A jack is a simple mechanical device that is used to lift a car. This is necessary to replace a tire or wheel, or repairs that require access to the bottom. They resort to using a jack in case of independent repairs outside of a car service. But jacks are used not only in relation to cars. They are often used to install structures at a given level or to lift loads

For any jack, lifting capacity, lifting height and pick-up are important. Often in the simplest jack these characteristics are weak and are not enough for the needs of the user. In this case, you can make an electric jack with your own hands. It will be more powerful and easier to use, you just need to tinker in the workshop. The electric version is much more practical, because it does not require human movements and can provide greater height.

Do-it-yourself electric jack (10 photos + video)

There is too little space in my garage and if you drive a car into it, you can only walk sideways on both sides of it; in case of repairs, when you need to jack up the car, you had to turn the jack in a very awkward position. At first I had a small rolling jack, if it was easier to position it at the right angle, but laziness is the main engine of progress, and having found in the garage a couple of unnecessary (but quite working) motors for window lifters from the TAZ and a standard jack from my Lancer, I decided to experiment, this is what I found in the garage:

The electric window regulator in my case is from a VAZ2110. The drive with cables is not useful to us, so we unscrew it and leave only the motor with the gearbox. You also need a tetrahedral head whose sides have 7mm edges.

I took the jack from a Lancer, but you can use any diamond-shaped screw jack. The fastenings can be made from strips of metal; I used furniture corners found in the garage.

we cut them and give them the required configuration and attach them to the gearbox

Next, we weld the mount and the head on the gearbox to the jack.

This design is controlled by a button from the same ESP

The tests were carried out on my father's Passat, powered by a spare battery; if you connect it to a running car, it will turn a little more vigorously.

Most popular models

Despite the fact that electronic devices appeared not so long ago, both leaders and outsiders have already appeared among them. The most popular among users of such products are the products of the German company Varta. Nevertheless, the American company Turbo does not lag behind its competitor.

Jacks from Varta

The main disadvantage is the not very outstanding load capacity - up to 2 tons. To some extent, the disadvantages include the heavy weight - 6 kg. However, this is a kind of “side effect” of the one-piece design, which gives the jack excellent stability.

According to driver reviews, there are no problems with the installation or operation of this model. There are no difficulties with installing or lifting the car. However, if the engine is turned off, the device operates noisier due to the reduced battery voltage.

In addition to the jack described above, many drivers like another model from the same company - V-CJ2.11W. The entire mechanism here is also solid and made of stainless alloys. By analogy with the previous device, this product also has a special remote control, which has only 2 buttons - for raising and lowering the machine. However, if power cannot be provided, a special lever is provided on the device for lowering.

V-CJ2.11W also does not have a large load capacity. The maximum weight is 2 tons. In addition, some drivers have problems during installation, since this device must be located on a flat surface.

Electric jack from Turbo

model Jack GB-A20

Drivers praise this product for its ease of use, excellent quality and lack of strict requirements for a flat surface. In addition, even when the engine is turned off, this unit operates without unnecessary noise.

Electric car jacks are quite specific devices that have not yet passed the “test of time.” Nevertheless, quite a large number of drivers are happy to use these products. Maybe it's time for you to join them?

Types and comparative characteristics

Probably every good owner has a jack in his tool kit. And those who often have to lift loads, repair a car, or change wheels know that, according to safety regulations, it is necessary to install several units of lifting tools for insurance.

Of course, an ordinary solid object can be used as a backup option. For example, everyone is familiar with laying bricks. But such a makeshift approach simply cannot inspire the necessary confidence. Therefore, sometimes you can approach the issue of safety more thoroughly and make a homemade jack for the garage. Moreover, this work does not involve any special difficulties.

The following types are popular today:

Each type of jack has its own advantages and disadvantages. Some are simpler in design (and therefore easier to assemble with your own hands), while others are considered the most reliable and powerful.

Screw

The design of a screw jack is as simple as possible and time-tested. For this reason, these types are considered the most common. Often, it is precisely these jacks that are included in standard motorist kits.

