A very fashionable ring light or circular shadowless illuminator, which is used in their work by photographers, videographers, and makeup artists, can be easily made with your own hands.

At the same time, at minimal cost, everything will look beautiful and functional. With the ability to adjust the light level and color temperature (warm, cool).

Advantages over studio lighting

The ring light is a mobile and compact lighting source. Unlike stationary studio light, you can take it and use it anywhere - at home, on the street, in clubs, discos, weddings.

Another advantage is the speed of setup. Turned it on and you can shoot right away.

This circular light also makes it easier to photograph with children.

The ring attracts attention and the child becomes quiet and interested in the process taking place around him.

Which is better - a ring lamp or a softbox?

This question worries many professionals, amateurs and bloggers. A bright ring light produces a perfect, constant, even stream of diffused light, while a softbox produces a limited, concentrated beam of light. This especially applies to long and narrow lamps - strip boxes. Often, to create a good picture you need several such sources - drawing and filling light.

Not every master has the opportunity to purchase several softboxes at once, and also to set them up correctly. A ring lamp with a tripod can be rotated at any angle, raised and lowered, and you can also install a phone or camera inside it, which is what many bloggers use. In addition, such a lamp can be controlled from the remote control without getting close to it.

Materials

Here's what you'll need to buy to make your own LED ring:

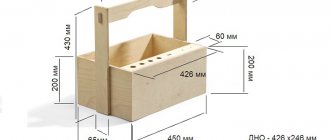

- metal-plastic pipe with a diameter of 25mm

The optimal pipe length for photo and video shooting is 2 meters. It will need to be bent and made into a ring with a diameter of 60cm.

The bigger the better option is not universal here. The specificity of the ring light is such that as the diameter increases, a shadow may appear in the central part.

And this is not acceptable. It’s not for nothing that such a ring flash was nicknamed the “shadow killer.”

For makeup artists, you need a smaller ring - 30-40cm. Stores often sell already rounded sections; ask the sellers.

By the way, you can also buy a children's hoop. The circle on it will be ideal from the very beginning and you won’t have to worry about bending a rigid pipe.

However, the thickness of the tube on it will be less, and this will not allow the implementation of some of the ideas discussed in the article later.

- buttons - one or two pieces

- LED strip SMD 5630 (60 led/meter) or more powerful 5730

Most importantly, when choosing an LED strip, pay attention to the color rendering index - CRI. For high-quality shooting, the CRI should be greater than 80, and preferably 90.

1 of 2

You can even order such high-quality ice tape from the Chinese. Where exactly, see the links at the end of the article.

If you are going to frequently transport your lighting or use it outdoors, then it would be logical to buy a waterproof tape with protection IP54, 65, etc. This model will withstand harsh working conditions much better than its counterparts.

However, due to the fact that the LED tape will still have to be cut into pieces, then the sealant will have to be cut off from the solder joints, the whole point of moisture protection is lost.

You can, of course, stick it not to the end of the ring, but to the inner rim in one piece, but the backlight in this case will be completely different and will lose all its advantages.

- power supply or Power Bank 12 volts

- plug connector

- Soldering iron and tin

- Nylon ties or clamps - if the quality of the adhesive base of the tape is not important

Cardboard based

Such a homemade illuminator can literally be made for pennies. You can purchase everything you need in special stores or on the Internet. The base is made of cardboard. It’s worth noting right away that making such a lamp out of paper is not an option.

What you will need for assembly:

- insulating tape;

- pencil;

- composite material;

- wire cutters;

- ruler;

- sheets of cardboard (the thicker the better);

- masking tape;

- scissors (can be replaced with a stationery knife);

- metal wire;

- LED strip (preferably with a color temperature of 4000K), possible with different color modes;

- hot glue;

- compass.

The manufacturing scheme is as follows:

- First of all, you should decide on the diameter. For example, the following are taken: the diameter of the ring is 4 cm, the outer and inner diameters are 35 and 31 cm, respectively.

