such a way that fuel is supplied to the nozzle not directly from the tank, but through a tube passing above the kerosene stove flame. Here it evaporates and, mixed with air at the outlet of the nozzle, ignites.

Gasoline, with its low vaporization temperature, will instantly boil in a hot tube, which is fraught with an increase in pressure in the tank, an explosion and a fire.

For Record to work reliably and safely, a new burner was required. I machined its parts from steel (but it can also be made from brass). The cap and reflector in the housing socket lie freely, without fastening; They are easy to remove if you need to clean the injector. The latter is protected from clogging by a fine-mesh metal mesh rolled into a roll (fastened with a drop of POS-60 solder).

The torch works in much the same way as a blowtorch. Under the pressure of the air pumped by the pump, gasoline rises to the nozzle and is injected into the space between the cap and the reflector. Here it evaporates, mixes with air, heats up and, exiting through the small holes of the reflector, ignites.

Burner design:

1 - body, 2 - nozzle, 3 - cap, 4 - reflector.

To operate the kerosene stove outdoors, I made a windproof cover from a 0.5 mm thick steel sheet that was placed over the burner. (As a last resort, you can use a suitable tin can, carefully cutting out its lid and bottom.) The height of the casing is approximately equal to the height of the burner body in the operating position, the diameter is slightly larger; the edges are perforated with Ø 8 mm holes in 15 mm increments.

Rice. 2. Windproof cover.

Such a primus is heated in the same way as a kerosene stove, using alcohol, denatured alcohol, gasoline or dry fuel. In inclement weather, it is better to take the latter, crushed and soaked in gasoline.

The burner flame should be pale blue. If it forms a torch, the primus is immediately extinguished and heating is repeated. The same is done when the flame hums and heats up the reflector. This means that the burner parts in the socket are installed incorrectly.

In addition, the safety rules specified in the operating instructions for the kerosene stove should be supplemented: do not use gasoline with an octane number greater than 93; do not pour it into a primus stove that has not cooled down or is running; do not mix with lubricating oils - this does not reduce its fire hazard. Finally, do not use leaded fuels - they are toxic.

Source

Precautions required when working with a blowtorch

When working with a lamp, strict adherence to safety regulations is required. The fact is that violations of the rules for working with this device can provoke an explosion of the device. A blowtorch is a fire hazard. The fuel storage tank is located very close to the open flame of the torch.

When operating the device, the following rules must be observed:

- It is prohibited to operate the tool if fuel leaks or fuel vapors are detected in the structure;

- It is prohibited to use fuel during operation of a blowtorch that does not comply with the manufacturer’s recommendations;

- It is prohibited to operate the device for a long time, since the close location of the burner provokes heating of the fuel cylinder above 50 degrees Celsius;

- It is prohibited to use the device if a malfunction of the safety valve is detected;

- Do not fill the tank with fuel while the burner is burning;

- It is not recommended to use the device in enclosed spaces.

In addition, it should be said that failure to comply with almost any of the safety rules when working with a blowtorch can provoke an explosion and unpleasant consequences.

Following simple safety rules allows you to achieve the most efficient operation of the device during operation.

Making a mini primus or burner at home

Each of us needs a heating device. Especially if it is small in size, it can be used not only at home, but also outdoors, which will undoubtedly appeal to fans of hiking, camping, fishing, and so on. The mini burner will easily fit in a bag or backpack. A mini burner will be useful for those who take only the most necessary things with them on a hike, since it is smaller in size than ordinary matches.

Making a mini Primus in the video:

In order to make a mini burner or primus at home, we will need absorbent napkins or a sponge, a star jar, an awl, lighter gasoline or medical alcohol, sandpaper or a metal sponge.

Since we will make a burner from a star jar, it will turn out to be very small, which means that it can be called a micro burner.

The first thing we need to do is make holes with an awl around the shiny line of the jar. The distance between the holes should be approximately 2 mm.

Attention. Follow safety rules when using a mini kerosene stove or burner. Do not open the burner until the fire has been extinguished, and do not keep flammable materials nearby.

In conclusion, here is some information that will be useful when using a mini burner: when using gasoline for lighters, the burner will burn for approximately 2 minutes 30 seconds. If you use 96 percent medical alcohol as fuel, the burner will burn for approximately 4 minutes 10 seconds. The height of the burner flame is approximately 11 centimeters.

Source

How to make a gas gun with your own hands - step-by-step instructions

Knowing the operating principle of the simplest gas gun, you can understand that making the same design at home yourself will not be a problem. The main thing is to select components. As a body, you can use either a piece of galvanized pipe on the outside, with a diameter of 100 mm (recommended - 200 mm), and any primus stove will be suitable as a burner (preferably with adjustable fuel supply intensity to the burner). All this can be purchased at a construction or household goods store.

Another nuance is forced convection. With a powerful gas flow, it is not necessary to install a system that will independently blow out heated air. The main thing is to use a pipe that does not have sealed ends, because in this case the air flow is created automatically (due to the difference in air temperatures at the ends of the cylinder).

