What is

The appearance of this piece of kitchen utensil is associated with the spread of potatoes in Europe. This began en masse in the 18th century. Tuber puree became a common dish in the last century. In each country it was made using a device consisting of a vertical handle and a working area. Today, a puree masher is also used in households. Sometimes it is also used for chopping refried beans, vegetables, and apples. It helps in creating some types of sauces.

The handle makes it easy to use while the potatoes are still hot. Boiled tubers do not come out of the pan. The crusher is easy to clean from food residues. The cost of the product is low, it is affordable for any family. Takes up little space.

It takes some effort to get the perfect puree. You need to thoroughly mash each potato. It’s especially difficult to start work, so you can’t do it without strong hands. As a result of the effort and time spent, you will get a wonderful side dish.

Varieties

There are a lot of potato mashers in the world. They differ in the type of working surface, shape, and material of manufacture. Despite such diversity, the item is easy to distinguish from other kitchen utensils.

The first crushers include stone devices of the ancient world. With their help, herbs, nuts, and roots were crushed. They looked different in different nations. Modern models are distinguished by sophisticated style and practicality.

Holders are made of wood, metal, plastic. To save space, models with folding handles have been invented, when the design has a steel roller that holds it in a vertical position.

There are museums where potato crushers are exhibits. Their variety is impressive. An example is the Potato Museum in Idaho (USA).

By type of pressure surface

The main part of the device is the pressing surface. It can have a wide variety of types. A frequently encountered model is a disk with holes. The tubers pass through them, as if through a meat grinder, turning into puree. The mashed potato masher may look like a zigzag. There are designs that combine both types - after the steel tubes there is a disk with small holes.

Solid options came from past centuries. They are easy to wash and can be used for crushing various products. In some villages they still make devices for crushing root crops and vegetables with their own hands. For this, a pine branch is used, at the end of which there are many sprouts. It is cleaned, the branches are cut, and bent in the opposite direction. The result is a handle with 5-6 bent knots. Passing through them, the potatoes are crumpled and mixed.

Modern models include metal spirals that resemble a whisk. Pushers in the form of paddles with many holes are practical. After making the puree, you can apply it with the same object. One utensil replaces a potato masher and spoon.

According to the shape of the pressing surface

The shape of the working surface is most often round. But there are also square, rectangular, crescent, and oval options. The holes are made in the form of round holes of various diameters, oblong slits. In solid models, the pressing surface contains protrusions that crush the root crop.

The effectiveness of original form models is difficult to assess. The pusher in the shape of a rocket looks unusual when the working surface consists of 12 rounded parts, reminiscent of smoke from a launched ship.

According to the material of manufacture

Among modern potato masher, one cannot single out a leader in terms of material type. Each of them has its own characteristics of use. You need to focus on efficiency, ease of cleaning, and safety.

- Metal products are light in weight and can mash several potatoes at once. To prevent aluminum from entering into a chemical reaction with products, it is coated with a special compound. Once it wears off, the potato masher becomes unusable. Models made of medical stainless steel, consisting of chromium and nickel, are more durable. The utensil is not suitable for Teflon-coated pans or ceramic containers. Preference should be given to models made of solid metal.

- Wooden masher consists of a pestle with a solid pressing surface. It is better to use juniper, which practically does not absorb moisture. The utensil is not deformed and preserves the inner layer of the pan. The disadvantages include the inability to prepare large quantities of puree and the absorption of odors.

- Plastic crushers weigh little, have a variety of shapes, and are compatible with all coatings, including non-stick ones. But such products break quickly and are only suitable for kneading warm potatoes. At high temperatures, plastic releases toxic compounds.

- Silicone - made from modern material, they are durable, suitable for hot products, can be cleaned in the dishwasher, and do not damage the dishes. Models can be used for no more than five years, after which they emit chemicals that are harmful to humans.

- Teflon - metal products coated with a special compound do not deform, preserve dishes, and mash large portions of potatoes. They require careful handling, since the Teflon coating can break off from mechanical stress or aggressive detergents.

If a wooden product begins to emit an unpleasant odor, it must be treated with a special solution. To do this, take a teaspoon of baking soda and clean water. The item is soaked for half an hour, rinsed with running water, and completely dried.

Presentation of a technology project on the topic “Tolkushka”

Add original materials and receive prizes from Infourok

Weekly prize fund 100,000 RUR

International distance Olympiads "Erudite III"

Available to all students in grades 1-11 and preschoolers

Record low registration fee

in various subjects of the school curriculum (separate tasks for preschoolers)

We are accepting applications

Description of the presentation by individual slides:

Creative project on technology Topic: “Pusher” Performer: Nikita Bachu Student 8th grade MAOU Secondary School No. 23 Leader: Manakov A.I.

