Homemade sharpening machine for metal cutters - Moy-Instrument.Ru - Review of tools and equipment

› Article tools

Loading... Best products from AliExpress HERE ⬇

Details 01/13/2017 11:03 Aleshkin 6804

A homemade device for sharpening cutters and other cutting tools.

During the operation of our machines, the need for such a device arose.

You can sharpen a drill by hand, but what about cutters, where there are not two, but four, or more edges only at the bottom, and you need a less precise geometry, and the size is small.

So I decided to make such a device.

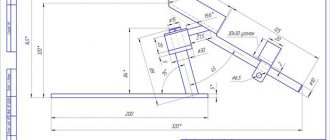

It's a simple back and forth feed mechanism, plus tilt and swivel.

It will be installed simply next to the sandpaper.

The materials available were aluminum, some steel, and sandpaper.

I will now show you how this was done in photographs.

Let's start with the device that must hold the cutter or drill, that is, the spindle, to install the tool.

To do this, I have such a part in it, Morse taper number two (KM2), this is what I need.

After all, my machines also have KM2 everywhere, and you can use their equipment, and mortises and drills with such a cone can be installed directly into the spindle.

I removed everything unnecessary from this mandrel.

The result is a small spindle that can rotate around its axis.

I'll do a little modification, drill a hole for a cleaning rod, which will secure the tool from suddenly falling out of the spindle.

Now the spindle will be able to accept any tool with KM2, both with a presser foot and with M10 threads, a drill or collet chuck, cutters with KM2 and all kinds of mandrels for disk cutters.

Now the housing for this spindle.

All that remains is to make a locking ring for the spindle and a handle.

Handle for rotation around the spindle axis.

This is what the first assembled part for my device looks like.

Fitting equipment, drill chuck.

Now you can work on the movement mechanism, it will be like a small cross table, similar to that of a milling machine only with rotation around its axis.

I am sawing a blank for the table.

Milling future movement axes.

Preparing a table for installing a spindle.

The workpiece is ready for dovetail milling.

I'm milling a dovetail.

I drill, cut the threads and add an axial movement nut.

I try on the guide for the table; the screw for it will be an ordinary pin.

The propeller supports are made from two small pieces of aluminum.

General view of the finished axle with fitting of the collet chuck.

The general appearance of the device is already emerging, but this is just a project.

I had some free time and I spent it in the workshop, working on the ears or hinges, for the tilt and the turntable with the axis.

So that the loops or ears were the same, I connected them immediately into one piece.

And then I drilled and bored holes for the axle.

I cut off a little excess aluminum and drilled it, then cut a thread for the hinge adjustment screws.

The second axis of movement in the trailer is no different from the first, only there is no feed screw and the table is slightly wider.

A turntable in the shape of an ordinary pancake.

This simple cylinder will serve as my tilt axis.

I tried everything on the table, all that remains is to drill and assemble this unit.

Drilled and assembled.

I assemble two axes into one whole device.

Again we drill and tap the threads for the screws.

I cut out a corner and put a pin on it to read the cutter strip when sharpening.

This is what the entire device looks like assembled.

Over the weekend at the dacha I couldn’t resist and carried out the first tests, tried to level and then sharpen the end of the cutter.

To do this, I secured my homemade device on the table with self-tapping screws, near the sandpaper.

Here is a video report on the experiment.

All that remains is to finalize the sharpening of the cutter strips and make a stop that limits the cutter from falling to the front, and finally, a table for this device.

For those who are interested in this topic, below is a link to the continuation.

Machine for sharpening cutters for metal: review of models, self-assembly

Devices for sharpening the end cutting elements of a milling-canter machine are divided according to the nature of the work and are divided into two types - universal and special.

Let's look at each of these options below.

1 Machines for sharpening cutters for metal - review of factory models

Sharpening cutters for working on metal and wood is done with your own hands using universal worm gear devices.

In addition, the cutting elements of the milling-canter machine can be sharpened using special devices.

