Omsa socks set

349 ₽ More details

Omsa socks set

349 ₽ More details

Non-woven wallpaper on a non-woven basis

A do-it-yourself barbecue made from a barrel will be an excellent tool for culinary art. You can install a stationary barbecue in the courtyard of your estate, but for this you will have to spend a lot of effort and time. It will be impossible to move a brick building to another location. The situation is completely different if the barbecue body is made of a barrel.

Types and features of barrels

Typically, steel drums have become widespread in the liquid transport industry. For example, oil, resin or gasoline.

Such barrels have a welded structure, this is done to impart corrugation and rigidity to the product.

By design, metal containers can be:

- open, in which the upper bottom is removed;

- closed, with two necks.

Reference! More detailed characteristics can be studied in the tables. The displacement and diameter of metal products are written there.

How to cut a barrel?

Using a marker and a ruler, mark cutting lines on the surface of the barrel. The barrel can be cut exactly in half, which will allow you to use one part as a lid or make another grill out of it. Another option is possible, when the cut off part is smaller than the main one.

In this case, the cutting line does not reach the ends by about 2-5 cm, so as not to disturb the rigidity of the barrel.

Procedure:

- The side surface of the barrel is marked according to the selected size and shape.

- Use a grinder with a cutting wheel to carefully cut off the required part.

- The edges of the cut on the barrel and lid are carefully cleaned of burrs, and unevenness is smoothed out.

The cut edges of the lid and side surface of the barrel must be secured with a corner, which is secured either with self-tapping screws or by welding. After welding, the edges are processed again with a grinder and a grinding wheel.

If you decide to cut the barrel in half, similar actions are performed, the only difference will be the passage of the cutting line through the end of the container.

Advantages and disadvantages of a metal barrel barbecue design

Like any design, a barbecue made from a welded metal barrel has its strengths and weaknesses. The advantages of such a device include the availability of primary manufacturing material. Metal barrels can be easily found and purchased. Such barrels can be found on notice boards.

Important! When purchasing a barrel, you should pay attention to the thickness of the container walls. This is a very important characteristic that requires special attention.

As a rule, 200 liter barrels do not have thick walls; their maximum thickness is 1.5 mm. Although, the optimal thickness is 1.8 mm

Disadvantages of a barbecue installation from a barrel:

- The previous point is the main drawback. The fact is that too thin walls cannot ensure the durability of the structure. It will quickly rust or become thin, especially if the grill is lit with wood rather than coal.

- Uneven cooking of food. Of course, if you cook vegetables on the grill, then their uneven cooking is not critical, but unevenly cooked meat is a drawback;

- High fuel consumption.

This is what refers to the positive and negative sides of a barbecue made from a metal barrel.

Creating a Frame

The frame, or stand, should have a height that is comfortable for the owner. The optimal option is considered to be 0.9-1 m (including the barbecue), but each person has their own preferences. There can be many options for frame design:

- A cross made of two rectangular frames connected in the middle part.

- Semicircles with legs into which the barrel fits.

- Conventional supports connected by a rectangular horizontal frame, inside which a barbecue (barbecue) is installed.

Other options are also possible.

There are no significant advantages of one method over another; the choice is determined by the taste and personal preferences of the owner.

What types of metal containers can be used to create a grill?

The best option that is worth considering is containers of 50-60 liters. But, they have a significant drawback in the form of a thin wall. They can serve as a portable or disposable barbecue.

If a durable and reusable design is required, then it is best to consider the option with a 200 liter barrel. They have fairly thick walls; if the choice concerns a container for making a homemade grill, then you need to pay attention to the following items:

- options for which the bottom cannot be removed. With such barrels, a lot of work will not be required and there will be no need to mount the bottom (which will then serve as the side wall of the barbecue);

- those in which edible oil was previously stored. Since such barrels are intended for transportation of both food and chemical liquids, it is better to give preference to those in which chemicals were not transported.

Reference! The last point should be given special attention, since cooking in a chemical barrel can pose a health hazard.

