3.Original plastic frame

Plastic spoons are an unusual material for decoration.

Ordinary disposable plastic spoons become an excellent material for decorating a mirror with your own hands. To make the frame look even more impressive, we recommend covering them with acrylic paints.

Simple but effective DIY mirror decor.

To fix several mirrors, you can use a single base. For example, wooden. Simply glue the mirrors using silicone glue.

Decorating a mirror with wooden cuts.

To make such a wooden frame you will need a thick branch. It will need to be cut into thin sections, which are then used as decoration.

Mirror decor for sewing lovers.

Those who are interested in sewing or embroidery will definitely like a mirror decorated with spools of thread. Simply glue colorful spools around the perimeter of the mirror.

Source materials

The mixture used to create the mirror is prepared from ingredients that can be easily purchased at a pharmacy or ordered online, in particular you will need:

- cleaning gloves, rubber;

- safety glasses, optional;

- glass cutting tools;

- detergent mixtures for cleaning;

- distilled water;

- 15% potassium hydroxide;

- 25% ammonia;

- a bottle of formaldehyde;

- nitrogen silver.

In addition, a laboratory scale or other device can also be useful for measuring chemical components.

Also, to create a mirror, of course, you will need glass. It is better not to use old and excessively thin glass, but otherwise almost any glass can be used. Glass from furniture or other structures will do just fine.

Styles

The interior in a classic style with a predominance of natural shades will be decorated with a wooden frame. As a decoration, you can make a carved and veneered design. The color of the frame can vary from natural to classic white and black.

The baroque room will be decorated with a frame with plaster molding. An abundance of openwork details can be achieved with the help of wood carving, but this requires special skill. Frame color – gold, bronze or silver.

Romantic Provence or ethno style welcomes frames made of natural wood with crossed slats. A floral print around the perimeter of the product is an appropriate decoration. Choose the color of the craft from among the bed tones, and it is not recommended to use flashy or too dark colors. Also, these styles involve decorating frames with beads, embroidery, and herbarium.

Experts recommend using frames with mosaics or pieces of slabs in rooms with natural styles. Fusion and art deco trends suggest a more daring decor. You can decorate a mirror using old disks, clothespins, plastic spoons and even eggshells.

Decorate frames in Art Nouveau style with glass, rhinestones, coins or beads, and for country style, select burlap and food supplies (coffee, cinnamon, curly pasta, plant roots).

Have you chosen a retro style? Then we make an antique frame. There are many ways to do this. You can use special tools, paint the product with golden paints, or destroy the top layer of varnish. An aged wooden frame is also suitable for Provence style.

Spectacular mirror for the living room.

A mirror like this, reminiscent of stained glass techniques, is easy to make yourself. To apply dark lines on its surface, use special glass paint or black tape.

We suggest you read How to wash your hands after gardening

An ordinary rope becomes a frame for a mirror.

A mirror frame made from thick rope will fit perfectly into a nautical-style interior. Additionally, it can be decorated with shells or pebbles.

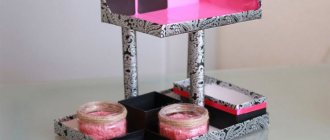

Making your own makeup mirror

The options proposed above are not suitable for professional activities. However, this is not a reason to worry; you can make a decent option on your own.

How to make a makeup mirror:

- The first thing to do is choose a shape and find a frame for the future mirror.

- Cut quality glass to the shape of the frame.

- Buy the necessary raw materials - silver nitrate, alcohol, respirator, plasticine.

- The glass must be treated - it is advisable to wash it with a degreaser or alcohol.

- Make small sides using plasticine - it’s easier to remove it later.

- A glucose solution is sprayed onto the glass and allowed to dry on its own.

- After this, a solution of silver nitrate is poured onto the glass and left to dry.

- After 15 minus, the remaining solution is poured into a special container.

- After this, the mirror is washed with clean water and left to dry in an upright position for 24 hours.

- The finished mirror is removed from the plasticine sides and washed a second time.

The better the glass is treated before coating, the fewer bubbles and errors it will have. For professional activities, it is better to use silver spraying, as it guarantees long service.

Video bonuses

Video tutorials will be a great addition to the above ideas, thanks to which you can gain inspiration to create something new and original.

DIY mirror decor. 6 DIY mirror decor ideas. Mirror decor in the shape of the sun. Decorating a mirror is easy and simple.

Continuing the creative activities, here are some ideas on how and what to make a lampshade from, as well as tips on how to revive old things using decoupage.

