In the age of electrical appliances, it is not surprising that we are surrounded by electricity. However, not everyone knows that special devices are needed to obtain voltage. Ordinary things will be enough, including food that everyone has at home. True, the voltage and capacity levels will be far from the usual power sources, and in real conditions you cannot use such a battery, but you can try it as an experiment. Below are instructions on how to make a homemade battery from scrap materials.

You can make a battery yourself from improvised materials that every home has.

How to make a battery at home from scrap materials

Electricity surrounds modern man constantly. But even against this background, it is surprising that tension is present in ordinary things and products. Using them, you can make a simple battery at home and recharge a non-power-intensive device, such as a radio, flashlight or phone.

Lemon battery

In order to make a battery from fruit and scrap materials, you will need the following components:

- lemon;

- steel object;

- copper item;

- two insulated wires.

Before you start creating a simple battery, you need to strip the steel and copper items. This can be done with sandpaper.

Advice! It is convenient to use nails as a steel object; you almost always have them in the house. As a copper coin, you can use a coin of 10 or 50 kopecks.

Next, you need to stick them into the lemon at a distance of 3-2 cm from each other. And connect wires to the improvised contacts. They can also be carefully inserted tightly to the contacts. The copper element will act as a plus, and the steel element will act as a minus.

Interesting! You can also use an apple instead of lemon. But it is necessary to choose sour fruits, as this is necessary for the reaction.

A homemade battery based on one lemon or apple can produce approximately 0.5-0.7 Volts. This is not enough to charge a simple mobile phone or receiver. If you need a voltage of 3 to 5 Volts, then it is quite possible to do this. The growth occurs due to an increase in the number of fruits.

Important! Lemons can be charged to increase their charge. For example, when connecting to the crown or to charging a mobile phone.

Creating a battery from a lemon or an apple is possible thanks to a chemical reaction between copper and steel. It occurs under the influence of acid in the fruit. The improvised battery will not stop working until the acid leaves the fruit or the contacts dissolve.

Glass container with electrolyte

This design is very similar to the first battery created. To assemble it you will need:

- glass container (glass or jar);

- zinc or aluminum plate;

- copper plate;

- wires;

- ammonium chloride;

- water.

It is desirable that the areas of the aluminum (anode) and copper (cathode) plates be the size of the palm of your hand. This will increase the battery efficiency. Solder a wire to each plate. Then place them in the jar so that they do not touch each other. It is also important that the records are higher than the can.

To prepare the electrolyte, you need to mix ammonium chloride and water. Take 50 g of powder for 0.1 liter of liquid. Then pour the resulting mixture into a jar. The electrolyte can also be made from sulfuric acid. The solution should be 20%.

Important! When making an electrolyte from sulfuric acid, it is necessary to pour the acid into water. Otherwise, the water will boil from contact with the acid and both liquids will splash out from the reaction. When working with a caustic substance, you must wear safety glasses and special gloves.

Pour the prepared solution into the jar to the brim. By combining these several elements, you can get a good battery that can charge even an energy-consuming device. This battery is an analogue of a salt battery, as it is similar in composition.

Coin battery

A structure made of coins as the simplest galvanic element is also called a Voltaic column. To make it you will need:

- copper coins (50 or 10 kopecks);

- foil;

- paper;

- vinegar or very salty water.

For the beauty of the design, it is necessary to choose coins of the same denomination. Also, before the experiment, dip them briefly in vinegar. This will remove plaque and dirt. Then you need to cut out elements in the shape of coins from paper and foil. Their number should be 2 less than coins.

The voltaic column is assembled like this:

- The paper is soaked in a solution of vinegar or salt water and attached to a coin.

- A circle of foil is placed on top of the paper.

- Next, the next coin is placed.

- The stages are repeated until the selected amount of coins runs out.

- The design should be such that at one end there is a coin (+) as the last element, and at the other end there is foil (-).

The more coins are used in the experiment, the more voltage the battery will produce. It is important to understand that after the experiment the coins will not be suitable for use. Elements become covered with rust.

The charge occurs due to the fact that an electrolyte (vinegar or saline solution) placed between two metals (foil and coins) creates a potential difference.

Battery in a beer can

To create a battery with your own hands in a beer can, you need to take:

- aluminum can;

- coal from a fire in the form of crumbs or dust;

- paraffin candle;

- graphite rod;

- salt and water;

- foam more than 1 cm thick.

