One of the most popular power tools, which is used with equal success in production and at home, is an electric drill.

The drill is a universal assistant. It’s not difficult to expand its capabilities; you just need to buy additional attachments, and there are a great many of them. Some allow you to drill into walls, others allow you to mix building mixtures, and others help you cut sheet material.

At the final stage of manufacturing various decorative products, an attachment for sanding wood is indispensable; with its help, you can create a perfectly smooth surface. In this case, you do not have to spend money on buying a full-fledged grinding machine.

Range of accessories

Electric drill attachments are replaceable tools for various purposes, which are driven by the drill motor. For fixation in the cartridge, each of them has a connecting pin. The right attachment will help you perform a whole range of jobs without the need to purchase expensive tools.

Among other things:

- removing traces of corrosion from the metal surface;

- removal of old paintwork;

- cleaning welds, removing burrs;

- milling of soft material;

- polishing of metal products, including those with complex geometry;

- grinding the inner surface of the holes;

- sanding the wood surface;

- polishing varnished products;

- polishing glass and grinding its edges;

- grinding and polishing various small parts.

The industry offers a wide range of ready-made accessories, so you can choose the right tool for any type of work. Some types of attachments can be used together, allowing you to turn your drill into a small, portable machine.

When choosing a nozzle, in addition to its purpose, you should pay attention to the manufacturer and country of production. Too often you can find cheap, low-quality tools, the use of which will not give the desired effect, and in some cases can cause serious injury.

Drill attachments: is it worth buying?

Most often, an electric drill with attachments is used when there is no special tool, and its purchase is not justified. For example, you should not buy a grinder if you only need to sand a single workpiece. It is much more practical to buy a drill with a set of attachments and use it as a universal tool.

It should be noted that the choice of accessories for drills is very wide. They are not limited to simple grinding and polishing tools. If necessary, a drill can take on the role of a router, screwdriver, jigsaw, construction mixer, and even metal scissors.

Note! Plus, a drill with an attachment is an excellent option for processing workpieces in hard-to-reach places.

Among the disadvantages of this tool, we can only mention the low efficiency of an electric drill when working with some types of attachments; for example, it is much easier to grind a large area with a full-fledged grinder. However, given the affordable price of even the highest quality attachments, a set of basic ones should be in every home workshop.

An old hand drill - what you can do with it yourself

The hand drill is a trouble-free drilling tool that was extremely popular half a century ago. As soon as electric drills appeared, the demand for hand-held devices decreased, but did not disappear completely.

Today, this tool is probably gathering dust in the garage, and everyone wonders what can be done with an old hand drill. You can try to sell the tool, but don’t rush, you will be able to get no more than 100 rubles for this tool, but by making useful homemade products, you will get a unique unit.

Let us consider in detail what can be made from the tool in question.

Interesting facts about hand drill

Since its invention, the tool in question has been actively used for drilling wooden and metal structures, but such a device is not intended for drilling concrete.

This is due to the fact that the device does not have a shock function, so it is almost impossible to drill a hole in concrete with such a tool. However, home craftsmen found a way out of the situation.

While drilling concrete, periodic hammer blows were applied to the heel, which allowed the drill to advance into the material.

The main drawback of the tool is known to everyone who has ever used it. It involves the need for physical effort. If drilling wood required little effort, when working with metal and concrete, it took at least several hours to achieve results.

The operating principle of the tool in question is simple, and consists of transmitting rotational manipulations from the handle to the tool chuck through a pair of gear drives.

Gears help increase the rotation speed of the chuck, but at the same time reduce the torque. The simple and uncomplicated design makes the tool in question not only repairable, but also durable.

All that is needed to extend the service life is to monitor the amount of lubricant on the gears of the tool.

So, if you remember the design of the hand drill mechanism, as well as what it is, then it’s time to figure out what can be made from this tool.

Device for tightening and unscrewing long screws

To unscrew or screw a long self-tapping screw into wood, you will need to put in a lot of effort. If you've tried doing this with a screwdriver or electric drill, you know that it's quite difficult to do.

The self-tapping screw will “go” into the wood to a certain depth, but it is almost impossible to tighten it completely with electric tools.

It is also extremely difficult to do this manually, so you should call an old hand drill for help.

