To view a high-quality image from a projector, you need a special design - a regular white wall will not always satisfy your needs. It is quite possible to make a projector screen with your own hands, and your homemade screen will be no different from the analogue from the store. Let's consider what materials are needed to make this structure.

Pros and cons of self-assembly

The advantages include:

- Experience gained while working with electronic equipment.

- Possibility to create a device according to an individual design.

- Opportunity to obtain ready-made equipment at the lowest cost.

Now let's look at the cons:

- Self-production narrows the range of applications for such a screen; a homemade LED screen is most likely not suitable for street use.

- There is no warranty service.

- Without certain knowledge, it is difficult to achieve the desired image parameters.

- Assembly may take an indefinite period of time due to the lack of any parts, which entails a loss of profit.

- There is no guarantee that it will last long.

- It is difficult to assemble a large device.

It is possible to make an LED screen with your own hands if you are a specialist in this field and you have prepared a detailed project for manufacturing the product, describing the installation method, the number of LEDs, size, etc.

Many believe that the most optimal manufacturing option would be LED strips and a microcontroller.

Whether you start making it yourself or use the services of experienced professionals, in any case, your decision to have an LED screen will be justified by its many advantages

:

- Attracting the attention of a large number of people;

- Spectacular and bright design for various events;

- Ability to transmit various types of information;

- Minimal maintenance costs;

- An opportunity to stand out among competitors.

This entry was posted in. Bookmark the .

LED screens, or, as they are often called, LED displays, became available for mass use relatively recently. It would be more correct to call this electronic device an LED display (light emitting diode) instead of the Russian abbreviation. Along with these names, the term “LED screen” is often used.

The first video screens appeared more than 20 years ago, but their brightness (individual pixels were on gas-discharge lamps) was not sufficient to reproduce high-quality images, especially on sunny days. In addition, the maintenance of these devices was very difficult and expensive.

Rapid progress in the technology for producing bright, high-quality and at the same time inexpensive LEDs in primary colors (red, green and blue) has made it possible to take a rapid step forward in the LED screen production industry. A huge range of possibilities for creating video images, managing color, brightness and dynamic images has made a real revolution in the outdoor and interior advertising market (small screens - from 1.0 x 1.0 m, where display of large-scale images is required).

In large Russian cities, littered everywhere over the past 20 years with faceless 3 x 6 m billboards, the gradual introduction of this modern technology has begun. Modular assembly principles and Arduino hardware and software allow you to assemble an LED screen with your own hands.

Selecting material and format

For the manufacture of projector displays use:

- Banner fabric. The most popular option. It has a high reflectivity and is available in a wide size range.

- PVC film. One of the best materials for making projector screens. It is easy to find a roll of the required size. The only drawback is the high cost.

- Cardboard or fiberboard. A good option if you need to save money. The product cannot boast of picture quality or durability, but it performs the main task.

- Thick fabric (sheet). It is recommended to paint the material with white paint or make a backing of dark cardboard. This will increase reflectivity, making the image clearer.

- Drywall. It will help you get a high-quality picture with minimal time investment. The material is easy to process.

- Wall. Apply several layers of white matte paint to get a dense color - the monitor for the projector is ready. Of the minuses: there is no way to move the product.

- Covering for suspended ceilings. Among the advantages, we note the high quality of the picture. The disadvantage is low strength. The material is resistant to fire, punctures and direct sunlight.

In this video you will learn how to make a screen:

Image format is one of the best factors in determining the choice of coverage. So, we can get a high-quality and clear picture on the projector display. There are five options:

- for cinemas (full screen mode) - 2, 35:1;

- standard - 1:1;

- video format - 4:3;

- widescreen - 16:10;

- for TV - 16:9.

Note! If you plan to use the projector to watch modern films or as a computer monitor, it is better to give preference to the 16:9 format.

LED lamp device

The LED lamp consists of the following six parts:

- Light-emitting diode;

- base;

- driver;

- diffuser;

- radiator.

The operating element of such a device is an LED, which generates a stream of light waves.

LED devices can be designed for different voltages. The most in demand are small products of 12-15 W and larger lamps of 50 watt.

The base, which can have different shapes and sizes, is also used for other types of lamps - fluorescent, halogen, incandescent. At the same time, some LED devices, for example, LED strips, can do without this part.

An important design element is the driver, which converts the mains voltage into the current on which the crystal operates.

The efficient operation of the lamp largely depends on this unit; in addition, a high-quality driver with good galvanic isolation provides a bright, constant luminous flux without a hint of blinking.

A conventional LED produces a directional beam of light. To change the angle of its distribution and provide high-quality lighting, a diffuser is used. Another function of this component is to protect the circuit from mechanical and natural influences.