But, despite the fact that they are easy to assemble, it will be very difficult to reproduce the mechanism yourself, because you will need to repeat the special thread pattern that is applied to the lifting lever and stop. The teeth are given a trapezoidal shape for the following reasons:

- such a thread has a self-extinguishing function (does not unwind under the influence of a load);

- the transmitting force is increased many times (use limits: from 500 kilograms to 10 tons), which ensures ease of operation.

Such lifting tools are no more expensive than other analogues, so there is little point in creating a homemade screw jack.

Rack and pinion

Rack structures are used primarily for lifting loads to great heights. They also have optimally calculated force.

The mechanism is also quite complex. The technological effectiveness lies in the fact that the lever gradually sets in motion the gear, which moves along a vertical rack with special locking holes.

It is difficult to make a rack structure with your own hands.

Pneumatic

Pneumatic or bottle jacks work on the principle of pumping compressed air into a special container, which squeezes out the rod and lifts the load. Such models have good load capacity, and the range is limited only by the length of the lifting rack.

You can make a homemade pneumatic design by purchasing only the main mechanism with compressed air. And it is quite possible to make levers and additional parts (wheels, stops) with your own hands, having previously calculated everything.

Hydraulic

Perhaps the best option for a do-it-yourself lifting mechanism is a hydraulic one. As a rule, the design involves the creation of a rolling mechanism on wheels and ease of lifting.

The principle of operation of a hydraulic jack is the same as that of a pneumatic one. It is not compressed air that lifts the rod, but oil, which has a low compression ratio. For this reason, hydraulic jacks are used in professional auto repair shops (some models are capable of lifting loads of up to 20 tons).

And, of course, if you reproduce the design in your own garage, you will get a useful and irreplaceable tool.

Varieties according to control method

Before you move on to studying an electric car jack, you need to know what types of such tools are available for sale and understand what is the advantage of models with an electric drive. Based on the type of control, car lifts are divided into the following categories:

- Mechanical.

- Hydraulic.

- Pneumatic (inflatable).

- Electrical.

Mechanical auto jacks are the easiest to use, but most trouble-free devices. They are mainly used for working with passenger cars due to their low load capacity. Structurally, they can be made in a rack or screw version.

Hydraulic jacks operate on the principles of fluid pressure in lifting cylinders. They have maximum load capacity and pressure ratio, but are demanding in terms of routine maintenance.

Pneumatic lifts consist of an air chamber, which, under air pressure, expands and lifts the car. Such a tool has a good load-carrying capacity, but is rarely used for large, heavy vehicles due to the need for a compressor to create the appropriate force.

How to make a garage jack with your own hands

Among the large number of schemes for home-made devices, screw and hydraulic mechanisms are popular. And if in the first case excellent thread cutting skills are required (it is made in complex shapes), then the hydraulic option is easier to make.

Building a circuit

The hydraulic homemade jack is great for DIY use. And there is no doubt about its ability to ensure safety, because the oil cannot unexpectedly lose its properties and fall from its maintained level. Therefore, when working, it is important to pay attention, perhaps, only to the strength of the levers and their reliability.

Popular diagram of a homemade hydraulic jack

Selection of material and preparation of tools

In a homemade design, it is important to take care of strength. Therefore, metal is chosen as a building material. For the frame use:

- channel 10 millimeters;

- channel 12;

- rods 12 millimeters;

- wheels for moving;

- rubber part for cup device;

- fastening material.

To adjust the material you will need:

- welding machine;

- grinder with circles for cutting metal and grinding;

- metal drills;

- wrenches and screwdrivers;

- measuring tool: tape measure, ruler, marker.

The supporting part is secured by welding to create a solid and strong structure. The upper rotating parts are attached to bolts or rods.

Assembly of the structure

First, an L-shaped base is created from a 12 mm channel. A hydraulic bottle jack is attached to it. Afterwards, using bolts, the upper lip is attached to the base, on which the jack rod will act. The rod is secured using a rotating rod.