If convection is still necessary, then a regular household fan is simply installed at the back of the pipe. The main thing is to adjust the rotation speed of the blades so that the air flow created does not lead to extinguishing the burner. As a rule, 200 - 300 rpm is sufficient.

In total, to create a gas gun with your own hands you need:

Step 1. Select a suitable case. Ideally, a steel pipe with a diameter of 200 mm and a length of at least 80 centimeters.

Step 2. Prepare a hole in the upper part of the pipe for installing a nozzle with a burner. This can be done using a step drill. The standard inlet for the nozzle is about 25 mm (then you can install a water tap, but a gas tap is recommended - they are structurally different).

Step 3. Mount the burner. All this is secured to a washer or coupling that is tightened on the outside of the pipe. A fire-resistant sealant (automotive sealant, the one used when installing gaskets in the cylinder block) must be added under all fasteners to avoid gas leakage and backdraft in the combustion chamber.

Step 4. If necessary, install a fan behind the pipe. It is not necessary to make everything airtight, the main thing is to create a directed air flow.

Important Congratulations on the Day of Remembrance of Internationalist Soldiers in verse and prose

Step 5. Connect the resulting gun to a gas source (propane or methane - depending on the type of burner installed) and conduct a test run. Automatic ignition in such a system, of course, is not provided, so the burner will need to be started manually.

During a test run, the most important thing is to make sure that there are no gas leaks (recheck all connections), as well as that the burner is heating normally (it should not overheat, become covered with soot or turn red).

The test run and performance check are carried out outdoors and not indoors. But it should be remembered that such devices are very dangerous, so trying to make them yourself without proper experience is not the best solution. And when working with them, there must be someone nearby so that if any breakdown occurs, they can immediately turn off the device.

You should not use self-made heat guns specifically for heating. They are better suited for quickly drying a room or for heat treatment of surfaces (for example, to combat mold and mildew).

PETROL ROAD

The Record kerosene stove lay idle in my garden house for a long time. At first I wanted to throw it away, because nowadays you rarely find kerosene even in the countryside, but then I changed my mind and decided to switch to a more affordable fuel - gasoline. However, you cannot simply replace kerosene with gasoline. The first one has a high vaporization temperature, so the Record burner is designed in such a way that fuel is supplied to the nozzle not directly from the tank, but through a tube passing above the kerosene stove flame. Here it evaporates and, mixed with air at the outlet of the nozzle, ignites.

Types and classification

Based on their intended purpose, devices are divided into professional and household.

The first include:

- Burners for work related to metal processing: soldering, forging, welding.

- Devices for general construction, road work, roofing, wood burning, and removal of old paint.

- Technological equipment for various purposes. For example, drying chambers, food industry tools.

For household purposes, this includes a gas stove, nozzles for home stoves, heating boilers, and gas convectors.

Household devices include home workshop devices. This is where you most often find do-it-yourself burners, not only manufactured, but initially designed to perform specific tasks.

They are arranged according to two main schemes:

- injection or injection;

- with complete preliminary mixing of the working mixture, or ejection.

In the first type, air (or oxygen) is captured by the supplied gas stream. In the latter, the gas-air mixture is obtained in a preliminary chamber.

Communities › Autonomous Light and Heating for Road Trips › Blog › Fuel for Primus stoves

The most common primus stoves among gasoline ones are the Shmel type family - from 1 to 4. They work according to the instructions - on motor gasoline... With a little - BUT - when these Primus stoves were designed, gasoline contained a minimum of additives. now the picture is different. Moreover, when some gasoline is burned, the aroma is such that you want to throw the primus far away... and never cook anything else with it or light it. what to fill in this case? If resources allow - despite recommendations - feed Bumblebee with 80-type gasoline or Galosh. Aka Nefras 80/120. It’s hard to say based on the manufacturers who is nicer and who is worse.

The use of Galoshes or 80th will significantly reduce or almost eliminate the formation of soot in the primus burner. This fuel has many advantages... But there are also disadvantages - price and availability. But if there is a separate fuel for the primus with a calculated volume for use, it is better to use it. But if there is not enough or in a critical situation, use gasoline from the car’s tank - if it is possible to drain it from there, of course. Yes, the primus may become clogged with carbon deposits, but at least you will have food and warmth. As an option.

Regarding Americans like COLEMAN - only Galoshes... only hardcore...

As an option - 80 straight-run gasoline. It is cheaper in bulk than Galoshes - but it is not available everywhere... In extreme cases - gasoline from the tank... but if the Primus has a generator tube, its service life on gasoline can be several days, and sometimes several hours of operation. Otherwise, it’s just a generator to be thrown away... It’s practically impossible to revive it or clean it... Its cost after the currency jump is more than.

