What can you use to make a car stand with your own hands?

A do-it-yourself car stand is made from metal water pipes and other pipes. It is very reliable and allows you to adjust the height.

When repairing a car yourself, it is important that it does not roll away, because this can lead to serious injuries, damage to equipment or the vehicle itself. Therefore, supports are used for many repair work. And an inexpensive solution would be to make your own car stand.

Design

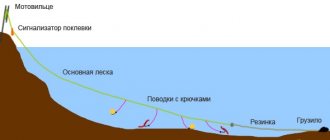

A do-it-yourself or purchased car stand has a simple design. It is equipped with a tripod for installation on the floor, a mount that holds the car by the sills. Sometimes equipped with a height adjustment mechanism. But this lift is not used instead of a jack. Therefore, the car is first lifted with a jack, and then supports are used.

DIY car stand

Is it possible to keep rubber in a metal structure?

The fact is that it is necessary to adhere to strict rules for saving tires, which include maintaining a certain temperature, air humidity, etc. A metal garage can get very hot in the summer and it will be very dry inside, which is unacceptable for rubber. If such a structure is located in the shade of trees, then as a last resort you can leave the wheels in it, but only in a suspended state.

Building racks for storing tires with your own hands is not so difficult, the main thing is to think everything through correctly and be patient. And what materials to use to implement an idea is an individual choice for everyone.

Types of stands

Do-it-yourself car safety stands come in several types. They are divided into regulated and unregulated. The supports differ in the material from which they are made.

Car safety stands

A DIY wooden stand for a car is the simplest type of tripod. It is usually unregulated, but has sufficient reliability. Metal supports are often made or purchased. They are usually adjustable and fit both cars and trucks.

Unregulated

Non-adjustable tripods are cheap. This DIY wooden car stand is very quick to make. They are also made from other materials.

Adjustable

Adjustable stands for the car, purchased or made by yourself, are equipped with a mechanism that allows you to change the lifting height. It is very convenient to use. But ready-made devices are expensive. And making them is more difficult than ordinary supports. Metal or iron and wood are used for manufacturing.

Adjustable car stands

Such supports are used in garage auto repair shops. You can also use them to repair your car if the work is complex.

What can you make a rack for storing wheels from?

The raw materials from which the shelves are made must be durable and able to withstand the weight of tires and rims. Based on the type of materials used, the racks are distinguished:

- metal;

- wooden;

- combined.

After putting things in order in the garage, you can find unclaimed blocks of wood or long-abandoned metal profiles that are used to make shelves. If there are none, you need to select and purchase the desired material.

ATTENTION! Tires and rims are heavy, so the material chosen must be strong enough to accommodate the maximum amount of rubber on the shelf.

Possible drawings of racks for wheels

Storage products are distinguished by type of design:

- floor;

- wall;

- hanging.

For vertical placement of tires, frame racks are used, and tires with rims are laid horizontally on shelves.

Before making any design, even a very simple one, a sketch is made. The rack is designed for vertical storage of tires without rims. The drawing includes the dimensions of the product, as well as the distance between the individual frame elements.

Takes into account the radius of the wheels that will be stored - this affects the size of the transverse beams connecting the vertical posts. The sketch reflects the number and length of longitudinal slats, depending on the number of intended products that will be stored on the rack.

REFERENCE! The standard executive dimensions are considered to be a height of 2 m and a width of 1.5 m. But if the room conditions or user requirements do not allow these values to be observed, then this is not a violation of the design, but only individual characteristics.

Drawings of shelves for wheels

When designing a temporary horizontal arrangement of tires, the sketch provides for such a width that will allow the rubber to lie firmly on the surface. This storage method is used for tires with rims. The height between the shelves is made larger than the width of the wheels that will be stacked on it, while the number of stacked products is recommended to be no more than two. The dimensions of the structure must be larger than the tire parameters and allow free use of the internal space for storing tires.

Metal rack for vertical storage of wheels

The reliability and durability of metal structures is higher than wooden ones. The use of metal and its profiles will allow you to make a practical tire rack.

What materials will you need?

- corner size 35–50 mm;

- profile pipe of rectangular cross-section, say 40x15 mm or similar;

- To ensure rigidity, additional spacers from a profile strip with a width of 35–50 mm are used.

If you do not have a welding machine, you will need mounting bolts with nuts and washers. The threads must withstand the load, so it is recommended to use the M8 connection size.

ATTENTION! For ease of making connections, the rectangular pipe is selected in such a way that one side corresponds in size to the size of the corner.

