On your own plot of land, first of all you need to take care of providing it with water for irrigation, drinking and other needs. To do this, it is enough that a well is built, and from it it will always be possible to extract the required amount of necessary moisture at any time of the year. But to lift liquid, as you know, you need a pump that runs on electricity. But what if the site is located far from civilization and there is no electricity? In this case, you can do without a pump by using other methods. These methods will now be discussed.

We make a pump that pumps water by itself

In order to make a water pump with your own hands, you will need the following materials:

- Two check valves.

- Plastic pipe for soldering.

- Tee.

- Knee.

- Threaded ends.

- Various containers.

- Soldering iron or torch.

- Lathe or threaded ends.

Step 1

First of all, you need to purchase two check valves with any thread.

Step 2

In order not to buy threads, you need to take a plastic pipe for soldering, which will be processed on a lathe.

Step 3

Let's start cutting threads on a lathe.

The finished threaded pipe should fit perfectly into the check valve.

We screw the second pipe to another check valve.

You can also use threaded ends to avoid having to machine the pipes. But they are quite expensive.

Step 4

This is what the finished design looks like. The water flows up. Then they go to the supply hose, where the faucet will be installed. An expansion tank will be installed in the center.

Step 5

This is what the finished structure looks like, pumping water into the tank.

How it works? This design is capable of pumping water into a tank located at a height of up to three meters. Water enters the pipe, one of the valves allows water to flow up, but not back. The second valve is the opposite and provides pulsation.

We unscrew one of the valves so that the structure starts working.

For correct operation of the valve, a continuous supply of water is required. The diameter of pipes and hoses can be any. The wider, the more water flow you will get. In this simple way, you can arrange regular watering of your garden beds if there is a pond near the site.

VIDEO: How to make a pump that works without electricity

How to make a pump that works without electricity

The pump pumps water on its own. Without using extraneous energy.

Main stages of work

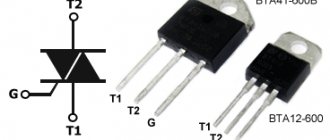

For this homemade product, you will need two check valves with ½-inch threads (but you can take valves with a different thread - for a specific pipe diameter).

Then you will need to cut the plastic pipes into pieces of suitable length and thread the edges so that you can “seat” the check valves.

In principle, you can use ready-made adapters for plastic pipes. But if you have a lathe, it will be cheaper to cut the threads (using a lathe you won’t be able to cut straight, since the plastic is soft).

At the next stage of work, we assemble the entire structure. In addition to the pieces of plastic pipe, you will also need two tees and one corner. Please note that the check valve on the center pipe is installed with the arrow up, and the second one with the arrow down.

The operating principle of this homemade device can be seen in the video on the website. Write in the comments what you think about this homemade product.

Methods for lifting water without an electric pump

If you are deciding how to raise water to a height, you cannot do without a pump. Only for lifting you will have to use not electric, but hand-made home-made devices, the operation of which will require the application of muscular force or the energy of the current water flow.

Archimedes screw

The invention of a screw device for supplying water to heights to fill irrigation canals was made by Archimedes around 250 BC.

Fig.1 Operating principle of the Archimedes screw pump

The device consists of a hollow cylinder, inside of which a screw rotates; during operation, it is lowered into the water intake source at an angle. As the propeller blades rotate, they capture water and the propeller lifts it up the pipe; at the top point, the pipe ends and the water is poured into a container or irrigation channel.

In ancient times, the impeller was rotated by slaves or animals, in our time there may be problems with this and you will have to additionally build a wind wheel to drive the propeller into rotation or strengthen the muscles yourself.

Extraction of water by air pressure

This unusual method is perfect for extracting water from a mine without a pump. That is, you can use any manual hose pump that operates without electricity. Making such a system is quite simple. First you need to completely seal the top of the well. Two holes are made in it: the hose from the pump is inserted into one, and the water supply pipe is inserted into the second. When working with such a device, pressure is created in the shaft, which pushes the liquid out.

If the air pressure entering the shaft is powerful, then it is quite possible to do without an electric pump. But it must be taken into account that such pressure will push water not only up, but also down into the aquifer. The consequences of this will be described below. This method can be used in conjunction with standard approaches. It is especially relevant if the pressure in the pit is not strong enough, even for an electric pump.