There are generators WITHOUT a capillary tube... But these are old models and they are not common in our country - which is why they are rarely used. On kerosene - gasoline stoves WITHOUT alterations and modifications - as a rule - DO NOT work.

Kerosene primus stoves of the Record-1 type.

Everything seems clear - they run on kerosene. Type KO-25. Kerosene for lighting... According to the manufacturers - the same Yashim and Vershina... But again, you can take a portion and burn it in a primus... If the smell when burning is disgusting, then the kerosene is of the appropriate quality. Of course, any kerosene, when burned, produces a corresponding exhaust - there are also completely disgusting brands - but everything is relative.

In some circumstances, a primus of the Record-1 type and others of this type may well become... multi-fuel... The simplest design of the burner allows it to work on almost anything that burns... To do this, you need to have replaceable nozzles for the burners with the appropriate diameters for a specific fuel. Without modifications Such primuses are capable of burning gasoline, kerosene, white spirit, solvent, some solvents and degreasers - in extreme cases in the absence of other fuel. You can also use alcohol with an appropriate jet as fuel.

The same white spirit has a more pleasant odor when burned compared to kerosene.

Therefore, in order for the burner to become omnivorous, either the cable is removed from the generator... or maintenance of the burner is done every day after its use with the installation of a jet corresponding to the fuel. Either good fuel like Galoshes... or gas - in the case of an evaporator tube or a generator - is a completely acceptable option. Many burners in their configuration have replaceable jets for different fuels - gas, gasoline, kerosene, diesel fuel - which makes them even more versatile - but for the most part without modification - they also remain demanding on the quality of the fuel - otherwise the resource and time of their operation - can be significantly reduced.

Tags: primus, fuel, burner

Comments 19

Heh, I thought the mixture would work. Thank you for the article

Vershina is a rare product, in Moscow they only sell it in OBI, I have seen a bunch of construction and household goods. Has anyone tried to fill galoshes from the top of the zipa, what are your impressions? (I used Vertika Degreaser myself, I liked it, it doesn’t smell, it burns well, but it’s not enough for more than 3 days - it’s volatile) so I think maybe the galoshes will last longer in a zipper - at least 5 days.

Strange. We have plenty of it anyway. I don’t immediately remember what the degreaser is. Perhaps the same nefras.

and in Moscow they sell it in Obi, but there is plenty of it on sale everywhere in a green bottle with a yellow label, but this thing is smelly and clearly contains impurities. The top is IMHO cleaner and there is almost no smell.

Vershina is a rare product, in Moscow they only sell it in OBI, I have seen a bunch of construction and household goods. Has anyone tried to fill galoshes from the top of the zipa, what are your impressions? (I used Vertika Degreaser myself, I liked it, it doesn’t smell, it burns well, but it’s not enough for more than 3 days - it’s volatile) so I think maybe the galoshes will last longer in a zipper - at least 5 days.

To prevent it from evaporating, I pour it into a bottle every time; it’s also useful for a primus stove. And the “top” is a really cool nefras.

from my experience, the Top (but evaporates more strongly) - it smells the least of all, I took a “Yashim” galosh (the same Nefras80/120) but the smell is an order of magnitude stronger, I can leave the top open, but I can smell the smell if I bring the open neck to my nose, but “ Yashim” you feel open a meter away...

I mean drain the fuel from the primus after use so that it does not evaporate. I know about the top, I’ve been using it for about 8 years. But when I need a large volume, I buy Ryazan 80/120 on tap, I usually take a 20 liter canister, it’s enough for a year. Yaroslavsky stinks and if the nozzle is slightly worn by the needle, it smokes mercilessly.

Please tell me, is nefras/gasoline suitable with these characteristics? -NEFRAS C2, (gasoline-solvent) - Product description NEFRAS C2 (GALOSHA GASOLINE) JSC Naftan

Description: nefras S2-80/120 (TU 38.401-67-108-92) is a mixed-type gasoline solvent that contains no more than 50% of hydrocarbons of each group. Main performance characteristics: quickly dissolves organic compounds, evaporates quickly, is characterized by corrosive aggressiveness. Belongs to the group of solvent gasolines. Scope of application of nefras S2-80/120: the product is used in the rubber industry, as well as for degreasing surfaces intended for gluing, and for the purpose of thinning paints and enamels. It is possible to use nefras S2-80/120 as fuel for catalytic heating pads and gasoline blowtorches. Technical characteristics: Name of indicator Norm according to GOST (TU) Density at 20°C, g/cm3, no more than 0.700 Fractional composition: initial boiling point, °C, not lower than 80 98% distilled at a temperature, °C, not higher than 110 100 % distilled at a temperature, °C, not higher than 98 residue in the flask after distillation, %, not more than 1.0 Bromine number, g bromine per 100 cm3 of nefras, not more than 0.08 Mass fraction of aromatic hydrocarbons, %, not more than 1, 5 Passes the oil stain formation test Mass fraction of sulfur, %, no more than 0.001 Content of water-soluble acids and alkalis, none Content of mechanical impurities and water, none When purchasing in bulk, there is a DISCOUNT system! Manufacturer: Open Joint Stock Company "NAFTAN", Republic of Belarus, Vitebsk region, 211441, Novopolotsk, 375(214)59-82-57

DIY gasoline burner

Gasoline burners quite often help out fishermen. They can be divided into 3 main types:

The latter type of burners is designed to operate on various types of fuel. It just so happened that gasoline devices appeared a little earlier than gas ones. Despite the fact that quite a lot of time has passed since the advent of gas burners, gasoline burners are still used in our time.

