Design Features

A grain crusher is like a coffee grinder enlarged 10-20 times.

But the difference between one and the other machine lies in some parameters.

- Unlike a coffee grinder, a grain crusher grinds grain not into a fine, powder-like powder, but into a coarse-grained substance.

- The grain crusher is capable of grinding tens of kilograms of grain in one grinding session.

- The more grain you need to grind, the longer the device works. For example, to satisfy the monthly demands of a chicken coop in which, say, 20 chickens lay eggs every day, more than one hundred kilograms of grain will be required. To grind 10 buckets of the same wheat or oats, it will take at least one and a half hours of operation of the unit.

The design of the grain crusher includes a number of components.

- Protective housing – made of metals, plastic and/or composite.

- A support that is permanently installed in a specific location or removable (portable).

- Bracket adjustable with nut and bolt.

- The second base has a softener in the form of a rubber “shoe”.

- A pair of engines and the same number of sets of pulleys with a diameter of 6 cm. They are equipped with mortise bolts and keys.

- Seals that soften vibration from motor shafts.

- Knives that chop grain and grass. Both chopped ingredients are the basis of compound feed.

- A funnel with a lid into which unground grain is poured. The second funnel allows the crushed raw materials to be poured into a previously prepared container.

- Frog type lock.

- Removable gratings that allow fractions of different sizes to pass through.

- Rubberized wheel.

Each of the above components can be easily and simply installed on an old washing machine.

A grain crusher made from an activator washing machine (or automatic machine) is a device that has the highest performance and capacity compared to similar ones made from other electrical appliances.

Components selected and/or made by hand must be compatible with the overall dimensions of the final device.

No one will install knives that are several times smaller in diameter into the tank for an activator washing machine - the operation of such a device would become extremely ineffective. A volume of grain that would normally be ground in 20 minutes would take an hour or an hour and a half with reduced knives. In other words, the homemade device is physically balanced.

Similar to the device of a coffee grinder, in a grain crusher the knives, combined with the shafts of electric motors, immediately start when the device is connected to the household lighting network. They finely chop small branches, seeds and grass. The crushed raw materials fall on a sieve, which removes husks and small debris. What has been filtered passes into the container through a funnel, collecting in it.

Types of grain grinding machines

Types of machines for grinding grain

Depending on the grinding method, design and location of the working parts, there are 4 types of grain crushers:

- Rotary – crushing of grain in such devices occurs due to a rotor located horizontally and moving at high speed.

- Hammer crushers - the design of such grain crushers includes a rotating vertical drum and stationary hammers located in a circle, against which the grain is crushed. When grinding in this way, the finished flour is poured down and, passing through a sieve, ends up in a container placed under the deck of the housing.

- Roller crushers crush grain due to 2 rollers located in one chamber, rotating towards each other. At the same time, the gap between them is so small that the incoming raw material is not simply crushed, but, due to high speed, is crushed into dust. The advantage of such devices over others is the ability to crush grain with high humidity.

- Millstones are grain crushers in which grain is crushed when it gets between two discs (millstones) located with a small gap. In this case, one disk rotates at high speed, and the second is stationary.

Among these varieties, the most common are rotary and hammer ones - they are more productive, reliable, and easier to repair and maintain.

What can it be made from?

Let's look at how to make different components for a grain crusher at home.

- The grinding tank is made of thin (0.5-0.8 mm) stainless steel. A metal frame with a valve is fixed next to the base. The outer part of the body is made of a seamless metal pipe with a diameter of 27 cm. The wall thickness of this pipe can reach 6 mm. Inside the same pipe there is a stator, for the manufacture of which a pipe of a slightly smaller diameter was used - for example, 258 mm. In both sections of the pipe, holes are drilled to secure the loading hopper, remove crushed grain, install a grid with the required mesh size, and hangers to secure the shipping hopper. Both pipes are mounted in such a way that they are held in the grooves of the auxiliary flanges located on the side. The latter are connected to each other using several pins. One of the flanges has an internal thread for studs. The second one is drilled in several places. Both flanges also have holes drilled through them to secure the journal bearing housings and are secured to the metal frame using bolts and nuts.