The tool for screwing or unscrewing long screws does not need to be modified. You just need to clamp a bit in the collet chuck of the device of the appropriate size and get to work. The efficiency of using hand tools when screwing long self-tapping screws is an order of magnitude higher compared to low-power screwdrivers and high-speed electric drills.

!Achieving the result depends on the correct choice of bit for the head of the screw being screwed in.

Making a screwdriver attachment from a hand drill

Few people know what can be done from an old drill, so don't be in a rush to recycle or sell this invaluable tool.

From it you can make a device for a screwdriver, which is designed for screwing and unscrewing various fasteners. These can be not only long self-tapping screws, but also bolts and nuts.

The secret of this device is that you can make a very useful thing out of an old drill, which will allow you to get to hard-to-reach places and then unscrew the fasteners.

The principle of making an attachment or device for a screwdriver from a hand drill is to perform the following manipulations:

- First, we free the tool from unnecessary parts. To do this, remove the chuck from the tool, as well as the handle.

- The thrust heel is also dismantled, which will not be needed in the new device.

- The shaft on which the cartridge was located has a fairly large diameter. It will not be possible to install a shaft of this diameter into a screwdriver chuck, so let’s start grinding it down

- It is recommended to grind the shaft to reduce its diameter on a lathe. The use of an emery wheel or grinder for such purposes is not recommended, since the grinding will be uneven

- To grind a shaft on a lathe, it will first need to be removed from the tool. It's not difficult to do this. In the mechanism, near the bevel gear, which is mounted on the shaft, there is a hole with a cotter pin. This cotter pin must be knocked out, thereby disconnecting the gear from the shaft

- After grinding the shaft down to 8-10 mm on a lathe, it should be installed in place, not forgetting to pin it. The shaft is made of hardened steel, so before grinding it, it is recommended to do heat treatment (heat it with a blowtorch)

- The shaft is driven by a ball bearing, which can be lubricated to extend its life.

- The first part of the work is completed. The shaft that was ground off will be used as a transmission device on the new device. The working element on the device will be the shaft on which the handle is attached

- The second shaft has a specific hexagonal shape, which should also be machined so that socket heads or other attachments can be put on it. The simplest option is to make a square shape from the hexagonal shape of the end protrusion for securing the heads

- This can be done using a grinder and a cutting wheel. In this case, only heads for screwing and unscrewing bolted connections can be installed on such a shaft

- If you plan to use the device for other purposes, then threads can be cut on the shaft by first making it cylindrical and grinding it to the required size

- A drill chuck must be screwed onto the cut thread, into which you can install various attachments - bits, mixers, drills, cutters, etc.

- Please also note that to install the chuck on the secondary shaft of the device, you will also need to cut an internal thread for control fastening of the collet chuck

- To complete the manufacture of the device from an old hand drill, it is necessary to cut off the remaining part on which the thrust foot was attached

- After this, the homemade device is ready for use. All that remains is to fix it in the screwdriver chuck and test it

The advantage of such a device is that it increases the torque. The screwdriver drives a small diameter gear, which transmits force to the larger gear.

A small gear is attached to the large gear, and the force is transmitted to the second large gear, on which the secondary shaft is located, thereby reducing the rotation speed, which means increasing the torque. As a result, the device allows you to unscrew and tear off stuck and rusted bolted connections.

However, do not forget that the main role is played by the screwdriver, which must have the necessary power reserve, otherwise its engine may suffer.

What are the advantages of using an old drill attachment for a screwdriver?

Having figured out what can be done from an outdated hand drill, you need to find out the advantages of this device. These advantages include:

- Torque increases 6-7 times. This means that the force from the screwdriver increases by so many times

- Ability to access bolts and nuts that are in hard-to-reach places

- To make the device, you will not need additional materials, since everything can be done with your own hands.

- No need to purchase additional consumables

In addition to the fact that the device can be used for screwing and unscrewing fasteners and large screws, the device also allows you to quickly tighten and unscrew them. You will definitely be satisfied with this device. How to make it is shown in detail in the video instructions below.

What else can be made from an old hand drill - a quick-driver

The above describes the process of making a homemade product from an old two-speed drill, which has 4 gears. However, there are also single-speed devices that can also be used to make homemade products.

This type of tool can be used to make a screwdriver that can be operated with one hand. This is very convenient when the other hand is busy.