The urgency of the problem lies in the fact that potato masher machines are available for sale in stores in our city, but they are all the same. Because of this, I came up with the idea of creating the creative project “Tolkushka”. In this project, I bring to your attention an easy-to-manufacture product that does not require large investments, which we developed and manufactured in a creative association. You can give it to your loved ones or friends, or keep it as a keepsake. Object of study: existing potato masher. Hypothesis: if we develop and independently manufacture an original potato masher, then housewives will like it more than the version from the store. Purpose of the work: to create a product for use in everyday life, in order to preserve and develop applied creativity.

Originality Durability Practicality Safety

Our product must meet the following requirements: Strength; Reliability; Manufacturability; Economical in manufacturing; Environmental safety of materials; Safety for others; Practicality

Choice of material. Before making the “pusher”, I chose the most alternative of the materials we had, and it was birch wood. Birch wood has a uniform structure. It contains practically no natural resins. Materials made from this wood have high strength, especially under impact loads. Often used for furniture production.

Selection of tools and equipment

Economic justification Birch harvesting - found in the workshop of the technology room; Wood varnish 500ml – 145 rubles; Brush – 20 rubles; Scotch tape – 50 rubles. Tools and equipment were provided by the technology teacher. Result – 215 rubles.

Ecological justification Come on, friends, in any weather Let's take care of our native NATURE! And from our caring love. The earth will become richer and more beautiful! Remember, adults, remember, children! Remember that the beauty on the planet will depend only on us. Don't forget this now. Save the living planet for the people. And let him praise the anthem of life - NATURE!

Conclusion about the work done So the work on my project has ended. I put a lot of effort and perseverance into making it, and got great pleasure from making it. I really like my product. I showed my work to my friends and parents and they said that the work was done well and neatly. It follows from this that I achieved my goals.

Thank you for your attention

International distance Olympiads "Erudite III"

Available to all students in grades 1-11 and preschoolers

Record low registration fee

in various subjects of the school curriculum (separate tasks for preschoolers)

We are accepting applications

- Manakov Albert IgorevichWrite 1285 02/06/2019

Material number: DB-424858

- 30.01.2019 98

- 15.01.2019 87

- 09.01.2019 149

- 25.12.2018 711

- 20.12.2018 126

- 17.12.2018 97

- 07.12.2018 108

- 16.11.2018 70

Didn't find what you were looking for?

You might be interested in these courses:

All materials posted on the site were created by the authors of the site or posted by users of the site and are presented on the site for informational purposes only. Copyrights for materials belong to their legal authors. Partial or complete copying of site materials without written permission from the site administration is prohibited! Editorial opinion may be different from those of the authors.

Responsibility for resolving any controversial issues regarding the materials themselves and their contents is taken by the users who posted the material on the site. However, the site’s editors are ready to provide all possible support in resolving any issues related to the work and content of the site. If you notice that materials are being used illegally on this site, please notify the site administration using the feedback form.

Puree press

The mash press allows you to make perfect mashed potatoes without any lumps. This is achieved thanks to small holes located evenly in the base, on the sides of the base. The mass of tubers is saturated with air, making it light and tender.

Main advantages of the press:

- It is not necessary to drain the water - it will drain from the holes;

- saves time - in one click you get a plate of side dish;

- ease of the process - fill the container 2/3 with potatoes, press the lever;

- practicality - it can be used for preparing a variety of purees, juices, and mousses.

You need to choose high-quality products without damage, with well-treated seams. Some models may cause rust. It is important to wash the press completely to prevent rotting.

The classic model includes a handle, a piston, and a container with holes in the base. The device has two holders. There are designs with replaceable disks in which the holes differ in diameter and number. Some devices resemble a mill because they have a rotating handle.

Famous brands

The product will serve for a long time if you choose it taking into account the basic criteria. It should be durable, with a non-slip handle. Lightweight models are more suitable for work. Burrs, cracks, stains, and roughness on the surface should alert you. A foreign chemical smell is a reason not to choose this crusher.

List of famous brands:

- WMF is a German manufacturer that creates stainless steel crushers.

- Rondell, a German cookware manufacturer, makes stainless steel mashers in the shape of a bent spatula.

- Gefu - utensils from Germany, the material is stainless steel.

- Tefal is a French company that produces models made of plastic, coated with Teflon.

- Krauff, a German manufacturer, creates pusher blades from durable food-grade silicone.

- Tupperware is an American company that produces a solid steel model with a round base and oblong holes.