- The rotor is assembled on the basis of prefabricated metal pushers and is equipped with washers. If necessary, these pushers are reversed. After assembly, the rotor is checked for imbalance. If beats are still detected, the rotor is balanced immediately - parasitic vibration can shorten the service life of the entire device.

- The drive shaft contains feather keys and ball bearing sets. Protective washers for ball bearings are based on the requirements of GOST 4657-82 (size 30x62x16).

- The supporting frame with the table is manufactured in a welded version. The starting material is steel angle 35*35*5 mm. The valves are made of thin sheet steel.

- Having prepared the necessary materials and workpieces, we begin to assemble the grain crushing device.

Schemes and drawings

The grain crusher from the washing machine contains the following components:

- grain bin;

- frame;

- rotor;

- shaft;

- unloading hopper;

- pulley (the requirements of paragraph 40 of GOST 20889-88 are met);

- V-belt;

- electric motor;

- frame with table;

- loading and unloading valves (valves).

Drawings of analogues made on the basis of a motor from a vacuum cleaner, electric drive of an angle grinder, drive and mechanism of a meat grinder differ little from the device made on the basis of a (semi-) automatic washing machine. The principle of operation of the device is no different - which cannot be said about the type of chopping mechanics used.

Master class on making a grain crusher from a washing machine

If you have purchased a new automatic washing machine, do not rush to throw away the old type of device. It will definitely make a high-quality and productive grain crusher. You just need to develop a detailed drawing and purchase some elements.

What you need for work: prepare the essentials

The list of materials and tools will depend on the chosen scheme. Most often, only the motor from the washing machine is used. However, if desired, you can also use a tank.

You will also need:

- rolled metal: plates, pipe sections;

- fasteners;

- sealant.

Device diagram

In terms of its design and operating principle, a grain crusher is similar to a coffee grinder. During the manufacturing process, the main attention should be paid to the knives and the hopper for receiving the finished product.

Preparation of prefabricated elements

- We begin work by preparing the grain bin. We increase the diameter of the drain hole to 12 - 15 cm to ensure sufficient performance of the device. From pipe sections we make pipes of the required size and configuration for discharging crushed grain.

- We cut three knives from durable steel. These should be plates 20 cm long and 1.5 - 2 mm thick. To make the device last longer, you can use a hand saw to make these elements. We drill a mounting hole in the middle of the prepared plates. We sharpen the parallel sides.

- We make a filtration grid that will not allow whole grains to leave the container. Its diameter should be slightly larger than the diameter of the manufactured pipe. The holes in the filtration grid must ensure the unhindered passage of crushed grain.

Attention! The diameter of the filter grid holes should be 3 – 4 mm.

We are preparing a container for crushed grain, or we are thinking about a way to secure the bag to the outlet pipe. To prevent the formation of excessive dust during operation of the device, the receiving hopper must be sealed against the outlet pipe.

Assembly of the structure

We assemble as follows:

- We install a discharge pipe into the expanded opening of the tank, ensuring sufficient tightness of the connection.

- We install the knives on the motor shaft. To avoid overlapping of the blades during operation, be sure to tighten the clamping nut after each plate.

- We attach a filtration grid in front of the outlet pipe. It should be located at an angle of 15 - 200 to the horizontal. Considering that the bottom of the washing machine tank is inclined to ensure complete drainage of water, there should be a right angle between the base and the installed plate. To fasten the plate we use bolts.

- We coat the joint with sealant to eliminate the presence of gaps and cracks through which whole grain could mix with crushed grain;

- Let's start the device. Let's check its functionality.

- If you don’t have a solid washing machine, but you still have a working engine, you can also use it to make a grain crusher with your own hands.

Grain crusher from a grinder: drawings for making photos

A homemade grain crusher can be made from an ordinary angle grinder (grinder); this article provides drawings of a grain crusher made from an angle grinder, as well as photos and videos of making this homemade product.

This version of the crusher, of course, is not designed for large volumes of grain, but it is quite suitable for making dirt or feed for chickens or a small number of chickens.

If you need to quickly make a simple and practical grain crusher, you will need the following materials:

- Angle grinder.

- Used metal saw blade.

- A piece of thick plywood.

- Metal bracket.

- Bolts, washers, nuts.