This device is called a quick-twist, and the principle of its manufacture is as follows:

- Take an old clamp or weld a U-shaped frame on which the homemade components will be located

- On one side, weld a fixed handle, as well as a movable trigger (made of steel with a thickness of at least 1.5 mm), which is connected to ¼-1/5 of the bevel gear from the tool

- On the other side of the U-shaped frame, a shaft is attached, on which a cartridge and a bevel gear are fixed, connected to the half-gear from the trigger

- When you press the handle, the cartridge moves due to the transmission of torque

- A bit of the appropriate type is fixed into the chuck, after which you can start working

This homemade product has one drawback - it is necessary to disconnect the bit from the fastening element in order to return the handle to its original position. An example of such an invention is shown in the photo below.

Making a machine for winding coils from a drill

What else can be made from an old hand drill that has been gathering dust in the garage for more than 10 years? Of course, you can make a simple device that will allow you to wind coils. You can wind not only threads and ropes, but also wire, for example, when rewinding electric motors.

The design of such a machine is very simple, and to manufacture it you will need to use the following devices:

- Vice - a fixed handle or tool stop located in a horizontal position is attached to them

- A block of wood of the appropriate size, which is located near the cartridge. This block acts as a stop, holding the tool in a horizontal position

- A reel or other devices are attached to the tool chuck, onto which material is wound - wire, rope, threads, etc.

A photo of such a device is shown in the photo below. If you attach a sharpening wheel to the chuck, the tool can be used as a hand sharpener.

Drilling machine from hand drill

To prevent the old drill from sitting on a shelf in the garage, it is proposed to make a manual drilling machine from it.

The advantage of such a tool is that you can always carefully make a hole in wood, glass, plastic, metal and even ceramic tiles using the appropriate types of drills.

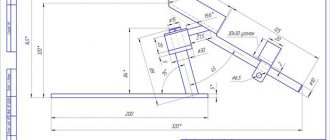

The manufacturing principle is simple, and lies in the fact that you first need to make a frame with a movable frame on which the hand tool will be installed.

- For manufacturing you will need a board, metal corners and cylindrical guides, for example, studs, on which you need to grind off the threads. The length of the pins affects the amount of tool movement

- First, a base is made to which pins are attached, located straight on one side of the wooden frame

- Holes are drilled in the corners for the studs

- These corners with holes are put on studs

- A wooden board of the appropriate size is attached to the corners, which will serve as the basis for securing the tool

- The drill is installed and secured to the moving part

- To ensure smooth movement of the bed, a latch is made that acts on the pin, thereby limiting the movement of the movable bed

The design of the device can be different, and it all depends on your own ingenuity, but the principle of creating such an invention with your own hands is shown in the photo below.

Making a ratchet from an old hand drill

The range of tool capabilities does not end there. You can also make a convenient ratchet wrench from an old and unnecessary hand drill. Moreover, it can be used as a regular wrench, that is, tightened by hand, or in tandem with a screwdriver.

To make the tool, you will need two bevel gears and a drill shaft, as well as steel tubes, plates and a welding machine. The process of making the tool is shown in detail in the video material. The result is a universal hand tool that is definitely stronger than modern ratchet wrenches.

As you can see, a hand drill is a very interesting tool from which you can make various homemade products, expanding your capabilities and also simplifying your work. If you come up with something else that can be done with a hand drill, be sure to share it, as it will help people use an outdated tool to do new things.

Types of nozzles

There are a huge number of accessories for drills. Some of them are designed for ease of drilling, others allow you to create large diameter holes, and others help with grinding and polishing. There are also highly specialized devices, for example, a cutter for a mini-drill for wood, which turns a hand tool into a mini-milling machine.

It is not always necessary to have a strictly vertical hole passing through the entire workpiece. There are times when it is necessary to drill at a precisely specified angle, and also several parallel holes. Here the drilling angle limiter will come to the aid of the master. Basically, these are lightweight structures that fit onto the drill and ensure its precise positioning.

Another useful accessory for an electric drill is a depth stop. The limiter is included in the basic package of delivery of almost any drill. The device is extremely simple - it is a metal rod that does not allow drilling deeper than the specified value.

Features of work using corner adapters

Naturally, when carrying out work using angle attachments, it is necessary to comply with safety regulations. In addition, during work it is advisable to apply the following practical tips:

- The bit or drill must be securely fastened in the adapter, just as the adapter itself must be securely fastened in the main tool;

- If the adapter is installed on a drill, it is preferable to hold it with both hands;

- Regardless of the device used for corner work (drill or screwdriver), you should not put excessive pressure on it;

- It is prohibited to change the operating mode until the rotation of the device has completely stopped;

- The operator must use personal protective equipment during operation;

- Immediately after completing the work, it is forbidden to touch the nozzle, because it will be extremely hot.