- To draw an even circle, you can use a compass. Cut two rings in this way.

- Using hot glue, attach a wire to the first ring. This will make the finished tool more durable.

- Any sufficiently thin but hard object will be suitable for the handle. It should be flat, like a large ruler, so that it is comfortable to hold in your hand. In this example, a layer of composite material is used.

- Place the composite on the first circle, as shown in the photo, and glue the second cardboard ring on top. All resulting gaps also need to be filled with hot glue.

- For convenience, as well as to hide all possible defects in the cutting, wrap it overlapping with masking tape.

- Now you need to wrap the cardboard with LEDs.

A ring of this size will require approximately 5 m of tape.

Making a cardboard lamp with an LED strip will not take much time, and it will not cause any particular difficulties. If you reduce the dimensions, then the option is perfect for a phone.

Step-by-step manufacturing instructions

First of all, insert buttons into the rounded tube along the edges. You don’t want to farm and disconnect and reconnect the power cables every time you turn the backlight on and off.

Any push-button switches that are slightly smaller in width than the diameter of the pipe will do. Use a screwdriver to drill two through holes.

Place the nuts inside the pipe, right in the center of the holes, insert the buttons and tighten them in place.

If you have a button without a nut, you can simply glue it there with a heat gun.

The contact pads of the buttons where the wires will be connected should protrude slightly from the back of the tube.

In order to close the ring, you will need a small piece of wood with a diameter slightly smaller than the internal size of the tube. You can also use polypropylene trim.

Plan off the top layer from it and insert both ends into the ring, closing the contour.

The base of the shadowless illuminator is ready.

In order not to constantly hold it in your hands, you can choose a mount for it with a clamp. For example, a holder from an old flash or photo umbrella, with which the circle will be mounted on a tripod.

Fix it with self-tapping screws exactly in the middle of the two buttons.

In addition to the advantage of mounting on a tripod, this thing will make it convenient to hold the ring in weight without blocking the LEDs and the light flux with your palm.

We proceed directly to the light and installation of the LED strip. There are two options to choose from here. Make the backlight warm or cold depending on the photo and video shooting conditions.

This is where two buttons come in handy. Place the “cold” LED strip on one side of the hoop, and the “warm” one on the other. By simply turning the ring over and turning on one or another button, you can select the desired color.

A more expensive option is to buy a two-color LED strip instead of the usual ice strip. Or use similar strips.

In any case, the tape itself will have to be cut into separate pieces, since it will not be possible to neatly fold it whole around the perimeter. And if you succeed in this trick, the ribbon will shine inside the ring, and not directly.

The locations of the cuts are indicated by special icons.

On the back side, all LED strips have an adhesive backing, similar to double-sided tape. Remove the protective layer and glue the tape around the perimeter of the ring in small pieces.

In this case, try to place the incision sites as close to each other as possible. Next, solder all the cut contacts and connect them together.

How to avoid making basic mistakes and damaging the LED strip, read the article at the link below:

What is a ring lamp?

This name refers to a spotlight made in the form of a ring, hollow inside. Its diameter varies from 30 to 48 cm, which provides the opportunity to choose a device according to your needs and tasks. The ring light is emitted by LEDs located around the perimeter, which are covered on top with a matte light diffuser. As a rule, professionals choose models with a light transmission index of within or more than 95 RA. The power of a good ring lamp is 80-105 W, and the number of LEDs exceeds 450-480 pcs.

What does a ring lamp look like?

Externally, it is a large luminous ring mounted on a tripod. In the professional environment, lamps with a diameter of 45-48 cm have become widespread, but simplified models of smaller sizes can be found on sale. A large ring lamp creates a glow temperature from 2000 to 5500 K, which makes it possible to “play” with the warmth of light and thereby create natural contrast and achieve rich colors. A special flexible holder, installed directly on the main tripod, allows you to rotate the lamp in a variety of directions.

Brightness adjustment

By the way, if the tube from which you made the ring light is of a wide enough diameter, you can glue a second row of tape next to it.