First you need to cut off the top of the can. Then make a circle out of foam plastic that fits the bottom of the jar. It is necessary to make a non-through hole in the circle for the rod. Place polystyrene foam at the bottom of the jar and stick graphite into it. It is important that the rod is positioned exactly in the center of the jar. The space around the graphite rod must be filled with coal.

Important! The graphite rod should not touch the can.

Then all that remains is to make a saline solution using 0.5 liters of water and 3 tbsp. spoons of table salt. Stir the solution until the crystals dissolve, it is better to do this in warm water. Pour the electrolyte into the jar and seal it with wax. It is important that the graphite rod looks outside the can.

Connect the wires to the graphite rod (cathode, plus), and the body of the aluminum can (anode, minus). In order to obtain a voltage of 3 Volts, you must connect at least 2 cans in series. The resulting battery can power a light bulb, calculator and watch. They can also be recharged.

Battery made from potatoes, salt and toothpaste

It is worth noting that the potato battery is used only once. The design is not designed for reusable use. It can be used to start a fire by shorting wires.

To make a battery with your own hands you will need the following components:

- large potatoes;

- insulated copper wires;

- toothpaste;

- toothpicks or thin wood chips;

- salt.

Potatoes must be cut lengthwise in such a way as to obtain the largest possible cut area. You need to make a hole in one of the potato parts using a knife.

You need to pour salt into it and mix it with toothpaste. There should be enough mixture to reach the edges of the hole. The end result is a bowl of half a potato filled with electrolyte.

In the other half of the vegetable, it is necessary to make two holes at such a distance that they are both above the electrolyte when the halves are connected. You need to insert copper wires into these holes, having previously stripped 1-2 cm of insulation from the ends. Connect the two potato halves together and secure with toothpicks.

You must wait at least 5 minutes. Then, by connecting the wires, you can get a spark. A potato battery will help you start a fire by setting fire to flammable materials.

Conclusion

All of the above methods for creating batteries are not full-fledged substitutes for them. But they can be collected for the sake of an interesting experiment to clearly demonstrate the operation and structure of galvanic cells.

How to make a galvanic cell at home

Electroplating is a branch of electrochemical science that studies the deposition of certain elements onto any surface.

Using electroplating at home or in industry, you can apply a thin layer of metal to a product, which will act as a protective layer or perform decorative functions.

Recently, decorative coating has been gaining popularity among those who want to give an original gift to their friends and family.

General information

Galvanic coating can be technological or decorative and protective. This is a thin metal layer that, depending on the galvanic elements, can perform aesthetic functions. Electroplating does not increase the strength of the product, since in this case large production capacities are required, but for beauty and giving “freshness” it is quite suitable.

Galvanic reactions occur using direct electric current. A solution - an electrolyte - is poured into a special dielectric container, into which two anodes are immersed. Anodes must be made of a metal that will be deposited on the product being coated.

The workpiece is connected to the negative terminal and placed between the anodes. It acts as a cathode. The anodes, in turn, are connected to the positive contact of the power source.

They become part of the circuit, conducting current into the electrolyte and giving it their metal elements. The electrolyte transfers the necessary particles of the workpiece, they gradually envelop it with a thin layer.

The area of the anodes must be several times greater than the size of the workpiece.

In other words, galvanization is the transfer of solution metal molecules to the product while an electric current flows through them.

Any galvanic process can be broken down into general steps:

- Assembly of galvanic installation.

- Preparation of electrolyte solution.

- Sample processing and preparation.

- Start of the galvanic process.

Necessary equipment

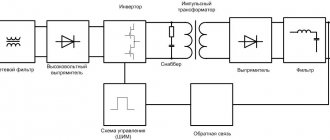

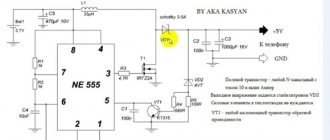

You can prepare the equipment yourself. First, a suitable power source is selected. This can be a battery (for processing small-sized products) or a battery. A step-down power supply is suitable, which produces a direct current output of up to 12 volts. Sometimes an inverter from a welding machine is used. A rheostat is selected to regulate the current strength.

A wide and deep bath is selected from a neutral material that is resistant to chemically aggressive substances. It must be taken into account that the electrolytic solution during the galvanic process can heat up to ninety degrees Celsius.

Two plates are prepared that will be conductive anodes.

To heat a container with electrolyte, you need an electrical device with the ability to smoothly regulate the temperature. Most often they use the soleplate of an iron or a small electric stove. With their help, the solution is heated to the required temperature and the reaction is accelerated.