Sharpening tool

To sharpen cutters on the outer surface - the backing - use cup-shaped finely shaped wheels. They are installed on a sharpening machine, which ensures the direction angle of the edge and the movement of the sharpening tool along the entire length of the part being sharpened. The machines operate automatically according to the specified settings. Devices for manual adjustment are driven by a person. They only help maintain the desired angle.

Sharpening of turning tools for metal is carried out on sharpening wheels with medium and fine grain wheels. Finishing is carried out on polishing diamond wheels and whetstones. The correctness of the angle is checked with a special template.

Sharpening of disc cutters is carried out on 2 planes. First, the inner cutting edge is processed with a thin circle moving perpendicular to the plane of the disk. Then the back side is sanded. In this case, the cutter rotates by 2–5 teeth after each pass of the circle. This ensures uniform sharpening. The number of teeth in one step of the tool should not be a multiple of their total number. For example, for a disk with 20 cutting edges, a step of 2 to 3 protrusions is selected.

Milling cutter sharpening machine

Machines for sharpening cutters for wood and metal

Wood and metal cutters have a complex tooth shape, which necessitates the use of a special machine for sharpening cutters. To do the job, you also need to know the geometry of the tooth. This takes into account what material the tool is made of.

Mill sharpening machine

Machine Applications

A sharpening machine is a device with which you can sharpen cutting tools: cutters for wood, for metal. The range of sharpening machines varies from large industrial models to versions that can be used in home workshops. The machine can be used for sharpening cutters for wood or metal.

The machine is often used in established industrial production, when there are many cutters available and they are often used. If only burrs have formed on the cutting edge due to incorrect processing modes, then the problem can be corrected using a whetstone or file.

Conventionally, the following classification can be made:

- The universal machine is suitable for sharpening not only cutters, but also other cutting tools.

- A specialized machine is used to process only one type of tool, for example, cutters.

The universal machine is equipped with normal and special devices that are used to secure and install the tool, additional measuring mechanisms that allow you to maintain the sharpening angle of the cutters.

Universal sharpening machine with accessories for sharpening cutters Specialized sharpening machine for sharpening end and cylindrical cutters

Specifications

When choosing machines for sharpening cutters, you should pay special attention to the technical characteristics. The main indicators include:

- Operating voltage. Many models operate on a standard 220 Volt network. Options with a higher power rating operate at 380 Volts.

- Power consumption is also an important indicator. It can vary in the range from 200 to 5,000 watts.

- Spindle rotation speed without load. This figure can vary from 900 to 3,000 rpm.

- The accuracy with which cutters can be sharpened. The accuracy indicator often depends on the design features of the model.

- Abrasive feed rate.

- Feed type: mechanical and electric. Some models have an electric drive, others mechanical. The electric version significantly makes the design more expensive, while the mechanical version requires certain skills from the master.

- Range of sharpening angle. The angle can be called the most important indicator. The cutting edge is formed by two planes located at a certain angle.

- The presence of special water baths that allow you to cool the abrasive material while the machine is operating. An increase in the temperature of the abrasive material can lead to significant heating of the cutting edge, causing it to change its performance.

- Availability of ventilation. During sharpening, the metal layer is removed from the cutters, and the abrasive material also flies off. This moment determines whether the workplace is clogged, and the ventilation system will help keep the equipment clean.

- Noise indicator during operation. The drive and motor make noise when running. High noise levels make work much more difficult.

- Availability of a protective casing. During sharpening, abrasive chips and metal fly off, which can get into your eyes. It is the protective casing that protects the craftsman from chips and abrasive crumbs.

According to the layout, machines for sharpening cutters are also available in floor-mounted versions. The traditional drive involves the use of an electric motor and a V-belt drive.

Design Features

Despite the fact that there are quite a few models of machines, their design is somewhat similar. Features of the typical design include:

- The main part of the body is represented by an electric motor.

- If it is necessary to change the rotation speed, a V-belt drive can be included in the design.

- An abrasive wheel is fixed to the shaft.

- The stand is necessary to secure the tool being processed.

- There is a block with a button to turn the equipment on or off, as well as elements for adjusting operating modes.

Other elements may also be present.

Many people decide whether it is worth spending money and purchasing special sharpening machines. Their use can be defined as follows:

- The process is significantly accelerated: the high speed of rotation of the circle speeds up the process of removing the required layer of metal.

