Any work process can be mechanized. Hand drills, planes, saws and other tools have long become electric. Progress has not bypassed the ordinary hacksaw. An alternative to it was a reciprocating saw.

The tool copes well with its intended purpose - cutting with a blade. Using special attachments, you can not only saw, but also clean and process various surfaces. A reciprocating hacksaw can handle almost any material. It cuts wood and metal with equal ease. Even brick or concrete are no exception to the list.

Rating of the 10 best reciprocating saw models

Each manufacturer has top models that sell well and work stably. They are the ones who annually make it into the TOP 10 rating. Let's consider the rating of reciprocating saws included in the top best saws for the garden and home for 2022.

Average price segment of reciprocating saws

Makita JR3050T

A well-known brand, synonymous with quality. The reciprocating saw of this model has a power of 1000 W.

Reciprocating saw Makita JR3050T

Capable of withstanding high loads. Reliable, has a long network cable; The function of quick replacement of the saw part is available, there is a smooth speed control.

Stomer SSS-1000

A classic, recognizable design familiar to several generations. Fast operating speed, power 1100 W. Smooth adjustment of operating speed, however, there is a significant drawback: the weight is more than 3 kg.

Reciprocating saw Stomer SSS-1000

The price is very good, but it is reduced due to some external details, for example, there are no rubber pads on the handle and body, the vibration is more noticeable than the first model in the rating.

AEG US 400 XE

Reciprocating saw with 400 W power. It is light in weight, very convenient to use, and suitable for indoor work where space is limited.

Reciprocating saw AEG US 400 XE

A tangible bonus: a 36-month warranty on the original product from the manufacturer. The saw is easy to use, has an average degree of vibration, and is considered the best in the category of low-power devices from AEG.

Ryobi CR1201

Reciprocating saw with battery capacity 1.2. Popular due to its compactness, reliability, convenient design and handle.

Reciprocating saw Ryobi CR1201

There is a pendulum function, therefore, the tool is protected from overheating. Works with materials such as drywall, wood, polypropylene, ceramics, metal.

Dewalt DCS380B

Sold without battery and charger; these components must be purchased separately.

Reciprocating saw Dewalt DCS380B

Operates with a voltage of 20 V, weighs less than 3 kg, and is equipped with an electric brake. The instrument is made in classic yellow-gray tones. The design resembles the Stomer SSS-1000.

Metabo PowerMaxx ASE

A unique model in its price category. Minimum weight (1.2 kg), maneuverability, excellent build quality.

Metabo PowerMaxx ASE reciprocating saw

Equipped with a 10.8 V Li-Ion battery. Warranty service: 60 months. from the manufacturer.

Budget reciprocating saws

Continuing the rating, we note budget models suitable for low-intensity work and periodic use.

Bosch PSA 700E

Among the expensive brothers of the model range, this reciprocating saw is the most budget-friendly.

Reciprocating saw Bosch PSA 700E

Stroke length 20 mm, can cut steel up to 1 cm thick. Tool power is 710 W.

Interskol NP-120/1010E

Reciprocating saw with a power of 1010 W, operates on a network with a standard voltage of 220 V. Weight more than 3 kg, suitable for professional use.

Reciprocating saw Interskol NP-120 1010E

It has an affordable price due to the fact that the country of origin is Russia. It has proven itself to be a reliable and powerful device.

Hammer LZK650B

The power of the saw is 720 W. Used for cutting wood and metal.

Reciprocating saw Hammer LZK650B

The tool comes with a long warranty and is similar in appearance and ergonomics to more expensive Bosch models.

Ryobi RRS-1801M

Budget model weighing up to 2 kg. The battery must be purchased separately.

Reciprocating saw Ryobi RRS-1801M

Recommended capacity is 18 volt maximum. The stroke is 22 mm.

Delivery set, appearance

The Skil 4600 Combisaw model can be found on sale in two configurations, the differences in which are the number of complete files and the presence/absence of a carrying case. I got the maximum one. The case is enclosed in a bright cardboard shell, which aims to attract the attention of the store’s customers and contains information about the internal contents. The front part shows the hero of the review and the main ways of using it.