Creating a Frame

The frame, or stand, should have a height that is comfortable for the owner. The optimal option is considered to be 0.9-1 m (including the barbecue), but each person has their own preferences. There can be many options for frame design:

- A cross made of two rectangular frames connected in the middle part.

- Semicircles with legs into which the barrel fits.

- Conventional supports connected by a rectangular horizontal frame, inside which a barbecue (barbecue) is installed.

Other options are also possible.

There are no significant advantages of one method over another; the choice is determined by the taste and personal preferences of the owner.

What are the features of a barbecue made from a metal barrel?

Before starting work, it is important to become familiar with the metal structure and its main design features. The requirements for the primary material from which the barrel will be made depend on this. These features include the following indicators:

- the main feature will be considered that a 200-liter barrel is the best option for cooking;

- in order to quickly clean the inner surface, the two halves of the barrel will be folded together;

- the lower part of the fryer consists of a pair of elements intended for combustible fuel and the cooking product;

- the upper part of the grill will serve as a lid that protects the product from a gust of wind;

- For greater convenience, a stand and handles are attached to the barbecue.

The metal from the barrel should not come into contact with food or melt easily.

What tools and materials will be needed?

To build a barbecue, you need to select and prepare a metal barrel in advance.

It is imperative to remember that the container should not have previously been used for storing lubricants and flammable materials. It is best to prepare a completely new container. In addition, to create a barbecue you will need door hinges so that the lid of the structure can open. Next, you need to prepare rubber wheels to move the object. It is necessary to select a handle for the door (preferably metal), a wire mesh and steel corners (their size should be from 45 mm).

In addition to materials, you need to select all the tools for the job. You will need a tape measure to measure all the parts, a grinder for sawing, and a welding machine. In addition, it is better to immediately prepare an electric drill, a cutting disc and a grinding disc, as well as metal sheets, bolts and a jigsaw for metal surfaces.

The barrel can be of any size. In addition to the barrel, you can use a gas cylinder.

Preparatory work

Before using the barrel, you need to thoroughly clean it of various contaminants and rust. It is necessary to pay attention to the fact that no chemicals or harmful substances should have been transported in the barrel. The barrel will be in fairly close contact with the food, so if the harmful fumes heat up, the food will not only acquire an unpleasant taste and smell, but may also be dangerous for further consumption.

Reference! Metal tends to absorb odors and harmful substances upon prolonged contact with some kind of chemical.

You also need to prepare all fastening elements: screws and nuts. This is very important for assembly. In addition, do not forget to draw up a drawing of the future barrel for frying shish kebab. The user must understand what result to strive for.

Container cutting

According to the drawn up drawing, the metal barrel is cut. Typically there are two options:

- some part is cut out of the barrel;

- the metal barrel is cut into two parts;

To ensure that the products are not traumatic, the cut edges must be processed.

Design features of the barbecue

When building a barbecue with your own hands, you should take into account the nuances of cooking meat over coals using this method and the ease of use of the fireplace:

- on the one hand, the cylindrical shape of the barrel and pipe is ideal for the fryer, allowing to reduce the number of welds;

- on the other hand, the coals will be covered in an uneven layer, the meat in the middle part of the grate will dry out/burn, so a removable grate should be placed inside to distribute the heat evenly and remove ash;

- the upper part cut from a pipe/barrel automatically becomes a lid that protects from rain and maintains the temperature inside the fireplace;

- the stand can be another pipe or barrel installed vertically, metal trestles, arches with stands, or the frame of a used sewing machine.

Attention! Unlike refractory bricks, steel, even thick-walled, burns out upon contact with open fire. Therefore, you should not make fires in metal barbecues; it is better to use ready-made coal to increase the service life

Making barbecue installations

Any user can independently make a barbecue installation and choose one option from several.

Barbecue installation with cutout

The design is a solid metal barrel with a cutout on one of the parts.

