Small do-it-yourself winch for 1 ton

Hi all.

I want to share with you a small homemade product. Quite the same, I had this idea in my head for a long time, and finally figured out how to do it so that it would not be difficult, + - compactly and on a budget. The basis was taken from a primary or secondary (I don’t remember exactly) shaft from a broken motorcycle gearbox.

I moved the gear to the edge so that there was more space for the cable, placed a large washer on the other edge and welded it in a circle.

The result is this design. On one side there is a gear and on the other there is a washer.

Next, you need to make a ratchet that will lock the shaft and prevent the cable from unwinding.

To do this, I ground off the slopes of all the teeth on the gear with a grinder on one side.

Stoppers will rest against these teeth, which will prevent it from rotating in the opposite direction. Also, these stoppers will rotate the shaft, creating a kind of ratchet mechanism.

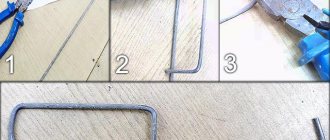

Now we make two U-shaped profiles in which this shaft will be attached in the middle.

Now, we make stoppers that will stick into the gear and stop it. I made them from Soviet bolts (strength 10.9) and hardened them in oil, but still, it seems to me they turned out soft, it’s better to make them from the shanks of old, broken drills.

On the one hand, we make a plane, and on the other, we round it. And when we rotate the gear, it will only spin in one direction and stop in the other. (I showed this in the video)

Then I cut a rod with a diameter of 20mm, drilled a 9mm hole in it into which the stopper would be inserted, and cut a couple of threads at one end to support a spring that would push the stopper into the gear. Well, in order to unwind the winch in the rod, I made a cut and attached a lever to the stopper, by which you can pull the stopper and release the gear.

Such stoppers were made on both sides.

Also, I made a whole detailed video on this winch, if anyone wants to repeat it, watch it.

Source

Second idea: how to easily attach a cable to the wall

A hole is drilled in the cap nut, clamped in a vice.

An extension nut is welded to the workpiece with a hole, and the seams are cleaned with a grinder.

The cable is threaded, the tip is crimped with a suitable piece of tube using pliers.

A piece of a bolt without a head (one thread) is screwed into the prepared hole in the wall.

A blank of nuts with a cable is screwed onto the thread.

Pulley hoists: from calculations to reeving

A chain hoist is a portable block system designed for lifting and moving loads of varying degrees of severity. This device is used in the construction industry, logistics, mountaineering and during rescue operations. To make a chain hoist with your own hands, you need to know the design features of this device, methods of attaching ropes to a forklift, and reeving technology.

General information about pulley hoists

A pulley block consists of 2 or more pulleys (blocks) connected using rope ropes or chains:

Simple pulleys can consist of 1 pulley and rope. In them, the roller is located above the load: on the ceiling, beam or support. The first end of the rope is connected to the hook and goes down to the load being lifted. A man pulls on the other end of a rope, lifting a heavy object. Complex lifting devices include several simple pulleys and provide greater gains in strength.

The operating principle of pulley blocks is based on the rule of leverage. A rope is thrown over a stationary pulley. The load is raised to a height by applying forces commensurate with the weight of the object being lifted. The length of the rope or chain should be comparable to the height to which the load is lifted. To reduce the amount of effort required, it is necessary that the moving block moves parallel to the load.

There are the following types of pulleys:

Pull blocks are used for the following operations:

Various types of cranes, hydraulic and electric drives are equipped with pulleys. They were also used in older elevator prototypes.

Purpose and design specifics

These devices are made of durable materials - it is thanks to metal that a reliable fastening is ensured that can withstand increased loads. Structurally, the clamp consists of an arc and nuts.

It is advisable to use several clamps - professionals advise using at least three. However, if the load is excessively high, then it is better to choose other methods of fixation and refuse to install a large number of clamps.

High-strength steel is additionally treated with galvanization. This protective layer protects the elements from corrosion and also minimizes the impact of other external factors.