- 5 liter plastic bottle.

- Metal sieve or pan.

We will make a homemade grain crusher from these materials, but first we will familiarize ourselves with the drawings of a grain crusher made from an angle grinder.

Grinder grinder manufacturing process.

Let's start by making the base; for this we will need a piece of thick plywood in which we will cut holes for the body and shaft of the grinder, as well as a hole for the hopper for filling grain.

You can fix the grinder in the base with a metal bracket and bolts.

Now we will make a knife for our grain crusher; you can cut the knife from a metal disk from an electric saw. The edges of the knife need to be sharpened.

To make the working chamber of the crusher, you will need a metal sieve or any suitable container with a diameter of about 20 cm, a depth of no more than 5 cm. In the container you need to make holes of the same size with a diameter of about 3 mm, in fact you need to make a sieve, the grinding size will depend on the size of the holes in the sieve .

We attach the sieve with bolts to the base of the grain crusher.

The crusher is almost ready, now we will make a hopper for filling grain, as an option you can use a 5 liter plastic bottle, cut off the bottom of the bottle and insert the neck into the hole in the base of the crusher.

A homemade grain crusher made from an angle grinder is ready for use, I also recommend watching a video showing the crusher in operation.

(2 ratings, average: 4.50 out of 5)

sam-stroitel.com

Making your own grain crusher from a vacuum cleaner

If you don't have a washing machine, look for a vacuum cleaner. It can be used in whole or in part. It all depends on which design seems more attractive to you and what skills you have. We invite you to get acquainted with a possible implementation option.

We prepare everything necessary for work

To make a grain crusher from an old vacuum cleaner, you should prepare:

- metalworking and metal-cutting tools;

- sandpaper;

- drill;

- fastening elements;

- pipe sections about 15 cm long for making an outlet pipe;

- ready-made knives or metal plates for their manufacture;

- a lattice with small cells, which is necessary for the manufacture of a sieve intended for sifting grain. If this is not available, you can use a metal sheet in which holes of the required diameter are drilled.

Attention! The above list is approximate.

Device diagram

The design of the device depends on which part is used. Most often, preference is given to options that involve the use of one engine. It is installed on the base, under which there is a container for receiving crushed grain.

Preparation of prefabricated elements

At the preparatory stage:

- we make the base using plywood, laminate or rolled metal;

- disassemble the vacuum cleaner to remove the engine;

- drill a hole in the base. Its diameter must correspond to the diameter of the motor shaft;

- If there are no ready-made knives, we make them from metal plates. With a thickness of about 1.5 mm, their length should not exceed 20 cm;

- If there is no ready-made sieve, we make it from a metal sheet.

Assembly of the structure

The process of assembling a grain crusher from a vacuum cleaner includes a number of stages, each of which deserves special attention:

- Using a nut, fix the knife on the motor shaft;

- install a sieve;

- We place a container under the sieve into which the crushed grain will flow.

Attention! Installing a tin box for loading grain will simplify the crushing process.

A grain crusher made from an angle grinder or a washing machine: is it a myth or reality?

A self-made grain crusher is not inferior in functionality to standard purchased products. The main unit is an electric motor, which has sufficient power and rotation speed.

Therefore, models made from a washing machine or from an angle grinder are very popular. Such homemade designs are indispensable at home.

In this article we will tell you how to make such a unit with your own hands from scrap materials.

Grinder grinder

A hand saw with a rotating blade is an indispensable thing for the home and in general for the household. Farmers have figured out how to significantly expand the functionality of this power tool. A grinder makes an excellent homemade grain crusher. No drawings are needed to make this design. It's done like this.

Take a sheet of durable plywood. This will be the basis of the entire structure to which the remaining parts will be attached. You can use a piece of laminate. Two holes are cut in the plywood, the saw body is inserted into one, and a grain receiving hopper is inserted into the other.

The body of the angle grinder is secured with a metal bracket and bolts. Instead of a cutting disc, a knife is made of metal with a double-edged sharpening. This will be a grain crusher.

To the bottom of the plywood sheet, you need to attach a mesh of the appropriate size using bolts. Such meshes can be purchased ready-made or made by yourself. For example, use a saucepan with holes drilled in the bottom or an old colander.