Additional equipment in production are wheels (suitable from old household appliances). They will help you move the large structure around the garage.

An example of a homemade hydraulic jack

How to choose a quality tool: comparison of manufacturers and models

Despite the fact that electric jacks have already taken one of the leading positions on the market, there are several brands that are especially popular among both experienced and novice car enthusiasts.

The most popular manufacturers include the German company Varta and the American company Turbo. American electric jack

To manufacture the well-known modification of the diamond-shaped electric jack V-CJ2.02, a steel alloy is used that does not rust. With a one-piece design that can be detached individually, these jacks offer high reliability and excellent stability. In the instructions, the manufacturer indicates that the design can be used even if it is snowing or raining outside.

Important! The main disadvantage of an electric car jack is the relatively low load capacity, which is no more than 2 tons, as well as the large weight of the assembled Kraftool jack - up to 6 kg. When reading the reviews of motorists, we can conclude that practically no problems arise during the operation of such a mechanism.

Checking for correct operation

Of course, after completing the assembly, it is important to check the resulting homemade jack under “combat conditions.” The hydraulics are designed to lift even a heavy vehicle. Therefore, we check the work under load. A car is best. By the way, tests will reveal design flaws and errors.

And only after checking (even repeatedly) the homemade jack is ready for full operation.

Electric jack VARTA V-CJ2.11W

Long searches in stores and on the Internet were a little disappointing: there are only a few models on sale. We found two electrically driven rhombic mechanisms and two pneumatic lifts, powered either by an electric compressor or by exhaust gases. In any case, they all live up to the title and save the owner’s energy, requiring in return only some mental effort. What we liked the most was the electric jack. Pneumatic ones lost in the “Safety” and “Ease of Use” categories, as well as in price. However, they are well suited for changing wheels off-road.

Electric jack VARTA V-CJ2.11W

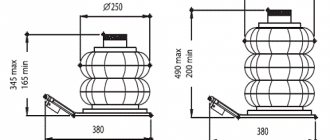

Designed for vehicles weighing up to 2 tons,

lifting height 180–400 mm,

impact wrench torque 380 Nm

Approximate price - 3500 rubles.

In fact, a whole set of tools for changing wheels: in a plastic box with convenient locks, in addition to the jack itself, there is also an electric impact wrench with an extension and 17, 19, 21 and 23 mm heads! The manufacturer also did not skimp on spare fuses and an adapter for connecting directly to the battery terminals. The cord is long enough to reach any of the wheels. The support platform was made from a bolt, cutting a groove in its head. The minimum height of the threshold of a car must be at least 160 mm (many cars cannot be raised this way). The bolt head is not covered with anything: it will definitely damage the paint on the threshold. With the engine not running, the jack works very loudly, but sluggishly. It seems that the motor is about to jam or burn out. The mechanism should be set almost level, otherwise it will turn inside out. The LED in the control panel will help you not to miss in the dark. If the jack suddenly breaks, it can be lowered using the included plastic lever, but this is a very slow process. The impact wrench more than exceeds the factory torque standards. You just have to wait for the eighth or tenth blow. Long, but effortless.

Electric jack Turbo Jack GB-A20

Choice of ZR

Nominal load capacity 2000 kg,

maximum - 3000 kg,

lifting height 120–350 mm

Approximate price - 2300 rubles.

heating elements

Such a device has a number of pros and cons. Let's start with the advantages:

- Fast heating at the power specified by the manufacturer.

- Easy installation and possibility of direct connection to the thermostat.

- Stable load resistance.

The disadvantages include susceptibility to deformation due to mechanical stress, as well as connection only to a network with a voltage of 220 V. To reverse, you need to purchase an inverter of a suitable modification. Another significant drawback of this method of heating incubators is inertia.