To prevent disengagement and breakage, you should learn how to use the cable clamp correctly. There is nothing complicated about this - just put the ends under the arc and tighten it with nuts. They twist in different directions, and the rope remains in the spaces between them.

The nuts must be tightened until the cable is completely tightened. If a loop is being created, the cut end should be on top, above the whole piece, but directly below the arc. The clamping element - the nuts - will be at the bottom.

Calculation of the chain hoist

Before manufacturing a chain hoist, it is necessary to calculate the main technical characteristics of the load-lifting structure. Calculations are required for drawing up drawings and are made according to the parameters of the working premises and the weight of the load.

To determine the loads affecting the block system during operation, it is necessary to calculate the parameters acting on individual blocks:

The equation used to find the moments of force is as follows: SM * R = SC*R + l*SC*R + N* g*d/2, where:

The efficiency of the pulley is determined by the following formula: η = SC/SM. This parameter is influenced by the quality of the blocks and the complexity of the circuit. There are the following efficiency levels of the block system:

When calculating, it is also recommended to determine the efficiency of the remaining bypass rollers, depending on the design features of the lifting mechanism.

Methods for attaching a rope to a lifting mechanism

The cargo rope allows you to automatically fix the lifted load, which affects the passage of knots. It must be filled in such a way that there is no possibility of chafing due to frequent contacts with other parts of the lifting structure. There are 3 main methods of attaching a rope to a pulley system:

To secure crane ropes, you need to secure 1 end of the rope with a lock or cable clamp. On winches, the cable is fixed to special fastenings using a wedge and a clamping bar.

The simplest do-it-yourself lifting mechanism

In home workshops you can make a simple chain hoist from scrap materials. It is capable of lifting light loads and can only be used for occasional jobs. To make a chain hoist with your own hands, you need to purchase the following components:

A bearing is installed on a steel stud, a nut is screwed on and locked. A hook is attached to the stud to reduce the effort required to rotate the homemade shaft. The first end of the rope is located on a static platform. To lift the load, you need to pull the second end of the cable up. For ease of operation, it is recommended to make an additional block and pass a rope through it. This will allow you to connect the rope to the winch and fix the transported object in an intermediate position.

Fourth idea: fastening the cable in the frame of a steel structure

The bolt is secured in a vice, and part of the thread is cut off with a grinder. A through hole is made in the workpiece using a drilling machine.

A cap nut is screwed onto the prepared bolt, and a hole is also made in it.

The nut is unscrewed, the bolt is inserted on one side of the iron blank, and the prepared cap nut is put on and tightened on the other side.

A steel cable is threaded into the hole in the blanks, the end is crimped with a piece of tube using pliers - ready!

Refilling chain hoists

Reeving is a procedure for changing the location of pulleys and the distance between them. The purpose of this operation is to regulate the speed and height of lifting loads in accordance with a certain pattern of cable passage through the blocks of the lifting mechanism. There are the following types of reserve:

There is also variable reeving. It can be either double or quadruple. The movable rollers are mounted on several movable cages held by a rope. The reeving ratio is changed by lowering the hook suspension onto the support while reeling in the rope.

Source

How do we make lifting easier?

A cargo pulley is a system consisting of ropes and blocks, thanks to which you can gain effective strength while losing in length. The principle is quite simple. In length we lose exactly as many times as we win in strength. Thanks to this golden rule of mechanics, you can lift large loads without exerting much effort. Which, in principle, is not so critical. Let's give an example. Now you have won 8 times in strength, and you will have to stretch a rope 8 meters long to lift the object to a height of 1 meter.

The use of such devices will cost you less than renting a crane, and besides, you can control the gain in strength yourself. The pulley has two different sides: one of them is fixed, which is attached to the support, and the other is movable, which clings to the load itself. The gain in strength occurs thanks to the movable blocks, which are mounted on the movable side of the pulley. The fixed part serves only to change the trajectory of the rope itself.

