Every car owner knows that the main “sores” of a car are hidden in two places: in the engine compartment and under the bottom. You can get to the engine by opening the hood. But you won’t be able to fix the suspension or remove the transmission without getting under the body.

To perform work under the bottom of the car, you can use a pit, a lift or an overpass. The pit can only be installed in dry soil, so it is not available in all garages.

A lift is an expensive pleasure that a repair shop can afford. As a result, the average car enthusiast is left with a homemade overpass for the car, which does not require large costs and time to assemble.

In this article we will look at the most popular and affordable structures, and also describe step by step the process of their design and installation.

The need to install a mini-overpass. Device

A modern car is a technically complex device that requires periodic maintenance, replacement of components and consumables, and minor repairs. Many inexperienced motorists prefer to carry out a routine inspection of the car exclusively at a service station and pay out of pocket even for an oil change.

More experienced drivers do most of the work themselves. To do this, a homemade overpass is often installed in the garage - a structure with which you can examine the bottom of the car.

There are two types of overpasses:

- Full size.

When driving onto this structure, the car rises above the ground by about a meter. You can examine the bottom, hood, and carry out the necessary manipulations. Suitable for servicing passenger cars and light trucks - Mini overpasses.

Provide partial lifting of the vehicle. This is enough to carry out cosmetic repairs on your car yourself. Suitable for partial entry of passenger cars

To a first approximation, the functions of the overpass are similar to the inspection pit. It provides access to the underside of the car. However, if the level of groundwater is high at the site where the garage is being built, it is not advisable to equip an inspection hole: it will constantly be filled with water, which will require the installation of an additional drainage system, and corrosion will appear on the metal parts of the car due to increased moisture.

A full-size overpass is a monolithic structure that can be found in auto repair shops and along busy highways. Its installation requires a lot of space - the length of the product is about six meters above the ground plus the driveway. The construction of such an option in your own private garage is justified if the building is designed for two parking spaces, one of which is empty.

A mini-overpass is a small portable structure designed for partial collision with a car. It is based on two independent parts that are not connected to each other. The car drives onto the prepared platform with its rear or front wheels, rises slightly above the floor or ground and allows the car owner to carry out an initial inspection or cosmetic repairs.

The advantage of a mini-overpass is the ability to use it in limited space. After work it can be put aside. The main disadvantages of the design are as follows:

- To enter the platform, pinpoint precision is required. Otherwise, the structure may overturn or the vehicle may be damaged.

- Structural elements are installed in places where there is no possibility that they will diverge in different directions from the slightest push of the wheels.

Main types

Based on the type of construction, there are two types of overpasses for cars:

- Full-size ones allow you to repair a machine that is completely raised above ground level by 1 meter. They are bulky and require a lot of space. Suitable for both passenger cars and trucks.

- Mini overpass. It consists of two small, independent from each other, beveled on one side of the podium. The auto overpass allows you to lift the car from the front or rear wheels. Used for partial inspection of the bottom. The disadvantage of this design was the need for the driver to have pinpoint precision when driving on it.

Main types of road overpasses

Depending on the budget and complexity of the repair, there are two types of overpass structures:

- Allows you to raise only one axle of the car (front or rear).

- Full-size (designed to accommodate the entire car).

The first option is economical and convenient. The mini-overpass for partial entry has small dimensions and weight. It is easily installed on a level surface and removed after the repair is completed. The main disadvantage is that it is not as convenient to use as a full-size design, since the lift of the car here does not exceed 50-60 centimeters.

The full-format option is more expensive and more difficult to implement, but gives the car owner simultaneous access to all body components. Let us note in passing that, regardless of the type of overpass, for its high-quality production you need to make a drawing, and during assembly, accurately maintain the dimensions of the structure.

Three groups of sizes are especially important:

- height and width of the supporting pedestals of the “chairs”;

- length of the ladder (entrance and horizontal);

- ladder width.

In addition, attention should be paid to the junction points of the ladders with the pedestals. They must support the weight of the car without deformation.

Stationary

Full-size overpasses are of the stationary type. They are installed along highways, on roadsides, and at service stations. The platform is raised high above the ground and allows for a detailed inspection of the car from the bottom and for carrying out repair work. Designed to support the weight of cars and trucks.

The strongest and most durable structure is made of metal. To create an observation deck, brick, wood, pipes and channel are used.

Advice! If the garage is built for 2 cars, but there is only one there, then the free space can be allocated for your own overpass.