Moreover, they are not just used, but used more and more intensively. The thing is that each type of burner has a number of advantages and disadvantages. Under certain conditions, gasoline burners show better results and high efficiency. This article is aimed at introducing readers to the advantages of gasoline burners.

Catalytic heater: design and operating principle

Today, the climate control equipment market offers a large number of different devices that differ from each other in operating principle and efficiency; some devices are more effective, some are less effective. One of the devices with improved heating properties is a catalytic heater.

Italian model Bartolini Pullover K with a power of 2.9 kW

The catalytic gas heater is used for additional heating of various premises: country cottages, offices, trading floors, cottages, garages, workshops, change houses, etc. But it is not recommended to use this device in buildings where fuels and lubricants are stored.

Design and operating principle

During operation of the catalytic heater, thermal energy is released due to the oxidation of fuel vapor (gas or gasoline) on the surface of the catalyst plate, which is made of fiberglass and coated with a thin layer of platinum powder. The entire surface of the plate is covered with many small holes through which fuel passes and burns on the surface.

This process is often called “surface combustion”, it is safer, more efficient and environmentally friendly compared to “open flame” combustion, despite the fact that the plate temperature can rise to +500°C. During flameless combustion of fuel, an oxidation process occurs, as a result of which thermal energy is released, while fuel consumption is minimal.

This principle of operation makes it possible to almost completely eliminate the appearance of unpleasant odors of combustion products in the heated room.

Important! Despite the low emission of combustion products, a catalytic gas heater must be installed in a ventilated room with two ventilation holes located opposite each other, the diameter of which depends on the power of the heater. The hole size must be at least 25 cm² for every 1,000 W.

The service life of the catalytic plate is 7-8 years; after failure, it can be replaced with a new one in specialized centers.

The design of a gas catalytic heater consists of the following elements:

- The catalyst plate is the main working element of the device. In addition, some models are equipped with a tubular electric heater, which is an additional source of heat;

- Control Panel;

- A metal casing in which a container with fuel is installed. In addition, there are models without a housing; they are more compact and can be used during camping trips to heat a tent or heat a vehicle.

Operating principle of a catalytic heater

The catalytic burner design can also be equipped with:

- A fan that distributes heated air throughout the room more efficiently and evenly;

- A heat fan that allows you to increase the heater power;

- A horizontal position sensor, which automatically turns off the device if it is installed at an angle or has been subjected to a sudden mechanical impact;

- A flame combustion degree sensor that turns off the gas catalytic heater if the flame exceeds the limit value;

- A carbon dioxide level sensor, which also turns off the device if the concentration of carbon dioxide in the room exceeds 1-1.5% (depending on the manufacturer).

Advantages

- A catalytic gas heater consumes oxygen, but this consumption does not exceed the maximum permissible standards.

- Safety and autonomy. Most models are equipped with a sensor for monitoring the presence of gas in the air, which turns off the device if the maximum value is exceeded.

- Mobility.

Large appliances are equipped with 4 wheels, with which even a pregnant girl can move the heater around the room. Before moving the device from place to place, it must be turned off. - Several operating modes. The Bartolini Pullover K catalytic burner (like many other models) has 3 operating modes with different fuel consumption. With this you can use the heating device more efficiently and economically:

- Mode 1 (1200 W) – fuel consumption 100 g/hour;

- Mode 2 (2400 W) – 200 g/hour;

- Mode 3 (2900 W) – 300 g/hour.

Flaws

- High price. The price of the Bartolini Pullover K model with a power of 2.9 kW is 10,500 rubles.

How to make a mini soldering torch

The design features are that it is very easy to operate; there are no traces of soot or repulsive odors when using the gas burner. This device is compact and can be used virtually anywhere.

The main component of the burner is the industrial valve. You can purchase a new part, however, and used ones that are in working order are quite suitable.

The process of making a burner with your own hands begins with the handle, then the body and nozzle are made.

In order to obtain a burner that is safe to operate and does not waste fuel, you need to make it a rule to avoid scaling and adjusting the example circuits.

To be fair, it is worth noting that not all gas appliances are calculated according to the laws of gas dynamics.

But if the manufacturer changes the dimensions of the design parts, then the Reynolds number of the fuel (or intake air) will go beyond the limits indicated in the original product.

The burner with such “improvisation”, if we give an optimistic forecast, will begin to smoke and will be “gluttonous”, or even be completely dangerous in operation.