{img:2:click:small}

The back contains the same information, but in more detail. The pictograms display the main characteristics and advantages of the jigsaw. Unfortunately, there is not a single word in Russian.

{img:3:click:small}

The side edges are nothing special.

{img:4:click:medium}{img:5:click:medium}

Removing the cardboard cover from the case, you can see a “Chinese” craft of rather average quality. The plastic is processed horribly. Our diplomat copes with his functions, but his appearance leaves much to be desired. In the photographs I tried to choose the best angle so as not to scare off a potential buyer.

{img:6:click:small}{img:7:click:small}

It’s very good that the case has full (albeit plastic) hinges. This indicates a potentially quite long service life. Many models have a simple plastic connection instead of hinges, which breaks after a couple of dozen opening/closing of the lid (people have to screw in normal metal hinges themselves).

{img:8:click:small}

Inside, in addition to the tool itself, you can find instructions in a large number of languages, including Russian (in a separate brochure), tips on using the device, a set of saw blades, and a hex key.

{img:9:click:small}

All promotional videos on the Internet indicate that the kit should include a flexible blade for metal, but for some reason it was replaced with a blade for wood. In total, we have three blades for a reciprocating saw (two for wood, one for metal) and three jigsaw files (one for hardwood, the second for curved cuts in wood, the third for precise cuts in metal).

Additional designations: HSC (high carbon steel) - high carbon steel, hardness 45-48 HRC, for working on soft materials such as wood, chipboard, fiberboard, plastics; BIM (bi-metal) - highly elastic, unbreakable connection made of HSS (high speed steel - high-speed steel, hardness 61-65 HRC) and HCS.

{img:10:click:small}{img:11:click:small}

The jigsaw itself does not stand out visually in anything remarkable.

{img:12:click:small}{img:13:click:small}

As we can see, it was produced in China, perhaps this can be attributed to flaws in the quality of workmanship (the edges of the plastic on both the device itself and the protective case are poorly processed, there is an indentation at the bottom of the mark on the support sole).

{img:14:click:small}

On the handle you can find an icon indicating the universal functionality of the device, as well as two buttons - on the bottom there is a power trigger, and on the side it locks in the working position so that your fingers do not get tired during long-term work. There is no rubber pad on the handle, which is a pity.

Currently reading: Made with a jigsaw

{img:15:click:small}

On the front of the jigsaw you can see a protective plexiglass screen and an indicator of the cut location printed on the sole.

{img:16:click:medium}

Following the path of universalization, the manufacturer equipped the device with a conventional screw clamp for blades. Next to it you can find a nozzle for blowing away chips and sawdust.

{img:17:click:small}{img:18:click:medium}

The sole of the jigsaw is cast and made of aluminum. There is no tilt adjustment.

{img:19:click:small}

In the tail part on the power cable there is a compartment (quite a useful thing) for a hex key. I advise you to install it this way - there is less chance of losing it.

{img:20:click:small}

And just below you can find a red latch with a picture of a lock. It is responsible for raising/lowering the handle, which allows us to transform our device from a jigsaw to a saw and back.

{img:21:click:small}

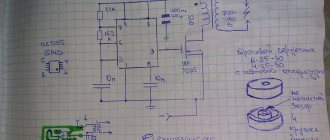

How to disassemble a reciprocating saw

In the case of DIY repairs and maintenance, the question often arises: how to properly disassemble the tool? Given the relative simplicity of the design, no difficulties should arise.

You can gain access to the motor and other elements of the electrical part by opening the plastic case. To do this, you need to unscrew the screws in the handle and around the perimeter of the case, if necessary, pry up the plastic parts with a screwdriver and remove one of the halves.

The gearbox is opened in the same way. The only caveat is that the screws can be hidden by a protective rubber-coated casing. It can be easily removed. To do this, you need to dismantle all the mounted elements (stop, guides, etc.). Then you need to unscrew the outer screws holding the casing and remove it by pulling it towards the saw blade mounting.

The gearbox housing usually consists of two longitudinal halves. By unscrewing the screws they can be easily separated.