For grinding and polishing

One of the most popular attachments are devices for grinding and polishing the surfaces of metal and wooden products. They differ markedly from each other in execution and purpose.

Plate

They are almost a complete analogue of the sanding pads that are used in electric sanders. The only difference is that instead of a connecting thread they have a pin that is clamped into the cartridge. Actually, if necessary, you can use the working part of a grinding machine for a drill, having first screwed a regular bolt into it.

The material from which this nozzle is made can be any. There are metal models, plastic ones, and rubber ones are often found. The latter accurately follow the contours of the workpiece, creating a perfectly flat surface. The cutting part of this attachment is sandpaper. It is sold in the form of ready-made discs that have a special coating that prevents slipping.

Cup

Cup-type attachments are used for roughing the workpiece. With their help, old paintwork is removed from wood, scale is removed from metal, and rust is removed. Structurally, it is a bowl-shaped body, inside of which hard bristles made of springy wire are laid. At the bottom of the cup there is a pin for fixing in the drill chuck.

Disc and fan

Disc nozzles have a structure similar to cup nozzles. The only difference is that the brush is not limited by the size of the body, but, on the contrary, comes out of it, forming a kind of prickly “sun”. The nozzle is convenient for processing large surfaces, but requires caution during operation - one ill-considered movement is enough to damage the product and possibly cause injury.

Fan nozzles have a similar design. Their working part is petals made of sandpaper on a fabric base. This attachment is convenient for working with aluminum parts and cleaning cast workpieces from slag.

Drum or cylindrical

Nozzles in the shape of a cylinder, on the outside of which an abrasive material (sandpaper) is fixed, are intended for processing the internal surfaces of cylindrical holes. Most often they are made of metal or rubber. By selecting the grain size of the skin with this device, you can process a wide variety of materials, from wood to metal and glass.

Polishing attachments

The final stage of product processing is its polishing. Polish parts that have been milled and varnished. This procedure is performed using special pastes that are applied to a soft moving surface. Felt, leather, foam rubber or fabric can be used as such. Structurally, this attachment is a disk made of soft material, in the center of which there is a pin for fastening in the cartridge.

How to make a drill press

A stand for a drill for vertical drilling is not difficult to make. More effort will be required when constructing a drilling machine. This device is large in size. But if you follow the recommendations, you can make an improved compact device.

To make a drilling machine yourself, you need to use a stand, the creation of which was described in the previous paragraph. Next you need to complete the following steps:

- Disassemble the drilling tool and remove the motor and starting device from it.

- Secure the engine to the stand using clamps.

- Prepare a separate box in which to install the starting device.

- Increase the length of the wires from the starter and install the box on the base of the stand.

- Firmly secure the cartridge by first placing it on the shaft.

The small drilling machine is ready. You don’t have to disassemble the tool, but then the machine will turn out to be bulky. Or it is possible to use engines from any household appliance. In this case, you will need to purchase an additional cartridge.

Drilling machine device

For curved cutting

There is an interesting device that allows you to turn a drill into a jigsaw. The device is fixed in a chuck and makes it possible to cut wood-based sheet material, plastic and even thin sheet metal. The cutting tool is a movable file.

This device is a useful thing in the household, but the nozzle has a fairly high price. If you need to make curved cuts frequently, you should consider purchasing an inexpensive jigsaw.

There are other similar devices. Drill attachments for drilling round holes in wood are very popular. They help overcome the drill size limitation typical for most models and drill a hole of any diameter.

Classification of attachments for wood processing

Prices are indicative, in relation to the Moscow region, in Russian rubles

By type of abrasive

- Hard fabric.

- Foam rubber.

- Plastic.

- Sandpaper of different grain sizes.

- Rubber.

- Cord brush.

According to the degree of wood processing

- Abrasive (rough).

- Grinding.

- Polishing pads (soft and super-soft pads).

By execution

Depending on the configuration, the attachments are used not only for surface treatment of wood. They can be used to grind (polish) holes (as a replacement for a sander). This is easy to do with cylindrical (thin) or conical devices.