And one more important note regarding the manufacturing features of the burners: it is impossible to increase its power above 10 kW. And that's why

With a burner efficiency of 95% (which is an excellent indicator for an amateur invention), with a device power of 1 kW, it will take 50 W to self-heat. It is theoretically possible to get burned on the structure, but it is not fraught with explosion.

But if you build a burner with a capacity of 20 kW, 1 kW will be superfluous. Threshold manifestation is expressed by the structure being hot or bursting into flames. Therefore, those burner drawings that are oriented at 7-8 kW should not be considered.

How to choose a tent heater

It is generally accepted that tourists, fishermen and simply lovers of outdoor recreation are unpretentious people: they are not afraid of snow and rain, and they can spend the night anywhere.

In fact, everyone loves comfort, some are just too lazy to create it. Tourists are creative people and approach the issue of heating a tent head-on. After all, taking care of high-quality heating of the tent, especially in the cold season, is not a whim, but a necessity, the failure of which is fraught with unpleasant consequences for health.

When planning an outing in the cold season, every reasonable tourist should worry about the heating system of the tent.

There are several options to solve this problem:

- buy a heater;

- use available means for heating;

- make a stove with your own hands.

Types of heaters

As for ready-made solutions, the industry offers for tents:

- portable liquid fuel heaters;

- gas heaters;

- heaters based on the principle of a burning candle;

In order to choose one of them, you need to know the features of each individual device.

Gasoline heater

This is a rather ancient invention, which was successfully used by Soviet tourists. Modern manufacturers continue to produce the much-loved gasoline burners, which are in constant demand.

Gas heater option for tent

The cost of branded devices of this type starts from 5,000 rubles. You can find cheaper models. Their main advantage is reliability and power. They are able to work in the most severe frosts.

Gasoline burners do not smoke, operate quietly, and can be used indoors. Therefore, gasoline heaters will not leave the market soon. There are some drawbacks: they require certain skills from users, are easily flammable and have a number of requirements for fuel quality. In addition, low-quality gasoline can clog the burner.

Transporting such devices is not easy - gasoline smells strongly, and the heater must be packaged carefully.

More convenient combined multi-fuel burners have appeared, for which gas and liquid fuel are suitable. They have one significant drawback - a higher price. The cost of such models starts from 10,000 rubles.

Gas heaters

In this video, they will tell you how to use gas tent heaters correctly. Enjoy watching!

This is the most popular type of heating. Here prices are in the range of 2000 - 7000 rubles. There are several types of such devices. They are heated by a gas cylinder and have various heating elements that allow you to control the temperature.

According to the type of heat emitter they are divided into:

- ceramic infrared;

- heaters with a metal emitter;

- catalytic gas heaters.

There are two types of design: the burner is connected to the cylinder through a special hose, or the burner is placed on the cylinder. They all differ in working volume. There are models designed for 2 - 3 hours of operation without refueling, others work longer.

Infrared heaters with ceramic element

The operating principle is based on converting the heat of the burner into infrared radiation with high efficiency.

Their advantages:

- small size and weight;

- efficiency;

- release of a minimum amount of harmful substances;

- versatility;

- safety.

Power of ceramic models: 0.5 – 1.75 kW. Cost: 2000 – 4000 rub.

Heaters with metal emitter

Type of heater with a metal emitter

Outwardly, they resemble a cap made of steel mesh. This is a protective screen that separates the hot burner. A parabolic reflector is installed behind it. Such stable burners are capable of creating comfortable temperature conditions over large areas. Configurations of this type can be equipped with one or two burners.

But their efficiency is lower than that of the previous type. If for ceramic ones it is up to 50%, then here the maximum figure is 30%. The fuel consumption of such burners is also higher. It should be remembered that they do not heat much better.

This design uses a fiberglass panel. A layer of patina is applied to it, which is a combustion catalyst. These are the most efficient burners. The efficiency of such devices is about 100%.

Such heaters are chosen by those who are environmentally friendly: the fuel burns without flame. The device heats the air quickly, operates silently, and is the safest in terms of sudden ignition.

The cost of such devices is 1000 rubles. (for small heating pads), and 3000 - 7000 rubles. for more powerful heaters. The disadvantages include the desire of manufacturers to make the components of this heater as in demand as possible.

They cannot be replaced with similar ones; for most, only “original” cartridges are suitable. The disadvantage of all gas heaters is failures when operating in severe frosts. You may need to insulate or heat the cylinder.

Candle based heaters

This is what candles for heating a tent look like

An alcohol candle is a budget option for a heater. Homemade devices based on this technology are often used. This type is not suitable in severe frosts: it cannot be used at air temperatures below 5 degrees. The candles burn out quite quickly. Therefore, such devices are more suitable for short-term heating of the tent of winter fishing or hiking enthusiasts.