All mechanical “filling” is removed without much effort. Anyone can find the cause of a malfunction or simply change the lubricant, even with minimal experience in repairing power tools. Assembly is carried out in reverse order.

A reciprocating saw is a simple and reliable tool. On average, the service life without the need for repairs is about 3–5 years. The only condition for trouble-free operation is the use of high-quality consumables and timely maintenance.

Testing. General impressions

{img:22:click:small}

There is no support roller for the jigsaw file, because The reciprocating saw blade is set with its teeth in the opposite direction. This reduces the quality of straight cuts. The base plate of the jigsaw is cast. On the one hand, this is a plus, because thereby imparting rigidity to the structure. When using stamped soles, when the support area is small, there is a lack of rigidity, which causes certain inconvenience.

Therefore, cast plate is preferable. But there are pitfalls here too. For example, if dropped, the casting may break. In our case, there is no space for installing an anti-splinter liner. And such an insert is an important detail. It allows you to avoid chipping and temporarily increases the resistance of the file to lateral slips.

In addition, there are no holes in the sole for attaching the jigsaw to the table with the file facing up, and there is no way to install a parallel stop, which again limits its range of use. As mentioned above, there is no adjustment for the inclination of the base plate; therefore, it will not be possible to make cuts at an angle.

Yes, such functionality is rarely required; it is often difficult to set the sole position back to zero. But why was this feature taken away from a potential buyer? This may be important to some. On the other hand, the sole of the jigsaw is always perpendicular to the file, which is convenient in everyday work.

{img:23:click:small}

As you can see, the jigsaw blade is tilted forward, which raises certain questions. The most correct and universal position is strictly vertical. Tilt of the blade can cause problems with some types of cuts.

{img:24:click:small}

Currently reading: Fucked with a jigsaw

Well, let’s check in practice what our review hero is capable of.

As you can see, the device is working. And it works well. Now about the nuances. It is extremely difficult to use a saw to make an accurate cut according to the mark. If possible, it is better to make a small cut with a regular hacksaw, and only then use our combination saw. All because of the high starting speeds. When contacting a hard material with insufficient initial pressure (show me a sniper who can immediately apply force exactly at the right point) and fixing the surface, small jumps of the file are observed, which can shift the cut line by several millimeters and leave unnecessary marks on the surface of the product.

If accuracy is not required, then the process does not cause any particular complaints. When using high-quality canvases, everything is simple, quick and without unnecessary effort. Cutting bars, tree branches, plastic and metal pipes does not cause any difficulties. Well, the light weight of the device allows you to work for quite a long time without interruption.

In jigsaw mode, working with an aluminum workpiece caused certain difficulties. The cut was carried out in three approaches (in the video they are glued into one) with the saw lubricated with oil between each of them. Pine bars, platbands, drywall, metal profiles, plywood - everything can be processed without problems.

But you will have to suffer with curved cuts in plywood. If you follow the mark on the sole, you will inevitably leave the cutting line. The molded front part of the support sole and protective plexiglass make it inconvenient to control the cut according to the position of the file. You have to look from the side. In any case, at times the saw may move to the side, so it is better not to count on completing the task the first time and in one sitting.

The main thing is not to rush, then everything will work out. Special devices such as a vice, clamps, parallel stop, various guides, etc. make the task very easy. As you can see in the video, blowing off sawdust, although a useful function, everything flies in different directions very strongly. Therefore, the work area cannot be kept clean.

In addition, I recommend listening to the manufacturer and working only with safety glasses. Your eyes will be healthier. In my opinion, it would be better to install a pipe for connecting a vacuum cleaner. During operation, the saw does not heat up strongly. The instructions recommend taking breaks every 20-30 minutes during prolonged work.

Causes of possible breakdowns of electric chain saws

The most common cause of breakdown of electric chain saws is a short circuit, which occurs due to the accumulation of condensation inside the electric tool immediately after it is turned on. According to the findings of experts in this field, this occurs mostly in the spring, after winter storage of electric saws. A short circuit can be prevented if you bring the tool into the room for a day before use.