Features of unpowered water pumps

You never know where knowledge of school subjects will come in handy. Especially in physics. This device, which is built on knowledge of physics, will be discussed. This pump is solely a consequence of the development of both human progress and innovative thinking. To operate, it does not require electricity or fuel, it does not even need to do anything additional. But the pump is capable of producing good pressure and raising high columns of water, which many, without understanding it, call cheating. But this is far from true.

Features of a well without pumping equipment

What to do if the pump gets stuck in the well?

How to clean a well yourself?

The importance of protecting the source of water intake and the design of the head

On your own plot of land, first of all you need to take care of providing it with water for irrigation, drinking and other needs. To do this, it is enough that a well is built, and from it it will always be possible to extract the required amount of necessary moisture at any time of the year. But to lift liquid, as you know, you need a pump that runs on electricity. But what if the site is located far from civilization and there is no electricity? In this case, you can do without a pump by using other methods. These methods will now be discussed.

Making a water pump

At first glance, such a unit does not inspire confidence, because in our understanding the pumps are somewhat larger and generally different. But in fact, absolutely all the components of this unit are working, and not from any fuel, but from the ordinary laws of physics that are taught in the 8th grade. The point here is the difference in pressure created inside such a pump. The valves are configured in such a way that at a certain pressure one opens and the other closes. This is very similar to the good old accordion-type manual pump, where when pressure was applied to the operating valve, air came out, and when it was released, water flowed into the free space.

Basically, this design is made of pipes (foam vinyl chloride). It looks like a straight pipe with valves, revisions and plugs, which are mounted on a wider section of the pipe. The pipes themselves are either glued or soldered together using special equipment.

The widest part of this design is the buffer or receiver, which is necessary to equalize and accumulate pressure. There are entrance outlets on the sides. But is it worth looking at the other side? No, they are about the same. Only with the condition that the right valve is the inflow of water, and the left is the outlet.

It turns out that the water flow is supplied to the right valve. By the way, you can use ordinary ball valves instead of valves. After this, the water goes to the tee. The tee separates the flows: one flow goes up to the valve, which closes at a certain pressure, while the direct flow goes to the valve, which opens when the required pressure is reached. After this there is another tee, but this time to the receiver, and after that to the exit. It is also advisable to use a pressure gauge that will show the pressure depending on the installation location. Usually they put one pressure gauge on the inlet, but you can also put it on the return valve.

In general, we realized that water is supplied to the ball valve on the right. Next comes the tee. Tee, separates the flows. It flows up to the valve, which closes when there is sufficient pressure. And the direct flow is supplied to the valve, which opens when the desired pressure is reached.

Then, the tee goes again to the receiver and to the output. Oh, and a pressure gauge, but it may not be there, it’s not that important.

Self-made versions without power supply can be made with your own hands. If you take into account all our recommendations. In this case, you cannot do without gasoline.

Design #8 - device from a washing machine

Often, parts or even entire units from old things remain on the farm. You can remove a centrifugal pump from a washing machine that is no longer needed. This pump is perfect for pumping water from a depth of up to 2 meters.

Necessary materials:

- centrifugal pump from a washing machine;

- petal valve from a washing machine or homemade one;

- plug, bottle stopper;

- hose;

- preferably an isolation transformer.

If you use a ready-made valve from a washing machine, it needs to be modified. One hole needs to be plugged, for example using a bottle cap.

Excess pump holes must be plugged. If the case is metal, grounding is required

We connect the petal valve to the hose and lower it into a pit or well. Connect the second end of the hose to the pump. For the system to start working, it is necessary to fill the hose with the valve and the pump itself with water. All that remains is to connect the transformer, and the pump is ready for use.

Real benefits

In fact, it is not exactly a pump, but rather a pressure amplifier. This is due to the fact that it requires a certain pressure to work. This type of product is also called “hydrofor”, because both have a water seal that opens and closes the valve when a certain pressure is reached. The receiver must always be in an upright position.

According to some tests, the pump calmly draws water from streams and lakes, but not at great speed. For those who often have to go to the river for water, creating such a pump is quite a good and thorough task.

But it is better to use such a pump not on its own, but in conjunction with several such pumps: they will not interfere with each other, but the amount of water will be much greater.

Plus, you can combine them at the outlet into one water supply pipe, but the main thing to remember: the pipe must be twice as wide in diameter if there are two of these products. This is due to the fact that the basic operating principle of such a design may be disrupted and the pumps will cease to function normally.

How to pump out wastewater

You cannot use a regular pump to pump out liquids containing feces. This can lead this unit to rapid failure, since it is simply not suitable for this. Therefore, you will need to purchase a drainage or fecal pump that is designed to work with contaminated liquids.

using a sewer pumping machine

Today the buyer has a choice of:

- Submersible pumps;

- Semi-submersible pumps;

- Surface pumps.