Types of pulleys are distinguished by complexity, parity and multiplicity. In terms of complexity, there are simple and complex mechanisms, and the multiplicity means a multiplication of force, that is, if the multiplicity is 4, then theoretically you gain 4 times in strength. Also rarely, but still used, a high-speed pulley block is used; this type gives a gain in the speed of moving loads at a very low speed of the drive elements.

Nuances when working with different types of cable clamps

When using a cable clamp, it is important to take into account such parameters as the guaranteed clamping force and the maximum diameter of the cable. Dimensions are no less important, since regardless of the type, it is recommended to use several clamps at once (at least three!), especially when working with loads whose weight cannot guarantee safe lifting or moving.

In the presence of a nut made according to GOST 5915-70 and a spring washer (GOST 6402-70), for ropes with a diameter from 5 to 62 millimeters, clamps made according to the DIN 741 standard are used. In this case, the design of the element allows the use of a locking bar, which in turn this guarantees a more reliable fastening of the bracket and cable.

The clamping block is made by stamping using steel grade from St. 3kp and higher. The use of cast pads in production is allowed only for products whose operation requires low clamping forces.

It is prohibited to use clamping cables that do not have a galvanized anti-corrosion coating!

As for fasteners with a flat clamp, these should use threads made in accordance with GOST 24705-81. In this case, the plates are used to fix cables with a diameter of 4.6 to 30 millimeters. For the manufacture of linings, steel grade St.3 should be used.

When using several clamps sequentially, the step between them should be at least 6 cable diameters.

Duplex double clamps absorb shear force due to the bolted connection, as a result of which the diameter of the fastener will directly depend on the diameter of the cable. It is recommended to adhere to the following ratios:

It is not recommended to use wedge clamps when lifting loads. This is due to reduced operational loads on the fasteners, since the axes of force in this case will coincide, without causing shear stresses. DIN 15315 regulates the performance characteristics of wedge clamps. In the case of a screw clamp of a rope or cable, high-strength fasteners with a strength class of at least 5.6, treated with a special protective anti-friction material .

It is important to note that such a connection occasionally needs to be tightened!

The barrel clamp is often made using aluminum and is therefore not suitable for large diameter cables. The range of diameters is limited to 2-8 millimeters. The advantages of the clamp are its compactness and the absence of any protruding parts, which makes it possible to use it in small spaces.

How does a simple block design work?

Let's first consider a simple assembly pulley. It can be obtained by adding blocks to a support and a load. To get an odd mechanism, you need to secure the end of the rope to a moving point of the load, and to get an even one, we fasten the rope to a support. When adding a block, we get +2 to strength, and a moving point gives +1, respectively. For example, to get a pulley for a winch with a multiplicity of 2, you need to secure the end of the rope to a support and use one block that is attached to the load. And we will have an even type of device.

The operating principle of a chain hoist with a multiplicity of 3 looks different. Here the end of the rope is attached to the load, and two rollers are used, one of which we attach to the support, and the other to the load. This type of mechanism gives a gain in strength of 3 times, this is an odd option. To understand what the gain in strength will be, you can use a simple rule: how many ropes come from the load, this is our gain in strength. Typically, pulleys with a hook are used, on which, in fact, the load is attached; it is a mistake to think that it is just a block and a rope.

Specialized and wedge clamps - what are their features?

Many construction jobs cannot be done without a strong clamp. Construction has always been characterized by the presence of a large number of operations. You definitely need to lift something up, pull a load, and in this case it’s building materials; you often have to fix various objects. For such work you need strong spring-loaded clamps. Not only do they allow you to connect the cables, but you can also attach a load to them. Such devices are not very different from standard clamps.

In addition to the usual metal arc, they have a pair of levers that are equipped with movable brackets. This design solution helps ensure a highly durable and durable connection. With its help, you can securely fasten any object to a cable of different thickness. Lately, wedge clamps have become the most popular among specialists. This is an excellent connecting element for copper and aluminum wires, the cross-section of which can range from 35 to 100 square millimeters. Only this type of clamp is good for connecting steel-aluminum devices. Such devices consist of a body and a wedge, which is wear-resistant. Forged cast iron steel is used to make the body, and the wedge itself can be made of bronze or various aluminum alloys.