The most convenient diameter of the working surface is considered to be 7-8 cm, the handle should be 25 cm long. The loop for the handle allows you to secure the product to the railing.

Technology for manufacturing wood products “MAKING A PUSHER”

For preschoolers and students in grades 1-11,

a record low registration fee of 25 RUR.

Description of the presentation by individual slides:

Municipal budgetary educational institution "Oboroninskaya Secondary School" of the Mordovian district of the Tambov region Project on the topic: Technology of manufacturing wood products "MAKING A CUTTER" Author of the project: 9a student of the municipal educational institution "Oboroninskaya secondary school" Pelekshin Oleg Teacher: Gudukhin S.P.

The goal of the project is to produce a useful product for household use.

Project objectives 1. Justify the significance of choosing this product. 2. Present the design development. 3. Develop a technological process. 4. Calculate the cost. 5. Identify the environmental aspect of the project. 6. Evaluate the product.

Structural development Optimal dimensions: Length of the working part - 80 mm, diameter - 50 mm. The working part of the pusher smoothly turns into a handle. Optimal handle dimensions: length - 150 mm, diameter in the middle part - 10 mm. For ease of use, the end of the handle should be thickened and have a hole for hanging the product. These sizes were chosen to be light and easy to use.

Technological process Select a block 60*60*270. Find the center under the tailstock and make a notch under the front headstock on the end parts of the block. Mark the block and process the edges with a plane to an octagonal shape. Install into lathe. Process with a roughing cutter along the entire length up to a diameter of 52mm. Grind clean to a diameter of 50mm. Mark the elements of the part. Grind the handle according to the drawing. Sand the product, cut it off and drill a hole in the handle with a diameter of 3 mm. Coat the handle with varnish Process map Equipment and tools

Cost calculation The cost of one crusher is 11 rubles. 42 kopecks, which is four times lower than the market value. Detailed cost calculation

Environmental aspect of the project When processing wood, the waste will be: small shavings, sawdust, cuttings of boards. The trimmings can be used to kindle the stove, sawdust - as bedding for animals and subsequently as fertilizer, also as insulation and filler for the manufacture of chipboard and fiberboard. Thus, the waste is environmentally friendly.

Information resources Magazines “School and production”. Textbooks: Technology. Simonenko V.D. Technology grades 5-11. Project activities in the classroom. Ponomareva N. A. Project method in labor school. Kagarov E. G. www.lesmaster.ru www.sdelaemsami.ru/stoliar.html

Why teenagers want to work and how teenagers can earn money correctly: psychological and legal aspects

March 2 – 4, 2022 19:00 (Moscow time)

Certificate for each participant

Discount on courses for all participants

Material number: DV-107544

Didn't find what you were looking for?

You might be interested in these courses:

Drawing of a wooden crusher

Sawmilling and woodworking waste from the most common coniferous and deciduous species is used as raw material for the manufacture of various household products.

In order for the products to better retain their shape and size and not come apart, they are made from dry wood. On collective farms, state farms and inter-farm associations, wood must be dried to a moisture content of 10.12% before processing. In organizations and enterprises that do not have artificial dryers, natural air drying is performed. Then the products are dried on racks arranged in workshops near central heating pipes.

KITCHEN CUTTING BOARDS

Kitchen cutting boards are designed for cutting dough, cutting meat, sausage, cheese, cleaning fish, vegetables and fruits (15, 16). They are made in various sizes from soft hardwood and softwood (9). The following defects are allowed in the wood: hard knots, fused, size ds 15.20 mm, in the amount of 3 pieces, on a board with an area ds 0.1 m2, cross-layer with deviation of the fibers from the straight direction up to 10 cm per 1 m of length, redness and hard darkness, false core, curling, blueness, through cracks no more than 5 mm long at the ends, tarring no more than 5 mm deep. On the front surface of the boards, superficial traces of tobacco, loose falling knots, sprouts and tar, as well as shells and hard fused knots (at the junction of the handle with the board) are allowed.

The preparation of elements of kitchen cutting boards should be mechanized as much as possible. For this purpose, auxiliary enterprises, collective farms, state farms and inter-farm organizations for the production of household wood products use circular saws and pendulum saws, planing, drilling and grinding machines.