The installation algorithm is quite simple:

- the metal barrel is placed on one side;

- on the side part where the cutout will be, markings are made along which the hole will be cut;

- on one side of the barrel, when cutting out, you need to leave 3 centimeters from the edge;

- on the second side the cutout must be at least 2.5 centimeters;

- using a grinder, cut out the lid in the barrel;

- where the loops are installed, a cut is made and the loop is mounted;

- try to minimize unevenness during cutting;

- hinges are installed;

- a metal profile is welded inside;

- hinges are installed to secure the lid.

At this stage, installation work can be considered complete.

By cutting into two halves

To do this you need:

- cut the barrel into two parts, you need to ensure that the cut is not completed completely.

- the loops are welded in order to connect the two parts;

- two halves are cut to the end;

- holes are made for mounting handles;

- the internal surface is cleaned of dirt and plaque;

- the body and supporting structure are combined;

- Several holes are drilled in the bottom of the structure for air circulation.

If desired, you can make a grill from one half and not install the lid.

Barbecue combined with smokehouse

Barbecue smokehouse made of two barrels

If you want to make a more complex design, which also includes the function of a smokehouse, and you have two metal barrels, you can try making this option. The most difficult thing in it will be connecting two containers to each other and making a door at the bottom of the barrel for storing firewood.

Look at the attached video - any good owner can make such a barbecue from a barrel with his own hands.

How to make a barbecue smokehouse

Manufacturing algorithm:

- additional containers are being prepared that will serve as a firebox;

- a hole is made into it so that firewood can be placed there;

- holes are made so that there is traction;

- connection holes are installed, a chimney must be installed.

- the firebox and grill are connected using a welding machine;

- the cover is drilled;

- Holes are drilled at the bottom so that fat and juice can drain out.

At this point the installation can be considered complete.

Making a portable barbecue

A stationary hearth is unsuitable for country picnics, so a collapsible or transformable metal barbecue is built with your own hands from sheet steel. The main nuances of a mobile hearth are:

- the height and width of the bottom and side walls, all dimensions of the end walls remain unchanged;

- the legs are made removable (less often they are mounted on hinges), the length depends on the size of the car trunk;

- on the side and end walls, shelves are bent from below, onto which the bottom is placed after assembly;

- the walls are connected by slots directed in opposite directions relative to each other or are also hinged to the working/transport position.

Read more information about making this type of barbecue here.

Thus, knowing the dimensions for preparing barbecue and the approximate number of users, you can make a mobile iron barbecue. To build a stationary one, you will additionally need welding equipment (although you can do without it), but all the necessary information is above.

Barbecue from a metal barrel 200 liters

How to make a roaster yourself from a 200 liter barrel.

Marking and making the cover

The principle of operation is no different from previous works.

- the surface is thoroughly cleaned of paint;

- the inside is also processed;

- markings are made on the proposed cover;

- use a grinder to cut out the lid (the cut is also not completed completely);

- hinges are installed;

- The corners are trimmed using a hacksaw.

This completes the process of cutting out the lid.

Surface cleaning

It will depend on what substances were transported in the container. If these were edible oils, then you can use the usual singing agent and warm water.

If heavier substances were used, the surface firing method should be used. You can move on to the next stage.

Installation of the brazier

To prevent the lid from falling through, two metal elements are attached that will serve as fastening. At the same stage, the grate is installed.

Reference! For convenience, a handle is built into the lid for more convenient use of the fryer.

How to choose a barbecue option

To decide what you want to get as a result, it’s best to start by taking a piece of paper and a pencil and sketching out a drawing of a barbecue stove, the way you see it in your mind. When you display your idea on paper, it will be easier for you to make a choice by searching for the most suitable project on the Internet along with a diagram of its construction. When sketching, keep the following points in mind:

The style you want your BBQ oven to be. It must match the landscape design of the site, the interior of the veranda or hall in which you want to place it. Building size

If the furnace is massive enough, it will be necessary to build a reliable deep foundation. Try to immediately “fit” the barbecue into the place of future installation on the sketch. You also need to consider the shape of the firebox and chimney, as they play an important role in the design of the stove. Decide right away whether there will be a roof over the barbecue, what the roof should look like, what style and shape you want to get. Do you need additional elements for a barbecue oven: an oven, a smoker, a hob, a built-in cauldron and other devices. Will the building be clad with finishing materials, and what should it look like in the end? It is important to consider the design of the fireplace grate, if one is provided. Will there be cutting tables nearby, a place for firewood, running water and a sink, electric lighting?