If it is necessary to install aluminum or steel-aluminum wires in bolted clamps, where the cross-sections are very large, then it is necessary to use special gaskets that are made of soft aluminum tape. The use of such an addition in work will give the fastening the greatest mechanical strength. It is important to remember that after installation, such clamps must be tightened again ten days later . The lift should be done like this. The first step is to press the hinge part of the aluminum housing, then you need to insert a steel anchor, and then the aluminum housing is inserted again using a steel mechanism.

Complex block system - how to calculate the gain in strength?

Now we will find out how a complex type chain hoist works. This name refers to a mechanism where several simple versions of this cargo device are connected into one system; they pull each other. The gain in strength of such constructions is calculated by multiplying their multiplicities. For example, we pull one mechanism with a multiplicity of 4, and another with a multiplicity of 2, then the theoretical gain in force will be equal to 8. All of the above calculations take place only for ideal systems that have no friction force, but in practice things are different .

In each of the blocks there is a small loss in power due to friction, since it is still spent on overcoming the friction force. In order to reduce friction, it is necessary to remember: the larger the bend radius of the rope, the less frictional force will be. It is best to use rollers with a larger radius where possible. When using carabiners, you should make a block of identical options, but rollers are much more effective than carabiners, since the loss on them is 5-30%, but on carabiners it is up to 50%. It is also useful to know that the most effective block must be located closer to the load to obtain maximum effect.

How do we calculate the real gain in strength? To do this, we need to know the efficiency of the units used. Efficiency is expressed as numbers from 0 to 1, and if we use a rope with a large diameter or too stiff, then the efficiency of the blocks will be significantly lower than indicated by the manufacturer. This means that it is necessary to take this into account and adjust the efficiency of the blocks. To calculate the actual strength gain of a simple type of lifting mechanism, it is necessary to calculate the load on each branch of the rope and add them up. To calculate the gain in strength of complex types, it is necessary to multiply the real forces of the simple ones of which it consists.

PVC Boat Anchor Cam Stopper

Those who have read the article: “About Fish Hook, friends and good deeds” (fish-hook.ru/ar...elah-501/), already know what such a device is needed for. Therefore, I won’t repeat myself, I’ll get straight to the point:

Please note: This cam stopper has a flat and hard plastic base. Therefore, PVC is not suitable for gluing onto the side of a boat!

The stopper is designed for installation on the sides of rigid boats. To adapt it to an inflatable boat, I installed it on a removable platform.

Stopper characteristics declared by the manufacturer:

- dimensions: 64x30x29 mm;

- weight: 50 g;

- cable diameter: 3-8 mm;

- working load: 100 kg.

To begin with, I took it apart and examined it:

Top row of installed balls.

The stopper cams rotate on balls, which are installed in two rows in each cam. Since I will be making my own platform for the stopper, the base, which is in the photo below, and the blue spacer at the top, were not useful to me.

The cams and balls are made of hard plastic. The cam axles are made of stainless steel. The springs are made of elastic brass. Nothing here can rust or jam. The cams have travel limiters in the form of movable pins. They are also stops for the spring plates. The springs are in a free state - the cams are compressed. The springs are in a compressed state - the cams are spread apart.

When inspecting the stoppers, I discovered that the cams had increased end play. To eliminate it, I ground down the top of the axles to the amount of play. But it could have been left as is.

After that, I assembled the stoppers. You can start making the base. First, to make the platform, I used 4 mm thick getinax.

Getinax is a durable material and easy to process.

But when I installed the stopper on the platform, I discovered that the cams did not secure the anchor cord very well. When the cord was pulled, it constantly tried to jump out of the grips. Why is that? I began to understand the reason. It turned out that the whole issue was the misalignment of the cord and cams.