After sorting the waste pieces by size and type, they are cut to a given length and the handle is cut out. If the waste is taken from unedged material, then its edges are sawn down to width. After this, the layers, edges and ends of the boards are thoroughly planed, as well as sharp corners are rounded and handles are processed. The surfaces of the boards must be flat, smooth, cleanly and evenly planed, and the front surfaces of the boards must be sanded. The edges of the cutting boards that make up the board must be tightly grooved without gaps, the dowels fit tightly into the grooves, and the sides are adjacent to the edge and ends. Sharp edges on the handles, edges and sides of the boards are removed and rounded. The joints of the sides are cut “on a mustache”. The boards are secured with nails no longer than 50 mm (the number of nails is at least 3 in each board). The panels of each board are assembled from wood of the same species. A hole with a diameter of 15.20 mm is drilled in the handle on a drilling machine. Finished boards are inspected and marked. Boards of the same size are folded in pairs so that their front surfaces touch and placed in bundles.

The following deviations in the dimensions of kitchen cutting boards are allowed: length ± 10 mm; width ±5 mm; thickness ±2 mm. Kitchen cutting boards are manufactured in accordance with OST 13-35-83.

MANUFACTURING A POTATO MASHER AT THE WOODWORKING CLASS

The word technology comes from the ancient Greek techne

- “art, skill, skill” and Latin

logos

- “teaching, word, science.”

Under technology

understand a set of techniques and methods for obtaining, processing or processing raw materials, materials, semi-finished products or products carried out in the process of production.

Technology (or technological processes) is also called a certain sequence of production operations, actions that ensure the production of any product of a given quality. Accurate execution of all operations and adherence to their sequence are a guarantee of the production of products of the specified quality and in the required quantity.

Technology as a science deals with identifying physical, chemical, biological patterns in order to develop and use the most efficient and economical production processes.

One of the most important goals

Learning woodworking at the “Jack of all trades” group is to develop in students the correct attitude to the surrounding reality and corresponding beliefs. It is well known that only that knowledge becomes a person’s beliefs that is acquired consciously, “passed through the hands.”

The ability to think, to look for new, non-standard solutions are qualities without which effective work in any sphere of human activity is impossible. An important task

woodworking classes in the “Jack of all trades” club is to develop a creative attitude towards work in students. It is based, as research by psychologists shows, on developed technical thinking. It is characterized, in particular, by the ability of spatial imagination and the ability to connect theory with practice. Experience shows that one of the methods for developing creative thinking in school workshops is solving technical problems.

Technical tasks include tasks for reading graphic images, as well as design and technological tasks with economic content. Their decision is based mainly on the knowledge, skills and abilities acquired by students in previous classes.

In order to decide what we will make in a mug for the family, we need to determine what it needs. Marcus Aurelius also said: “Firstly, do not do anything without a reason and purpose, and secondly, do not do anything that does not benefit society.” Work in the “Jack of All Trades” circle is based on the implementation of creative projects. The result of a creative project should be a real product, made at a sufficiently high technological level, capable of becoming a competitive product on the market or satisfying the family’s needs for something.

Wood products are currently in great demand. Such as kitchen boards for cutting food, kitchen sets consisting of a potato masher (potato masher), rolling pin, hammer, a number of products for household needs: door handles, files, chisels, hammers. The proposed products, produced by high school students, will have a low cost and, accordingly, an affordable price for most buyers, including the poor.

MANUFACTURING PARTS FOR WOOD PRODUCTS

Wood is one of the most common materials that man learned to process in ancient times. With the help of an ax, knife and other tools, people made houses, bridges, windmills, fortifications, tools, dishes and much more.

And these days we are surrounded by a large number of wood products: furniture, musical instruments, children's toys, kitchen utensils, etc. The unique beauty of the processed surface of a wood product always attracts the eye.

Wood as a natural structural material is obtained from tree trunks by sawing them into pieces.

MANUFACTURING PRODUCTS WITH A CIRCULAR SECTION

When manufacturing products with a circular cross-section, it is necessary to show possible ways to improve technological processes; familiarize yourself with the techniques of manufacturing cylindrical parts with hand tools and on a machine.

Equipment used: ruler, pencil, thicknesser, plane, file, hacksaw, awl, cutters, sandpaper.

Students are shown samples of products that contain round parts and tenon joints (overlay). The attention of the circle members is drawn to the symbols of these elements on the drawings. They dwell in more detail on sawn rials for making products.

Students are shown samples of lumber, as well as particleboard and fiberboard. They talk about the advantages and disadvantages of these plates, their manufacture and use. Pay attention to the flaws and defects of wood, which must be taken into account when choosing blanks for the manufacture of parts. These are knots, cross-layers, twists, cracks, wormholes, etc. Knots make it difficult to process wood, disrupt its uniformity and reduce its strength. Cross-layering - the oblique direction of the fibers - reduces the strength of the wood and makes it difficult to process. Cracks violate the integrity of wood and deteriorate its mechanical qualities. Wormholes are winding grooves filled with dust. They reduce the strength of wood. Processing defects include foreign inclusions (stones, sand, wire, nails), as well as burrs, flakes, dents, and chips.