The design is elementary simple and does not require significant investments. Its essence is this: fill the container with alcohol, immerse the wick in it and set it on fire. For safety, various covers are used. They must withstand high temperatures, since the candle flame heats up to 120 degrees.

Paraffin and wax candles also produce a certain amount of heat when burned and can heat the tent by several degrees. Various devices are installed on them that make such heaters safer. However, such heaters cannot be left unattended.

Portable ovens

Example of a portable tent stove

There are homemade and industrial stoves for heating tents. They operate mainly on solid fuel. These are the familiar “potbelly stoves” that are suitable for a large tourist group. They are indispensable in extreme tourism. But they take up enough space and require chimney installation and constant attention.

This pays off with high heat transfer, but their dimensions and weight are not for small tents.

How to heat a tent using improvised means?

To solve the problem you need a coolant.

Video: an example of making such a burner

The best thing in the world is something made with your own hands. It is, like nothing else, pleasing to the eye and extremely pleasant to use. This is explained by the fact that when using such things, we involuntarily remember the production process, which always leaves only pleasant memories, even if some difficulties arose in the process of creating the craft.

For those of us who love to relax in nature, in tents or without them, and at the same time appreciate warmth and comfort, there is one irreplaceable thing on a hike that each of us can easily do ourselves. Such a thing is a camp burner. This homemade product will help you heat a tent without exposing it to the risk of fire, heat up cold food, boil a kettle, and the like. In general, the thing is quite useful, interesting and, most importantly, easy to make and use.

The filler you choose should be placed tightly on the bottom of one of the jars, in a layer of 3-7 centimeters. Next, we put one can on top of the other, so that they fit snugly against each other.

Additionally, we can solder them together, however, in this case the burner will be non-inventory, that is, the filler cannot be replaced, as a result of which it cannot be used more than a few times. Now we just have to punch small holes in the middle of our “lid”, as well as on the sides of the burner, like a gas stove.

Now we have reached the finish line - all we have left to do is set fire to our unit. To do this, it must be filled with a fuel and lubricant - alcohol or acetone is best. It will also work on gasoline or kerosene, but then you will have to get used to the constant soot.

A primus is a small device used for heating small objects or preparing food, which is simply an irreplaceable thing in the country. By the way, a home-made primus stove is practically no different from its factory prototype - it can also be used to prepare and carry out various processes of heating parts. Often, such homemade primus stoves are very popular among avid fishermen who simply cannot imagine their fishing without tasty and aromatic fish soup in nature. Also, do not forget about lovers of hiking, for whom this device is simply an irreplaceable thing that helps them survive even in the most extreme recreational conditions. So, having acquired everything you need, you can safely begin the work process of creating a primus stove.

Initially, you need to prepare the beer cans by carefully sanding them so that all the design and paint are removed from them. After that, making an indent of 2 centimeters from the edge of each can, you need to cut off the bottoms. Glass wool is placed in the bottom of the jar, and then covered with the second bottom of the jar. This is done in such a way that the edges of the bottom, which is located on top, fit as tightly as possible inside the bottom. Now they need to be squeezed well together. As a result, they must be connected very tightly. For additional fixation, you can use regular electrical tape. If you don't have electrical tape at hand, you can replace it with tape. Taking a pushpin that has a long tip, five holes are made in the middle of the upper part of the resulting structure. Also, additional holes are made along the entire perimeter of the circle behind the rim, on which a beer can is usually placed.

Pre-prepared gasoline or kerosene is slowly and carefully poured upward so that it gets inside the device through five holes made in the center. During the process, you need to monitor the stream - it should be slow and uniform. In addition, it is best to pour fuel in small portions until liquid dangling begins to be felt inside the manufactured device. A special structure is made from wire, on which you can then place, for example, a cauldron of suitable size. To do this, on a wire about 60 centimeters long, marks of 25 centimeters are made from the end of one and the other side. After which it is bent down so that it resembles the letter “P”. It is turned over with its back down and bent forward again, making indentations of 10 centimeters on both sides of the existing bends.

Homemade alcohol burner similar to a blowtorch

If you are in the country where there is no access to a gas main, you have probably encountered the need to use an appliance similar to an electric stove. Quite often, people use stoves or stoves that are powered by liquefied gas cylinders.

An alternative solution could be a homemade device that runs on liquid fuel. If you are the owner of a suburban area, and periodically try to solve the problem of heating rooms and cooking, then, quite possibly, an alcohol burner is suitable for you.

It can also become an indispensable attribute if you prefer to go on overnight hikes in your free time.

DIY alcohol burner. Useful homemade products

If you are in the country where there is no access to a gas main, you have probably encountered the need to use an appliance similar to an electric stove. Quite often, people use stoves or stoves that are powered by liquefied gas cylinders.

An alternative solution could be a homemade device that runs on liquid fuel. If you are the owner of a suburban area, and periodically try to solve the problem of heating rooms and cooking, then, quite possibly, an alcohol burner is suitable for you.