Considering the possibility of voltage surges in electrical networks, it is advisable to monitor the operation of the tool during voltage changes. If such fluctuations occur, repair work must be postponed. In addition, you should remember the need for breaks during work. An electric chain drill must be allowed to rest from time to time (the tool cannot function continuously). After each use, the tool chain must be sharpened and straightened.

It is several times easier to work with such a tool, since there is no need to exert more effort. If this is not done, then a dull chain will provoke the possibility of additional load on the engine, which ultimately leads to premature failure of the electric saw.

Now you know the answer to the question of how to choose the right electric chain saw yourself.

What to pay attention to

Close attention should be paid to the following components and parameters:

Fastening the blade to the rod. The file should not dangle. Backlash indicates a poor-quality connection.

Noise during operation. Excessive noise in a medium-power model indicates poor-quality assembly and fitting of parts.

Vibrations. The larger they are, the more tired you will feel after a short period of work. An extremely useful thing is a special balancer that dampens vibrations. It greatly improves the ease of use.

Comfortable grip. For occasional home work, almost anything will do

In a more expensive tool, pay attention not only to the handle, but also to the forend of the body. There are models in which there is also a handle, and a rotary one.

Power cord length

To work in the garden and outside, a “carrying” will be required in any case. But it would be better not to create a tangle of wires indoors. In good units, the cord length is at least 3 m.

Reciprocating saw malfunctions and repairs

Any tool experiences stress during operation. Over time, components and parts wear out, which leads to breakdown. Each device is characterized by typical malfunctions associated with the failure of certain parts.

Blade holder

During operation, the blade flies out of the fixing device. Malfunction is rare and typical for cheap devices. The cause may be wear on the retainer.

Sometimes there is no breakdown. A blade with the wrong shank will not hold securely. There are frequent cases of counterfeit consumables. In this case, the diameter of the hole and the dimensions of the back of the file may not coincide with the original. This leads to poor fixation.

Bushings

The rod that moves the blade has guide bushings. They are usually made of brass. Over time, they wear out, which leads to backlash. The first signs are increased vibration during operation and deterioration in the quality of the cut. The malfunction is eliminated by replacing worn parts.

Bearings

Extraneous noise and increased vibration may indicate bearing wear. The cause may be poor lubrication or lack thereof. In such cases, there is only one way out - replacing parts and lubricant.

Gears

The worm gear experiences the greatest load. It sets in motion the entire mechanism inside the gearbox. Depending on the design, a straight or bevel gear is used. Rotation is transmitted from a “worm” located at the end of the rotor shaft. It is he who wears out the most. The second place is occupied by the gear, which may have wear.

Electrical faults

Typical breakdowns include: malfunction of the speed controller or start button, wear of graphite brushes, poor contact in the terminals. The motor windings may fail. In all cases, you will have to purchase additional spare parts for the tool.

Possible malfunctions and ways to eliminate them

| Symptoms | Possible reason | Elimination method |

| The electric motor does not gain full power and does not develop maximum speed | Carbon brushes have become unusable Low voltage in the network | Replace brushes Find another power source or use a transformer |

| Increased vibration is observed during operation. The saw blade is loose | Disc is unbalanced The saw blade is not securely fastened The saw is worn out | Replace the saw blade Tighten the flange bolt Replace the saw blade |

| The saw blade is in contact with the miter saw rotary table. | Incorrect disk installation | Adjust the saw blade according to the recommendations in the operating instructions in the “Adjustment” section. |

| The disc gets stuck in the cut and overheats greatly | The saw blade is dull The blade is not suitable for the work being performed | Replace the blade with a good one. Use a saw blade suitable for the material and work being performed. |

Reciprocating Saw Blades

The functionality of a reciprocating saw depends on the blade used. The package includes a set of blades for different types of material. They differ in pitch size, shape and size of teeth, material, presence or absence of diamond coating, etc.

The cutting element for a reciprocating saw is selected taking into account the material with which you will have to work.

In this case, pay attention to the size and pitch of the teeth, as well as their shape and degree of sharpening. It should be understood that a large tooth helps speed up the work, and a small tooth improves the quality of cutting the material.