- A more accurate result can be achieved. The sharpening angles have clear limits; without the use of machines it is almost impossible to maintain them.

- The quality of the work performed is much higher.

- Even an untrained master can do the job, since the work is almost completely automated.

The machines are used in workshops for medium and large-scale production. Only in this case is their purchase justified.

Disadvantages of use

You can also highlight some disadvantages of the application:

- The electric drive consumes quite a lot of energy. With constant use, the cost of paying for electricity will be very high.

- The cost of the machines is very high. At the same time, we note that the price depends both on the main performance indicators and on which company is the manufacturer.

- It is necessary to carry out constant maintenance of the equipment to keep it in proper condition.

- You need to find a place to install the equipment and equip it correctly. Some models require rigid mounting.

Similar disadvantages can be identified when considering sharpening machines.

In conclusion, we note that there are quite a few types of cutters, each with certain qualities that are worth considering. That is why you should purchase not a specialized, but a universal version of the sharpening machine.

, please select a piece of text and press Ctrl+Enter.

Main characteristics

Since finger cutters are designed for processing any surface, each of them has its own characteristics. These include:

Wood end mill

Milling tools for wood processing are made of steel, which has increased strength and has the exact shape of the pattern of the working part. But it is worth noting that depending on the surface being processed, it is necessary to select the appropriate type of cutter. For example, to work with plywood you will need a cutting part made of harder alloys, which increases the work process.

In addition, they also have several varieties, namely they are solid and prefabricated. The latter have quite a significant advantage, since they have the ability to set the knives to the required size and are very easy to replace if necessary.

One of its advantages is that it can be used to insert door hinges. First of all you need:

- To mark the loop, to do this, you need to attach it to the location and mark it, best with a paint knife. But it is recommended to attach the hinges to several self-tapping screws so that there is no displacement.

- Then you should press two small bars against the door, thereby making a place where the soles of the cutter will rest.

- After this, a slot cutter with a straight attachment is loaded into the tool. In this case, the work must be carried out carefully so as not to go beyond the marked marking lines.

- To establish the required hinge cut on a hand cutter, it is necessary to set the appropriate depth. The correctness can be checked on any wooden block, and only then carry out actions on the surface of the door.

- After cutting out the door hinge, it is necessary to process the made recess with a chisel, if necessary.

- When all the grooves for the hinge are made, you can install the doors.

For PVC and aluminum

This variety is intended for processing these materials and is used for:

- milling drainage surfaces;

- milling a groove for a lock;

- processing of PVC and aluminum profiles;

- cleaning grooves for seals.

As for the milling cutter for aluminum, it has a specific structure, since this material has certain features, namely the adhesion of chips, which complicates the process. Due to its specificity, such a tool eliminates the possibility of inaccuracies or distortions in relation to the specified parameters.

For metal

Basically, such equipment is used in production and is considered simply an indispensable tool. Its main purpose is:

- Milling grooves for locks.

- Cleaning the grooves and special grooves into which the seal will then be placed.

- Creating drainage holes.

- In addition, it is widely used in the automotive industry for work requiring milling.

Diamond cutters

Any work on surface treatment requires compliance with GOST, which, in turn, improves quality

Particular attention is paid to actions related to concrete and stone surfaces, both internal and external.

Therefore, diamond cutters are ideally suited for grinding operations. Thanks to this tool, work with such surfaces is carried out with the highest quality possible, while spending very little time.

Among the varieties of this type, the diamond finger cutter is used for work on granite and marble. This material is quite strong in structure, and with the right selection of tools, you can work not only on granite and marble, but also on other stones. In addition, the diamond cutter is quite durable, which allows you to save money on frequent replacement of the worn-out working part of the tool.

Regardless of the work performed, it is worth considering the fact that for each type of material used, an appropriate cutter is required. The thing is, depending on the structure and hardness of the material, it is necessary to select the appropriate diameter of the tool

In addition, it is very important to take into account the speed of its revolutions. This is due to the fact that the higher the speed, the more the tool heats up.

