DIY sports equipment: basic rules

You can make almost any sports equipment yourself, from simple weights to sports complexes.

The most common strength exercises can be performed at home with dumbbells.

The best, of course, are metal dumbbells, but they are much more difficult to manufacture than other designs. It is necessary not only to make the disks, but to choose the correct width of the pancakes, and to make the locking locks in a quality manner according to the calculations. You can make several heavy and several small pancakes.

The diameter of the bar (handle) must be within 3 cm; this condition must be taken into account when manufacturing dumbbells and barbells. Weights allow you to perform exercises of varying loads.

Before you start practicing at home, carefully check your equipment for the integrity of both collapsible and permanent products.

We collect shells from concrete

The cement base allows you to get heavier dumbbells and barbells than using plastic bottles. The pancakes are not only more impressive in weight, but also look much more solid. They are cast from cement mortar in a special mold, inside of which there is a neck. The disadvantage of this design is that the load of the projectile cannot be adjusted or adjusted to suit someone else.

To start working with a different weight, you will need to make a new barbell or dumbbells. Weighting agents, in fact, are individual, and also quite fragile and “free-flowing”. The last drawback is eliminated by introducing PVA glue into the solution. And if the classes are not conducted according to the principle of powerlifting, when the apparatus is thrown onto the floor, then it will last quite a long time.

To make concrete dumbbells (bars) you will need: a metal pipe of the required length, bolts or screws, cement mortar, PVA, and a mold for casting the weight.

How to make dumbbells. How to make a dumbbell

Step-by-step instructions for making cement projectiles:

- At the ends of the pipe, holes are made in four directions using a drill. Screws are screwed into the holes made so that they are fixed as securely as possible at the ends and form a peculiar cross shape. They become the framework that holds the cement.

- The pancake pan is made from a flat mayonnaise or paint bucket. You can use another container. The main thing is that the weight be selected so that it is necessary for training and suits the body of the student. Glue is added to the solution for hardness or oil paint is introduced.

- Place a pipe in the poured mixture and wait about four days until it completely sets. Repeat the manipulations described in the previous paragraphs for the second side. Make a support. The structure is tied up or suspended for another four days.

- When the cement has completely set, over the next week the projectile is soaked at least twice in water so that it gains even greater strength.

Shells poured into a two-liter mold can weigh about 5 kg. The exact weight is determined by the composition of the mixture involved.

To do the Farmer's Walk, you don't need to make any apparatus. It is enough to take two ordinary cans and hang them on a stick. You can use tires filled with sand or any other filler. It is difficult to perform other exercises with a similar design. They require the use of full dumbbells.

What can be used from improvised means

People often stop playing sports due to lack of sports equipment. There is always a way out: any projectile can be replaced with a heavy object that is at hand. Some physical exercises do not require special equipment.

The most common equipment is an ordinary plastic bottle, from which I make dumbbells. To weigh them down, various fillers are used: water, crushed stone, sand, cement, small metal parts, etc.

Homemade punching bag for the home gym

A punching bag is one of the most necessary equipment that will help you practice your punching power and technique. Making it yourself is quite simple:

- To do this, you need to take an old fire hose and rip it apart along one of the folds;

- You should end up with a strip of tarpaulin, which must be washed and boiled so that the fabric is not too hard and does not hurt your hands;

Making dumbbells with your own hands

At home, you can make both small and large dumbbells.

The first step in manufacturing is to decide what they will be made of.

From plastic bottles

To make plastic dumbbells from plastic bottles, you will need the following materials:

- bottles (2 pcs. of the same volume);

- handle 30-40 cm long (wooden stick or metal rod);

- scotch tape (insulating tape);

- filler (sand, crushed stone, small metal parts).

After all the material has been prepared, you must:

- take bottles and fill them with filler;

- wrap the handle with electrical tape in the middle (10-15 cm);

- insert one end of the handle into the neck of the first bottle until there is no movement;

- to prevent the filler from seeping through, coat the joint of the handle with silicone or glue;

- connect the second bottle to the handle, then process the joint;

- wrap the assembled structure around the handle, strengthening the connection.

From cement

Heavier dumbbells are made using a cement base. The disadvantage of concrete dumbbells is that it is difficult to evenly adjust the weight of the weighted plates, and this design is not dismountable. If a different weight is required for sports, a new apparatus will need to be made.