From this we can conclude that blades with large teeth should be used for rough but fast processing of products, when quality is put into the background, and speed remains a priority component of the process.

In specialized stores there are short and long canvases (within 100-400mm), with and without spraying. The removable elements are unified in shape and size, so they fit almost any model of electric hacksaws produced by different manufacturers. The optimal file length is 120-170mm. It is these canvases that give the most accurate cuts.

Blades are produced in which the pitch and size of the teeth are variable - increasing from the shank to the end of the blade. They are convenient because using different sections of the blade, one saw can provide different processing parameters.

Initially, all tools were designed for 1/2″ saw blades. Today, the range of saw blades is quite wide - they are designed for different materials and different cutting lengths. New tools, such as reciprocating saws from Bosch or Black & Decker, require the use of special saw blades. For both models, manufacturers offer a wide range of saw blades for working with various materials.

It is more rational to choose a saw model that will fit as many different saw blades as possible. Using flexible saw blades, you can, for example, saw off an old pipe flush with the wall surface. Special saw blades are also produced for sawing various building materials. The retractable saw base allows optimal use of the saw blade when sawing thin materials.

The hacksaw blade is the main working part of a reciprocating saw. Its length, width, thickness and shape vary for different applications. All of them are made of high-strength tool steel and are durable and elastic.

- There is a generally accepted marking of the fabric material:

- HCS - the blade is made of high carbon steel, the teeth are large, located at an equal distance from each other. Such blades are used for cutting relatively soft materials: wood, panel materials, rubber and plastics.

- HSS - high-speed tool steel. Used for aluminum, thin-walled rolled products.

- BIM - bimetallic blades made from HSS and HCS type plates. They are distinguished by high strength and high flexibility. Used for cutting mixed materials: wood or aerated concrete along with nails.

- HM/CT - carbide blades. It is used for hard materials or for highly abrasive porous materials, such as concrete structures, metal, fiberglass, tiles.

Electric hacksaw from a grinder

Materials and tools used by the author:

List of materials:

- old hacksaw; - a piece of iron pipe; - sheet iron; - bolts and nuts; - one bearing; - paint for metal.

Homemade manufacturing process:

Step one. Hacksaw

First of all, we need a hacksaw; an old tool will do, but it will need to be sharpened. Remove the handle from the hacksaw; it will not be needed. If desired, the hacksaw blade can be significantly shortened, since its stroke will be small.

Step four. Hacksaw blade

Let's prepare the hacksaw tightly; we need to drill a hole in it of such a diameter that it will fit the bearing installed on the angle grinder shaft. The author drilled the hole on a drilling machine using a step drill.

Next, the hole needs to be given an oval shape so that the blade moves only in one direction. Here files and a drill will come to our aid.

Step five. Frame

Almost all the parts are ready, all that remains is to make the frame, here we will need sheet iron. We cut out two plates and drill a hole in one according to the diameter of the clamp, weld this part to the clamp, this will be the base.

You also need to drill holes in both plates for the bolts that will hold the plates together. The bolts need to be welded to the base.

At the end, all that remains is to modify the hacksaw blade, drill 4 holes in it in the places where the connecting bolts are located. The holes need to be bored with a file to an oval shape. As a result, the bolts will serve as guides that will hold the hacksaw blade.

Step six. Painting and assembly

We paint all the parts so that the homemade product does not rust and looks good. Well, then everything can be assembled, install the base and eccentric, and then all that remains is to install the hacksaw blade and the upper part of the frame. The homemade product is ready, you can test it, but don’t forget to lubricate everything well! The tool cuts bars, and even logs. Of course, the productivity of the saw is not very high, since the stroke of the hacksaw is too small.

In general, the homemade product deserves attention, since everything is done quite simply. This is the end of the project, I hope you liked it and found new ideas for yourself. Good luck and creative inspiration if you decide to do this again. Don't forget to share your ideas and crafts with us!

Source

Which model of reciprocating electric saw to buy - recommendations from the editors of HouseChief.ru

Our editors recommend choosing models based on the tasks you plan to solve.