The photo shows that the cord is located at a certain angle to the axis of the cams. This is due to the platform and the height of the cams themselves. Therefore, the cord easily slipped out of the grip. The red line shows the cam axis. Green - acceptable axis location when the axis is perpendicular to the cord. Blue - the desired location of the axis in relation to the cord. With this position of the cams, the cord will no longer slip out of the grip.

How to fix it? Everything turned out to be very simple: you just need to use a curved plate. To make it, we had to use another material, namely aluminum.

In the barn I found a panel from an old concert power amplifier.

Thickness - 3mm. More than enough.

I cut out a new plate with a jigsaw. When I tried to drill holes in it with a mini-screwdriver, this happened!

Chinese drills are the best in the world! I had to go to the barn for normal drill bits and drills.

The plate is ready. All that remains is to give it a marketable appearance and bend it. The area is sanded and polished.

I bent the top of the plate about 45 degrees.

I fastened the rollers with countersunk screws. The screws turned out to be very long.

I cut them flush and sanded them. There should be no sharp edges or burrs!

One stopper is ready! It even works great in water!

In the image and likeness of the first plate, I made a second one, for the second stopper.

Finished products on board the Bark.

Now the cord comes out of the grip as it should. You can hook the stopper to the boat rail.

For the nose handle. For the towing eye. For small and frequent trips, you don’t have to drag a dirty anchor into the boat. Let it hang outside!

It hangs a little low, but I'll think of something! The weight of such an “anchor” is 6350 g.

The finished stopper was put to the test: I fastened it to the fence, attached electronic scales to the cord and began to pull. It was possible to pull back to a force of 38-40 kg, although the scales were up to 45 kg. I couldn’t do it anymore - my legs were slipping. The total weight of the stopper with the carabiner was 100 g. Well, that's pretty good. My motor develops a force of about 20 kg. This means that if the cord from the stopper is attached, for example, to a tree, then the five-horsepower motor will not be able to tear the boat off the stopper.

In order not to move the stopper from the left side to the right, I made two of them. The removable option is also convenient because I can remove the stopper from the Bark at any time and put it on the Pelican. It will depend on what kind of boat I'm using. Or two at once.

In order not to be accused of plagiarism, I’ll say right away that it wasn’t my idea to put a cam stopper on the platform. You can find photos online:

For example, here. Or this.

There are simply no other options for attaching the stopper other than on board or on the platform. And I just shared my version.

Everyone: seven feet under the keel and a reliable anchor!

Rope and its role in the operation of the pulley system

You should also not forget about the friction of the rope, since its branches can twist among themselves, and the rollers under heavy loads can converge and pinch the rope. To prevent this from happening, the blocks should be spaced relative to each other, for example, you can use a circuit board between them. You should also purchase only static ropes that do not stretch, since dynamic ones give a serious loss in strength. To assemble the mechanism, either a separate or a cargo rope can be used, attached to the load independently of the lifting device.

The advantage of using a separate rope is that you can quickly assemble or prepare a lifting structure in advance. You can also use its entire length, this also makes it easier to pass knots. One of the disadvantages is that there is no possibility of automatic fixation of the lifted load. The advantages of a cargo rope are that automatic fixation of the lifted object is possible, and there is no need for a separate rope. The important thing about the disadvantages is that it is difficult to pass through the knots during operation, and you also have to spend a cargo rope on the mechanism itself.

Let's talk about the reverse motion, which is inevitable, since it can occur when the rope is caught, or at the moment of removing the load, or when stopping to rest. To prevent backlash from occurring, it is necessary to use blocks that allow the rope to pass in only one direction. At the same time, we organize the structure so that the blocking roller is attached first from the object being lifted. Thanks to this, we not only avoid backtracking, but also allow us to secure the load while unloading or simply rearranging the blocks.

If you are using a separate rope, the locking roller is attached last from the load being lifted, and the locking roller should be highly effective.

