The most powerful bow as a hand weapon (excluding crossbow) is considered to be a compound bow. It is a very powerful throwing weapon with pleasant ergonomics (or even design). The projectile exit speed is about 90-100 m/sec. The design is initially capable of confusing due to the presence of a large number of elements of very different shapes. An arrow is usually used as a projectile - long, with feathers and a feathery tail.

Compound bow.

What is a compound bow

The essence of the design is the presence of a pair or several pairs of asymmetrical blocks with eccentric axes. This device works as follows:

- The tension of the bowstring bends the shoulders, which are tightened by cables.

- The cables go through blocks that wind them, twisting and moving around their axis.

- The tension of the bowstring and the shape of the blocks create potential energy, which, when the bowstring is released (when the fingers unclench and nothing holds the bowstring), turns into kinetic energy.

- In this case, the extremely sharp, impulsive movement of the bowstring gives movement to the arrow, which leaves the bow guides with high acceleration and rushes in a certain direction.

The high pulling force of the bowstring, which seems directly proportional to the tension force, is created largely thanks to the blocks: contrary to the first impression, the archer's muscular force expenditure becomes lower, and the bow's tension becomes greater.

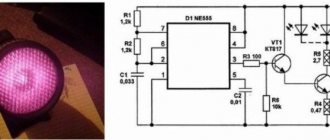

Compound bow. The most interesting thing is the distribution of the appearance of energy over time. Maximum kinetics is imparted to the arrow not at the very beginning, when the shoulders begin to work, but at the end, when the blocks are activated, which rotate the shoulders with acceleration. This adds acceleration to the arrow.

The downside to the operation of the blocks is that when collecting the cables and tightening the bowstring, a certain moment of their peculiar bending occurs: the block is rotated, after which the reverse opening requires a little effort.

This leads to the fact that holding a compound bow in a tensioned state is much less energy intensive than for other designs. As a result, aiming and waiting are performed for an increased amount of time.

These and some other features of the compound bow make it an almost ideal weapon for a hunter or fisherman.

The evolution of the bow to a block design brought its production into the enterprise: while a conventional bow was made by hand, with the development of technology and increasing demands, such a design became quite complex. However, it is possible to create a compound bow on your own, even at home.

Varieties

Among all the popular models of bows for hunting, the following classification can be distinguished. Each option is more complex in design than the previous one:

- The traditional bow for hunting seems to have come to us from our ancestors - similar weapons were used in the old days. It is made only based on the dimensions of the hunter - height and arm span. The design is simple, so you can easily make a homemade bow for hunting; you only need one piece of wood to make it. They are not very powerful, although they are quite large, so they are unlikely to be suitable for a modern hunting enthusiast.

- The composite model is made on a wooden (modern bows are made from composite) base, which is supplemented with internal linings and tendons. The main element requires careful preparation, however, the finished products are much closer in shape to sports models than simple ones.

- A compound bow is a powerful hunting weapon that has sufficient ergonomics and a high arrow launch speed (90 m/s or more). Their production has moved to factories, since the design of the blocks is difficult for manual assembly, and it is unlikely that you will come across a good homemade compound bow. For the most part, these models are sporting, but such weapons are best suited for hunting purposes.

Tools and materials

Compound onions are made in a number of ways and in various designs:

- from lumber and round wheels;

- from plastic pipes (PVC or other elastic polymer) or skis;

- from metal springs or simply metal plates with high shock absorption.

It is possible to create a design yourself. People have long tried different methods in large numbers.

For example, a tolerable onion at home is made from the following materials:

- lumber bars without visible defects, dimensions – 50x4x2 cm, 2 units;

- bars measuring 17x4x2 cm, 2 units. (cuts are made in each for springs);

- bars with a length of 45 cm, 2 units;

- springs – 2 units; Necessary parts for collecting onions.

- metal wheels, 2 pcs. (symmetrical ones are also allowed - the size is suitable for a car window lift);

- steel furniture corner, 8 units;

- steel door hinges (suitable for furniture), 2 units;

- corners with a width of up to 4 cm, 2 units;

- studs with a length of up to 5 cm (under the axes of the blocks), 2 units;

- U-shaped fasteners (for fastening blocks), 4 units;

- self-tapping screws for wood, up to 35 units. regular and up to 5 units. longer;

- synthetic rope or bowstring cable - depending on the size of the assembled structure.

To process materials and install elements you will need the following tools:

- wood hacksaw or jigsaw;

- a hacksaw for metal (will replace the first one if it is missing);

- screwdriver for hardware;

- file and sandpaper.