Other types of overpasses

This type of overpass can be used not only in the garage.

But not all of us have two cars or large garages in which to play football or hold a party, so it’s worth paying attention to mini-overpasses that can be dismantled or freely moved around the territory and stored in a garage or shed. Making them will require some ingenuity. Here are a few options for you to choose from:

- rectangular trapezoid;

- "rocking chair";

- reversible;

- based on sleepers.

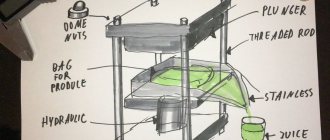

- One-sided pyramid. To make this type of platform you will need a minimum of effort, time and money. You need to have approximately 17 m of boards on hand, 5 cm high and 30 cm wide, maybe less if you are an ace at driving on a narrow gauge railway, but it’s better not to risk it. Next, we cut out two beams of the same length with the following dimensions: 45 cm, 70 cm, 95 cm, 120 cm, 145 cm, 170 cm and 195 cm. After all the parts are ready, you can start assembling - just connect them together so that at one end they create a plane, and at the other they look like a ladder. You can use nails or self-tapping screws - whatever is at hand or more convenient for you. The assembly process should have resulted in two pyramids, cut off on one side. But such an overpass is not yet suitable for a car to drive onto it. The two blocks may suddenly separate and cause damage to the underbody, or the vehicle may overturn. To prevent this from happening, we do the following. On the inner sides we install two metal corners with holes. Next, choose two metal or wooden slats. We make holes along the edges and attach them to the corners. After such an operation, the stands will not move to the side. When the car is already on top, carefully unscrew the safety crossbars and carry out the necessary repairs.

Overpass pyramid

A similar cut-down pyramid or trapezoid can be made from a metal channel; it will be much more reliable and durable. Instead of climbing with a “staircase”, you will simply need to make an inclined drive.

Note! Using such a device, the car can be raised by 30 cm; if a greater height is needed, add a few more bars of greater length. Be sure to install restraints at the front to prevent the vehicle from rolling forward, and secure the rear wheels.

Rocking type design

The “rocking chair” is also a very simple design that any car owner can make. Two boards are selected as thick as in the previous example, the length can be 1 m. We take four 10x10x30 cm blocks and place them as follows: one of them is on one of the edges, the second is almost in the middle with an offset to the first.

We recommend: Hangar or building, which to choose?

We secure it firmly and do not forget to place emphasis. Now, when the car runs over its wheels, the boards will be thrown over due to a shift in the center of gravity; with further advancement, they will be supported by two bars. All! The car is up! Repairs can be made.

You can vary the dimensions, focusing on the ground clearance of a particular vehicle and the length of the wheelbase.

High metal overpass

There is another version of this overpass, it is a little more complicated to implement, but much more reliable. Designs may vary. Here is one of them. Take a 30×30 corner, larger if possible, adjust the length based on your car. We will need 8 such segments. We connect them in parallel using reinforcement bars.

The result should be 4 bases of the same size. The lower parts can be made longer and wider for greater stability. Next we make two stops. One of them will be in the form of a bar, as in the previous example, we weld it to the edge. We install the second one with a slight offset from the middle.

But it should be made a little differently - in the shape of an isosceles triangle. We movably connect it to the lower base. If you do not touch the stands, they will be folded at an angle. When the car moves along them, the wheel shifts its center, aligning the horizontal, and rests against the block.

Now you can use the latches to secure the platform in this position.

Platform

Using a platform is an interesting approach to the matter. To make it, you need to get a corner we already love, or use a square profile.

Next, using a welding machine, 2 isosceles triangles are made so that the base is 1.5 times longer than the wheelbase, and the apex angle is obtuse. The platform is placed on them. Now everything is ready.

The car drives onto the structure and, resting against the limiters, reaches the end.

Note! Place stands under the rear wheels to prevent the car from rolling away when it is on an overpass.

From sleepers

The sleeper-based trestle is very easy to make. Two sleepers are laid, one in continuation of the other. Strong boards are laid on the part with the recess, after which a small slide is created.

That’s it – the platform is ready, you can move in and make repairs. The disadvantage is that the sleepers need to be stored somewhere, although it is unlikely that anyone will decide to take them away from you.

For this kind of platform it is not necessary to use sleepers; anything that can securely support the boards will do.

Note! When building a homemade overpass, do not forget to protect your car by installing limiters - they will prevent the car from falling off the overpass.