How to make a chain hoist yourself

In the household there is no need to lift weights every day, so for one-time work you can make a lifting device with your own hands. Everything you need for this can be found in the thrifty owner’s workshop:

The bearing is inserted into the roller and placed on the stud. Screw on the nut and lock it so as not to waste effort on turning the resulting shaft. A hook or slings are attached to the pin . One end of the rope, passed through the made block, is secured to a fixed support, and the other is pulled upward when lifting the load. The result was a simple chain hoist with a multiplicity of 2:1.

Since it is inconvenient to work with such a mechanism, you should make another block and, having secured it, pass a rope through it. Now it can be pulled down and even connected to a winch. In addition to improving working conditions, this will provide the ability, if necessary, to secure the load in any intermediate position.

For a DIY chain hoist, it is better to use a rope rather than a steel cable. Its advantage is that it allows you to quickly assemble or disassemble the structure. You should choose static types that do not stretch. Dynamic types “eat up” part of the gain in strength.

Methods for attaching a rope to a lifting mechanism

Now a little about attaching the lifting mechanism to the cargo rope. It’s rare that we have the right length of rope at hand to secure the moving part of the block. Here are several types of mechanism mounting. The first method is using grasping knots, which are knitted from cords with a diameter of 7-8 mm, in 3-5 turns. This method, as practice has shown, is the most effective, since a gripping knot made of 8 mm cord on a rope with a diameter of 11 mm begins to slide only under a load of 10-13 kN. At the same time, at first it does not deform the rope, but after some time, it melts the braid and sticks to it, beginning to play the role of a fuse.

Another way is to use a general purpose clamp. Time has shown that it can be used on icy and wet ropes. It begins to crawl only with a load of 6-7 kN and slightly injures the rope. Another method is to use a personal clamp, but it is not recommended, since it begins to creep with a force of 4 kN and at the same time tears the braid, or can even bite the rope. These are all industrial designs and their application, but we will try to create a homemade chain hoist.

Steel cable clamp - classification

Clamps come in different types. They are divided according to purpose, material used and design. You can also formally designate different lengths; the most popular is a cable clamp of 3 mm, 5 mm in diameter, but in special cases sizes up to 40 mm are used. Each species also has different subspecies. Clamps, which are divided according to purpose, are ordinary and reinforced, and according to the material used - steel and copper; an aluminum cable clamp is also popular; a galvanized steel version is used in particularly harsh operating conditions. Clamps, which are divided by design, are flat, arc-shaped, single and double.

Regular clamps are the most common. Typically, they are made from galvanized steel of class 2. In appearance, such clamps resemble closed loops at the base, which have two strong bolts. This type of product is for household use and is not intended for heavy loads. The reinforced version speaks for itself, its design is more thoroughly worked out, the shutter mechanisms are reinforced, and therefore the scope of their application may be more responsible.

Flat types of clamps are often made of high-strength carbon steel. The surface of these devices is galvanized. Their diameter can range from 2 to 40 mm. In shape, such clamps resemble a pair of plates that are connected to each other with a bolt and nut. They are typically used for splicing steel cables or other standing rigging. They are also quite suitable for creating loops at the end of the brace. Professionals recommend installing at least two clamps on one connection.

Flat clamps can also be classified as single or double. The main difference is the number of bolts available. Single clamps are fastened with one bolt, and double clamps are fastened with two bolts. In terms of application, such clamps are not particularly different.

Arc-shaped clamps are made of a cylinder that is bent in an arc, and fastening occurs using two bolts that are located at the ends. Devices of this type are most often used for connecting metal cables, but it is quite possible to use them for making loops. This type of clamps is more industrial; they are designed for heavy loads. A typical standard arc clamp can withstand a load of about 97 kilograms.