For the majority, they have virtually no difference, since everyone is engaged in pumping wastewater from any containers and reservoirs. But in fact, these units have differences that determine their use on a site or house.

Working principle of a water pump

Even if this seems like something fantastic and like a joke, the matter lies in one secret. The second name for such a pump is “water hammer”, and they work in this way: water flows along the main line and as soon as the pressure rises, the outlet valve closes sharply, and the water moves on by inertia, then a water hammer will inevitably occur, which will create a large and excessive pressure that will capable of opening the second valve. After this, the water will enter the receiver, which will compress the air.

When the pressure drops, the outlet valve will automatically close and the water will again flow through the middle and to the top, after which the water will run to the top.

Important points

When extracting water by increasing pressure inside the mine, several important factors must be taken into account. Firstly, the geological structure of the area where the well is located is taken into account.

Also important is the flow rate of the mine for extracting liquid from the ground and the productivity of the aquifer.

And, of course, the depth of the aquifer is taken into account.

If all this is not taken into account, the well may fail due to excess pressure. Simply put, liquid from the aquifer will stop flowing into the mine. This is due to the fact that the air formed inside will push almost all the water down, pressing it into the ground. Therefore, the air supply must be optimal. It should only be enough to push the water out and not create excess pressure.

Types of pumps

Pumps come in different varieties; they mostly run on electricity, but there are also options for running on other fuels, for example, diesel. Pumps are divided into two groups: positive displacement and dynamic. Displacement pumps operate on the principle that liquid enters the working chamber and is forced out of it. They are cyclic and hermetically sealed, and also have self-priming properties. Dynamic pumps do not have a working chamber. Pumps are also distinguished by implementation: mechanical, magnetic discharge, jet and cryogenic. Pumps are also differentiated by power and purpose. But in addition to this, there are also devices for special work, such as pumps for chemical liquids and sewage pumps.

Chemical pumps are needed for pumping various liquids, mostly aggressive ones, which conventional pumps cannot handle. Often, they have appropriate coverage. The main areas of application are the oil industry and the chemical industry. It can often be found in the paint and varnish industry.

Fecal pumps are used to work in contaminated waters and liquids. They differ from others in that they are designed for a much higher viscosity than conventional ones, and also easily cope with small medium-sized particles, including sand and gravel. Sewage pumps come in both submersible and semi-submersible types.

To learn how to make a water pump without power with your own hands, see the following video.

Groundwater in the basement - assessment of the situation

Before deciding to pump water out of the basement yourself, you need to evaluate the need for pumping and the available capabilities.

Why you need to take into account and analyze:

- Is it worth pumping out the water immediately or is there still time to wait and prepare.

- How prepared are you for immediate pumping of water? Do you have experience, tools and devices for this procedure.

- What is the rate of water inflow? It is important to understand whether the rate at which the basement is filling with water exceeds your ability to remove it. For example, if water continues to flow intensively, and you scoop it up with a shovel and take it out in buckets, is it worth doing this? After all, this can turn into a protracted and useless process. And if you use a pump with sufficient performance and automatic switching on when the liquid reaches a critical level, then most likely you need to start pumping out the liquid now. If the rate of water influx is not high and, moreover, the level stabilizes, then, of course, there is a need to proceed to the process of pumping it out immediately, using one of the methods discussed below. Example, if the basement has a size of 3x6 m with a depth of 2 m and it is flooded by 0.5 m, then when the water level rises by 50 mm per hour, you can start pumping out water if the pump has a capacity of at least 4-5 m³ /hour.

- What means will be used and methods of pumping water will be used. This will be discussed further.

How to clean, methods

Each method of keeping wastewater treatment plants clean and operational has its pros and cons. Effective cleaning depends on the design of the specific cleaning facility and the financial capabilities of the owners of country houses or private houses. The main ways to get rid of impurities include:

- using sewage pumps to pump waste fluid out of the structure;

- manual cleaning of the mine with a bucket is used after removing the liquid fraction from the pit;

- a sewer truck pumps the mass into a tank using a vacuum pump;

- the use of biological products in a septic tank with a sealed bottom for the decomposition of solid waste and recycling into water;

- chemicals are used in sealed septic tanks to process waste into water with subsequent pumping into a sewer machine:

- the use of a sludge sucker for the solid layer of sludge and waste at the bottom of the mine.