As you can see, there is no particular difficulty in lifting the machine for servicing. Now you know how to make a flyover from scrap materials that are found in almost every garage. Tell your friends and share your experience.

Collapsible

The collapsible overpass has smaller dimensions. It fits easily in the garage and, if necessary, is quickly assembled. Designed for inspection of a passenger car.

The design includes:

- 4 stands for supports;

- 2 pairs of platforms with a stopper to prevent the car from rolling away;

- 2 pairs of horizontal ramps for inclined access;

- several stiffening ribs for fixing parts relative to each other.

They are built from metal. The thicker and more durable the material chosen, the longer the structure will last.

General requirements

When manufacturing a standard overpass, a number of requirements must be met. This will help ensure convenient and safe operation of the vehicle.

- The height of the full-size repair structure is about a meter. This allows you to easily climb under the car, provide a sufficient influx of natural light to inspect the chassis, and carry out the necessary manipulations with spare parts and tools. The height of the mini-overpass with partial access is about half a meter: it does not involve detailed disassembly of the car.

- The width of the structure directly depends on the type and dimensions of the vehicle. You should not display the size down to the millimeter; when calculating the design, you need to make small allowances. The car must drive onto the platform without hindrance.

- Mini-overpasses are used for inspection and repair of passenger cars. For a stationary structure, an additional margin of safety is provided. Thanks to this, the product does not deform over time. You can also roll fairly heavy vehicles onto it.

Stages of preliminary work

Creation begins with a diagram and selection of the type of structure (stationary or portable) and the material from which the work will be performed.

General dimensions:

- height – up to one meter;

- width - about two meters;

- ride length – one meter;

- the length of the horizontal platform is from a third of a meter.

The overpass is two symmetrical combined structures. From the side in the drawing it is a rectangular trapezoid. The tracks must be fixed between each other to resist displacement when a car drives onto it.

The steel structure is mounted using:

- Bulgarians;

- nuts, bolts.

- welding machine;

As a frame, reinforcement and a forty-millimeter corner are used. The assembled structure is painted on top.

Material selection

There are many ways to make a do-it-yourself overpass or mini overpass for car repairs.

Brick construction

A brick overpass is a stationary structure that is more often used in rural areas or outside the city. Construction is carried out using the bricklaying method using cement mortar. The width of the structure corresponds to the distance between the wheels of the car.

This method has a number of disadvantages:

- It is necessary to allocate a plot of land for development. If the overpass subsequently needs to be removed, its dismantling will require considerable effort and time.

- After some time, under the influence of overloads, the brickwork may collapse, which may require its dismantling.

Overpass made of sleepers

The structure is based on several railway sleepers. The sleepers laid one on top of the other in a “slide” style form two bases. Tracks are laid across to ensure access. To prevent the sleeper trestle from moving apart during operation, it is carefully secured with brackets.

This design also has certain disadvantages.

- Sleepers are not so common in everyday life, and not every car owner has a few extra ones.

- It is impossible to install and disassemble such an installation alone. The sleepers are too heavy.

- Storage of railroad ties requires space.

The use of an overpass made of railway sleepers is justified in a summer cottage or garden plot, when the structure is left outdoors all year round. To protect against rotting, the product is impregnated with creosote.

Made of metal

Most often, the overpass is made of metal and wooden boards. Advantages of a metal overpass:

- Mobility. If desired, the structure can be made collapsible and assembled only before starting repairs. This saves space.

- Simplicity of design. You can assemble a metal overpass with your own hands using a minimum of tools.

- Durability. With proper care and timely inspection, a metal trestle can last about ten years or more.

There are also some disadvantages. The metal is initially susceptible to corrosion, so before work the material must be treated with special impregnations.

Among the main advantages of a wooden trestle are the ease of assembly and low cost of materials. It is easy to install and, if necessary, can be quickly dismantled and removed. You do not need complex specialized equipment; ordinary carpentry tools that are found in every home are sufficient. Among the disadvantages of wooden structures are low durability and poor resistance to rot and insects. These problems can be partially solved by treating with antiseptics, fire retardants and insecticides.

What to do if it is not possible to make an inspection hole

To repair the chassis, undercarriage, or engine compartment, inspection pits are often used, which are convenient in small garages where it is not possible to make an overpass to lift the vehicle.

However, there are times when it is not possible to make a hole in the garage. For example, a fairly common problem for making an inspection pit is the groundwater level, which can be very close to the surface. Because of this phenomenon, additional waterproofing may be necessary to prevent water from penetrating into the pit. Otherwise, car repairs can easily turn into taking a not-so-pleasant, dirty, cold bath.