By connecting it through the second button, you get a power-adjustable ring light.

Turn on one row - one level of lighting, press the second button - the brightness increases.

Someone will think that it would be better to use dimmers. However, the use of some dimmers in this case can negatively affect the quality of lighting. When adjusting the brightness of the backlight through it, stripes begin to run across the screen.

This will especially affect when the dimmer operates to reduce the brightness parameters. The smaller it is, the more noticeable the flickering will be. At maximum values, flickering will be practically not visible.

The problem is solved by purchasing a dimmer on a PWM microcontroller with a frequency of at least 15 kHz. However, all this costs a pretty penny in the final manufacturing price. Therefore, it is better to make two independent rows of tape and get excellent quality of light.

Also, some people put the tape in a transparent thermal tube for moisture protection. This is done after gluing and soldering it.

However, do not forget that in this way you significantly reduce the heat dissipation from the LEDs and the service life of your ring flash. This option can be used if your hoop is made of aluminum and there will be no problems with overheating of powerful diodes.

Next, solder the power wires, which are located at the beginning of the LED strip, to the output connectors of the buttons.

And connect a special male-female plug to the input contact of the button.

Voltage from the power supply will be supplied through it. You can secure it to the ring light using a nylon cable tie.

In fact, that's all. The LED ring is ready.

A selection of photos and videos of master classes

Ceiling lamps made from LED strip are a beautiful and economical solution that is appropriate in any interior. When assembling it yourself, the design turns out to be even more original, and the initial costs are also reduced.

Ceiling chandelier

LED lamp

Power supply 12V

All that remains is to apply 12 volts through the plug connector from the Power Bank, power supply, or compact assembly of 18650 batteries and check the functionality of the entire structure.

The power source, with its small connectors, can be clipped to your belt or put in your pocket. This is especially true if you are constantly moving when shooting, and the circular illuminator is in one of your hands.

If you wish, you can make a homemade battery holder like this.

And attach it to the hoop. Then there won’t be any dangling wires even close.

If the battery is large, it fits in a shoulder bag. And from it the wires are already led out to the power plug.

1 of 2

For a long photo shoot, it is better to have a more capacitive source or a spare Power Bank. This is explained not only by the speed of discharge and the short battery life of small batteries. What is important here is the quality of the pictures throughout the photo shoot.

For example, when the voltage drops from only 12.6 volts to 11 volts, the current consumption decreases. In this case, the initial brightness of the ring can drop by almost 30%!

Because of this, the pictures at the beginning of shooting and at the end may unpleasantly surprise you.

In order to find out how long your LED ring lamp for photography will shine, you need to divide the battery capacity by the current consumption of the LED strip.

Data on the tape is taken from the technical characteristics, depending on its type.

As you can see, there is nothing complicated in making a ring light. Everything is quite simple, elementary and inexpensive.

You can order the necessary components from our Chinese comrades:

SMD 5630 LED strip with CRI greater than 80 - here. Compact 12V power supply - here. Separate 18650 batteries from here.

Types of LED diodes used

When creating a homemade strip that glows in one color, semiconductors such as SMD 3028 or SMD 5050 are suitable. In the second case, three crystals are used, so the glow will be the brightest, but the electricity consumption will also be higher. Also, brightness depends on the number of elements located per 1 linear line. m.

The number of LEDs per conventional meter affects the total load of the product:

- 30 elements of SMD 5050 type - 7.2 W;

- 60 SMD Z528 - 4.8 W;

- 60 SMD 5050 - 15 W;

- 120 SMD Z528 - 9.6 W;

- 120 SMD 5050 - 25 W;

- 240 SMD Z528 - 19.2 W;

Boards with semiconductors arranged in several rows are called multi-row. In such cases, RGB technology is usually used, which allows you to get a multi-colored glow.

Due to the existence of several standards, manufacturers produce tape that operates from a 12 or 24 V DC source, or directly from a 220 V AC power supply.