Bowstring

An ideal bowstring should be thin, strong and not stretchable. The thinner the string, the better the bow performance. However, it must withstand a load exceeding 7 times the bow's tension. The best material in terms of availability, price and parameters is the so-called flax dredge.

Practice shows that an 8-fold folded drape can withstand a tension of up to 25 kg. It is possible to reduce the number of fibers to obtain better parameters, but this increases the risk of the string breaking and therefore the bow breaking.

You should remember to strengthen the fragments that work with the arrow (wrap) and griffins (loops). In these places the bowstring most often breaks. The bowstring has one or two loops.

In the case of two loops, it must correspond to a certain length of the bow. Once he has one, the archer ties the free end to the neck, drawing the bow. He then has the ability to adjust the degree of deflection of the bow.

Here's a note of terminology: the archer draws the bow, putting the string on, and draws it back in preparation for the shot.

There are many ways to weave fibers. Examples can be found on the Internet.

It also tells you how to make your own arrows for a bow.

Selection of components for onion harvesting

Components of a compound bow.

For the manufacture of a bow as a structure subject to repeated bending and high stress, it is important to select the highest quality materials.

Regardless of the type of material (wood, metal, fiberglass or ordinary plastic), no defects are allowed: curvatures, pores, cracks, foreign inclusions and knots can lead to breakage of the bow at the most important moment.

The bow itself is not as important as damage to the face and organs of vision, which are constantly near the weapon when using it.

Excessive humidity and mold are also unfavorable.

Making the handle

Preparation for onions.

Creating the handle requires care - the remaining parts will be mounted on it.

- Short ones are attached to the longest bar using furniture corners.

- After installation, the longest self-tapping screws are screwed in for reinforcement.

- The assembly is sanded with emery, during which the original shape and roundings are given.

- At this stage or earlier, planing with a knife is performed to obtain the required shape.

Material to create

Among wood species, yew is optimal - flexible and durable. Also suitable:

- willow;

- ash;

- juniper;

- cedar.

When harvesting with your own hands, cutting is carried out in cold weather. The bark is removed only after drying. It is recommended to use a variety of impregnations and protective compounds.

Gluing the handle

The most effective is a solid piece. If there is a need to increase its size or obtain significant arrow reach power, there is a way to create a multi-layer handle.

- Blanks made of plywood, boards or composite material are coated with glue (special high-strength - for composites or helicopter type) and wrapped in gauze.

- Fiberglass is much more reliable, but at home there are enough materials at hand.

- The blanks are laid out on top of each other and covered with glue.

- The resulting sandwich is assembled to the required thickness.

- At this stage, bending is performed - it will be difficult to bend the dried structure.

When forming, self-tapping screws are useful - but in small quantities and with a symmetrical installation.

Hole for fastening

Holes and grooves are made in the arms (short bars) for installing wheels.

- Pins with wheels are threaded into the holes.

- The studs are covered with angles or U-shaped brackets and attached to the handle with short self-tapping screws.

How to make and stretch a bowstring

In addition to synthetic rope, which has a limited service life due to abrasion, other materials are used:

- nylon thread (is wear-resistant, but the thickness leaves much to be desired);

- fishing line (designed for high dynamic loads);

- cord made of lavsan, polypropylene and other polymers;

- slings from climbers' equipment (Kevlar fiber created for extreme conditions).

Natural fiber works best.

- A string selected according to its length is placed into the grooves of the arms and wheels, and the ends are secured.

- The arms are screwed to the middle of the handle.

- Corners are mounted to them, and springs are placed on them.

- Changing the degree of initial tension of the bowstring is performed mechanically - by angular movement of the shoulders relative to the handle.

Making a bowstring with your own hands.

What do you need for arrows?

A stand is required for the arrow - it will save the bowstring itself and your fingers. A piece of sheet metal or hard plastic is suitable.

Arrows for a bow.

Shoulder gluing

A wedge-shaped notch is drawn on one of the shoulders (exactly on his back). The diagram can be found on the Internet. The cut should be 10-15 cm long. The marked fragment is cut out.

If something goes wrong, it should be corrected. The second shoulder is sharpened to fit the cut wedge. First with an ax or saw, then with a wooden file. It is important to adjust both shoulders so that (when viewed from behind) they form a straight line.

You can help yourself by drawing an axis of symmetry on them. Then three nails are driven shallow along these axes: one near the future connection and two on the griffins.