For example, if steel with a strength of HRC 38-47 is processed, and the metal cutter has a size of 3 or 6 mm, then the speed of rotation should be 25-25 m/min. But if it is necessary to produce on heat-resistant alloys with a strength above HRC 47, and the diameter of the cutter is similar, then the speed must be reduced to 10-15 m/min.

Video: sharpening finger cutters for a hand router.

Sharpening machine for metal cutters

On the website Stankoff.RU you can buy machines for sharpening cutters from leading manufacturers. There are more than 5 models of sharpening machines for wood end mills in stock and on order at the best prices. Only profitable offers with detailed descriptions and photos. Check prices with managers.

Scope of application

Milling and drilling tools come in a variety of shapes and materials.

Equipment made of carbide steel or cermets is highly resistant to wear, but requires regular restoration of the sharpness of the cutting edge.

The grinding machines for milling cutters offered by our company easily cope with metal processing and show high precision results while fully maintaining the complex geometry of the consumable tool.

The sharpening machines for sharpening cutters presented in our catalog are designed to perform multifaceted tasks and have wide adjustment capabilities for restoring the functionality of consumables with various geometric shapes.

When the cutting edge becomes dull, not only the quality and accuracy of workpiece processing deteriorates.

The area of contact between the tool and the material increases, the result is overheating of the metal, increasing wear of the equipment and increasing the load on the machine mechanisms.

Sharpening machines for wood cutters presented on our website are a necessary type of equipment in enterprises producing furniture and carpentry. Without regularly restoring the sharpness of cutters and milling equipment, it is impossible to process various types of metal. Universal and highly specialized units sharpen efficiently and quickly:

- cutters, dies, chisels;

- drills and shaped cutters;

- milling heads;

- gravers, punches;

- stubborn centers.

Equipment design

The movement of the working shaft of the grinding machine for end mills is provided by an electric motor. The design is stable and has a minimal level of vibration during operation. Setting the angles of primary and secondary processing is performed automatically using a guide.

The presence of an air bearing makes it possible to completely rotate the base for cone grinding.

Adjustment of the angular position of the spindle and grinding tool is carried out in a wide range of positive and negative values, and allows you to adjust the formation of the cutting edge with high accuracy.

The spindle is made of stainless steel, and the sleeve is chrome plated. Processing and finishing of the tool is carried out with round attachments made of a material with abrasive properties. When creating grinding wheels, different types of material are used. Typically, the following types of tools are used in the operation of a machine for sharpening cutters:

- abrasive;

- corundum;

- diamond;

- CBN

When processing, the end or side of the circle is used. The thickness of the removed metal layer and the cleanliness of the resulting cutting plane depend on the degree of grain size of the material.

Features of the models

Compact and easy-to-use types of equipment are used for domestic purposes, while industrial production requires more powerful and productive units.

Sharpening machines for cutters for metal or wood are equipped with numerical control and perform processing automatically, according to the established parameters for each type of equipment.

The operator has the opportunity to monitor the status of the process using the electronic display, which displays the shape of the cutting edge and indicates the processing time.

In semi-automatic types of equipment, a manual sharpening mode is used. The units have a simple design, allow for quick reconfiguration and do not require special training of employees. A machine for sharpening end mills with universal functions makes it possible to restore the sharpness of equipment:

- with a flat or radius end;

- by outer and inner diameter;

- with straight or inclined teeth.

Selection and operation

The correct choice of a machine for sharpening consumable tools is based on a set of technical characteristics and the specifics of the intended work. The main indicators of equipment take into account:

- the maximum possible diameter of the sharpened equipment;

- adjustable speed range;

- ability to change the angle of inclination of the working shaft.

To perform high-quality processing, the sharpening machine must be installed on a stable and level surface with an accurate horizontal level. It is especially important to correctly adjust the tool stop, which largely determines the result and safety of work. A reliable cooling system increases the working life of mechanisms and consumable tools.

» Machine » Sharpening machine for metal cutters

Wood and metal cutters have a complex tooth shape, which necessitates the use of a special machine for sharpening cutters. To do the job, you also need to know the geometry of the tooth. This takes into account what material the tool is made of.