The radiator is designed to remove heat, excess of which can damage the device. Reliable operation of the radiator allows you to optimize the operation of the lamp and extend its life.

The smaller this part, the greater the thermal load the LED will have to withstand, which will affect the speed of its burnout.

Make a frame

The frame will be the base on which the projector screen will be fixed. Creating a smooth frame will help optimize the screen as much as possible. Consider the following points:

A Brazilian travels 36 km by bike every day to take his loved one home.

Smooth and fresh skin: dermaplaning, or why a woman needs to shave her face

The money tree pleases with lush flowering: my secret is in caring for the leaves

- If the boards are too long, cut them to the desired length.

- Place corner braces on the four sides where the boards meet.

- Install screws into the wood strips through the corner brackets.

- Check how stable your frame is. If necessary, add additional parentheses.

Arduino and industrial solutions

The same addressing principles are used to create larger LED displays.

Outdoor LED panels will require more powerful light sources than a miniature LED display. max7219 are used as image output controllers, and a power driver on a ULN2803 chip is used for communication with high-power LEDs. It has eight control signal switching lines, which is ideal for our purposes.

In the design of large-sized advertising displays, super-bright LEDs with a luminous flux of 70-100 lm are used.

In single-color (monochrome) LED matrices, each element has two states: on/off. To transmit full-color information, RGB LEDs with PWM brightness control controllers for each color are used.

What tools and materials are needed

To make a monitor, you will need the following tools:

- fiberboard sheet;

- fabric for the screen (we take 2.6:1.6 m as an example);

- screwdriver Can be replaced with a screwdriver;

- wooden beam - 4 pcs., 2500:40:15 mm;

- sanding paper;

- aluminum box - 5 pcs., 2500:65 mm;

- self-tapping screws for fastening the structure;

- pliers;

- paint brush or roller, matte white paint;

- furniture stapler;

- construction knife or metal scissors;

- thin felt.

Don't forget to prepare the necessary material

Phone or tablet

You can also make a TV device out of a dusty device using a smartphone or tablet. In this case, any content from a mobile gadget will be displayed on the big screen, including online television.

HDMI

To use the mirroring feature, you will need an HDMI cable and a dedicated phone/tablet adapter. The connection process is as follows:

- Configuring the device for an HDMI signal source.

- Connecting equipment with wires.

- Set the optimal resolution for the display.

VGA

You need to purchase an AV adapter and a VGA cable, and also do the following:

Assembling the structure and connecting the devices to each other (note the “tulip” colors). Separate connection of the gadget to the power source. Outputs sound to external speakers via 3.5 mm MiniJack.

You can always load your favorite TV series into the memory of your tablet or smartphone and enjoy offline viewing by synchronizing your equipment via the USB interface. The resulting system cannot be called television, but this method is the simplest and cheapest.

How is the image displayed?

The selection of video footage and its replacement for broadcasting to the LED screen is carried out via Wi-Fi or USB. In the first case, information is received through the controller’s network card, and in the second, through a cable from a computer connected to the system. The controller converts the video into a digital stream and distributes the voltage across individual LEDs. The quality and order of display depends on the type of control system:

- synchronous control implies the simultaneous display of one picture on the screen and the source device, that is, live broadcasting. It is often used during sports broadcasts and concerts. To operate, a transmitter card operates on the source device, and one or more receiver cards connected to each other on the screen;

- Asynchronous display of information on the screen is associated with preliminary loading of information in the microcontroller memory. Loading is carried out from a computer via a cable or from a flash drive. The asynchronous system operates independently of the control computer and is equipped with several microcontrollers (depending on the size of the display).

A popular tool for programming and controlling LED screens is the Arduino hardware and computing platform . It has connectors and ports through which you can connect a variety of devices to create simple and complex automated systems, including LED screens. Arduino is programmed in C/C++ languages.

Aluminum based LED panel

Using aluminum sheet as a base for an LED panel has several advantages. Firstly, this design is more mechanically stable. Secondly, a material with high thermal conductivity is better than glass at removing the generated thermal energy from operating diodes.

In this article we will give an example of a small panel 28*26 centimeters, for which you will need:

- aluminum sheet with a width of 28 cm and a length of 26 cm;

- 5 meters of LED strip 5630 SMD;

- power unit;

- power supply wire;

- copper wire with a cross-sectional diameter of 1 mm for connecting pieces of tape into a circuit;

- soldering tools.

How to assemble a DIY LED panel on an aluminum base:

- The tape is cut at the marked places and glued to the base in several rows. In this example, the segments are laid in 20 rows of 25 cm in length.