It can also become an indispensable attribute if you prefer to go on overnight hikes in your free time.

Main advantages of devices

The mentioned burner can easily be made by you yourself. You can take it with you to the garage, to the country house or on a hike, as well as to those places where there is no electricity, main gas or wood stoves. Using such a device, you can quickly heat water, cook food or heat a room.

This invention is suitable for those places where it is impossible to make a fire, since the device produces a flame that is almost invisible, but it will be enough for cooking. An alcohol burner has many advantages, among them good performance in difficult weather conditions.

And this is true even if the outside air temperature drops to -40 degrees. If you make such a device yourself, you will be able to feel how easy it is to use, compact, economical and affordable in terms of purchasing fuel. The last factor can be called one of the most important advantages of such burners, since alcohol can be purchased everywhere.

Among other things, the cost of such fuel is low, especially when compared with kerosene or gas.

Homemade alcohol lamp from beer cans

I’ve had this idea in my head for a long time, and finally today I got around to trying this homemade product. A homemade alcohol lamp made from the bottoms of beer cans is, on the one hand, the simplest, fastest, cheapest and most accessible of survival crafts, and on the other hand, it is quite a functional thing that will allow you to boil a couple of cups of water in a very reasonable time in the absence of other fuel .

There are a huge number of options and instructions on the Internet; there is even a separate page on the English Wikipedia. There are step-by-step manuals and video tutorials.

However, the first two options I made were not very successful.

In the first, I didn’t like the shape of the flame, in the second, the thin aluminum of the beer can was completely torn, and only the third option, which you see in the photographs, suited me.

All you need is two empty beer cans, a paper cutter, a thick book, fine sandpaper and a thin awl or a pushpin with a plastic head. Quite an office tool. In just 10 minutes you will have a cheap and incredibly light tool for cooking or boiling water even in a confined space, such as a tent.

I won’t write detailed instructions, fortunately there are thousands of them on the Internet, for example here or here. Let me say briefly: we hold a paper knife in the book at a height of about 2.5 cm above the table level, and use it to draw a line on an aluminum beer can at the indicated height from the bottom.

It is not necessary to cut through; along this seam, thin aluminum is easily pressed and torn. Sand the cut edges with sandpaper. Before we cut off the bottom of the second can, slightly flare the first cut with the second can. Then we cut off the second can in the same way. We get two bottoms.

In one of them (which will be internal), using twisting movements of the pliers, we make small dents along the edge along the cut, so that later it will be easier to insert one bottom into the other. We fill the internal volume with cotton wool (mineral wool would be better, I think), and connect the two halves.

All that remains is to make a larger hole for pouring alcohol in the center of the upper bottom and many small nozzle holes around the perimeter. The burner is ready.

Actually, the video shows this process much more clearly:

To start the burner, you first need to heat it up a little, but then the evaporation of the alcohol is supported by the heat generated by the burner itself.

There are so many modifications of this design that exist! Here are a few of the most exotic:

True, I did not have time to carry out the most standard test - the time it takes for water to boil from such a burner, but there is still work to be done.

PS To understand the degree of epicness, here is a link to a huge topic on the Hanseatic League.

Burner manufacturing technology

An alcohol burner can be made in one of several ways. If you are new to this business, then you should choose the simplest method possible, which does not involve the use of plumbing tools.

The technology involves the use of two empty tin cans; they must first be cleaned and rinsed with running water. After this, the products should dry well. In the central part of one of the cans, 4 punctures should be made using nails.

The same holes should be made around the perimeter of the rim of the jar. This element will become a blank for the future burner, from which a flame will burst out when used.

This part must be cut off from the can so that the length of the side is equal to three centimeters. To do this, you can use household scissors, since the tin is quite thin and can be easily cut with any sharp object.

When an alcohol burner is being made, at the next stage it is necessary to cut off the bottom of the second jar; this must be done as carefully as possible so that there are no nicks.

Otherwise, you will need to use a file or sandpaper.

Safe alcohol burner made from aluminum can

Surely many have already seen an alcohol burner made from an aluminum can. One author suggested how it could be improved to make it safer and more convenient.

Now the burner will never explode when heated, as it has a special safety valve. In addition, the flame became more beautiful and even, which increased the efficiency of the burner.

As a result, the burner now looks like a regular kitchen burner.

Materials and tools for assembly: - aluminum can from beer and other drinks (the author uses narrow cans from Mio, as he makes a small Primus stove); - cotton pads, cotton cloth or sponge; - a jar of larger diameter (used for olives); - coin; - raw food and a frying pan (you can fry an egg to check).

To work you will need the following tools: scissors, a lighter, a needle with an awl (a sharp nail will do instead of an awl), pliers, a bolt with nuts or a self-tapping screw. Let's start assembling the alcohol burner:

Burner using a blowtorch: video instructions for making it yourself

Furnaces and boilers running on waste oil have long taken their rightful place among heating appliances. Exhaust is a cheap and sometimes free type of fuel; it is often used for this purpose in car repair shops and garages. Many craftsmen, when choosing a design, ask the question: is it possible to convert a gasoline blowtorch into a burner for mining?