Mill sharpening machine

The process of manual sharpening according to the type of cutter

Now let's briefly talk about the features of the tool depending on its configuration. The main problems are that it is not always easy to ensure uniform processing along the entire length of the cutting edge.

The peculiarity of manual sharpening is that the emphasis is provided not by the vice of the machine, but by a special device.

End

The cutting elements are located at the end and side. This allows you to make grooves along the edges. Processing takes place according to the following algorithm:

- Fastening of the cutter is horizontal in relation to the rotating one.

- Tilt it enough to achieve the required angle.

- The circle rotates with high amplitude.

- During installation, note the position of the cutting part upwards.

Sharpening end (finger) cutters

This is an elongated tool whose shank has a cylindrical or conical shape. Due to its appearance it has also been compared to fingers. Actions:

- Select a diamond stone to place on the edge of the table.

- If the tool has a large enough recess, then it should be secured along the tabletop.

- As you sharpen, the edge will become sharper and the diameter will decrease.

Recommendation: if the package includes a bearing, then it must first be dismantled, and in any case it would not be superfluous to clean the surface with a specialized solvent.

Disk

Essentially, it is a disk with teeth around its circumference that must be directed upward. If it is simple (unidirectional), then the cutter itself should be positioned vertically. And in the case of a versatile direction, the sharpening angle is the same as the angle of the cutting teeth.

Prefabricated

Their design assumes the presence of removable plates. Each one should be sharpened separately. It should be taken into account that they have several elements for processing - these are rear, main and auxiliary corners, as well as a transition edge.

Cutters with backed teeth

Such an instrument has a flat front surface, and the back is made in an Archimedes spiral. In order to sharpen the product, you must use a disc wheel

Each tooth must be ground down along the outer base, and it is also important to ensure that the same layer of metal is constantly removed

Sharpening cutters: for metal, wood with your own hands, types, application

Sharpening of different shapes of cutters is carried out using specialized equipment. This is a circular cutting tool, although its configuration can vary. The grooves and teeth located around the circumference come in different sizes, and when they rotate, the material is processed.

Types of cutters

There are several types of cutting tools. These include: cylindrical, end, disk, end and groove.

By type of purpose:

- angular;

- shaped;

- keyed;

- to provide T-type grooves.

On the surface:

- plastic;

- tree;

- metal;

- glass;

- others.

Sharpening is difficult, since the length of the cutting base is large. Therefore, specialized tools are used.

And in some cases, grinding is carried out manually, but the worker performing this work must have experience.

An employee who does not have the skills may allow defects and defects to appear on the teeth: cracks, burrs or cavities, due to which the tool will need to be ground again, and this will lead to a reduction in size.

Milling cutter material

The following materials are used for the manufacture of technological equipment:

- hard alloys;

- high-speed steel;

- metal alloys of increased hardness;

- metal ceramics;

- diamonds.

For direct cutting of metal, the edges of the cutting tool are made of:

- cardan wire;

- diamonds;

- hard alloy compounds;

- ceramic coating.

The difference in technological equipment is determined by its appearance.

Cutter tooth geometry

Productivity depends on proper sharpening of the teeth. Work surface configurations are used to solve even the most complex problems.

The design of a spiral cutter is carried out with a large and small inclination of the teeth at a given angle. The purpose of this type of tool is to carry out roughing and finishing operations, including variable steps.

The rake angle is the angle formed between the flat end and the flute edge of a standard cutter.

Angle value:

- small no more than 35;

- large 35 and above.

An excellent option for initial and finishing machining is the tooth angle of 38. Rectangular tools have the maximum value.

A tool with a variable pitch is in demand; the pitch of the spiral is measured along the length.

Application area

There are various types of tools to perform technological operations. Which cutter to use in this or that case, for this you need to take into account what material needs to be processed.

Common types include:

- Disk. Elements for cutting material are located on one or both sides at the same time. Used for cutting grooves, sampling, trimming and chamfering.

- End Designed for turning stepped and flat bases.

- Cylindrical. Available with helical and straight teeth.

- Angular. Used for cutting chip flutes in technological equipment.