Chemical reagents must be stored in tightly sealed glass containers. It is advisable to sign each item.

You will need a scale to accurately measure the mass of substances, since the required accuracy of the weight of the components is one gram. You can purchase such scales, or you can make them yourself, using old Soviet coins instead of weights. The weight of the “yellow” coins exactly corresponds to their face value.

Preparation of material

After the necessary substances have been collected, containers have been found, an electrical circuit with power has been assembled, and the heating system has been prepared, you can start cleaning the workpiece.

If the part is not cleaned well enough, the galvanic coating will not adhere firmly or be uneven. Sometimes simply degreasing the item is enough. A solution of acetone or alcohol can degrease the surface well; gasoline can be used.

Some craftsmen keep steel products in a sodium phosphate solution heated to 90 degrees Celsius. Non-ferrous metals can be cleaned in the same solution without heating it.

If the product has corrosion or other flaws, then the surface of the workpiece is sanded with sandpaper.

Safety precautions

Sometimes they talk about safety precautions for various work at home in passing. But when performing any galvanic work, safety must be strictly observed.

The danger lies in the use of toxic chemicals, the high temperature of the solution and the increased risks that accompany electrochemical reactions.

It is best to carry out galvanic work in a garage or workshop with mandatory ventilation or ventilation of the room. Particular attention should be paid to equipment grounding. It is necessary to observe personal safety measures, namely:

- The respiratory tract should be protected with a respirator.

- Hands and wrists should be covered in tall, durable rubber gloves.

- Shoes should protect against burns, and clothing should be covered with an oilcloth apron.

- Be sure to wear special safety glasses.

During work, it is not recommended to drink or eat, so that harmful and dangerous substances do not enter the esophagus.

Copper plating of the product

Before starting copper plating work at home, you need to prepare the necessary materials and equipment. You need to take care of the voltage and direct current source. There are many recommendations regarding current strength, the spread of which can be large.

Therefore, it is desirable to have a rheostat with the ability to smoothly adjust the voltage and to gradually complete the process. The source can be a car battery or a rectifier with an output voltage of no more than 12 volts.

For the first experiments, a regular battery from 4.5 to 9 volts will be sufficient.

Then a container for the electrolytic solution is selected, preferably made of heat-resistant glass. In any case, all containers for electrolysis must be dielectric and withstand temperatures of at least 80 degrees Celsius.

Area of use

Electrochemistry has many important applications, especially in industry. Its processes are used to make electric batteries. They have many uses including:

- A fuel cell converts chemical potential energy obtained from the oxidation of fuels, such as gas, hydrogen, hydrocarbons, and alcohols, into electrical energy.

- Various types of piezo lighters for gas.

- Electrical appliances such as mobile phones.

- Digital cameras are lithium.

- Hearing aids (silver oxide).

- Electronic watches (mercury/silver oxide).

- Military power sources (thermal).

- Batteries A, AA, AAA, D, C and others.

Using chemical reactions to produce electricity is currently a priority for many researchers. The ability to adequately utilize chemical reactions as a source of energy will greatly help solve environmental pollution problems.

DIY galvanoplasty

It is not difficult to assemble an installation for electroplating at home; equipment and materials for electrochemical deposition of copper are freely available. The exception is sulfuric acid, the acquisition and use of which is possible only by an organization with a special permit.

There are ready-made galvanizing kits on sale, but their purchase will not always be justified - it is much cheaper to assemble the installation yourself using available equipment.

With the help of a galvanic installation, which we will discuss in this article, you will be able to obtain copies of artistic products, regardless of the material from which they are made, and also, having the skills of modeling from plasticine or clay, reproduce your own works in metal.

In addition, using the electroplating method, you can implement many interesting projects, for example, metallize woven or knitted lace to make openwork compositions, make metal herbariums from flowers and leaves, metallize fruits, finish glass or porcelain products, increasing the layer of copper according to previously specified pattern, and much more.

Electroplating can be an excellent choice not only as an interesting hobby, but with the right approach and perseverance, it can become the foundation for a future business.

Equipment for electroforming at home

Galvanic deposition of copper at home is carried out in containers of any geometric shape. The size of the galvanic container depends on the size of future products or reproduced compositions. The material can be different; containers made of glass, ceramics or plastic are suitable.

The second key element of a galvanic installation is the direct current source. To carry out the work, use a low voltage current in the range of 3-6 V. You can use a battery or a rectifier. To measure the current you will need an ammeter, and to record the voltage you will need a voltmeter.

