The principle of spot welding is to join two metals under the action of an electric arc created by two movable electrodes (tips). High power electric current is supplied to them. When the electrodes are compressed at the site where the metal is pierced with an arc, a melt of a homogeneous structure is formed.

The spot welding method is often used in auto repair shops and private garages when body work is carried out. Very often, car batteries fail due to a broken contact; in order to change them, conventional soldering is not suitable; a stronger connection is needed.

Spot Welding Technology

The method is suitable for durable joining of heterogeneous alloys. Spot welding is called spot welding because of the size of the contact; it depends on the area of contact between the two tips or electrodes that form the electric arc.

To make spot welding, take two sheets of metal and a welding device. The process consists of several stages:

- the metal to be welded is placed between the tips, to which electric current is supplied;

- the power supply turns on;

- the stings connect with force;

- an electric arc occurs, it passes through metals, heats them up;

- Due to the compression force, the melt is compacted, resulting in a point connection of two sheets of metal.

The strength of the connection depends on the compression force of the tips, the power of the arc and the area of the tangent surface of the tips. They are made from alloys of high electrical and thermal conductivity; non-ferrous metals based on copper have such properties.

Types of welding according to the connection principle

In the process of independent work, craftsmen have to deal with one more parameter that distinguishes one model from other types. This is the principle of connecting surfaces. The following types of welding are distinguished:

- Seam welding.

- Butt welding.

- Capacitor welding.

Depending on the type of structure used, the shape and size of the holding clamps and the area of the main electrode change.

The areas of application of such devices are also strikingly different. Any resistance welding from the presented models can be assembled with your own hands from a welding machine.

Equipment

Ready-made machines for spot welding are either stationary or portable; they are convenient to use when carrying out repair work. Automatic welding machines are used in industry. There are portable lever welding devices called tongs.

Welding equipment is expensive, and you rarely need to use it. Craftsmen found a rational way out of the situation.

It is quite possible to make a spot welding device for batteries and a body yourself. It can be used to repair household appliances and create decorative metal products.

Designation on drawings

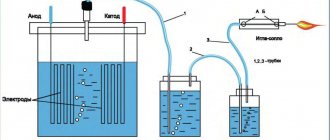

Sometimes a drawing or resistance welding diagram may be required to carry out the technology. It must have the correct designations of the parameters and important criteria of this method. Below is a photo with a diagram of this technology.

The welder should take note of several important symbols:

- in the diagram, the visible seam is marked with a solid line;

- invisible connection - dashed line;

- a visible weld point is indicated by a plus sign - “+”. It is done with basic solid lines;

- the invisible point is not marked in any way.

Welding, which uses contact in the form of electric current and pressure, is a popular technology with which you can create strong and high-quality connections. It is used in many areas of industry, including mechanical engineering and agriculture.

This method is suitable for products made of various metals, steels, stainless steel, it is easy to work with, and it is safe for humans and the environment. But still, before you begin, it is worth knowing in advance what kind of current should be used during contact welding; the quality of the work depends on this.

Welding of small parts

Sometimes it can be problematic to attach small contacts: a regular soldering iron is not suitable for this; the connection obtained by tinning is very fragile and cannot withstand high dynamic loads.

You can spot weld two small contacts using a low-power mini-welder. It is made according to the same principle as pliers, only the lower handle of the clamping device is permanently fixed, only the upper one moves.

The current source is fixed on a dielectric base, it can be:

- tree;

- plywood;

- non-flammable plastic;

- textolite

A transformer from a microwave oven or a ready-made TR1 is suitable as a current rectifier. If a transformer from a microwave oven is used, a wire with a cross-section of at least 8 mm2 in a durable heat-resistant braid is used as an additional winding.

When selecting electrodes, it is important to compare their thickness with the size of the wire. D The ends of the electrodes are sharpened to the required size. The smaller the contact area, the stronger the connection.

- DIY fan: how to make a homemade powerful fan. Basic parameters and properties of fans (130 photos)

- Why do you need a security alarm, what functions does it perform?

- How to choose winter workwear and not make a mistake - recommendations from the pros

The following is used as an electrode for spot welding:

- soldering iron tips;

- solid brass products (rods, hexagons, capillary tube);

- rods made of cadmium chrome bronze.

When choosing a lever, take into account the length of the working area - this is the depth to which the welded metal can be inserted into the welding device. To attach the tip to the handle, terminals are used: current is supplied to one end, the other part is secured with a self-tapping screw.

To select the correct pulse time, a resistor is included in the electrical circuit of the power supply. The power button is located on the handle or fixed on the power supply box. The wires and housing can be hidden in a single electrical insulator housing.

general information

A spotter is a welding machine used in body repair. At its core, a spotter is very similar to spot welding, but externally these are two completely different devices. Spot welding has two metal electrodes with sheet metal placed between them. In the case of a spotter, the technology is different. Let's take a closer look at it. The spotter has two terminals: ground and a wire with a working “gun”. The mass must be attached to the car body (do not forget to remove the battery from the car in advance). At the end of the “gun” there is a special clamp where you can install a special nozzle. When you press a button on the working “gun”, the welding current begins to flow. During the process, the welding site begins to gradually heat up. The resistance increases and the metal begins to melt in a certain area. At the same time, the rest of the body does not overheat. Metal is stuck, which can then be pulled out.

Let's explain it more simply. The spotter does not heat the entire part, but only a certain point (as is the case with spot welding). The heating is small, slightly less than the melting point of the metal. The fastening nozzle is pressed against the metal surface and at the moment of resistance it is securely attached, thanks to which you can then pull out the same dent in the opposite direction. Later the nozzle can be easily detached from the metal.

From spot welding there is both heat and force. The heating is carried out by the device, and the force is carried out by the master, who presses the nozzle to the metal. Therefore, this type of welding is not called spot welding, but resistance welding.

Battery device

A do-it-yourself mini-spot welding device is made using a car battery. Its power is enough to weld a contact to another one that requires restoration.

Two brass or bronze rods are attached to a block with a copper alloy terminal block; they are insulated in the area of contact with the hand. It must be taken into account that during welding the rods will become very hot; the insulator-connector should not melt.

The disadvantage of this device is the lack of a switch and high battery power. You must work with the device carefully so that there are no burns in the contact area.

How to choose an air conditioner for your home or apartmentDo-it-yourself bait - composition, application features and storage methods (115 photos and videos)

DIY sliding gates - how to build simple and automatic gates. Schemes, drawings and review of the best ideas (90 photos)

The purpose of the spotter and its features

A homemade spotter is used for car body work. This is done when, for some reason, to level the surface of the part . You can locally heat the metal using the specified tool if there is minor damage to the body area. It is important to figure out how to make a spotter with your own hands in order to get a high-quality and functional product.

The welding process looks like this. Fasteners are fixed in place of the damaged metal. A device is connected to it and the dents are pulled out using auxiliary devices or with your own hands. The body repair tool makes it possible to quickly and efficiently restore a car without painting the damaged area. The good thing about a spotter is that during its operation it is possible to keep the functioning of every part under control. This is due to the fact that the likelihood of overheating and breaking the wires is quite high.