You can use a 5 liter plastic bottle as a grain bin. A budget do-it-yourself grain crusher is ready for work.

Grain crusher from a washing machine

At home, a grain crusher can be made from an old washing machine. This will be a more advanced model than the previous version.

At its core, the washing machine is already a ready-made feed cutter and grass cutter; you just need to slightly modify the design.

https://youtu.be/wBZq-9tJ1lc

It is worth noting that it is recommended to use old washing machines as a basis. They are usually cylindrical in shape and the motor is located at the bottom.

In order for the grain crusher to work properly, the “washer” must be equipped with an additional engine. It is installed in the upper part, directly under the top cover.

Install the motor on metal corners or plates. As in the previous case, you will need to make a metal knife with a double-edged sharpening; the cutting edge should not reach the walls a little.

The second knife is installed on the base engine, which is located below. In order for a homemade grain crusher to work with maximum efficiency, the cutting knives must rotate in opposite directions.

A hole is cut in the top lid for pouring grain. It is recommended to design a small funnel so that the work can be carried out with minimal losses and greater convenience. As a funnel, you can use any plastic container with a wide neck or make a small box out of tin.

Considering that the upper motor will operate in an aggressive environment, it is necessary to supplement it with a dustproof casing. You can make it yourself from an empty paint can. Near the lower motor, a hole is cut in the side wall to allow the crushed grain to exit.

The operating principle of this design is simple and intuitive. By and large, the product resembles a large coffee grinder. Due to the large cutting plane and versatile rotation, the feed cutter effectively crushes any type of grain crops.

It makes no sense to provide specific drawings, because the model of the washing machine used as a basis may vary. The main thing is to understand the general principle of operation of the device. It is worth noting that this is the kind of do-it-yourself grain crusher that is most often used at home.

Grain crusher from a vacuum cleaner

At home, you can make a grain crusher from an old vacuum cleaner. Actually, the vacuum cleaner itself is not needed, you only need an electric motor. As a base, you can take a sheet of durable plywood with a hole cut in the center. The engine working shaft will come out through the hole.

To make a knife, you can use a metal plate about 200 mm wide and 1.5 millimeters thick. A vegetable cutting disc works well. The knife is secured to the motor shaft using nuts.

As a working chamber, you can use a ready-made metal sieve, but it is better to make it yourself. If you plan to grind not only grain, but also vegetables for your home, then the mesh should be removable, with different cell diameters . Such interchangeability is not provided for in purchased products.

To make a sieve with your own hands, you will need a thin sheet of metal, about 700 mm long. The workpiece is rolled into a ring, the edges are bolted or riveted. The lower edge is bent outward; the width of the folded part should not exceed 15 mm. The bend is necessary to secure the mesh.

A receiving hopper for finished products is installed under the sieve. Any container that has the volume you need is suitable here. This could be a basin or an ordinary tin bucket. To feed grain into the working chamber, you can construct a tin box. To control the supply of raw materials, it is recommended to add a movable damper to the box.

From the information above, we can conclude that a grain crusher, regardless of materials, works on the same principle. To make a high-performance feed cutter for your home with your own hands, you just need to show a little imagination. The required elements you will need:

- Electric motor. At home, a motor with a power of 1.5 - 2 kW, with a rotation speed of about 150 rpm, will be sufficient. Even if you don’t have old household appliances that can be disassembled, you can buy such an engine at any flea market. It makes no sense to use more powerful motors; electricity consumption will increase, and accordingly the economic benefits of operating a home-made unit will disappear.

- Cutting plane. Can be made from any durable metal sheet in minutes. You can use ready-made discs from vegetable cutters and blenders.

- Sieve. The diameter of the cells depends on the fineness of the grind. You can purchase a finished product or make your own design with interchangeable meshes.

Even if you buy all the necessary parts, the cost of a homemade feed cutter will be much lower than the price of any store-bought model. At the same time, the performance of a homemade unit will be no worse.

Source: https://fermerznaet.com/selhoztehnika/obrabotka-kormov/zernodrobilka-svoimi-rukami.html

From the Bulgarian

A characteristic property of a manual electric grinder is the axis located perpendicular to the cutting disc. To make a grain crusher from an angle grinder (grinder), do the following.