Electric jack Turbo Jack GB-A20

Another diamond jack with an electric motor. At first it may seem that this is a clone of the VARTA V-CJ2.11W, only without a wrench. However, this is not quite true. The supporting platform here is larger, with a diameter of 50 mm, and is also made of plastic - the risk of damaging the paint is minimal. The lower edge of the jack can be lowered to a minimum level of 110 mm - this will fit under almost any car. With the engine not running, the jack operates quietly, without strain. With it running, it’s a little faster and a little quieter. The plastic locks of the suitcase, which in this case is smaller in size due to the lack of a wrench, open and close with great force. The kit includes three fuses, an adapter with alligator clips for connecting directly to the battery terminals and a plastic crank for emergency lowering of the jack.

Pneumatic jack "Atoll-AG 47×61"

Load capacity 3 t,

working pressure up to 0.7 atm,

lifting height 50–610 mm

Ceramic samples

The ceramic heating element (12 volts) is a pulse unit consisting of a pair of working parts. The voltage is measured with a standard multimeter. The exact characteristics are indicated in the passport, and the nominal value is 12 volts with the possibility of breaking the circuit after reaching the temperature limit of 230 degrees. The thermal fuse provided in the design is responsible for this position.

You can make a miniature heating element (12 volts) yourself. To do this, you will need nichrome with a diameter of up to 0.1 mm, slightly larger steel wire and asbestos thread with a thin sewing needle. First, the wire winding made of steel and nichrome is securely fixed by twisting.

Next, a circuit is assembled that serves as a determinant of the number of coils of the heating coil. After connection, the voltage is gradually increased, according to the readings of the voltmeter and ammeter. At a value of 12 volts, the approximate power of the device will be 5.5 W. This invention can be used to operate an electric soldering iron or similar tools.

Pneumatic jack "Atoll-AG 47×61"

Designed to work with a compressor. In addition to the inflatable pillow, we found in a convenient bag an adapter for connecting a compressor, two protective mats, a repair kit (glue, patches), and gloves.

The most difficult thing when working with such a jack is to place it correctly under the car: it is necessary that the upper and lower platforms are strictly under each other, otherwise the cushion tends to slide out from under the body to the side when inflated. We succeeded on the third (!) attempt. A compressor with a capacity of 35 l/min lifted the Daewoo Matiz in 4 minutes, and the Ford Mondeo in 4 minutes 20 seconds. Due to the constant tendency towards misalignment (the problem would not arise if the cushion was made like the bellows of an accordion), such a jack is unlikely to be a replacement for a standard one, but it is just right for lifting a car stuck in mud or deep snow.

By the way, we found another use for the Atoll: it’s very comfortable and not cold to sit on!

Inflatable jack "SOROKIN 3.693"

with exhaust hose 3.699

Load capacity 3 t,

lifting height 50–460 mm

Approximate price - 3500 rubles.

Design features of the electric jack

Before buying an electric jack for your car, it is recommended that you familiarize yourself with all existing models and varieties of such designs. Familiarization with the available advantages and disadvantages of the Kraft hydraulic 3 t rolling jack will help you avoid purchasing a counterfeit unit. So, as for the types of car lifts, they are divided into the following groups:

Electric jack

- mechanical;

- hydraulic;

- electrical;

- pneumatic or inflatable.

The simplest and most reliable design is a mechanical jack. But the small lifting capacity allows the use of mechanical lifts only for the repair of passenger cars. The design of a mechanical automotive device is characterized by the presence of a screw or rack and pinion mechanism.

The operation of the hydraulic unit is carried out thanks to the pressure of a special oil, which, in turn, increases the load capacity and transmission of pressure forces of the mechanism several times.

The main disadvantage of hydraulic pumps is the constant need for maintenance.

Diamond jack 2 tons Kraft KT 800025 is represented by an inflatable cushion, for the manufacture of which strong material is used. Due to the fact that the chamber in the cylinder is exposed to air, it gradually begins to inflate, as a result of which the vehicle rises. The advantages of such tools include ease of operation and good load-carrying capacity, but even so, pneumatic jacks are extremely rare. This fact can be explained by the fact that the use of such a device is possible only with the help of a special compressor.

Even though electrical structures require electricity to operate in most cases, they can also operate autonomously.