We create a simple lifting mechanism with our own hands

But if you need a mechanism for cargo urgently or for a one-time use, but you don’t have time to buy it in stores and you’re sorry for the money, we’ll tell you how to make a chain hoist with your own hands. It’s good if you have threaded rods, bearings, a block, a cable, a hook, and a gear in your workshop. It will take a little time: you need to fit the bearings onto the stud. It is advisable to fix the nut from the stud so as not to waste some of the effort on turning the peculiar shaft. The end of the pin can be equipped with a gear, thus making a more convenient manual drive.

We throw a cable over the block and fasten it to a support, but at the other end we attach a hook on which we will hang the load. You can also fix a sling system at the end of the cable if the nature of the load does not allow it to be attached to the hook. In principle, the simplest version of the chain hoist is ready. All that remains is to get to work, observing safety precautions, which are the same for all mechanisms, both purchased and homemade. Carefully check all elements for integrity before work, and during work do not make sudden movements, lift the load smoothly, and, of course, do not stand under a suspended load.

Source

Comments and reviews 36

Only users with a rating above 20 can see the voting results (who voted and how).

Voted For: Aleks34Alexmartin

Voted against:

Great, I’ll show it to my fellow fishermen anyway, it’s very convenient, otherwise we’ll get tired of tying an anchor. Thank you, Sasha!

Only users with a rating above 20 can see the voting results (who voted and how).

Voted against:

Well, yes, Kostya! Useful little things make fishing much easier!

Only users with a rating above 20 can see the voting results (who voted and how).

Voted against:

I forgot to add: there are threads cut in the holes of the plates for attaching the stopper to the plate with screws. But I think this is already clear.

Only users with a rating above 20 can see the voting results (who voted and how).

Voted For: Aleks34

Voted against:

At first I had this question, but then I figured it out.

Only users with a rating above 20 can see the voting results (who voted and how).

Voted For: Aleks34Alexmartin

Voted against:

Thank you very relevant and useful information. Straight to the point.

Only users with a rating above 20 can see the voting results (who voted and how).

Voted against:

In 3 days, the opening of the boat season. So I'll test the stoppers!

Only users with a rating above 20 can see the voting results (who voted and how).

Voted For: Aleks34

Voted against:

Cool. And now I know where to put the sticker on the boat!

Only users with a rating above 20 can see the voting results (who voted and how).

Voted For: Aleks34

Voted against:

Cool! But anchoring outside for a motor boat, in my opinion, is unsafe. If it inadvertently comes off, and inadvertently always happens where it can happen, there could be trouble. Perhaps only for the smallest movements in displacement. It is better to make a pocket inside the boat so that you can put the anchor in it.

In a displacement boat this is not a big deal; you often need to change points on small rivers and fronds.

My friend’s anchor on the glider came off, hit the water, and then flew aboard the Compass 400 - it’s good that he was on a NDND boat, otherwise he wouldn’t have made it to the shore!

On the side of the handle near the driver.

Only users with a rating above 20 can see the voting results (who voted and how).

Voted For: Alexmartin

Voted against:

I saw a video at one time, but I can’t find anything where the anchor fell out of the boat while it was moving. There was a check in the engine, the man flew out and the boat drove at full speed in a circle until the gas ran out.

Only users with a rating above 20 can see the voting results (who voted and how).

Voted For: Alexmartin

Voted against:

On planing kits it is necessary to fasten the pin, in the Russian Federation they recently wrote how they stopped a circling boat, the pin was on the engine, the vest was in the boat, and the driver drowned.

Only users with a rating above 20 can see the voting results (who voted and how).

Voted For: Alexmartin

Voted against:

This is an inapplicable rule about the check! I have it fastened to my vest all the time. I won’t start the engine without a vest.

3xUgh and on wood!

Since the beginning of the water-motor season (since the 22nd), 3 people have already drowned. Two without vests turned over on mountain rivers, one in a vest, but did not insert the pin - when he hit a snag he fell into the water (the cause of death will be determined by an autopsy).

Only users with a rating above 20 can see the voting results (who voted and how).