Before practical work, they talk about how to reduce material costs and simplify the manufacturing process of products in order to reduce their cost. Students are explained concepts such as labor productivity, production costs, labor rationing, etc.

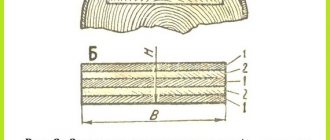

Next, students are explained the procedure for making a cylindrical part by hand (Fig. 1).

To do this, take a square block with a processing allowance of 5-6 mm. The width and height of the workpiece are divided into three parts in proportions 2: 3: 2 and precise lines are drawn. An octagon or circle is marked at the ends of the workpiece. Next, use a plane to remove the shavings until you get an octahedron, and then a hexahedron. The final processing is carried out with a rasp to the desired size, and then with sandpaper.

To manufacture such a part on a lathe (Fig. 2), select a block of square cross-section without knots and cracks with a machining allowance of 5-6 mm in diameter and 60-70 mm in length. Centers are marked at the ends of the bar and pricked with an awl. Next, use a plane to give the block an octagonal shape. The workpiece is secured in the machine and processed, accompanied by a demonstration. The tool rest is installed in such a way that its upper supporting surface is 2-3 mm above the level of the machine center line and is no more than 2-3 mm away from the workpiece. To check the gap, the workpiece is turned manually one revolution. First, the workpiece is rough turned with a semicircular chisel, moving it along the tool rest. During the first pass, remove chips 1-2 mm thick using the middle of the chisel blade. Further turning is performed with the side parts of the blade while moving the cutter both to the left and to the right. With this procedure, the surface of the part is less wavy. An allowance of 3-4 mm is left for finishing processing.

Before finishing, control grooves are machined along the edges of the workpiece to the specified diameter of the part. When finishing grinding, the oblique angle is placed on the edge with an obtuse angle downwards, and a sharp angle upwards. The chips are cut off from the middle or bottom of the blade. The surface of the manufactured part is cleaned with sandpaper attached to a wooden block. When cutting the ends, a slanting chisel is placed on the edge with an acute downward angle and a shallow cut is made. Then, stepping back a little to the side, they trim the end, cutting off part of the workpiece into a cone. When the diameter of the neck and end becomes 10-12 mm, the part is removed from the machine, the ends are cut off with a saw, and the ends are cleaned with a rasp and sandpaper.

CONNECTION OF PARTS

Students are explained that the parts they make can be connected in various ways. So, for example, parts with a round cross-section can be connected to other parts using round tenons, and parts of a rectangular shape can be connected with an overlay (half-wood) (Fig. 3).

Such connections can be end and middle. Students are shown examples of connections and told how to make them. Such connections are usually made with glue, but they will be more durable if they are reinforced with screws or dowels.

STRAIGHT OPEN STUD CONNECTION

At the same time, it is necessary to become familiar with methods of connecting parts that help improve the quality of products; Explore with students the process of making a direct open tenon joint.

Equipment used: ruler, square, thicknesser, saw, chisel, chisel, mallet, sandpaper.

Students are shown samples of products. Their parts can be of various shapes, and some of them are connected to each other by an open straight spike. They explain to Kruzhkova members that tenon joints are most often used in woodworking. There are many different types of such compounds. Each of them consists of a spike and an eye. They explain that the strength of such joints depends on the quality of the wood and the accuracy of manufacturing of individual elements. To do this job well, you must be able to read the drawing, select a workpiece of the required quality and carry out all the necessary technological operations in a certain sequence.

The drawing is read by the whole group. Determine the shape and size of the parts, ways to connect them to each other. Pay attention to the conventional images of individual elements of the product.

TECHNOLOGICAL CHART FOR MANUFACTURING, PROCESSING AND ASSEMBLY OF THE PRODUCT

The main stage in the manufacture of a product is the technological map. It consists of 3 columns, which sequentially, step by step, schematically show the stages of execution (manufacturing) of the product.

After drawing up the technological map, we proceed to the implementation of the product itself. As technological processes are carried out, it is necessary to make notes of the following nature in notebooks: tools..., equipment..., machines... (list names) were used to make the bar. So much time was spent. Work on the first day is 6 hours, of which 3 hours use electricity. Etc.

Let us give as an example a technological map for the manufacture of a potato masher (potato masher), since on its basis you can make a kitchen spatula, a kitchen hammer and a rolling pin