- In this case, it is convenient to connect the positive and negative contacts of the segments through one wire. That is, on one side a rod of copper wire is laid, to which the positive contacts are soldered, and on the other, a rod connected to the negative ones. The power wire is connected to the first one.

- It is also convenient to use a connector to connect the power supply.

- To insulate and give a more aesthetic appearance, you can stick electrical tape over the connecting wires, and then shrink it, heating it with hot air from a hairdryer.

The power consumption of 5 meters of tape in this device is 160 W. After adding 30% of the margin, the result is 208 W. To ensure stable operation in this case, a 250 W power supply is suitable.

Backlight repair

A SAMSUNG GH19LS monitor being repaired with the problem “turns off after a couple of seconds of operation.” The first thoughts arise about the power supply.

Apparently, the monitor has already been repaired since the electrolytes have been replaced. In addition, one of them clearly did not have enough height of the terminal and it was “extended” with a wire. The capacitors are at the wrong voltage rating. It is better to re-solder to those that are needed.

Lengthy repair process

The problem remains. The monitor does not turn on. Next you need to diagnose the converter part. Since the monitor goes out after a couple of seconds, and the power button itself is lit, this means that the backlight goes out. The problem is either in the lamps or in the transformers. When measuring the resistance of the windings of one of them, it turned out that for one transformer it differs by about 10 Ohms. This is a lot, and the difference in lamp consumption increases, which is why the power supply protection is triggered. The way out of the situation is to change the transformer. But it is not so easy to get.

Why two at once? Since the transformers are from a donor and are designed for different parameters, the backlight will light differently. That is, if you leave one “native” transformer, and replace the second failed one with a “donor” one, then there will be an uneven glow. And the inverter will fail sooner or later. In addition, the type of fastening of the terminals of the transformer from the “donor” is different.

There is another way out. The transformers are from a donor, but I had to put a whole board together with them. To do this, it was necessary to supply power and signal wires separately to them. By the way, when replacing a transformer from a “donor”, one more condition is still necessary - the size of the diagonal of the screen. The repaired monitor and the “donor” one must be the same size (or close) since the lamps are different, the current is different, and the voltage is different.

Donor transformers do not wear out as much as electrolytic capacitors.

Soldering is done in place of the power electrolyte of the new board, and the signal is in place of the cable, where according to the circuit there is a signal to turn on the backlight.

Works. The problem was the increased resistance of the winding of the backlight transformer. This may also be due to the end of its service life.

What are LED screens?

LED screens or LED screens are the name of the technology for broadcasting video content using LEDs combined into matrices or clusters of large screens. They are widely known to indoor and outdoor advertising professionals, as they are often used to create shop windows, signs and other advertising surfaces. But this is not all areas of use of LED screens.

The technology is based on a modular design. Due to the fact that LEDs can be placed not only on standard rectangular bases, but also on designer blanks, there is no limit to your imagination. The area of the LED screen does not in any way affect the quality of the junction of the modular parts. An absolutely complete, at first glance, structure, called a “Cabinet” or LED module, is mounted. Usually for outdoor advertising it is fixed with a supporting metal structure, a hermetic housing, and an indicator panel. The hermetic housing of the LED screen consists of an LED sheet on the front side, and a controller, electronics, power supply unit(s), and internal fan on the other side. The case has its own level of protection from weather conditions, temperature resistance, etc. Typically, LED screens can easily survive conditions from -60 to +60 Celsius, with uniform illumination and data transfer speed.

Using an LED screen indoors will help create a seamless video wall with excellent brightness characteristics and technical longevity (up to 10 years of continuous operation, subject to possible LED dimming of up to 50%), with reasonable and economical energy consumption.

LED screens are designed to present information vividly, and the quality of the image itself is determined by how large the area the screen itself occupies and how many LEDs form the visual unit of the image - the pixel. From one to several dozen LEDs can transmit one point on the screen. It is clear that in this characteristic - the more, the better in relation to the area of the entire screen. The number of LEDs per pixel also determines the overall power consumption. In general, LED screens consume more during the day, where you need to compete with the brightness of sunlight, and in the evening, even in economy mode, they look very bright. And since any device has its own control panels for all these indicators, you can easily monitor the content and indicators of the LED screen.

How to make an LED lamp with your own hands

To begin installing the lamp, you need to prepare two damaged fluorescent lamps with a power of 13 W and a length of half a meter. There is no point in buying new ones, it is best to find old ones that don't work. But they must be checked for cracks and chips.