If your garage has such a problem or you simply don’t want to waste your time and effort on digging and finishing a hole, then the option of making a trestle is perfect for you. Nowadays, there is quite a wide variety of this design, among them two main types of overpasses can be distinguished:

- Collapsible. This option is quite practical and convenient, and the main thing is that you won’t spend a lot of money on making such a device. A collapsible or, as it is also called, a mini-overpass is a lightweight, portable device that does not have large dimensions and is convenient to use. This device is easy to install when taking into account a flat surface and is also easy to remove after performing the necessary repair work. The only drawback of this design is that you cannot raise the car higher than 50–60 cm.

- Stationary. Manufacturing a full-size structure is much more difficult. To assemble this design you will need much more materials than for the previous version. However, this option has a huge advantage, since you can load the entire car on it. Thanks to this, you will be able to perform complete maintenance of the underbody of the car, and not just its front end.

Tools and materials

Independent production of a wooden or metal overpass requires the availability of certain materials and tools. There is no need to purchase complex specialized equipment; it is enough to purchase household power tools, which are sold in every store.

What is needed to build a metal overpass

To make a regular metal overpass, you will need the following materials and tools:

- Rolled metal.

- Welding machine with a set of electrodes.

- Grinder equipped with several cutting wheels.

- Pieces of reinforcement.

- Fasteners: bolts, nuts.

- Metal paint for finishing the structure.

Materials and tools for a wooden overpass

To make the simplest portable wooden trestle you will need a minimum of materials and tools:

- Boards 45–50 millimeters thick. If thinner boards are used, additional vertical supports are installed in the center of the overpass.

- Two wooden blocks.

- Two pieces of carriage plank.

- Screws (150), nails (300), screwdrivers, hammer, wood saw.

DIY metal structure

If a metal overpass is planned to be used in several places, or is needed only occasionally, the structure can be made in a collapsible version. This will allow you to quickly assemble it as needed within half an hour.

The assembly of a metal overpass occurs as follows:

- The bases of the cabinets are assembled.

The blanks are cut based on the size of the car wheels. The blanks can be laid out on a sheet of chipboard or other flat surface and fixed at an angle of 90 degrees (you can use a regular construction angle to determine the angle). After all measurements, the workpieces are welded together. All parts are connected at right angles - The racks are being assembled.

The height is about half a meter, the angle is about 120 degrees. Fixed, scalded. Corners and side walls should be equal - The upper supports of the pedestals are welded. To do this, the upper corners are connected to the racks, set at an angle of 90 degrees, and scalded.

- The finished supports are connected to the base, set at right angles and welded.

After assembly, you can additionally weld the main components - The dead end of the cabinet is welded. This is necessary to prevent the car from driving further and turning over. The part is made from a corner 63*63*5 mm.

- Reinforcing bars are welded to the finished cabinet.

To adjust the distance between them, you can use the same corner 63*63*5 mm. The reinforcement sections are laid so that their “herringbones” intersect. A regular construction corner with a side of 63 millimeters is used as a template. - Assembly of gangways (bridges).

The blanks are cut and fixed with clamps on the corners. Sections of reinforcement are welded to the corners, the distance can be determined using a template corner, the “herringbones” intersect. The corners are welded to the workpieces. The car will drive onto the overpass using these bridges - The final stage is adjustment. On level ground, both parts of the overpass are placed close to each other. The centers of the bollards are marked, the structure is adjusted to the width of the car. Holes are drilled in the ladders and cabinets, after which the elements are connected to each other using bolts. Thanks to the bolted connection, the overpass can be easily disassembled and reassembled later.

The finished structure is cleaned with a metal brush, degreased and painted.

The finished design will look something like this

How to make a collapsible car overpass yourself

Most motorists prefer collapsible overpasses. This is due to the fact that they can be made independently at minimal cost, which will allow them to quickly pay for themselves. At the stages of development of this auxiliary device for repairing a passenger car, it will be necessary to take into account some geometric parameters, which include:

- the width and height of the base pedestals on which the structure rests;

- length of the driveway and horizontal platform;

- width for inter-wheel space (track).

Basic knowledge in the field of strength of materials is welcome, which will help form strong components and joints of the product that can withstand the weight of the vehicle without rupture or deformation. You should not skimp on materials.