Manufacturers of reciprocating saws - a brief overview and comparison of the most popular brands

We will present to your attention a rating of reciprocating saws, but for now we will get acquainted with the best manufacturers of popular models.

Bosch reciprocating saws

In first place among the most popular brands are Bosch reciprocating saws. The Germans are famous for their love of home instruments, and in this niche they have also received well-deserved recognition from the Russian buyer.

Among the tangible disadvantages of Bosch equipment is their cost. But if you want high quality, you have to pay

Makita reciprocating saws

Makita is another brand that has long established itself in the market for special construction tools.

The Japanese instrument is distinguished by its versatility and high quality. Some models allow you to work even at an angle of 180°.

Reciprocating saws Zubr and Interskol

Zubr and Interskol represent domestically produced products. The tools of these brands are in no way inferior to their “star” neighbors in terms of their working qualities, while significantly gaining in the price segment.

Zubr brand reciprocating saws are cheaper to maintain and easier to repair. Components are always available, which makes this tool one of the most attractive, albeit domestic

Basic models of reciprocating saws for cordless apartments

For household purposes, a device with a 400-600 W motor is suitable. The traction should be enough to easily cut wooden branches and carry out simple carpentry and plumbing work in the garage.

| Model | Characteristics | Average price (as of June 2022), rub. | Average score, according to the editors of HouseChief.ru |

| Makita JR102DZ |

| 3 870 | 9/10 |

| BOSCH Keo |

| 5 445 | 8/10 |

| Ryobi RRS1801M |

| 3 135 | 7/10 |

Now let’s give some reviews about these models.

Electric hacksaw (electric saw) of medium power for wood for country work

If you have a wider range of tasks, then you can buy a more powerful saw - with a 700-1000 W motor. With such an electric hacksaw for wood, you can easily assemble a bathhouse from logs or destroy an old greenhouse. The cost of such a model will vary from 5,500 to 15,000 rubles.

| Model | Characteristics | Average price (as of June 2022), rub. | Average score, according to the editors of HouseChief.ru |

| Reciprocating saw Bosch PSA 700 E |

| 5 749 | 9/10 |

| Reciprocating saw AEG US 900 XE |

| 7 999 | 8/10 |

| Reciprocating saw BISON ZPS-750-115E |

| 3 690 | 7/10 |

Professional reciprocating plate (electric hacksaw) for metal and aerated concrete for dismantling

If you have serious work to do: cutting metal or brick, then a saw with a power of one kilowatt or more will suit you. Such reciprocating hacksaws for metal and aerated concrete most often have a double saw blade and wide gripping arcs.

| Model | Characteristics | Average price (as of June 2022), rub. | Average score, according to the editors of HouseChief.ru |

| Reciprocating saw Hilti WSR 900-PE |

| 28 000 | 9/10 |

| Reciprocating saw Stomer SSS-1000 |

| 10 000 | 9/10 |

| Reciprocating saw Makita JR3070CT |

| 13 200 | 8/10 |

As we can see, the cost of some models is far from affordable, so in some cases it is more profitable to contact a specialized institution and rent a reciprocating saw.

Do-it-yourself powerful electric hacksaw for wood [LIFE HACK]

An angle grinder is a universal tool. It’s hard to imagine almost any metal work without it. However, its scope is not limited to this - not a day goes by without a new purpose being invented for it.

How to make a hacksaw from a grinder is the topic of today’s article.

Basic rules for operating an electric chain saw

The electric saw is very convenient to use, but its disadvantage is that its power is low.

After purchasing the tool, making sure that it fits perfectly, in order to maintain the electric chain saw in functional condition, you should follow a number of basic simple rules. They must be followed based on the considerations that an electric chain saw is an expensive tool and must be treated accordingly.

The average electric chain saw can produce 30,000 revolutions per hour, which is significantly lower than when using chain saws.

For this reason, a tool powered by electricity is more suitable for performing not too large volumes of work. But as an auxiliary tool for a home craftsman, such a saw will come in handy.

In the event that the unit is usually used to perform such global work as collecting firewood, it must be done in the most economical mode with the obligatory presence of breaks. However, the ideal option in this case would be a gasoline chain saw.