- End. They are used for making ledges, contour recesses and grooves.

- Shaped. Designed for processing shaped surfaces.

- Worm-shaped. Processing is carried out using the rolling method - touching the workpiece with a tool at one point.

Wood cutters

The following tools are used for processing wooden structures:

- End. Outwardly they resemble a drill, but the conical part is missing.

- Edges. Used for cutting edges and various recess configurations. Tools for manual milling are structurally equipped with a bearing to regulate the depth of processing.

- Grooved. Used for cutting grooves.

- Copying. Arrangement of the milling head in the form of an arc.

Cutters for plastic

When processing plastic products, the following tools are used:

- End For processing large bases.

- Shaped. Used for cutting complex profiles.

- End. Used to produce pockets or grooves.

- For engraving. With its help, you can apply patterns or logos to the base.

Glass cutters

Diamond cutters are used to prepare glass products. Designed for creating edges and contours using manual or automatic equipment.

Methods for sharpening cutters

Sharpening cutters is difficult, since it is necessary to process curved and long surfaces. It is also necessary to ensure that the abrasive moves with precision along the edge.

Using the machine

The sharpening technology is carried out in stages:

- Fastening the cutter in a given position.

- Bring the surface to be treated to the abrasive wheel until there is no sparking.

- Removing a metal layer with a thickness of 25 to 50 microns.

- Sharpen each tooth separately. The work begins by positioning it in the groove formed by the tooth, and the needle should touch the surface of the instrument.

- Turn on the sharpening machine and, sequentially retracting the cutter, perform the operation.

To perform the work efficiently, each edge of the cutting base should be sharpened equally, that is, the movements should be uniform.

Using sharpening wheels

The choice of wheels depends on the material from which the tools are made. What kind of circles are there:

- Normal electrocorundum and white electrocorundum. Provides optimal sharpening of tools for metal or wood.

- Elborovye. Using wheels of this material you can sharpen high-speed steel products.

- Green and diamond silicon carbide are used for sharpening carbide products

Varieties

Cutters come in a variety of types - end, end, disk, slotted, cylindrical, groove. And these are not all varieties. They are also divided according to their purpose and are angular, shaped, keyed, for T-shaped grooves. Another division is based on the type of surface being processed:

- for metal;

- on wood;

- on plastic;

- on glass;

- and others.

Sharpening a cutter for metal is difficult due to the large length of the cutting surface. Such work is only possible with the use of special tools.

In some cases, you have to grind by hand, but this requires a lot of experience. Otherwise, all previous work will go down the drain. The grooves (teeth) will show nicks, gouges, chips and cracks.

The part will have to be ground again, which invariably reduces its size.

The peculiarity of sharpening is to ensure the movement of the emery along the edge. To preserve the profile of the structure, backed teeth are sharpened along the front base, and sharp or non-standard teeth are sharpened strictly along the rear base.

End mills

Sharpening an end mill is simple and can be done with a regular thin diamond stone.

In this case, the block must remain motionless (it is placed on the edge of the table or secured in a special way for working with deep grooves). The sharpening process is carried out directly by the cutter.

End mills are used for processing grooves, pockets, windows (grooves with access to only one machined surface).

Sharpening of cutters in Moscow can be done here. The price for the work is from 150 to 300 rubles, depending on the complexity of the cutter. For more details, contact us by phone +7. We guarantee our clients high quality and a guarantee for all work performed.

Machine for sharpening cutters for metal

Nikolay Chernak spoke about a homemade machine that he uses to sharpen end mills for metal. Acquisition history. One Sunday I stopped by a flea market and noticed that a man was selling an interesting machine.

As soon as the buyer showed interest, a man immediately came up and said that he also wanted to buy a machine and had been bargaining since the morning. He needs this machine to make wobblers for fishing. He wants to make a copier out of it.

Nikolay took this homemade machine for a while to review it.

Machine Features

Let's look at the capabilities of this machine and what it is intended for. Has length adjustment according to the cutter. That is, you can clamp long cutters. There are many holes and a groove for setting the required length. Emphasis.