Experienced motorists claim that there is no need to regularly connect the Kraft KT 820003 jack to a power outlet.

Often, in order to supply the structure with electricity, it is enough just to connect the jack to the on-board electrical network in the vehicle. The engine may be switched off. In order to bring the electric jack into working condition, you need to perform a number of the following functions:

- Using the cigarette lighter, you need to connect the device to the network.

- The signal that the unit has been connected enters the microcircuit through the wires.

- After which the microcircuit transmits a signal to the working cylinder of the jack.

Electric jack in action Please note! The required height for lifting the car is set by the driver using the control panel, which sends data to the microcircuit and the engine, as a result of which the structure begins to work.

Inflatable jack "SOROKIN 3.693"

An additional hose with a splitter for two exhaust pipes allows you to inflate this jack without the use of a compressor. Structurally, it is similar to Atoll-AG, but more compact and the material is thinner. Once again you will have to suffer, correctly positioning the support platforms so that the jack does not squeeze itself out from under the car. Thanks to the smaller cushion volume and exhaust gas pressure, the jack fills up much faster - the Mondeo lifted the rear wheel in just 40 seconds, and this at minimum idle speed! If you step on the gas, the car literally takes off. But when pumping, it is necessary to press the rubber cone as tightly as possible to the pipe and hold it with your hand so that it does not jump off under the pressure of the gases. You can’t do it without an assistant, but this is not the main disadvantage. The hose turned out to be short: it was not long enough to get to the right front wheel of the Ford. And one more thing: with a non-standard exhaust pipe tip, this thing is useless. Just remember the Honda Civic with its exhaust triangle!

How to make a jack with your own hands: instructions with photos and videos

Almost every person now has a car. For some, it acts as a source of income - taxis, buses, cargo transportation, etc. Some people just need it for transportation. But for true car enthusiasts, a car is the closest friend that helps out in difficult times and never lets you down. They take care of it, treat it with care, and repair it on time. Often such people are friends with technology in life and love the instrument. They like to do something with their own hands, because it brings great pleasure. Often you end up with some useful and interesting things for your car.

For example, it is a good idea to make a jack. Indeed, no motorist can do without this device. Many, of course, will now say that it is easier to go and buy it in a store. But for a true mechanic, building such a thing, especially for his car, will not be difficult. It is only important to know how to make a jack and what it will consist of.

Table of contents:

Types of jacks

Before you start making a car jack with your own hands, you need to decide what design it will be. To do this, you need to know the main types of these devices that can be found in stores:

- Rack and pinion. This type has been used for a very long time. It is based on a long metal strip with holes, a lever and a ratchet with a perpendicular end. By pulling the lever down, the ratchet lifts the weight along with it. By pulling it upward, it is triggered, locking itself into one of the nearest holes on the rail along with the load. Then the cycle repeats again;

These are the main types of jacks that are used most often. They are classified precisely by the type of force used (mechanical, hydraulic, etc.), but there are many varieties of them. For example, hydraulic devices can be haulage, cylindrical, trailed, or two-level. That is, there is only one type of jack, but there are several types. Therefore, there is a large choice in order to independently make your own model using a prototype.

Device performance characteristics

Any jack is evaluated according to individual parameters that determine its scope of application. In order for the tool to serve for a long time and without frequent repairs, these requirements must be met. The technical characteristics of the jacks are as follows:

- Load capacity - the maximum weight of an object for which the jack is adapted to lift. It is measured in tons or kilograms.

- Pickup height is the smallest gap between the floor, the ground, another base on which the lifting device rests, and its part for gripping the car in the lowest position.

- Lifting height is the highest position of the grip relative to the supporting surface. The working stroke is the difference between the extreme gripping points.

- Stability is the ability of a lift to remain in one plane under any vertical or horizontal forces aimed at bringing it out of equilibrium.

- Handle force is the force applied when lifting weights to the required level. This indicator is related to the mass of the load being lifted and the number of drive cycles to lift it to the top position. It is individual for each type of jack.