Next, you need to purchase an LED strip in the store. This must be approached responsibly, since the choice is very large. Tapes with natural or pure white light are best. Since they do not change the shades of surrounding objects and are super bright. Typically, these strips contain LEDs in groups of three. The power of one group is 14 W, and the voltage is 12 volts per meter tape.

After which you need to disassemble the fluorescent lamps into their component parts

You must act very carefully - do not damage the wires or break the tube, as this will release toxic fumes. All removed entrails should not be thrown away.

They may be useful in the future. Next, you need to cut the tape into sections of 3 diodes. After this, it’s worth getting expensive and unnecessary converters. Large, sturdy scissors or wire cutters are best for cutting the tape.

In the end there should be 22 groups

3 LEDs or 66 LEDs, which must be connected in parallel along the entire length. To convert alternating current to direct current, the standard voltage of 220 volts must be increased to 250 in the electrical network. This is due to the straightening process. The next step is to figure out the number of LED sections. To do this, you need to divide 250 volts by 12 volts (voltage for 1 group of 3 pieces). Having finally received 20.8 (3), you need to round up - you get 21 groups. It is best to add another group, since the total number of LEDs will be divided into two lamps. And dividing an even quantity is much easier.

Next, you will need a DC rectifier, which can be found in the removed insides of the fluorescent lamp. Using wire cutters, remove the capacitor from the common circuit of the converter. This action is quite easy to perform, since it is located separately from the diodes; you just need to break off the board.

Using superglue

and soldering, it is necessary to assemble the entire structure. Don't try to fit all 22 sections into one lamp. As mentioned above, you need to find 2 half-meter lamps, since it is simply impossible to place all the LEDs in one. There is no need to rely on the self-adhesive layer, which is located on the back of the tape. It won't last long. Therefore, it is better to use superglue or liquid nails to secure the LEDs.

To summarize, we can analyze all the advantages of the assembled product. The amount of light in the resulting lamps is 1.5 times greater than in analogues. But the power consumption is much less than that of fluorescent lamps. The service life of this light source will be approximately 10 times longer. And also one of the advantages -

this is the direction of light. It is directed straight down and has no ability to dissipate. Therefore, it will be best used at the desktop or in the kitchen. However, the light emitted is not very bright but has low power consumption.

Constant use of the lamp in the on state will consume only 4 kW of energy in a year. The cost of electricity consumed per year can be compared with the cost of a ticket in public transport. Therefore, such light sources are often used where constant illumination is required, for example:

- Street.

- Corridor.

- Utility room

- Emergency lighting.

Transparent lightbox (acrylight)

Transparent lightboxes became an original modification of the classic box.

In a standard lightbox, the image is on paper mounted inside the case. In acrylic, an image is formed when a layer of transparent acrylic is destroyed due to the reflection of light in it. Advertising agencies use CNC engravers with cutters and grinding attachments or laser engravers to apply images. At home, this effect can be achieved using matting compounds.

Acrylight assembly:

Dynamic Acrylight

By using your imagination, you can create a multi-layer acrylic with a dynamic image. Here is an example of such a design:

3D light box

The fusion of lightbox and acrylic technology allows you to create stunning compositions.

To make such a three-dimensional box you will need a very modest set of materials:

- LED Strip Light;

- silicate or acrylic glass;

- mirror or oracal film with a mirror coating;

- profile for the frame.

Video instructions for making a three-dimensional lightbox:

Please rate the article. We tried our best:)

Did you like the article? Tell us about her! You will help us a lot :)

Technical details

Both CRT and LCD displays can be re-qualified as TV. The main thing is that the device has a VGA input, through which the image will be transmitted from the receiver. The tuner can be placed both inside and on the body (we use glue or small screws). In the first case, you should be prepared to disassemble the device body and solder additional elements into it - not everyone can cope with such a procedure. The article will discuss only those methods that absolutely any user can use.

HDMI to VGA adapter

The connection of two devices will be carried out through a special adapter, the type of which is determined by the choice of data transfer interface

Please note that the final output of the adapter must always be a male VGA port

Making a LED

For ease of installation, it is better to take a nail 10-15 mm long with a large head and tin it well. It will serve as the base and heat sink for the crystal. Using a soldering iron, the tin on the cap is brought to a liquid state and the prepared carbide specimen is slightly pressed down with tweezers. Naturally, the emitting section should be directed upward. After the solder has solidified, you need to make sure that the crystal is securely fixed.

To make a negative electrode, you will need the sharp part of a pin and a single-core copper wire. As can be seen from the photo, both parts are tinned and reliably soldered together. Then a loop is made on the wire to give it the properties of a spring. The free end of the wire is soldered onto the head of the second nail. Both studs are attached to the circuit board at a short distance from each other.