One part is missing parts. Judging by the fact that there is a thread cut here, there must be chucks for clamping other cutters. There are not enough collets. There are 16 holes on the outside of the cartridge.

There should also be a pin here, insert it tightly and divide by a multiple. Movement by hand, a little tight.

Judging by the collet, if you find other sizes, you can install a fairly thick cutter in diameter.

The drive is carried out by two stepper motors. There is a reverse. Along the Y axis, automatic movement of the entire carriage.

That is, you can move it manually or with an electric motor. Electronics, 3 boards. She was faulty. The owner has renovated it. There is still no clear synchronization of the two motors. There is a stepper motor for feeding along the Y axis. It sets the carriage into automatic motion. By installing the stops, you can set the automatic feed to the left or right.

Features of cutters

Different materials are used to produce cutters. Tool steels suitable for wood are: high-speed, alloy and carbon. For processing metal, plastic, ceramics, and stone-like materials, hard alloys, diamonds, CBN, and mineral ceramics are used.

Steel for wood cutters

- The following grades of tool steels are used for cutting wood: U-9-A, U-8-A, U-7-A, KhV-5, 9-KhS, KhG, KhVG.

- High speed steel can be of normal performance. These are brands R-18, R-6-M-5, R-9, R-12, etc. The high-performance metal is alloyed with vanadium, cobalt, molybdenum and tungsten. These are brands R-6-M-3, R-18-F-2-K-5, R-9-F-2-K-10, R-9-F-2-K-5, etc.

Note! If a cutter has soldered teeth, this does not always mean that they are made of carbide. It can also be high-speed steel.

Teeth geometry

Shape of teeth.

According to their design, the cutters of milling cutters are divided into sharpened (pointed) and backed.

- For sharpened teeth, the section of the rear surface (width n) adjacent to the cutting part is a plane. Such incisors are sharpened along the back surface. However, if necessary, you can sharpen them along the front edge.

- In backed cutters of shaped cutters, the back surface has the shape of an Archimedes spiral. Processing it is technically very difficult. Therefore, such teeth are sharpened exclusively along the front edge.

Each tooth is a separate incisor.

It has standard parameters: back (a) and front (y) angles, area of the sharpened surface (n), slope angle (l).

- Platform n is a section of the rear surface of the cutter that is ground during turning. This is where the teeth wear out the most; their size affects the friction force between the cutter and the workpiece. Because of this, this surface should be maintained within the normalized range.

- The leading edge angle (y) is measured between the tangent to the leading edge and the radius of the cutter.

- The main back angle (a) is measured between the tangent to the back edge at the normalized point of the main sawing edge and the tangent to the rotation circle of this point. When this angle decreases, it reduces friction between the workpiece and the cutter.

- Not all cutters have an additional clearance angle (a1). It describes the expanded gap between the cut surface and the body of the cutter. The instructions indicate the need to sharpen this gap with a certain wear of the cutter and expansion of the area n. The purpose of the operation is to reduce friction between the tooth and the workpiece.

Cutter parameters.

- Based on the direction and configuration of the cutting edge, helical or straight teeth are distinguished. Their slope describes the angle (l) between the axis of the tool and the deployed helical edge.

The size of the angle depends on the type of cutter, the grade of its material and the type of workpiece being processed. When cutting wood, the main rake sharpening angle is selected in the range of 10-20 degrees, sometimes more. The back angle also fluctuates within a wide range of values.

Tips for use

When performing work, first of all, the following safety conditions must be observed:

- the wheel for sharpening cutting tools must undergo a preliminary rotation test;

- compare whether the permitted disk rotation speed will exceed the value indicated on the marking;

- do not use a fork-shaped tool - it does not allow you to adjust the gap on the sides of the disk;

- Before starting work, it is necessary to balance the abrasive disc.

You also need to remember the rules.

- When installing tools, they must be thoroughly secured in a vice or sharpening device. If the cutter is poorly secured, it can be torn out, which threatens the failure of the disk.

- When sharpening, do not lean towards the tools to control the process.

- You can determine the quality of sharpening by moving the tool being processed from the abrasive to a safe distance.

- If the unit begins to vibrate during operation, it must be immediately switched off and the moving connections inspected.