Plate attachments

Available in several modifications. The difference is in the form of abrasive material. If wood sanding is required, then it is rubber (the more preferable option) or plastic. For polishing, it is advisable to purchase attachments with fine-grained sandpaper fixed on the working part. They can achieve higher quality (fine) wood processing.

Recommendation: Effective processing of wood with a plate-type drill attachment is difficult because it is difficult to hold the drill in a strictly vertical position. To achieve a good result, it is advisable to fix the tool and move the workpiece relative to the working part. The machine for attaching the drill is easy to assemble yourself.

There are nozzles on sale that provide for adjusting the angle of the abrasive mounting pin. But they are quite expensive, and not every store can buy them. Therefore, a machine with the ability to change the position of the drill is a more acceptable solution.

Drum attachments

Mainly used for processing the end parts of wooden workpieces and holes. They have a cylindrical shape and differ in the way the sanding tape is attached - using a bolt or special inflatable blocks. Some types of attachments of this type are also used in everyday life for plucking (at low speed) birds when it comes to a large amount of work.

Cup attachments

The assortment is significant. The differences are in size and abrasive material. These can be either metal “hairs” (hard wire) or thick fabric, leather, felt and even foam rubber. The choice of device is determined by the desired degree of wood processing. If you want to achieve a sharper highlighting of the texture of the material, then the wood pulp is sampled using just such attachments.

A variety of devices in this group are disk attachments. The difference is clear from the figure (the villi are located diametrically).

This type of attachment can also include fan devices. They are also called petal.

The main purpose is to polish wood at the final stage of processing.

For tightening screws

Perhaps this is the simplest and most popular attachment of all existing ones; in essence, it is a hardened bit with a cross for different sizes of screws. It is enough to clamp it into the chuck, and the electric drill can easily replace the screwdriver. The only condition for using the attachment is that the drill must have a speed regulator.

More complex devices are also available for sale that allow screws to be tightened at different angles. Separately, flexible devices with a cable in a sheath can be noted. With their help you can work in the most difficult to reach places.

Homemade drill accessories

Despite the fact that the industry offers a wide range of attachments, both in sets and individually, home craftsmen often make various accessories for the drill with their own hands. Such a desire can be caused by a number of reasons. Some people don’t have a suitable attachment at the right time, others are not satisfied with the quality of those that go on sale.

Drilling angle limiter

A very useful and very simple device is the angle limiter. Separately, it is worth noting that this attachment performs two functions at once. It provides a precise drill angle and limits the depth of the hole.

The main part of the nozzle is a clamp with a thickening in the upper part. The clamp is attached to the drill body. Two holes with a diameter of 6 mm are made in the thickening. A thrust bracket is bent from a wire of the same diameter at the required angle. A stop is attached to the bracket, allowing you to adjust the depth of the hole. It would be useful to make several replacement brackets with the most popular parameters.

For cutting round workpieces

The basis of many homemade products is a circle made of plywood or other sheet material. Most often it is cut using a jigsaw, but the same can be done using a drill. To do this, you just need to make a simple holder that works on the principle of a compass.

The device is a pin that is attached to the drill body with a clamp. The vertical stop moves along the pin and is fixed in the required position. The stop is held on the workpiece with its pointed end, and the rotating drill cuts out a circle. Instead of a drill, it is better to use a cylindrical cutter; with its help it is easy to make a high-quality cut without much effort.

Adapter for miniature drills

The chuck of a conventional drill has restrictions on the maximum and minimum diameter of the drill, and often it is necessary to make a hole with a mini-drill with a diameter of up to 0.1 mm. A standard chuck cannot compress a small shank, but if you first clamp the drill into a collet chuck for an electric motor, and then fix it in the drill chuck, the problem will disappear.

Device bed

The frame for the drilling device from the drill is made of metal (10 mm thick) or wooden (more than 20 mm thick) sheet. The massiveness of the bed that you will use as a base directly depends on the power of the drill used. The dimensions of the frame for a drill machine depend on the specifics of the work performed on such equipment. You can use the following recommendations for choosing frame dimensions:

- machines for vertical drilling - 500x500 mm;

- equipment for performing various technological operations - 1000x500 mm.

The metal frame is a thick plate with welded corners

The frame, made of metal or wooden sheets, is a very simple structure. A stand is placed vertically on it, the stable position of which is ensured by a special support. Such structural elements can be secured to each other using screw connections.