By answering these questions and displaying your ideas on paper, it will be much easier to decide on the model and see it at the installation site.

Height and dimensions of structural elements

When the drawing is made, it will be possible to put dimensions directly on it that will be convenient for the height of the owners and will help the building fit well into the overall composition.

The first thing that needs to be taken into account is the height of the location of the brazier, the hob, if provided, as well as the surfaces of the cutting tables - in order to make it convenient to make preparations and fry barbecue or shish kebab. It is important to calculate the height of the shelves and their number. Shelves should also be made at a height convenient for the owners.

Next, you need to decide on the size of the furnace base and accompanying buildings. These parameters will depend on the size of the area on which you plan to build a barbecue. The next size that needs to be determined is the height of the chimney to the ceiling (if installed internally) and at what level it should change its shape towards narrowing.

Another parameter that must be calculated in advance if the barbecue is installed under a finished roof is the location of the chimney so that it does not rest against the supporting roof beam

It should be located exactly between two beams. The dimensions of the furnace foundation should exceed the linear dimensions of the base by 15-20 cm in each direction.

Foundation

- To build a light stove, without additional elements, a cemented platform will be sufficient, and if it already exists, for example, in a gazebo or on a site, you can immediately begin laying.

- If the barbecue oven is installed on an unprepared site, i.e. “from scratch” on a plot of land allocated for it, for construction it will be necessary to build a foundation.

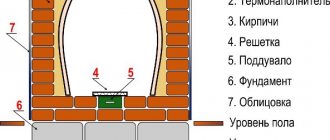

Approximate foundation diagram

- The first thing you need to do when starting construction of the foundation is to mark the area.

- The next step is digging a pit for the base of the furnace. It may not be very deep, since the building is not as heavy as a heating and cooking stove. Its depth can vary from 20 to 40 cm, depending on the soil on which the structure is installed.

- Having compacted the bottom of the pit, a sand cushion 10-15 cm thick is placed on it. A small layer of crushed stone, 8-10 cm high, is poured onto it.

- The formwork must be installed so that it rises 10-12 cm above the soil surface.

- Next, the reinforcement is installed - the diagram clearly shows how to do it correctly.

- The last step is pouring concrete mortar, with a proportion of sand and cement 3:1.

- The surface of the foundation must be well leveled; the slenderness of the walls of the building will depend on this.

Turkey breast kebab in homemade mayonnaise

For 4 servings:

- turkey breast - 650 g

- homemade mayonnaise - 150 g

- leeks - 4 pcs.

- salt pepper

Preparation

- For the marinade we make homemade mayonnaise - the recipe is below. Cut the turkey breast into pieces and leave in homemade mayonnaise for 2-3 hours.

- Tender turkey meat will cook quickly - just put it on skewers and put it on the grill, no more than 15 minutes.

- Serve the leek as a side dish: bake unpeeled over coals until black for about 20 minutes, pull off the top layer with a stocking - it will be soft and juicy inside. You can come up with any kind of vegetables or herbs as a side dish: bake carrots, zucchini, or simply serve shish kebab with a heap of herbs seasoned with olive oil.

Preparation: drawing up drawings, choosing materials

To make a country outdoor grill, improvised materials are suitable. You can use a metal barrel, an empty gas cylinder or bricks.

The creation of each design requires careful preparation, calculations, drawings and diagrams

Barrel

When choosing this material, you should make sure that the body is not covered with rust, has no dents or other deformations.

For grilling, it is best to use a 200 liter container. The thickness of the walls of such a barrel should be from 0.8–1.0 cm. This is enough to prevent the metal from burning through regular use. The height of the case is usually 85 cm, which makes the design convenient to use.

For this grill you will need the following materials:

- Barrel with a capacity from 50 to 200 liters.