In order to make dumbbells at home, you will need the following materials:

- metal pipe (neck);

- cement mortar;

- bolts, screws;

- form for casting pancakes.

Then you need to:

- At the ends of the neck, make four holes evenly for 4 bolts around the perimeter.

- Install bolts into the holes, which are holding elements for the pancakes.

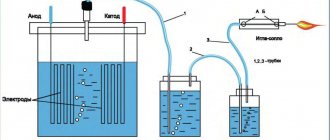

- Place the bar in a vertical position in the casting mold. Pour in cement mortar and leave in this position until the mortar is completely dry.

- For the second side, repeat the previous step.

You can eliminate the flowability of cement dumbbells by adding PVA glue or paint to the solution, and to increase the weight - crushed stone, gravel or small metal products.

Metal

Shells made of metal are considered the most reliable and practical.

To make dumbbells you need:

- Prepare a metal rod with a diameter of 3 cm (bar).

- Take a thin-walled pipe 15 cm long. The internal diameter should be slightly larger than the diameter of the neck.

- Place the pipe on the bar, then fix it in the middle.

- Make the required number of weight discs. This will require sheet steel.

- Use rings or a 2-3 cm long pipe as locking locks. Drill a hole in them and cut a thread for screwing in a screw. As a result, the screw that is screwed in will hold the plates by pressing them against the bar.

Pay special attention to high-quality pressing of the screw to avoid play. Collapsible metal dumbbells allow you to adjust the weight. It is also possible to make non-separable dumbbells, for this purpose welding is used as locking locks.

We create inventory from plastic

Do not skimp on adhesive tape and electrical tape - poor fixation of the dumbbell elements can lead to its destruction

You can assemble dumbbells quickly and very cheaply by using plastic bottles. Due to the simplicity of the design, you can practice with such projectiles immediately after production. For one dumbbell we need: 2 plastic bottles; filler; insulating tape/adhesive tape.

Manufacturing

- The middle part of the bottles needs to be cut out, and then the top and bottom parts must be reattached with adhesive tape.

- Then you need to fill the resulting containers with filler. Sand and cement are excellent fillers, but if you need more weight, then feel free to add nails, scrap metal, balls from bearings, in general, let your imagination run wild.

- After filling, you need to insert a wooden or metal shelf or pipe into both necks. Cover the areas with tape or duct tape. You will get a very comfortable, soft and non-slip handle.

Assembling the barbell

You can also assemble a barbell from plastic. Since it itself implies a lot of weight, you need a lot more bottles. For the bar you will need: plastic bottles, at least 8 pieces; filler; fingerboard; tape/duct tape.

Manufacturing

- As a neck we use a pipe and fittings that are comfortable for the hand.

- We fill the bottles in the same way as in dumbbells.

- Place the finished weight around both ends of the bar and wrap it with tape. We get four bottles on each side, between which the bar passes. Tape the weight securely to the bar so that it does not move or cause play.

- For a more impressive weight, we take another load and place it in the spaces between the existing bottles, like logs. We recommend wrapping each new layer with new tape - this way you can increase the weight of the bar up to 100 kg.

To make it easier for you to determine the size, number of bottles and their filler, we provide the following data:

| 2 liter bottle filler | Weight, kg |

| Water | 1,997 |

| Sand (compacted) | 3,360 |

| Sand (wet) | 3,840 |

| Lead | 22,800 |

| Crushed stone (pestone) | 2,600 |

How to make a barbell from improvised materials

You can make a barbell using available materials. Its design is practically no different in complexity from a dumbbell.

The main element is the bar; without it it is impossible to make a barbell. There are many options to make a barbell at home.

Plastic bottles

The design of a homemade barbell is identical to a dumbbell, and you can use bottles of water or other material for weighting. But for more serious weight loads, pancakes are made not from two bottles, but from 8 (4 on each side). The bottles are filled with filler, then 4 pieces are tightly fastened together, forming a square. After which the bar is installed in the space between the bottles and secured.

Wheels

Another easy way to make a barbell is to use car wheels as weights. As a rule, assembled wheels are used. This type of sports equipment allows you to throw the barbell onto the floor after performing an exercise, without fear of damaging both the barbell itself and the floor.

For such a rod, a plate with bolts is installed at the end in accordance with the bolt pattern of the disk.