- Mark and cut a rectangular piece from thick (1 cm or more) plywood.

- Cut a round hole in the cut piece of plywood - in the shape of the main structure in which the cutting disc rotated.

- Secure the plywood with the bolts and metal bracket included in the kit. The axis of rotation should be directed downwards.

- Make a cutter from a steel strip of suitable length, width and thickness. As in the previous case, the knives must be carefully sharpened and centered. Insufficient centering can eventually break the angle grinder gearbox.

- Not far from the angle grinder mounted in the tank for crushing grain, make a hole and provide it with a funnel. Through it, uncrushed raw materials are poured into the grain crusher. The funnel with a hole is placed not under the grinder drive, but above it.

- Below the drive, mount a sieve made from a used pan. It is drilled using a small drill (about 0.7-1 mm).

Assemble the grain crusher. Place it on a pallet or box. Under the lower funnel, where the crushed raw materials are poured, place, for example, a bucket. The funnel can be made from the cut off top of a plastic food bottle - the diameter of the neck is enough for the poured grain to easily and quickly pass into the grain crusher.

Making a loading funnel

Cut a piece of round pipe. We cut a hole in the homemade body. We install the pipe and scald it.

A slot must be made in the pipe to install a valve so that the flow of grain can be regulated. The author made the valve itself from sheet metal.

As a result, we have a loading funnel for feeding grain into the working chamber. A plastic bottle will be inserted into it.

From a meat grinder

To make sure that the meat grinder will grind the grain, you can use resins, for example, hazelnuts or walnuts in shelled form. There is no need to make a knife that performs the functions of a cutter “from scratch” - it is already included in the kit. For the small fraction of grain, you must use the smallest standard sieve, also included in the delivery set.

In order for the grain to be milled continuously, it is necessary to install a large funnel above the grinding mechanics, for example, from a 19-liter bottle with the bottom cut off.

A hole is made in the lid of a diameter at which the poured grain will not pass through the neck faster than it is passed in crushed form through the crusher of the meat grinder. In principle, the meat grinder does not need to be modified in any way. The grain should not be too hard - not all meat grinders can handle durum wheat equally effectively. If you cannot use a meat grinder as a grain crusher, use a coffee grinder.

How to make a crusher mill with your own hands

Making a grain crusher with your own hands is not that difficult. To do this, you need to have on hand a motor from an old household appliance, for example, a vacuum cleaner or washing machine.

In addition, you must have some locksmith skills. By the way, when assembling such equipment with your own hands, you need to remember the safety rules. Since all engines operate on electricity, it is necessary to take all measures to reduce the traumatic risk of the assembled product.

We must not forget that fast-rotating parts are used as a working body, which can cause injury to the person working on it.

Structure of a grain crusher, design features of the machine

Manufacturers put a variety of crushers on the market, with different characteristics, productivity, etc. Most of this equipment is easy to maintain and does not take up much space. As noted above, in practice crushers are used that use rotary or hammer principles in their operation.

Rotary machines have a drum with knives. In hammer mills, hammers are used as a working tool, which are loaded inside the drum.

By the way, there is equipment that uses compressed air as an energy source. The processed raw material moves inside the drum along with air. As a result of this, the quality of the resulting product increases dramatically. In addition, in this, and in many other designs, magnets are used that select metal particles that get into the mixture.

Making a grass grinder from a grinder with your own hands

Mown grass and small branches on your own farm are not garbage, but raw materials that can be used to create feed mixtures or prepare compost. But such raw materials must be crushed, and doing this manually is very difficult and troublesome. If you don’t have the money to buy a special garden shredder, you can easily make a shredder from a grinder with your own hands. Moreover, it is better to immediately make a universal unit that can chop not only grass, but straw, as well as branches of bushes and small trees.

The do-it-yourself branch chopper from a grinder is slightly different in design from the grain crusher described above, although it works on the same principle.

How to choose a grain crusher: expert advice

Choosing the right model

How should you choose a crusher that will meet all consumer requirements? To do this, you need to know the answers to some questions:

- Performance. A high grinding speed ensures high productivity in obtaining finished products, and accordingly, the use of such an installation will be highly efficient. Such installations can be considered the optimal solution for large farms. For home work, an installation with a low or medium processing speed of raw materials is sufficient.