When deciding what to do with silted drainage, you need to familiarize yourself with all the options for removing sewage and use the one that is more effective in a particular cesspool. 1) To pump out the sump, fecal, deep-well pumps . When choosing a pump, we focus on the following parameters:

— depth of the shaft and distance to the container from which the pumped liquid is removed;

— pump performance and power depending on the chamber volume;

— density of the pumped waste mass.

The most reliable and productive model for this work is a fecal pump with a grinder, which allows you to crush and pump household waste. 2) Manual cleaning of the cesspool is a forced procedure when there is no access to the drain. A popular method of cleaning, the work is unpleasant, but less expensive if you do it yourself.

For this operation you need inventory and the correct sequence of actions:

- used for work: shovel, bucket, rope; scraper, metal brush, gas mask;

— to remove sediment and dense deposits, the liquid mass is first pumped from the bottom of the well into the storage tank;

- using a gas mask, remove grease deposits from the walls of the shaft with a scraper and brush;

- silt deposits are removed from the bottom of the well, using a shovel and a bucket with a tied rope; it is necessary to attract an assistant who will pull out a bucket of waste and take it to a storage container;

— after cleaning is completed, a layer of gravel is poured onto the bottom of the pit for better drainage, and the walls of the shaft are disinfected with a special antiseptic or chlorine.

The same procedure can be applied to a silted outdoor toilet. Preliminary pumping of moisture is not required due to the lack of drains from the room.

Manual waste removal is possible with small dimensions of the drainage area. The construction of volumetric chambers must be planned near the road, for the access of specialized equipment. 3) It is convenient to pump waste liquid out of the mine using a sewer truck . For the equipment to operate, it is necessary to have access to the chamber so that it is possible to lower the suction hose to the bottom.

A vacuum pump uses a hose to pump liquid waste into a container on a vehicle for further disposal at a designated area.

The cost of the service of sewage disposal equipment is determined by departure, so a chamber with a small filling volume (less than the capacity of a car) will require frequent visits, which is disadvantageous for the home owner. In this case, it is more economical to have a storage tank with a volume no less than that of a sewage disposal unit and to invite equipment to pump out waste after it is filled. 4) The use of aggressive chemicals is effective, but environmentally unsafe. Nitrate oxidizers dilute sludge and solid waste and help eliminate odors.

But in order for the liquid after treatment with the drug to be safe, like nitrate fertilizers, it is necessary to monitor its concentration in the waste chamber.

Water hammer or how to make a free pump using water energy

In this article we will talk about how to create a pump that does not require fuel or electricity to operate. The article contains a description of the operating principle of the device, the main design elements, as well as a video of the assembly process of the basic model of the ram pump. You will learn how to assemble it yourself.

Hydraulics is a science as ancient as water itself. The laws of hydraulics apply to absolutely any fluid, and we will look at how to use these laws to organize a pump or pump using kinetic energy.

The prototype of a pump based on the action of water hammer was created in France back in the 17th century by the inventor of the hot air balloon Montgolfier. Almost simultaneously with it, inventors in England, the USA and Germany patented an identical design. In Russia it received the sonorous popular name “hydroram”.

Types of wells

Bore wells can be of two types: sand and artesian.

The first type has another name - filter well. It is drilled to the nearest aquifer in sandy soil. The depth can reach 30 meters, and the width of the casing pipe can be about 13 cm. The peculiarity of the structure of such a source is that a mesh filter is made on the walls of the pipe. To extract water from it, a deep or surface unit is required. It can last about 15 years. But the service life primarily depends on the depth of the aquifer and how intensively it is used. The second type is an artesian well. The water in it is extracted from great depths; it can reach 200 meters. It has increased productivity and high-quality water. It lasts much longer than the first type - more than 50 years. Accordingly, a more powerful apparatus must be used to lift moisture to the surface. To drill such a hole, permission is required from local government authorities.

Is it possible to get water from these wells without using an electric pump? Yes, it is quite possible, and from both types of mines. But it is important to take into account several nuances. Much depends on the hand-held devices that will be used. They usually do not provide sufficient pressure at depths greater than 30 meters. Therefore, such a system is relevant mainly for a sand well. But first, let's figure out how it is possible to lift liquid from such a structure without a pump, and what is needed for this.