Basic design

The mirror is a glass surface of varying degrees of purity, which is connected to a layer of reflective coating - amalgam. Surprisingly, the production of interior items familiar to modern people began not so long ago, although reflective surfaces were often found during excavations of ancient palaces, burial places of royalty, aristocrats, and noble people. Often these objects were exquisitely decorated with precious stones, and the handles of some specimens were made of ivory. Today it is difficult to even imagine that such a familiar household item could once have been an unacceptable luxury for most people.

In 1279, Franciscan John Peckham described how a mirror was made by treating glass with a thin layer of lead. This method of obtaining a reflective surface was not easy and even dangerous, since it involved the use of mercury. The product itself was not of high quality and had a cloudy surface. Despite all the shortcomings, it was this technology for the production of mirrors that was used without significant changes almost until 1835.

The production of modern accessories based on glass and reflective coatings began only after the industrial revolution. Since that time, production technology has remained virtually unchanged. Nowadays, two methods of making mirrors are popular:

- spraying aluminum, titanium, as well as other metals and alloys onto the glass surface;

- production of products from a silver solution, which is fixed with a layer of copper or special chemicals.

Another method that allows you to obtain a flexible, unbreakable surface is the deposition of metallic silver on celluloid.

In ancient times, the role of mirrors was played by ponds and metal plates polished to a shine - copper, tin, bronze, platinum, steel and even gold disks, which were polished with semiprecious stones or semi-precious stones with a high degree of reflectivity.

15. Bright frame from old magazines

Available paper frame.

Reading magazines can be useful when decorating a mirror. Cut the page into two or three parts, roll each of them into a tube. All that remains is to glue the paper tubes to the mirror or frame.

Old knitwear can also be useful.

Cut a knitted T-shirt into several fairly wide strips and braid them. Then glue it around the perimeter of the mirror, leaving the edges free, and hang it on the wall.

Mirrors for the most sporty.

Old rackets can also act as a frame for a mirror. Finding a ready-made suitable mirror can be problematic. But you can cut the appropriate size and shape in a workshop that specializes in working with glass.

Mirror fabric manufacturing technology

The production of mirrors in the modern world, in comparison with antiquity, is much safer, but no less interesting. Today, products are created by combining two components - ground glass and amalgam. Typically both components are produced in the same factory. The final product meets all standards and requirements, since the production has all the required ingredients and raw materials. But it happens that glass is produced to order from a mirror manufacturing company in another organization. The main requirement for such products is the highest degree of purification; they should not have impurities, since any particles in the composition change the quality of reflection.

Raw materials for glass production are thoroughly cleaned in several steps and then sent to remelting. What are mirrors made of:

- sand quartz;

- dolomite;

- soda;

- glass waste (shards);

- coal.

Before making a mirror, you need to prepare the composition for the reflective layer. Typically, silver oxide is used for this purpose. Typically, silver products darken when combined with oxygen, but the mirror manufacturing technology ensures that the original properties of the noble metal are preserved. As a result, the finished product has a reflective surface.

For manufacturing, a base in the form of a flat glass sheet is required. To obtain it, all components are crushed, then mixed to a homogeneous powder - glass batch. Next, using a conveyor, the raw materials are sent to the furnace, where melting results in a liquid mass.

To obtain the smoothest possible surface, baking is carried out at a temperature of more than 1500 degrees. The result of all manipulations is a glass sheet 3 x 4 meters, the thickness of which is about 4 mm. After cooling, it is sliced and checked for defects.

To obtain a reflective surface, a chemical composition must be applied to the workpiece using a special technology. The glass plane is polished to perfect evenness, then washed, dried, and then covered with a solution. Within 20 seconds, aldehydes are oxidized with an ammonia solution of silver oxide. When the reaction is complete and the composition dries, a mirror surface appears on the back of the resulting canvases.

To produce a reflective sheet in another way, a layer of a metal alloy of titanium and aluminum is applied to a perfectly flat glass plane. Next, the mirror cloth is checked for defects. A special dark green paint is applied to the reflective layer to protect it from damage. At the final stage, the created products are sent for packaging and delivery to the customer.

The children's designer

The children's room should also have a mirror so that the son or daughter can get ready for school on their own. Details from the designer will help you decorate it. Depending on the idea, both large and small spare parts are used.

The parts are glued to the rim one after another. You can create an even pattern or distribute them randomly. In addition to geometric parts, figures, spare parts from vehicles and other construction sets are used.