- Price. The equipment must not only ensure high quality of the resulting product, but also generate certain income to recoup the investments made in this equipment.

- Grinding degree. The device must be selected based on the type of livestock and poultry the produced feed will be intended for.

- Drive station power. The greater the power of the installed power plant, the greater the productivity of the installation. It must be taken into account that the higher the engine power, the higher the energy costs.

- The company is a manufacturer. Undoubtedly, there are world-famous companies that produce shredders, but you need to think three times about how quickly the funds invested in brands will pay off.

When choosing a model, you must be guided by the characteristics specified by the manufacturer.

Crusher balancing process

Most equipment that uses rotating components as a working tool undergoes a balancing procedure. This work can be done either independently or with the help of invited specialists.

When balancing, the following sets of work must be performed:

- identifying the causes of vibrations and eliminating them;

- monitoring the condition of equipment in terms of vibration;

- balancing shafts in existing bearings;

Why is balancing necessary? The answer lies on the surface. The thing is that the presence of excessive vibration leads to failure of the bearing units, and as a result, everything can end very sadly.

Grain crusher performance

The process of functioning of a rotary chopper involves the movement of the cutting knife. It is needed to crush the masses that should be fed inside the receiving hopper.

The hammer preparation can grind grain efficiently using hammers that are attached to a strong base.

- Products obtained using a hammer machine will be considered the most effective. This can be achieved with the help of a high amplitude of movement of the hammers, which are capable of crushing even individual grains of grain.

- At the same time, the impact crusher can consume much less electricity and has a high productivity factor.

- If the farm has a large number of adult livestock and poultry species, it would be best to buy an impact crusher. But in the case when a farmer breeds smaller poultry and a large number of young livestock for trade, then the optimal choice in this case will be in favor of hammer grinding of grain.

- It is imperative to test a device that you have produced yourself. It is worth remembering that the grinder engine requires regular lubrication, otherwise it will quickly break due to abrasion of the main elements in the device.

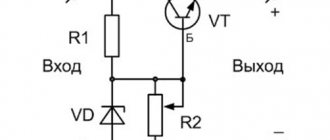

Homemade grain crusher: diagram

The grain crusher consists of the following units:

- Gate valve for regulating the flow of grain into the working chamber.

- Grain bunker.

- Electric motor on/off button.

- Electric motor.

- Sleeve.

- Axis.

- Washer.

- Screw.

- Screw.

- Base.

- Working chamber housing.

- Container for crushed grain.

- Bolt.

- Screw.

- Metal mesh (sieve).

Diagram of the crusher working chamber.

Recommendations

To ensure that the shredder's performance is high enough, follow the advice of experts.

- Insulate the motor using an additional casing made from, for example, a large tin can. The fact is that the motor gets into a dusty environment - this dust is formed when grinding dry grain. The engine may become clogged with deposits, and its operation will slow down - a noticeable part of its useful power will be lost.

- Do not use the grain crusher at maximum speed, trying to grind tons of grain in one go. A large farm with large numbers of farm animals will require two or more grain crushers. It is better not to skimp on equipment so that it does not break down after a few days, but works for a number of years.

- Use grain collection containers with as large a capacity as possible.

- Clean and lubricate the mechanics every three months or six months. Regular maintenance - and scheduled replacement - require bearings, without which no electric motor would work.

- The listed measures will allow the user to process large volumes of grain without investing extra in repairs and without stopping urgent work.

Peculiarities of crusher operation

In order for the grinder to serve its owner for as long as possible, you need to adhere to the following basic rules:

- monitor the temperature of the running engine - the motor from the angle grinder is not designed for long-term operation. If it overheats, it will quickly fail;

- If during operation the unit begins to vibrate strongly, you need to check the fixation of the nuts and bolts. If necessary, they will need to be tightened all the way;

- Regularly check the integrity of the receiving hopper - this is especially important if a drinking water bottle was selected when assembling the unit.

In addition, it is necessary to sharpen the edges of cutting knives in a timely manner. If they are not sharp enough, they will not be able to chop grain or branches.