Voted For: AlexmartinMux

Voted against:

Mish, well, that’s what I said: “For small and frequent transitions.” For example: I am drifting along the right bank of the Khopr, making short stops at interesting places. Gradually the bank becomes flat and you need to cross to the arcing bank. In these cases, the anchor does not need to be pulled into the boat.

I can’t even imagine a boat flying on a planing plane with an anchor overboard! What if she’s also a dolphin?

A boat should have a pocket for an anchor! For now, I'm using a regular aluminum pan of the right size.

Only users with a rating above 20 can see the voting results (who voted and how).

Voted against:

Sasha, it’s a funny thing, but it’s not really needed on your boat

Bark took care of the anchor fastening and mooring, even over the top, making four handles on the sides, a bow handle and an oarlock eye

I make a loop anywhere in the rope and throw it over the eye, it holds perfectly and there is no hint of dropping, and I would be more careful with the line: it (the Barkov one) stretches a lot, but on the old boat it tore, some kind of tricky knotless weaving has unraveled.

On the one hand, the abundance of handles is even more annoying, where it is not necessary, it is more convenient to carry such a small boat by the bow handle and two attached to the tails, and on the other hand it is convenient to anchor. I somehow found myself in a boat where there was nothing to attach to in my usual way, it was uncomfortable. I think that PVC handles should have a ring and nothing else

Only users with a rating above 20 can see the voting results (who voted and how).

Voted against:

Zhenya, well, I disagree!

Apparently our fishing spots are different and your current is less. That noose you showed me is unraveling at once. The cord simply slides around the handle if the other end of the cord is not secured. I’ve already tried a figure eight and wrapped the cord around the handle many times - I’m tired of it! But try tying the line when the anchor is already in the water and the current is pushing you. Do you think I wanted to bother Sanya, spend money and time making the grip? Necessity forced it.

There is nothing tricky about weaving a rail on Barka, Zhen: you move it towards each other. At the same time, it blooms and expands. You pass the free end of the line several times between the strands, and then hide it in the middle of the line. That's the whole trick. This must be done on a lowered boat.

Only users with a rating above 20 can see the voting results (who voted and how).

Voted against:

No, Sash, I have nothing against it

Maybe the conditions are different, or the rope is different, but I’m mostly on the Don, the pull is great, I always stand at the same anchor, both on the old boat and on this one, the loop - the harder it pulls, the tighter it tightens. Five stars for your device, everything was great as always! I'll take it into service if I change the boat

Only users with a rating above 20 can see the voting results (who voted and how).

Voted For: Alexmartin

Voted against:

Zhen, perhaps my cord is more slippery. I bought a regular, cheap, linen one.

Are you planning to change the boat? I can guess which one you want! Happy NDND!

Only users with a rating above 20 can see the voting results (who voted and how).

Voted For: Alexmartin

Voted against:

I also have household goods, but not slippery 6 mm. I haven’t fully decided on boats yet, maybe a little more than 330-340, not very wide, according to NDND, not all are definitely good, expensive and also quite heavy with an indivisible weight, bags of 35 and 25 kg are one thing, or one 50, but for me it’s drag it to the 3rd floor and often walk about 50 meters across the yard with a boat when I can’t park the car at the entrance.

And there is quite a lot of negativity regarding inexpensive NDND. On the last rides I looked at the guy's Kasatka, a cool boat, well made. In Barki there is some kind of cute provincial handicraft, everything there is clear, like a factory

Lately I’ve gotten used to assembling a boat quite quickly; there are small nuances that, if you don’t know, you don’t pay attention to. And this friend, with whom I was riding, assembled his killer whale 385 himself in the same time as me, 290 cm, pumped it with a Bravo compressor, I just helped him throw it into the water.

A friend received an NDND, we still can’t test it under the motor, I want to feel the unsurpassed driving performance that is talked about so much, the Compass 350 weighs 60 kilograms in a bag, he and his wife often go fishing, I don’t know how they will move this boat out of the car, dragging it It’s also a shame to drag it out of the cabin.

Source