Advantages and disadvantages

Why make this homemade product if you can simply insert a longer file into the jigsaw? How are the efforts justified?

Well, firstly, even the longest electric jigsaw file is inferior in size to a reciprocating saw file. This modification makes it possible to saw thicker objects. Secondly, sawing fairly thick bars is simplified by the fact that this product allows you to cut downward and away from you, while a jigsaw, for example, can only cut forward and away from you.

Of course, this homemade product also has some disadvantages. For example, a small amplitude value for a fairly long “Sabre” canvas. An electric jigsaw has a less comfortable handle when used as a converted piece of equipment.

In any case, if the use of this tool is required only occasionally, then it is quite suitable as a worthy replacement for the original, thanks to which you will not have to spend money in vain.

Features and malfunctions of reciprocating saws

At first glance, it seems that a reciprocating saw is a simple hacksaw or an electric jigsaw, however, this is not so, because they have significant differences from each other. To cut an object with a hacksaw, you need to exert your own physical effort, but in a saber, almost all the work is done for you by an electric or battery-powered motor. The main features of the saw, unlike a jigsaw, are:

- appearance similar to a drill;

- the ability to saw in a horizontal position, which allows you to reach hard-to-reach places;

- greater freedom in cutting direction;

- fast processing of materials;

- the need for a “steady hand” to perform the work accurately;

- the ability to replace the blade with other attachments, which increases the scope of the tool.

The main malfunctions of reciprocating saws include the following.

- Sudden stoppage of the blade. It is usually associated with exceeding the permissible loads, the need to sharpen the cutting blade, as well as failure of the brushes.

- Crooked cut. The reason here may be the installation of the wrong cutting element, wear of the key or screw, or the need to clean the holder prism.

- Inability to turn on the device. The fault lies with a faulty cable, overload and motor failure.

- The appearance of dark small shavings, which are a characteristic feature of a blunt saber blade.

Any malfunction or breakdown requires qualified repair. Therefore, eliminating them yourself is not recommended; it is better to take the tool to an official service center.

Making a nozzle

We disassemble the hand saw into pieces, removing the handle.

To ensure reciprocating movements, we will make an eccentric. To do this, a washer, bearing, washer and M14 nut are put on the angle grinder spindle. To shift the center of the structure, it is necessary to insert a piece of M8 bolt into the gap between the spindle and the bearing. It needs to be cut to the height of the bearing. We secure the parts with a nut, now the eccentric can rotate without friction on the spindle thread.

To secure the saw, we repeat the same steps as on the standard protective casing of an angle grinder. A piece of pipe with a length equal to the distance between the beginning of the gearbox and the middle of the eccentric bearing. We partially divide it into 2 rings. The cut needs to be more than half. The cut line runs opposite the edge of the seat for attaching the casing.

Now cut the bottom ring.

An M6 nut is welded to the edges of the cut. With their help, the ring will tighten like a clamp when tightening the bolt.

A hole is drilled in the hacksaw blade 1 mm larger than the outer diameter of the bearing. It is slightly bored at the top and bottom. It is not easy to do such work, since the steel is hardened.

2 identical rectangular plates of arbitrary size are cut from sheet steel. A 40 mm hole is drilled in their center.

One plate is welded to a clamp tube.

A 6 mm hole is drilled in the corners of both rectangles. They should be opposite each other.

Holes are marked on the hacksaw blade, as on plates. They are drilled and then bored with a file to allow the blade to move. You need to sharpen in both directions in a horizontal direction from the centers of the holes.

For aesthetics, you can paint it with aerosol paint from a can.

To use the attachment, you need to lubricate the contact surfaces of the blade and pressure plates with grease.

The parts are tightened together with bolts and nuts. You need to pull it loosely. Lock nuts are placed on top to prevent the blade from being unscrewed or pinched.

An eccentric is assembled on the grinder, and the attachment is placed instead of the protective casing. All reciprocating saws can be used. After use, the equipment can be removed and the angle grinder can be used as usual. And we start sawing work.