Hydraulic ram design

Conventional pumps consist of a pumping device (closed impeller, piston, membrane), an activator (internal combustion engine, electric motor, other drive), a pipeline and a valve system. The design of a hydraulic ram pump is extremely simple; its uniqueness lies in the fact that the activator and piston are the agent itself (water). Its design is notable for the fact that it has no mechanical moving parts (except for two primitive valves), and does not use fuel and lubricants and areas under constant pressure.

The base of the pump is a solid tube with three elbows, which can be assembled from ordinary fittings and pipe available at any plumbing store.

First withdrawal. A supply pipe (feeder) is connected to it; we will talk about it separately.

Second branch. A check valve, an expansion tank with soft walls and an outlet pipe are connected to it through nipples and couplings. A plastic bottle is quite suitable as an expansion tank; on factory models, full tanks are installed in a metal case with a rubber membrane.

Water extraction by hydraulic ram method

This is another non-standard way of extracting water without a pump: in this case, a hydraulic ram is used - a device designed to mechanically lift liquid from any well, even an artesian one.

This device operates on energy obtained from the flow of water. By raising water to a greater height and lowering it down, the liquid is pushed upward. This design consists of the following components:

Due to the opening and closing of valves in a certain sequence, liquid circulation occurs. It accelerates through the supply pipe and a hydraulic shock is created, displacing the liquid out into the outlet pipe. Such a device is difficult to make on your own, but it is easy to purchase. And this will be the best solution for areas where there is no electricity.

How and why a hydraulic ram works

The main feature of this pump is that it uses the kinetic energy of water that is already in the flow. That is, to supply water to a height, a level difference is necessary. It can be minimal - 0.5 m, but the higher this figure, the more efficient the pump. We deliberately do not provide a hydraulic calculation - it is extremely complex and comes down only to the optimal proportion of the height difference between the water intake point, the working part of the pump and the upper drain point. Since this device will be installed in specific conditions, it is reasonable to determine all values locally.

Water entering the feeder, under the influence of gravity, tends to the lowest point, creating excess pressure to which the hydraulic valve responds. At the moment it is triggered, water is blocked in a closed system and a water hammer phenomenon occurs, which pushes water through the check valve into the expansion tank. The elastic walls of the tank accumulate excess pressure from water hammer, but not in water (it is incompressible), but in air. This pressure pushes water through the outlet channel (hose, pipe), and the check valve prevents the pressure from equalizing.

The principle of operation of a hydraulic ram pump in the video

After the pressure in the expansion tank is released, the hydraulic valve opens again and the cycle resumes. Water supply occurs in pulses. Many have already guessed that the operation of the pump is made possible due to the difference in the density of the media - incompressible water and air, which easily accumulates pressure. The entire force of the water hammer goes into compressing the gas (air) in the expansion tank, which then supplies water to the top.

How to pump out a hole without a pump

The use of the so-called mechanical “old-fashioned” method is justified only in conditions of complete absence of electrical energy.

Standard technology using improvised means makes the work process rather unpleasant, but quite effective:

- If necessary, homogenize the liquid inside the pit with special substances.

- Change into suitable work clothes that provide good protection from accidental water.

- Securely attach a strong, but not too thick rope to the handle of the bucket.

- Scoop the water out of the hole with a bucket and lift it up with a rope.

- Pour the raised liquid into a special container for subsequent disposal.

After emptying, the pit should be washed with water under pressure to prevent the formation of deposits on the tank walls, which significantly reduce the total volume.

Methods for pumping water without an electric pump are labor-intensive and require a lot of time to build an easy-to-use and practical device.

Feeder and hydraulic valve

These two elements are the main ones in the design that you plan to create yourself. The entire operation of the unit depends on their size and design.

Feeder

It is a closed channel connecting the water intake point and the water hammer point. Ideally, this is a long, level pipe located on a slope. The water in the pipe is the very piston that creates excess pressure - the cause of water hammer. Therefore, the larger the cross-section, the more powerful the ram will be. The diameter of the feeder pipe should be within reasonable limits - from 50 to 150 mm. This value must be correlated with the diameter of the remaining channels of the system and the required feed height.

We recommend installing a socket in the intake part of the feeder for better water capture.

Optimal ratios of hydraulic ram pump diameters

| Feeder, mm | System, mm |

| 50 | 16 |

| 100 | 32 |

| 150 | 32–50 |

In the latter case, with a feeder length of 10 m and a drop of 1.5 m, water will be supplied to a height of 10 m at a speed of about 1500 l/hour.

Hydraulic valve

The factory model of this device may be expensive due to the material, gaskets and spring set to a certain pressure. In our case, when we use free energy, which simply does not make sense to save or take into account, the very fact of blocking the flow of water is enough. A self-made hydraulic valve is quite suitable for this.