At the final stage, power of the appropriate polarity is supplied to the legs of the nails. The electrical circuit is closed with a needle, which is fixed at the point of the crystal with maximum luminescence. By gradually increasing the supply voltage, you can determine the value at which the brightness stops increasing rapidly. As a result of the measurements, the voltage drop was 9V and the forward current was 25 mA. When the polarity is reversed, silicon carbide stops emitting light, which partially explains its semiconductor properties.

I wouldn’t be surprised if experienced radio amateurs express their negativity towards the resulting unusual design, which resembles a simple LED. However, sometimes collecting such things yourself is interesting and even useful. An example is amateur radio clubs for schoolchildren, in which children become familiar with the properties of different materials, learn to solder and learn the basics of semiconductors.

Advantages of LEDs

Nowadays you can find a huge number of types of chandeliers with LED lamps in stores. They have different advantages and disadvantages. Modernization of energy saving

lamps allows you to take full advantage of fluorescent light. This applies to the most common lamps with an E 27 base. And the old representatives of this family were endowed with an unpleasant flicker. Fluorescent light sources are truly a miracle. Compared to them, incandescent lamps are losing ground very much. Their high energy consumption and low light output do not offset their high color rendering index.

Durability is their main advantage. Mechanically it is strong and reliable

. It is known that its operating life can reach up to 100,000 hours. They are also considered environmentally friendly light sources, unlike fluorescent lamps, which, in turn, contain mercury. But as you know, fluorescent lamps have some disadvantages:

- The vapors contained in the pipes are quite poisonous.

- Due to frequent switching on and off, they can quickly fail.

- The design itself requires some disposal.

The LED lamp can be considered the second revolution in the field of lighting. It works 5-10 times longer, is more economical and does not require any special disposal. Although there is a minor drawback - it is much more expensive.

In order to remove this small minus and turn it into a good plus, you can build a lamp from an LED strip with your own hands. In this way, the cost of the light source can be reduced. It will be much lower than that of luminescent analogues . And also this lamp

will have a number of advantages:

- The lamp life will be a record 100,000 hours, but only with proper assembly.

- The cost of a homemade device is no higher than that of a fluorescent lamp.

- The watt/lumen efficiency is far superior to all comparable products.

But there is also one drawback - there is no warranty for this product. It must be compensated by the skill of the electrician and strict adherence to the instructions.

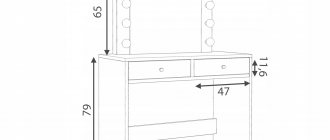

Correct size calculation

To properly build a projector screen with your own hands, you need to take into account the location of the projector and the viewing angle of the audience. The screen is located in front of the audience, and not in front of the projector - this is the basic rule that guarantees the success of the planned event.

The height of the canvas should be approximately 1/6 of the distance from it to the last row of spectators; only if this condition is met, the information will be perfectly readable. The first row should be no closer than two screen heights: for example, height = 1.5 m, which means that the first viewers should sit at a distance of 3 m. Experts assure that it is from this distance that the perception of the plot or information will be comfortable. The lower edge of the canvas should be at least 1.2 m from the floor level - viewers sitting at the very end of the hall will see all the information without shading.

What is the screen made of?

The modular assembly of an LED screen involves the creation of a large canvas from many individual modules. These are standard-sized blocks that consist of several dozen LEDs that act as pixels and an electronic control circuit. The control board controls the joint glow of the module, and also has cables and connectors for connecting with other modules. This kind of puzzle potentially makes it possible to assemble a screen of any size.

Today you can buy modules for assembly in electronics stores, in specialized departments on the market, or order them on international online platforms like AliExpress. In all three cases, the block will most likely be made in China, but this does not mean low quality by default. Good products come from the land of dragons. To choose it, you should consult with experts and read reviews about certain brands.

Basic functional characteristics of P10 modules:

- size: length – 320 mm, width – 160 mm, thickness – 20 mm;

- weight – from 600 to 700 g;

- pixel pitch – 10 mm;

- number of pixels per m 2 (resolution) – from 256 ˟ 192;

- screen brightness – from 6000 to 7000 cd/m2;

- working life – up to 50,000 hours;

- half brightness angle – 120˚;

- comfortable viewing distance – 7 meters or more;

- maximum power consumption for street use is 500 W/m2.

An alternative to electronic LED blocks is LED strip. It can also be laid out as a screen to broadcast images. However, this material has characteristic disadvantages. First, installing a large number of tapes in the form of a screen is more difficult, since they are not originally designed for this purpose. Secondly, LED strips do not have sufficient resistance to destructive environmental factors: temperature changes, contact with dirt, moisture and dust, and ultraviolet radiation.