- To make the legs - 4 steel tubes, 110 cm long, 3–4 cm in diameter.

- To strengthen the structure, two similar tubes of 60 cm and two of 40 cm.

- 2 metal door hinges.

- For handles on the body and lid - 3 “U”-shaped parts made of thick reinforcement.

The “H”-shaped base will make the barrel structure stable

Gas cylinder

When making a grill, old cylinders are often used. Propane containers are best suited. Their wall thickness is 3 mm, and their diameter is 29 cm. Thus, the body will not burn out, and the roasting pan will be quite spacious.

To make a grill from a gas cylinder, you can use materials similar to the option from a barrel.

A gas cylinder is a convenient container for making a fryer

Brick

Not every type of brick is suitable for building a grill. For this purpose, cladding (for the body) and fireclay (for the combustion part) are used.

To build such a grill you will need:

- 150 red bricks;

- 35 fireclay bricks;

- ready-made lattice or 30 steel rods 5 mm thick;

- reinforcing bars for foundation reinforcement;

- concrete mix grade M 300;

- sand;

- gravel.

This design requires a solid foundation in the form of a slab foundation.

To find out the volume of the concrete mixture, you need to multiply the height, width and length of the future foundation. For convenience, it is recommended to use these parameters in meters: 1.6·1.6·0.2=0.512 m³.

In order for a concrete base to be strong, it must be reinforced. To do this, use a mesh of metal rods, which is made from reinforcement with a thickness of 0.5 to 0.8 mm. The size of the mesh cells is 10x10 cm.

It is more convenient to calculate reinforcement in linear meters. To find out how many rods are needed for the mesh, you need to divide the length and width of the base by the cell size: 160:10 = 16 pieces - this is the number of rods placed across the width of the slab. Since it is square in shape, the same number of rods will be needed along the length of the slab: 16+16=32 pieces.

To further strengthen the foundation, you will need two such grids: 32+32=54 rods. Now you need to find out how many linear meters you need to purchase: 54·1.6=86.4 m.

Fireproof building material used to make outdoor grill

Lattice

You can buy a grill grate at any hardware or sporting goods store, but it’s cheaper to make one yourself. To do this you will need stainless steel wire 3–5 mm thick.

You can also use:

- steel corners with a side width of 2 to 5 cm (for effective heat they are installed at an angle downwards);

- Cut strips 3–5 mm wide from sheet steel.

The optimal lattice size is 40x60 cm.

The rods will be located perpendicular to the wide part of the lattice. To find out how many rods are needed, you need to divide the length of the lattice by the width of the rod and the cell (usually this parameter is 5 mm). Now you can make the calculation: 60:1=60 pieces. The width of the grid will be 40 cm, therefore: 60·40=2400 cm, or 24 linear meters.

Handles will help you remove the mesh

Required Tools

To make a metal grill you will need the following tools:

- hand circular saw;

- file;

- hammer;

- welding machine;

- electrodes;

- yardstick.

If a brick structure is being made, you will need:

- shovel;

- concrete mixer or solution container;

- trowel;

- building level;

- brush;

- cord;

- pencil or marker;

- polyethylene.

Construction of a fireplace inside a gazebo

A wood-burning fireplace covered by a gazebo is a stationary structure that cannot be moved and disassembled for storage during the cold season. Therefore, its construction must be approached with maximum responsibility.

Particular attention should be paid to the foundation, as it must withstand a heavy fire. Below is a detailed plan that will help you create a cozy corner where you can cook your favorite dishes in the fresh air at any time of the year. Here you can read how to make a 3x4 gazebo from wood

Here you can read how to make a 3x4 gazebo out of wood.

Laying the foundation

Dig a pit no more than 0.5 m deep under the base. Fill the hole with gravel approximately halfway. Then compact the gravel thoroughly. As a result, you will end up with a kind of pillow.

Then you need to install formwork around its perimeter. Next, install reinforcement, which can be iron rods or steel mesh. Next, you need to pour concrete into the formwork. After about three days, as soon as the concrete has hardened and dried, you can remove the restrictive elements.