Is it possible to make a blowtorch work during mining?

The principle of operation of a conventional blowtorch is to ignite gasoline vapors, which are pushed out under the action of compressed air. This effect is achieved by forcing air into the burner fuel tank.

What happens if you pour used oil into a blowtorch?

Oil itself, even under pressure, does not evaporate well - it needs to be heated. Due to poor atomization, the flame will be uneven and it will be difficult to ignite the burner.

The oil burns with the formation of a large amount of soot and soot, so the jet will quickly coke, its cross-section will decrease, and the lamp will fail.

Increasing the cross-section of the nozzle will also not give the expected effect - the oil will be sprayed in large drops, which will not allow obtaining a uniform flame of the torch.

In addition, used oil often contains impurities: diesel fuel, gasoline, antifreeze and even water, which can lead to flashes inside the lamp. To use waste as fuel for a blowtorch, you will have to install a filtration system, which will further complicate the task.

Considering all the difficulties, using a gasoline blowtorch as a burner during mining is difficult and unsafe. Therefore, it is necessary to modify or completely change its design.

How to make a burner for mining yourself

For successful combustion of oil, you must either preheat it to the evaporation temperature - approximately 300 degrees Celsius, or finely spray and enrich the oil vapors with air.

Design and use of a blowtorch

A blowtorch is one of the sought-after tools in the arsenal of any craftsman. And this is not surprising.

With its help, many types of work related to soldering and heating can be performed. Using a blowtorch is very simple, but we must not forget about safety measures.

How to use

Before we talk about how to use it, we need to remember where a blowtorch is generally used. Among the areas of application are the following:

- soldering metal parts using molten solder;

- heating the elements to be joined by welding;

- heating pipes with frozen liquid in the event of malfunctions and accidents on pipelines;

- removal of old paint and varnish coatings from metal and sometimes wooden structures;

- heating rusted joints to facilitate their disassembly;

- heating and cooking food on the go;

- Use a blowtorch with extreme caution to warm up internal combustion engines before starting them in very cold weather.

In almost all cases, the lamp must be used the same way. It is filled with flammable liquid and ignited. The differences relate to the amount of time the flame is exposed to, the adjustment of its intensity and how to properly direct it.

Device and principle of operation

A blowtorch consists of a fuel reservoir, a pump and a burner. The tank stores liquid hydrocarbon fuel. It could be gasoline, kerosene, alcohol.

Gasoline is most often used as the most accessible and cheapest type of fuel. A hermetically sealed filler neck is provided for filling with fuel.

The pump serves to create air pressure in the tank. It is under its influence that the fuel enters the burner, in which combustion occurs, releasing a large amount of heat.

The burner has a rather complex design. The fuel, before reaching the nozzle, passes through a small reservoir that encircles the flame in a ring. At this time, it is heated up so that at the exit from the nozzle it passes into a state close to vapor.

The size of the flame depends on the amount of fuel entering the nozzle and is regulated by a special tap with a needle that closes the outlet. Fuel consumption also depends on the size of the flame.

Preparing for ignition

You need to start using a blowtorch by checking its serviceability and functionality.

During inspection, make sure that all threaded connections on the filler neck and pump are clean and functioning well, while ensuring the tightness of the internal volume of the fuel tank.

The condition of the rubber gaskets also affects the tightness. It is also necessary to pay attention to the ease of rotation of the adjusting screw. It is prohibited to use a faulty blowtorch, as fuel vapors escaping from the tank may ignite.

The housing must be clean and not oily. It is not recommended to use dirty tools, as some oils can also ignite when heated.

To refill the blowtorch without spilling gasoline, you must use a funnel of the appropriate size. The reservoir is filled no more than three quarters so that air remains inside, which will be compressed by the pump, creating pressure.

It is necessary to use only clean fuel without impurities and with a minimum amount of additives.

The adjusting screw is closed before filling. Next, create a slight pressure in the tank by pumping 10-15 times. Now you can use the blowtorch!

Ignition and warming up

To light the lamp, you need to pour a small amount of gasoline into the metal cup provided by the design at the bottom of the burner.

It is ignited with matches or a lighter and, when burned, heats the “jacket” of the burner, inside which the fuel will subsequently be heated.

As the gasoline burns in the cup, you need to slowly open the control valve, pointing the burner at a brick wall or a sheet of fireproof material to speed up the heating of the burner.

The tap must be opened extremely carefully, because fuel that is not heated to the required temperature will splash out and ignite. It is necessary that it falls into the cup.

When the blowtorch burner warms up and the fuel from the nozzle begins to burn with a steady flame, you need to use the pump to increase the pressure in the tank. When working with a blowtorch, you need to make sure that the body does not turn over, otherwise fuel will not flow into the burner.