Concrete pancakes

To make pancakes from concrete, you must first make a mold for pouring the solution. Place a cylindrical object in the center of the mold. The diameter of the cylinder should be slightly larger than the diameter of the neck. Then the cement mortar is diluted, which is poured into the mold until completely dry.

In order to make the rod more stable, it is necessary to install metal sheets (inserts) when pouring. All concrete weights for barbells must be made in pairs and have the same weight.

The bar must have a locking element that will prevent the plates from moving to the center. Additionally, locking locks must be made.

Making a rod

How to make a barbell at home? We offer several simple methods.

Method one

You can make a barbell from sand and ordinary plastic bottles. Here's what you'll need:

- plastic bottles with caps (volume depends on the desired weight);

- electrical tape or tape;

- sand;

- a durable shovel handle or metal pipe;

- two lids from canisters or five-liter bottles;

- plasticine.

Instructions:

- First you need to fill the bottles with sand and screw them tightly. The number of containers will depend on the desired load.

- Then you can go in two ways. First option: connect three or four bottles together by wrapping them with electrical tape or tape. You will get a kind of volumetric disk. A homemade barbell will be placed in the hole formed between the containers.

- The second option is more complicated, but it will allow you to make separate homemade pancakes and increase the weight if necessary. Take a couple of bottles, place them next to each other and wrap them with tape several times around the entire perimeter, running it along the lids, sides and bottoms. There will be a hole between the covers intended for putting on the bar.

- Next, you should make some kind of plugs for the neck, which will reduce the risk of accidental slipping of the discs. Take a large canister lid, fill it with plasticine and place it on the edge of a metal pipe or shovel handle.

Method two

A homemade barbell can easily be made from empty paint cans. Prepare:

- two tin cans of paint;

- cement and water;

- metal pipe;

- drill and bit.

Process description:

- First you need to measure the diameter of the pipe and select the appropriate drill. Next, drill one hole in each jar, approximately in the middle on one side. The holes should be located at the same level.

- Place a metal pipe into the prepared holes.

- Prepare the cement mortar by mixing the powder with water in the proportions indicated in the instructions on the package. Fill the jars with this mixture, adhering to the desired planned weight.

- Now the cement must dry completely so that the discs become rigid and the bar is securely attached to them.

Method three

You need:

- two old unwanted footballs or basketballs;

- drill;

- sand or small stones;

- universal glue or tape;

- metal pipe or shovel handle.

Description:

- In each of the balls, use a drill to make a hole with a diameter corresponding to the diameter of the pipe or handle.

- Fill the balls with sand or small rocks.

- Place the edges of a pipe or handle into the holes, which will act as a neck. Next, secure the joints with glue or tape.

- The homemade ball barbell is ready!

Instructions for assembling a homemade rod

The bar is the most important part, thanks to which the barbell is able to withstand heavy weight loads. The safety of performing exercises depends on the quality of the bar.

When making the neck, it is necessary to use durable materials. In order to make a fingerboard, you will need steel reinforcement, an iron pipe or a crowbar. When choosing a material, pay attention to the thickness, as it should be comfortable for a clenched palm.

The entire process of making a barbell at home can be seen in the video

Record sizes and weights

Modern gyms have long rows of dumbbells of varying weights. Most often, their maximum weight is up to 50 kg. But there are iron monsters in the world that exceed this figure. For example, there is a popular video on Youtube where Rich Piana and his colleagues are trying to lift a dumbbell weighing 170 kg

!!!

And in the gym where Ronnie Coleman worked out, there are his personalized dumbbells, each of which weighs 113 kg

. Yes, the 8x Mr. Olympia used them in his training. Anyone who can lift them will receive a free annual subscription to this gym. Unfortunately, it was not possible to find information on the Internet whether such lucky people exist.

Sports doctor, nutritionist, rehabilitation specialist

Provides general consultations on nutrition, selection of a diet for pregnant women, weight correction, selection of nutrition for exhaustion, selection of nutrition for obesity, selection of an individual diet and therapeutic nutrition. Also specializes in modern methods of functional testing in sports; athlete recovery. Other authors

Current prices for sporting goods are sky-high, so it is much more profitable to make high-quality equipment at home. The barbell is the optimal athletic equipment for developing various muscle groups. It doesn’t take much effort to make a barbell with your own hands for an individual or outdoor sports ground. To create it you will need a minimum of materials and a standard tool.