To place the mold and anodes in the galvanic tank, it is necessary to provide suspensions. The form is suspended on a copper or brass wire and placed in a container at a distance of 15-20 mm from the anode.

The electrodes connected to the positive terminal of the current source (anode) are also suspended on copper or brass, while the wire hooks are not immersed in the electrolyte, otherwise deformation of the suspensions is possible due to corrosion of the hook. The form is connected to the negative terminal of the current source.

Copper plates with a thickness of 3 mm or more are used as anodes. of sufficient size. The surface area of the anodes must exceed the surface area of the mold.

To control the temperature of the electrolyte, you can use a regular mercury thermometer.

Preparation of electrolyte for electroplating

copper sulfate in solution – 150-180 g/l. Copper sulfate powder is dissolved in hot water and, after cooling and filtering, sulfuric acid is carefully poured into it in small portions at a rate of 30-35 g/l.

If the content of copper sulfate in the solution is exceeded, copper sulfate begins to crystallize on the walls of the galvanic container and on the anode; in this case, it is necessary to analyze the electrolyte (see.

“Analysis and adjustment of copper plating electrolyte”) and, according to the results, add water or acid.

An excess of sulfuric acid in the electrolyte can lead to copper deposits that are brittle and fragile. Lack of acid causes the deposition of a loose and porous layer.

To improve the quality of the resulting copper deposits, experts advise adding alcohol to the electrolyte in an amount of 8-10 g/l. Alcohol in a small amount improves the structure of the coating, making the copper finely crystalline, harder and more elastic.

The quality of the electrolyte and the resulting copper deposit may be negatively affected by the possible presence of organic impurities in the solution. To eliminate them, add 2-3 g/l of potassium permanganate or the same amount of crushed activated carbon to the heated solution. After cooling to 18-200C and filtering, the solution can be used.

When used intensively, the electrolyte must be filtered to remove sludge - powdered copper, graphite and dust.

Sludge gradually accumulates in the solution, settles on the bottom and walls of the container, fine particles form a suspension that can contaminate the resulting copper deposits.

The amount of sludge is influenced by the quality of copper used in the manufacture of the anodes, as well as the increased current density in the process.

The article Analysis and adjustment of copper plating electrolyte discusses the method for determining the content of copper sulfate and sulfuric acid in the electrolyte solution, and also provides a calculation of the number of components.

Electroforming process

The temperature of the electrolyte during the galvanic deposition of copper is 18-200C and can increase to 280C due to the release of heat during the electrolysis process.

The process begins at a minimum current density, which is maintained until a metal layer is formed on the surface. The operating current density is set only after the metal layer has covered the connected conductors.

The maximum current density in the process depends on the thickness of the conductors, which in turn depends on the size of the future composition and the mold material.

In any case, the higher the current density, the more intense the metallization process.

It is better to understand the features of the process using specific examples of using the electroplating method at home.

Copying bas-reliefs, embossings, medals, clay and plasticine products

To make copies of such objects, plaster molds are used. Making a plaster mold is simple:

- gypsum is diluted in water until a creamy mass is obtained;

- the surface of the object to be copied is lubricated with a solution of paraffin in kerosene (for easy dismantling of the mold after the plaster has hardened);

- apply a thin layer of gypsum with a brush to the surface of the product (to prevent the formation of pores);

- a side is installed around the mold (to prevent the plaster from spreading);

- fill the surface of the product with gypsum (gypsum sets quickly, so they do it quickly);

- remove the mold after the plaster has dried;

- I connect conductors to the mold and install it in a galvanic bath (see What is electroplating. Connecting molds to a current source).

Metallization of lace

Metallization of lace compositions is an interesting technique of electroforming, in which woven or knitted lace, tulle lace and other compositions made from threads are covered with a layer of metal. Such products can serve as decorative elements of various artistic compositions, or be used directly for the manufacture of such compositions.

Copper quickly darkens in air; therefore, as a rule, lace compositions metallized with copper are additionally coated with a thin layer of precious metal using the electroplating method. Electroplating silvering or gilding is carried out in the usual way.

The production of a metal lace composition occurs as follows:

- the lace is stretched and attached to a frame made of wire (insulated) or wood;

- impregnate the material with a wax composition for electroforming;

- place the material between two sheets of paper and iron it to remove excess wax;

- an electrically conductive layer is applied - finely dispersed graphite or a conductive composition;

- connect thin copper conductors and install the frame in a galvanic container.