- Gear ratio is the ratio of the length of the hydraulic pump plunger to the length of the jack plunger. (The plunger is a special piston that is used in mechanisms that require the creation of higher pressure compared to conventional piston pumps).

- Versatility is the ability of the lifting mechanism to work with machines of different weights and regardless of their location.

Skills required when making a jack

It’s worth saying right away that needlework is not an easy task and requires certain skills. In our case, these are practically all the abilities that a novice mechanic should have:

- welding is the most basic thing required when working with metal. Since the structure will be assembled from scratch, it will only need to be welded. Moreover, this must be done with high quality so that the end result is a durable product;

- cutting - it is enough to be able to cut iron with a grinder. It’s good if you have the skill of cutting with an oxygen torch;

- processing - without the skill of using a file or a grinding machine it will be difficult;

- turning do without it, but if you are interested in it, it will be much easier when manufacturing and processing some parts;

- painting - a handmade item must be painted.

If you have the above skills, then no problems should arise in the process of making a jack. The higher the level of mastery of the tool, the better the product will be.

Tools and materials for a homemade jack

In order to make a jack, you must have the right tool. The first step is welding, since with its help the assembly will take place. It is desirable that it be a semi-automatic device with carbon dioxide. Then the seams will be much smoother and there will be no excess slag. Second, and no less important, is the grinder . It’s good if the assortment includes both small and large. With their help you will cut blanks from steel. You will also need a drill , because you will have to make more than one hole. To easily process iron parts, you definitely need an electric sharpener . It is key in the fitting process. In addition, it is advisable to have hand tools : files, needle files, whetstones, hammers, screwdrivers, rasps, levers with a set of taps, sledgehammers, vices, etc. The more devices you have at hand, the easier the manufacturing process will seem.

DIY hydraulic rolling jack

The base (both the lifting arm and the lifting platform) of a hydraulic jack can be made from a channel. A conventional hydraulic bottle jack is used for lifting force. To move the jack, you can attach wheels (can be replaced with bearings, rollers or something similar).

Construction of a homemade hydraulic rolling jack

It is recommended to install the bottle jack on a movable “swing” platform, since during operation the jack slightly changes its angle, and some compensation for movements is required. The platform should sway slightly from side to side. It can be made from the same channel by drilling a through hole in the lifting base and placing the “swing” on the bolt so that there is a small gap of 0.5-1 cm between the base and the platform.

Movable platform for bottle jack

To increase the strength of the structure, it is advisable to make braces from rods on both sides of the base. The thicker the rods, the better. They are welded to the base.

The device operates from a bottle jack. When it is moved by a special handle-rod, it rises, which moves the lifting arm upward.

The process of working a homemade hydraulic rolling jack

A drawing of such a hydraulic jack for making it yourself is shown in the image below:

Drawing of a hydraulic rolling jack that you can make yourself

Also watch a few videos where you can learn more about how to make a hydraulic jack with your own hands:

Lift design

Anyone who has ever seen a car can imagine what a car jack is like. It must be included in the necessary tool kit of any machine. A good driver will always check its availability before leaving, since when changing the wheels with something, you need to lift the car. Often, looking into the trunk of a new car, you can see the simplest and most unreliable diamond-shaped lift. Then there is a need to replace it and purchase a more modern tool, which, according to its design, is divided into several types:

- Rhombic.

- Screw.

- Roll-on.

- Rack and pinion.

DIY pneumatic jack

As an example, we will also consider a pneumatic device, which is the easiest to make . So, you will need:

- Air bag. The main working part, which can be found at a disassembly site or on the market. Its role can be played by an ordinary rubber cylinder from the air suspension of a car. It is best suited from a cargo one, since it is much stronger and can withstand strong pressure, which increases the lifting moment. But it has a large height, so placing such a jack under a car with low ground clearance will not always work;

- Two bolts. They will be needed to make a valve for the pillow. In general, it initially has a factory threaded hole into which a high-pressure tube is screwed. Now, instead of it, we need to select a bolt of the same diameter, and then find another one that will serve as the top cover. They need to be drilled so that when connected to each other, a cavity is formed inside them. Then we place the ball from the bearing and a strong fitting for inflation inside the upper bolt. Now the entire structure can be welded and screwed into the hole of the pillow.