Construction of a wooden mini overpass

After various repairs, trimmings of boards may remain. It is rational to use them to make a trestle with your own hands, since a wooden product will have minimal weight with optimal strength. A popular design is a pair of meter-long bars with an approximate cross-section of 200x200 mm. On one side, wooden blanks are cut at an angle of 40-450 to form the drive-in part. Next, we nail the parts onto a two-meter board with a cross-section of approximately 200x40 mm. We place the finished products under the wheels and can drive onto the mobile mini overpass made of boards using one of the bridges. For optimization, we recommend placing a front block on top as a sliding stop. Although the lifting height is small, it will allow a number of operations to be carried out under the machine.

Another wooden variety is a structure made from scraps of boards with blanks of equal thickness. Typically, the base for each support is a pair of strong, wide slats, about 40 mm thick. and 1.5-2.0 m long. They are filled with steps across the planks to the desired height (about half a meter). The front part is also equipped with anti-rollback. For ease of carrying, the structure is equipped with straps made of durable material. The total cost of the product is minimal.

Metal version of a homemade overpass

A do-it-yourself metal overpass installed in a garage or on a level area is more reliable. The product will be much heavier than its wooden counterpart, and also more expensive to manufacture. However, the homemade product will last much longer and will be able to withstand heavy vehicles. To make a metal slide you will need any material:

- profile rolled products (hollow square or rectangle);

- pipes or fittings;

- corner.

Everything is joined together using a welding machine. We recommend painting the finished product. We recommend making vertical posts from profile pipes. It is preferable to make the horizontal platform from reinforcement, and the entrance - in the form of steps from the corner. It is advisable not to increase the approach angle, so 30-350 will be the optimal value. The horizontal part at the top is completed with a vertical stop that prevents rollback. The height of the racks is selected at the request of the car owner. The design can be used both for full vehicle entry and as a mini-overpass for entry via one bridge.

Other types of overpasses

Convenience for users is provided by the collapsible type of overpasses. The option belongs to an intermediate type between stationary and mobile structures. Due to its large dimensions, when assembled, the slide provides a lot of space for repairmen, and when disassembled it takes up little space. The constructor consists of elements:

- four base cabinets;

- two horizontal slabs for moving;

- two inclined slabs for entry.

The pedestals are arranged in a special way so that each of them is under the wheel of a car. A maneuver in which the horizontal beams are removed, while the car remains standing on the pedestals, helps improve accessibility to the wheel arches. For a stationary version of the overpass, you will need to find a flat, free area. Cabinets are usually made of brick, cinder block or poured concrete. We weld entry and horizontal beams from metal corners, reinforcement and rolled steel. With proper planning, a reinforced site can accommodate not only cars, but also trucks.

Making a wooden mini-overpass

The simplest wooden overpass is assembled from two pairs of wooden beams with a cross-section of 20–20 cm. The beams are knocked together in pairs and cut at an oblique angle. The improvised overpass is ready.

An improved wooden overpass is assembled from scraps of boards, which are assembled into a wide “pyramid shield”. On one side there is a stepped slope for cars to drive in.

Another version of a mini-overpass is assembled from four 50-mm boards, two blocks, lining and fasteners.

- The blocks are sawn to equal lengths. The upper edge is cut at an angle, leaving a small stop at the end.

- Arrival boards and bases are attached to the deck. Long nails and screws are used for this.

- Safety strips are nailed to the sides of the decks.

- Blocks are nailed on top, limiting the movement of the car further than the overpass.

Assembled from four boards and beams

A similar design is used for repairing passenger cars. For heavy transport it is worth installing a stationary overpass.

Conclusion

Each motorist chooses which type of overpass to assemble based on current needs and prospects. The optimal option is a mini version or a prefabricated structure. Craftsmen choose between cheap, practical wooden products and expensive but durable metal structures.

The best prices and conditions for the purchase of new cars

Most car enthusiasts prefer to repair and customize their vehicles themselves: for some it is a way to save money, and for others it is a hobby. But not all garages are equipped with an inspection hole, and climbing under the hood just like that is too inconvenient, and even dangerous.

Video: Assembling a metal structure

Every car owner can make a mini-overpass on his own. It is very important to check the strength of the structure before driving a car onto it and starting repair work.

- Author: Maxim Ovsyannikov

My name is Maxim, 33 years old. Higher education. I have extensive experience in construction and renovation. I hope my articles will help readers save on calling specialists. Rate this article:

- 5

- 4

- 3

- 2

- 1

(34 votes, average: 4.2 out of 5)

Share with your friends!