If all three “coincide” with each other, then the bow is straight. Epoxy resins are generally suitable for gluing. After joining, everything is twisted using carpenter's clamps or rope or twine.

Note!

DIY vices: simple and reliable homemade vices from A to Z (190 photos)Do-it-yourself vibrating table - selection of materials, components and assemblies for a vibrating table with a step-by-step manufacturing description

Do-it-yourself grain crusher - operating principle, types and features of creating a device for processing grain crops

The seam reaches maximum strength after a week, but you can work on the bow after two days. After gluing, it is recommended to check whether the levers have shifted relative to the axis. The previous template is used for adjustments.

Excess wood lying outside the lines drawn on the template is removed. A second template is drawn showing the thickness of the shoulders. If your shoulders are bent, it is better to draw this line with a ruler. After application, the allowance is removed. Traditionally, you can use a plane, saw or axe.

In this form, the onion should resemble a strip with a rectangular cross-section. The surface of the convex is rounded with a file so that a cross section in the shape of the letter “D” is obtained.

The process of making a combat bow with your own hands is progressing slowly but surely.

Bow assembly

The process occurs without any particular difficulties. However, deviations may occur that can be easily eliminated:

- the selected material must be qualitatively homogeneous; if critical defects appear, the part must be mercilessly replaced;

- it is optimal to purchase blocks - for the first model, ordinary wheels are also suitable, but for high shot power you will need real products with eccentrics;

- To modernize and increase accuracy, a stabilizer and a rod are installed.

Bow hunting

Due to its quality and properties, the bow is suitable for hunting birds and animals. But the following fact is of critical importance: the use of a bow (not just a compound bow, but such weapons in general) as a hunting tool is prohibited at the legislative level. It is not included in the lists of hunting weapons.

The use of a bow is allowed only for entertainment and sports purposes, subject to safety precautions.

- However, in fenced areas, training use for hunting purposes is allowed - with strict control of the actions by an experienced shooter and without the presence of unauthorized persons. The danger of a bow lies precisely in the fact that a mushroom picker or simply a lover of forest species is under the threat of a silent shot and the arrow itself.

- The bow is selected or made exclusively for yourself, otherwise posture and muscle function will be negatively affected.

- It is important to move slowly with a bow.

- If the arrow is inserted and the bowstring is pulled, it is never allowed to point the bow at a person.

- The shot (like releasing a bowstring) is done softly. To protect the hand and fingers, special gaiters are common - archer's gloves.

Hunting with a compound bow.

Barrel processing

So, where do you start making your own bow? From barrel processing. Below are the instructions.

The cut of the trunk should be cut with an ax so that it has straight cut ends, which should be painted with rubber paint. This will allow you to monitor the wood as it dries and possibly prevent cracking.

The trunk is then sawn in half. If there is any knot, the cut line should go through it. For this operation you will need 2 wedges and a hammer. You can use an ax as a wedge, but you should understand that the ax can be broken. One wedge is driven into the thicker end of the barrel.

When wood cracks, a second wedge is driven into the crack to free the first. These steps are repeated until two pieces of wood are obtained.

Note. If the barrel breaks asymmetrically, it should not be “straightened” under any circumstances. It is possible that one of the parts will no longer be good for anything and will have to be disposed of.

The bark is removed using a sharp ax (or another tool, such as a plane). Afterwards the tree is placed in a dry and cool place.

The main idea of these actions is to dry the wood slowly and evenly. In the notes of ancient masters it was written that the target humidity should be 10%. If there is nothing to measure this, then you just have to trust your instincts.

The above actions can be separated from each other even by a break of several days. There's no rush here. Drying should last at least 2 months.

After about 5 weeks, you can gradually move on to the next stage. The wood is still too wet, but removing any unnecessary excess will speed up the drying process a little.

If during this time the pieces of wood begin to become covered with white mold, you need to place them higher in a drier place so that they do not collect moisture from the ground. If cracks appear during drying, the wood should be moved to a cooler place. The reason for these unfavorable problems is the lack of bark on the trunk.

Note!

Do-it-yourself compressor: selection of materials and tools for assembly at home + step-by-step instructions for making and assembling yourselfHomemade products for the garage with your own hands: options for products for arranging a garage, detailed diagrams and drawings for creating with your own hands

Do-it-yourself press - design features, choice of manufacturing materials. Step-by-step instructions for making it yourself + simple diagrams and drawings

Then the most beautiful piece of wood is selected. Now you can get to work. When creating a compound bow with your own hands, the steps may vary.