In principle, such a homemade device can easily lift any passenger car. It is enough to place the pneumatic cylinder under the platform on the bottom and connect the high pressure hose to the fitting. By supplying compressed air, the cushion will begin to rise with the car.

The principle of operation of a homemade pneumatic jack

For convenience, such a jack can be completed by inventing a reliable platform with wheels. Thus, if you take a cylinder for disassembly, then a home-made device costs almost pennies.

Improved air jack on wheels

You can also watch several videos on how to make a pneumatic jack with your own hands:

The most successful models

Trade enterprises offer a huge number of different models of electrified car lifts. They amaze with their functionality and versatility. The choice is very difficult. Many people try their hand at making an electric jack with their own hands, to suit their personal requirements. But we can give as an example a couple of samples that will not amaze with unusual properties, but are quite typical for this segment and will satisfy the widest needs of car enthusiasts.

The model of the electro-hydraulic jack 12 volts, with a wrench, in the case Sorokin 3. 562 is a balanced multi-purpose device, equipped with additional accessories. It is suitable even for SUV owners, since the load capacity of this model has been increased to three tons. In addition to its usual purpose, it can be used as a compressor or flashlight. The possibility of unscrewing nuts from other objects is indicated by the name itself. It is powered universally, both from its own battery and from the car’s generator. This sample has all the positive qualities of instruments of this type.

Another representative of electric jacks that enjoys the trust of consumers is the Turbo Jack GB - A20 model. This model is also not deprived of advantages in the form of load capacity like the previous model, as well as a pickup level reduced to 110 millimeters.

Car enthusiasts appreciate this modification for its high-quality manufacturing and performance on any surface. This jack is distinguished by a reduced noise level.

Every year the number of cars on the roads of our country increases. The number of drivers who prefer modern and functional electric devices is also growing. Manufacturers are bringing new models of devices to the market in the fight for the love and wallets of motorists.

>

| SHARE: |

Recommendations and tips

The most important question remains. Is it even worth making the jack yourself? The answers to it may be different, however, after weighing all the nuances, you can come to a final conclusion. First, it’s worth understanding the cost. It is clear that no one will buy a tool for manufacturing, however, you will need material and some parts that will still have to be purchased. It is quite possible to buy a new factory jack for 5,000 rubles. The expenses for a homemade one will depend on what kind and type it is. So, making a hydraulic one will be the most expensive, but the pneumatic one discussed above is the cheapest.

In general, the cost of a jack is not so much that you have to rack your brains and make it yourself. If you don't care about it, then it's better not to bother with it and buy a new one at the store. But, if the process itself is interesting and you want to make something, then this is a great idea to test your skills. You might even be able to save 1-2 thousand rubles. That is, when there is a desire to do it, try, be smart and achieve results. But if the process of making a jack is not interesting to you, then it is better to postpone this matter.

The main thing to remember is safety measures. Any tool in inexperienced hands can cause serious injury. Also remember to wear safety glasses when working on metal and when welding to protect your eyes.

Useful modifications

A heating element for an incubator (12 volts) can be made in several ways. The first of them is heating using a carbon cord. Below are its features:

- Possible connection – 12-24 V.

- The device provides fast heating and active cooling.

- Temperature changes are eliminated due to the absence of inertia.

- With proper maintenance and braiding, the device will last for many years.

- It is possible to directly connect to the thermostat without fear of relay failure.

- Scope of application - heating floors or walls in utility rooms, residential premises, incubators, evidence, maintaining the microclimate in greenhouses and beds.

Winding is done carefully, using non-conducting parts made of textolite, ceramics or similar materials. The cord is connected to crimp sleeves to which a copper wire is connected. The heating level depends directly on the network voltage, which requires the inclusion of a stabilizer in the design.