Important! Make sure that the reinforcement under no circumstances protrudes beyond the upper edges of the formwork

Masonry of woodshed and portal

A stationary fireplace is usually a two-level design. The first tier is the woodshed, which is placed directly on the base under the stove. Dry logs should be stored here. The bricks and concrete base must be cleaned of dirt before laying. This measure guarantees reliable fastening of the bricks to the concrete plane.

Wet the base with water, then apply a setting agent and lay the initial row of bricks. Carry out the laying using the proven method: on edge and in a run, approximately 10-11 tiers.

After completing the construction of the firewood storage area, isolate its upper border from the second row. A steel corner and an iron grate can serve as a delimiter. The dividers should be flush against the top bricks.

Important! It is unacceptable to use sand-cement mixture as a connecting solution. It does not resist high temperatures when in contact with an open flame

The second level of the building is the portal

To lay the bottom of the portal, use fire-resistant material, placing it on a metal grate. Fill the seams between the bricks thoroughly with fireclay clay. The result should be a completely flat, stable surface. Next, lay the first tiers of the back and two side walls of the portal.

We suggest you familiarize yourself with information on how to build a 4x4 wooden gazebo.

fireplace tooth

Having completed the first two rows, proceed to laying the fireplace tooth. This element is the rear wall of the portal, assembled at a slope of approximately 60°. Its presence is necessary for the complete removal of volatile carbon dioxide.

For this purpose, treat the fireplace tooth with a grinder. From each building element of the first level, cut off a certain part at the required angle. The geometry of the side walls must correspond to the slope of the tooth and form a single whole with it. Place the top row just above the portal arch. In this position, it will ensure that volatile combustion products escape into the chimney.

Find out also how to build a gazebo with your own hands in one day.

Installation of a chimney

Also lay out the combustion product exhaust channel from refractory bricks. When installing, avoid gaps and cracks - seal them with clay in time.

By following this technology, you will provide the stove with excellent traction and protect the surrounding area from exposure to smoke. Another important point is the height of the chimney - it should be enough to ensure that corrosive gases do not penetrate the windows of neighboring buildings.

Where to start the manufacturing process

The first thing to think about is the type of model you would like to get. The most convenient way is to draw a sketch of the selected option. Next, to create a barbecue from a barrel with your own hands, drawings are drawn up, for example, as in the photo.

Scheme-drawing of one of the simple modelsDrawing of a complex barbecue

The provided drawing is just one of the possible options. The diagram should indicate dimensions that can be easily calculated taking into account the parameters of the barrel. This will help you not to be distracted by measurements and calculations while working.

Then we proceed to manufacturing the required parts, these include:

- pipes and angles of the required size;

- the required number of hinges, bolts, screws and other parts, according to the drawing.

Before starting work, you need to make sure that the barrel is completely empty and does not contain flammable or other harmful liquids. If necessary, it should be washed so that it does not ignite while using the welding machine. Metal containers for fuel and lubricants of 200, 100 or 60 liters are often used for barbecues.

The barrel is placed in an elevated area and secured securely, then the paint is removed from the surface. For this, a stiff brush is used or the process is carried out using a grinding unit with a flap disk. The paint removal procedure must be carried out, otherwise when heated it will bubble and create inconvenience.

Removing paint

Homemade mayonnaise

Ingredients:

- eggs - 2 pcs.

- olive oil – 150 ml

- half a lemon, mustard beans, salt, pepper

Preparation

- In a tall narrow container - a glass for a blender - you need to squeeze out the garlic, pour in olive oil and two eggs, add lemon juice, salt, pepper and mustard: grainy, Dijon, Russian - any will do.

- With the immersion blender turned off, lower it to the very bottom, turn it on at minimum speed and slowly raise it: when the consistency becomes creamy, the mayonnaise is ready - this is about 30 seconds.

- If you want to make it whiter, add a teaspoon of boiling water; if you want to make it thicker, add more butter or an egg. For the marinade, let's say, it needs to be thinner.

- If you need mayonnaise a la Caesar, before blending, you need to add anchovies, then a little Parmesan.