Preparing the Bar and Barbell Rack

The bolts must be long enough to securely secure the bar. For safety, a pair of nuts with a wide washer must be screwed onto the ends of the bolts, which will prevent the rod from accidentally falling off the bolts. If this sports equipment is not being built indoors, but on an outdoor sports ground, it is recommended that the bolts and connections be coated with paint, which will prevent corrosion.

You can use common household items to make a barbell to improve your fitness and exercise. Milk bottles, canned goods and other everyday items will help you stay in shape. This way you'll save money and stay in good shape!

What to choose from

A home bench press bench is most often included in a compact exercise machine or is itself a multifunctional sports equipment. Regular exercisers will probably end up with a simulator, so when choosing a prototype bench, you need to keep in mind what it will acquire later. The most common designs of sports simulators are 4-, 3-, and 2-support. “Support” in this case does not mean the number of points of contact with the floor (usually there are at least 4 of them, for stability), but the number of vertical force connections in the structure; it largely determines the capabilities of the projectile.

4-support projectiles, pos. 1 in Fig., are intended for developed athletes who operate with large, over 100 kg, weights. The racks for the barbell are located in them at the level of the shoulders of the person lying down, which greatly reduces the risk of injury: a barbell collapsing with the bar on the chest is very serious. 4-support exercise machines are heavy, cumbersome, and you can’t exercise with heavy weights in an apartment: falling on the floor, they give an instantaneous load of 5-8 of their weights, and the load-bearing capacity of the floors is 250 kg/sq. m.

For domestic conditions, 3-support exercise machines are intended, simple and with additional levers for weights, leg supports, athletic desks, etc., pos. 2 and 3. To ensure that the bar of the barbell in a 3-support machine also falls at shoulder level, their benches are made to “break”: it is dangerous to pick up the barbell with your hands behind your head. Therefore, in terms of dimensions, 3-support simulators are generally no smaller than 4-support ones, excluding those in which the barbell is taken from the approach, see below. The permissible working weight in 3-support equipment is usually 100-120 kg, including the trainee’s body weight.

A 2-support exercise machine is actually a bench for the press. For different groups of exercises, horizontal and inclined benches are needed, pos. 4 and 5: on a horizontal bench the abs swing, and on an inclined bench the lumbar muscles are also well loaded. A more complex structurally universal bench, pos. 6, serves in both capacities.

Note:

You can also do initial sets of hyperextensive exercises on an incline bench, see below.

The most advanced type of sports benches is a transforming bench with a breakable board, the inclination of the parts of which is individually adjustable, pos. 7. The transforming bench can be supplemented with a stand for a block with a load, a desk, pos. 8 and other devices. It makes sense to do one for yourself right away if you have the necessary working skills: then adding a barbell rack to the bench, we get a complete analogue of a 4-support exercise machine, only with less weight, pos. 9.

Note:

A common mistake when making transformable sports benches yourself is to make them according to a power circuit, as in Fig. on right. When performing exercises, significant forces arise, tending to “spread the bench of the legs,” and the welds turn out to be unreliable. In order for a projectile of this type to become durable, its supporting beams must be connected with a longitudinal beam, or two, from the same pipe.

Types of racks

To perform strength exercises, as a rule, two main design options are used:

- squat racks;

- safety racks.

The first option consists of two frames connected to each other. The long side of each of them is equipped with several stops that hold the neck of the projectile. If difficulties arise while lifting with weights, the athlete can use the limiters at the bottom of the frames.

Squat racks are identical to the design described above, with one difference - they are not as high and are more suitable for squats with a weight on the shoulders.

A variant of racks with separated frames without a connecting element is used, although not so often. This option is not the most successful due to the increased instability of the structure. When working with such a device, it is important to ensure that when the projectile returns to its starting point, the frames are symmetrical with respect to each other.

Moreover, a base that is too light can lead to the projectile falling and, as a result, injury. The only solution in this case may be to strengthen the racks - using bolts with which the structure will be screwed to the floor.

In order to avoid problems when working with racks, it is better to make them in the form of a solid structure based on the telescopic racks themselves of a relatively small height. The main disadvantage of the device may be the proximity of the connecting beam to the athlete’s legs in a position where he needs to remove the apparatus from the racks. Therefore, if you plan to make the structure yourself, place the cross beam a little further.