Pump with homemade hydraulic valve - installation video with comments

The ideal place to install such a pump is river rapids with their significant drops or streams.

Design #13 - Shukhov wick pump

The Russian inventor Shukhov became famous for many buildings, including the radio tower in Moscow. Below we will discuss another of his inventions - a water pump.

Pulleys are made composite. The depth of the groove should be slightly less than the swollen rope

The pump uses a special rope to operate. This rope consists of woven cotton threads with a total thickness of 5-6 mm, enclosed in a sheath. The thread is passed through the pulleys.

When movement occurs, the rope gets wet and wraps around the pulleys. The pulley (5) with the help of a spring (4) presses the rope against the pulley (3) with force. The squeezed water flows into the tray (7). Figure “c” shows sections of pulleys (3) and (5), respectively.

To operate the entire system, an electric motor of only 5-10 watts is required. Typically, such engines have 1500 rpm.

To reduce speed and increase force, you can use a worm gear, shown in figure “c”. It is quite possible to make it by hand. To do this, you need to find a suitable gear and make a worm from wire. Small forces on the shaft allow manufacturing inaccuracies.

With your own hands you can assemble not only a pump that pumps water for domestic needs, but also a device that can be successfully used in landscaping a site. The following article will present successful options for homemade fountain pumps.

Factory-made hydraulic ram pumps

Of course, such simple and reliable devices could not avoid claims for mass production. Currently, they are produced by both domestic and foreign companies. However, due to their specific nature of operation (part of the water is discharged through a valve), they have a rather narrow scope of application - in urban areas they are practically useless, but are indispensable in remote, undeveloped areas, eco-villages and farms.

Today in Russia, only one company produces these environmentally friendly and efficient devices - the Ural production artel. The model range is represented by Kachalych pumps GT-01 (190 USD) and GT-03 (110 USD), as well as their varieties.

Making a pump yourself will cost a little less, even if you purchase all the parts. However, real savings are achieved if available means are available - in this case, the pump will be practically free, while its performance can be significantly higher due to a larger feeder and the throughput of the entire system.

Any device or device based on the action of natural forces deserves close attention and development. By ignoring the free energy provided by nature itself, we risk suddenly being left helpless in the absence of gasoline and electricity. Transferring household farming to alternative energy sources is the key to peace and harmony with the environment.

Injection method

Currently, the method of waterproofing a cellar using construction injections is becoming increasingly popular. Carrying out work using this method will cost you a fairly large sum, and it must be carried out by professionals who have the necessary skills and the necessary equipment. The essence of the method is to create a moisture-proof polymer membrane and anti-filtration curtains. In this case, there is no need to dig a foundation or perform other labor-intensive work. This method is not only environmentally friendly, but also durable. However, using it yourself, without special skills, is strictly not recommended.

Homemade pump for pumping water: a selection of the 7 best options

After purchasing a plot of land, the summer resident begins to solve the most important problems: you need to start somewhere in order to settle down. The most important thing is to provide yourself with water. Indeed, since life arose in water, without it, all living things cannot exist for a long time. You can bring water from somewhere, but only for personal needs. The watering problem cannot be solved using this method. It’s good if there is water at least close to the site. Any, even small, body of water will suit you: a river or at least a stream. The ideal option is a spring, but such luck is rare. All that's left is to get a pump. By the way, at first, a homemade water pump will do. Its use will alleviate the problem.

Option #1 - American river pump

This pump model, which does not require electricity to operate, can be used by craftsmen who are lucky enough to purchase a plot of land on the banks of a small but very stormy river.

The hose is laid in the barrel in even turns without creases or kinks. And the entire structure as a whole looks rather simple, but with its help water is regularly supplied to the shore

To create a pump you will need:

- a barrel with a diameter of 52 cm, a length of 85 cm and a weight of approximately 17 kg;

- hose wound in a barrel with a diameter of 12mm;

- outlet (supply) hose 16mm in diameter;

There are also restrictions for the immersion environment: the working depth of the flow should not be less than 30 cm, the speed of water movement (current) should be 1.5 m/sec. Such a pump ensures that water rises to a height of no more than 25 meters vertically.

Components: 1 - outlet hose, 2 - sleeve coupling, 3 - blades, 4 - polystyrene foam floats, 5 - spiral winding of the hose, 6 - inlet, 7 - bottom of the structure. The barrel floats perfectly