- the material coated with a layer of copper is removed from the electrolyte, removed from the frame and given the required shape or mounted on the product to be decorated.

- The increased layer of copper is coated with a layer of silver (galvanic silvering) or oxidized (see the article Silver plating at home).

Making metal leaves or herbariums

Metallization of tree leaves does not differ from other electroforming techniques except for the method of obtaining the form. An imprint from the sheet can be obtained on a wax composition.

The heated wax is poured into a pre-made shell with low sides and allowed to cool until the surface of the wax composition hardens but remains elastic.

The sheet is placed on the surface of the wax and pressed against the glass. After which the glass is removed along with the sheet. A clear imprint of the leaf should remain on the surface of the wax composition.

In a similar way, an imprint of the reverse side of the sheet is made.

After the wax has completely cooled, finely dispersed graphite is carefully applied with a soft brush, copper conductors are connected, weights are installed and the mold is placed in a galvanic container.

Further work with the metal sheet print is a creative process. The result should be a metal sheet that follows the shape of the sample and exactly copies its surface.

Copper coating of wood products

Small wooden decorative elements are coated with a layer of metal to give them the appearance of cast products.

Before applying a layer of conductive substance (graphite), wooden products are impregnated (boiled) in a wax mixture, paraffin, ceresin or ozokerite.

Otherwise, due to its hygroscopicity, the wood will absorb electrolyte. Then graphite is applied to the products, conductors and weights are connected and dipped into the electrolyte.

The process is no different from the metallization of gypsum compositions.

Metallization of bird feathers

Bird feathers are dipped into a molten wax composition, paraffin, ceresin or ozokerite, then graphitized, a thin copper wire is attached, a weight is suspended and lowered into an electrolyte.

Metallization of fruits, plants and flowers

To plate plants and fruits with metal, you will need to first coat them with a thin layer of silver. To do this, plants are dried, treated with alcohol or a solution of sodium, barium or calcium chloride. Then prepare solutions:

- Sodium hydroxide 4 g per 100 ml of distilled water.

- Silver nitrate 4 g per 100 ml of water.

- Ammonia 7 g per 100 ml of water.

- Sugar 2.5 g per 85 ml of water.

Then the solutions are poured into a container and the plant is immersed in the solution. The surface is coated with a thin layer of silver (chemical silvering). The plant or fruit is then subjected to galvanic copper plating.

The methods of metallization of various products and forms described in the article are an example of the application of electroplating methods at home and in an art workshop.

The processes of galvanic copper plating are described in detail in the articles: Electroplating at home, Copper plating and can be applied to products made from various materials, including dielectrics, with a conductive layer applied.

How to make a battery easily

A battery is a chemical source of electrical voltage. All commercially available batteries have similar operating principles. The positive terminal of the product is made of manganese or lithium, the negative terminal is made of zinc or aluminum. You can assemble the battery yourself from simple materials.

Batteries are a source of electrical voltage.

Homemade battery from improvised means

The battery can be made from materials whose properties are similar to those of substances used in industrial conditions.

From lemon

The acid contained in the juice of the fruit acts as an electrolyte. Electrodes are made from thin wire, nails or needles. The iron element is the anode, the copper element is the cathode. The lemon is cut in half and placed in a small container (jar or glass). The wires are connected to the electrodes, the stripped ends are inserted into the pulp of the fruit at a distance of 1 cm from each other.

Using a multimeter, measure the voltage supplied by a homemade galvanic cell. If it is not high enough, several lemon batteries are connected in series.

Jar with electrolyte

Using this method, it is possible to assemble a device that resembles the world's first battery. Electrodes are made of copper and aluminum. Elements must have a large area.

The aluminum electrode is connected to the wire using a clamp or bolt, while the copper electrode is soldered. The parts are immersed in a jar at a short distance from each other. A lid with holes is used for fixation.

The following compositions are used as electrolytes:

Making batteries with your own hands.

- Ammonia. The substance is mixed with water in a ratio of 1:2. Ammonia cannot be used as an electrolyte. A suitable substance (ammonium chloride) has the form of a white, odorless powder. It is used as a fertilizer or soldering flux.

- Sulfuric acid solution.

The substance is mixed with water in a ratio of 1:5. You cannot pour the acid first. In this case, the added water boils and splashes fall on the person’s skin and clothing.

The solution is poured into a glass container so that the distance to the edges of the jar is at least 2 mm. Using a multimeter, measure the resistance and calculate the required number of batteries.

The principle of operation of a homemade element is similar to that of a salt power source.

Copper coins

The electrodes are made of aluminum and copper; 9% acetic acid is used as the electrolyte. Coins are cleaned of dirt by soaking them in vinegar. Circles are cut out of cardboard and foil. Cardboard products are soaked in a solution of acetic acid; they must absorb the electrolyte. A column is laid out from circles and coins.

The cardboard piece is placed first, the foil piece is placed second, and the coin is placed third. Wires are pre-connected to the extreme elements. Instead of soldering, the cables can be pressed to metal parts and sealed with tape. When the battery is used, the coin becomes unusable. You should not make power supplies from valuable products.

Potatoes, salt and toothpaste

The potato battery is intended for one-time use. It is used to produce a spark by shorting wires. To make the element you will need a large potato, insulated copper cables, salt, wooden sticks and toothpaste. The assembly is done like this:

- Potatoes are cut into 2 equal parts. A recess is formed in one half, where salt and paste are added.

- The ingredients are mixed until smooth. The electrolyte should fill the depression.

- In the other half of the potato, make 2 holes at a distance of 1-2 cm. They should coincide with the filled recess.

- The stripped ends of the wires are inserted into the holes, and the halves are combined. The wires must be immersed in the composition.

- Potato parts are secured with toothpicks. After a few minutes, the cables short out, creating a spark to start the fire.

Step-by-step instructions for making a battery

Cylindrical batteries with a height of 50 mm can be easily made at home.

Required materials and tools

Before starting the experiment, prepare the following materials and tools:

- corrugated cardboard;

- flat copper washers with a diameter of 1 cm - 12 pcs.;

- flat zinc washers with a diameter of 1 cm - 15 pcs.;

- purified water;

- heat-shrink tubing;

- acetic acid 70%;

- salt;

- soldering iron;

- containers for preparing solutions;

- multimeter;

- sandpaper.

Corrugated cardboard is one of the materials for making batteries yourself.

Cleaning the washers

The homemade battery is based on 11 copper-zinc washers that produce a voltage of 0.15 V. The parts must participate in chemical reactions, so they are cleaned with sandpaper. The result is a smooth, shiny surface.

Electrolyte preparation

Metals create electric current, but it requires a medium to conduct it. The electrolyte is made from 120 ml of water, 4 tbsp. l. salt and 30 ml of acetic acid. The ingredients are mixed and infused for an hour.

Working with cardboard

To form the required distance between the washers, lay out circles cut from corrugated cardboard. After cutting, the material is impregnated with the solution prepared at the previous stage.

Tube stretching

Before placing the copper-zinc washers, the tube is given the desired diameter. Using needle nose pliers, the product is stretched by 10% of its original size.

Device testing

Electrolyte-impregnated cardboard is placed on the copper washer. The multimeter is switched to constant voltage mode. The black wire is connected to the copper part, the red wire to the zinc part. A value of 0.05-0.15 V should appear on the device screen. This is enough to create a battery from 11 conductive components.

Final battery assembly

The elements are laid in the following sequence: copper - zinc - piece of cardboard. Each part is aligned perpendicular to the axis of the tube. For convenience, the washers are pressed with a thin rod. Having installed the last part, the homemade battery is compared with the factory one. If necessary, an additional zinc washer is introduced. The tube is heated, creating something like a battery. Excess is removed.

Contact installation

Using a heated soldering iron, solder points are welded to the ends of the resulting structure. When installed in the socket, the soldered parts must touch the contacts of the battery holder.

The design and principle of operation of the battery

Let's take a quick look at how the battery works. Let's say there is a container with acid in which zinc and copper electrodes are immersed. When the element gives current through the external circuit, the zinc on the surface of the electrode will dissolve. Zinc atoms dissolved in the electrolyte are current-charged ions that leave a pair of negatively charged electrons in the metal. The name of this reaction is oxidation.

While the zinc interacts with the electrolyte, two positively charged hydrogen ions from the working fluid “combine” with two electrons from the copper electrode, thereby forming a hydrogen molecule. The name of the reaction is reduction.

Electrodes made of copper and zinc are connected by an external wire - electrons are transmitted through it. Hydrogen, or rather its molecules, appearing on copper during reduction are converted into hydrogen gas.

Now about the electrolyte. Its acidity level directly affects the voltage in the galvanic cell. Less acidity means less tension. In working fluids with high acidity, the zinc electrode will simply dissolve, even when the circuit is open. Oxidation and reduction reactions are relevant when current can be transmitted through an external circuit.