Prepare the necessary tools

- grinder with cutting discs;

- screwdriver;

- measuring and marking tools;

- welding machine with electrodes;

- drill;

- hammer and plumbing kit.

Preparing the components of the rack

Before starting assembly, the material is cut into blanks that will be used in the manufacture of the rack. Depending on the required dimensions of the product indicated in the drawing, corners and rectangular pipes are cut into sections used as racks, longitudinal rails and stiffening crossbars. For ease of installation, the workpieces are laid out depending on the difference in size.

Assembling a rack with your own hands

- First, the joints of the parts are marked and the side posts are welded. The vertical supports are made from a corner, and the crossbars are made from a rectangular profile pipe. If the shelves are hanging, then the racks will have a trapezoid shape, and for a regular floor rack, they look like a ladder with a small number of steps.

- At the designed height, the longitudinal slats are welded first to one rack and then to the other. The material of the shared supports must be durable, so a corner is used.

IMPORTANT! The tires will rest on the longitudinal rail. To avoid deformation of the rubber, it is recommended to turn the corner so that the wheels touch the flat surface of the profile. Or use a round profile for longitudinal supports.

- The presence of a large length or height may compromise the rigidity of the product under load. To prevent this from happening, the structure is reinforced with diagonal or transverse stripes, which will not interfere with the placement of tires.

- When the finished structure is placed on the floor, metal “nickels” are welded under the support posts. Such supporting planes will not allow the rack to sag when fully loaded with wheels. Wall mounting will require mounting on hooks or using brackets with dowels.

Before installing the product in the required location, the metal surface is primed several times and then coated with paint.

Do-it-yourself wheel rack for the garage

Storing one set of tires does not require the manufacture of a standard rack that can accommodate several dozen tires.

Depending on the individual characteristics of changing wheels (with or without disks), the consumer allocates space inside the garage.

Considering the small size of the buildings that car owners have to use, it is recommended to install a shelf or wall-mounted rack.

The raw material can be used timber or an unclaimed metal profile that can be found in the garage. The shelf material can be combined, for example, the side posts are made of iron, and the longitudinal slats are made of wood, or vice versa. In the absence of welding skills, as well as for connecting iron products with beams, bolted connections are used.

ATTENTION! Before using wooden elements to make a frame structure, you must make sure that they have retained their strength properties and treat them with an antiseptic.

Using a self-made rubber storage rack will bring the car owner not only cost savings, but also moral satisfaction, thanks to the opportunity to contemplate his own product.

Rack for horizontal storage of wheels

The sequence of work is similar to assembling the rack. The difference is that the longitudinal slats are replaced with sheet material, and the height between the shelves corresponds to the width of one or two wheels, depending on the design solution. To save space, such products are often wall-mounted or hanging.

DIY stand - ready-made diagrams

You can make a car stand with your own hands. Drawings and diagrams are available online. But you can draw the layout yourself.

As you can see from the photo of do-it-yourself car stands, they usually create simple tripods made of wood without adjustment. They are used for repair and maintenance of passenger cars. The supports are light but durable.

But there are also schemes of more complex structures that allow you to adjust the height. Their creation usually requires experience working with metal and takes a little longer. But this DIY car stand is suitable for complex repairs and heavy vehicles.

Manufacturing instructions

A do-it-yourself car stand is made from metal water pipes and other pipes. It is very reliable and allows you to adjust the height. For manufacturing you will need the following materials:

Manufacturing instructions

Do-it-yourself car stand like this:

After assembly, the support can be painted or covered with other materials. It can easily support a passenger car and a small truck or SUV.

Source

Safety stand made of wheel rims for cars

Hello everyone, in this article I want to tell you how you can make a useful craft, namely a safety stand for a car from a simple, unnecessary wheel rim. So, we take a car rim and cut off the front edge with a grinder; from the photo I think it will be more clear which one it is))).

We also need a square profile measuring 60x60 and 50x50. We cut 25 cm from one and the other profile, then you need to drill holes.

In a 60x60 profile, we retreat 2 - 3 centimeters from the edge and drill a hole with a diameter of 15 mm, I selected the diameter of the hole for the bolt, almost any bolt will do, the main thing is that the length is more than 6 cm.

In a 50x50 profile, we drill holes every 3 cm, more often, less often, there is no particular connection to the size, but we drill as it will be more convenient for you.

Now we need to make a square hole in our disk in the middle, to fit the size of our profile 60x60. We apply, mark and cut out with a grinder.

Next, we insert our profile into the cut-out square hole, insert it until it rests against the table, it will be clearer in the photo, and only after that we scald it around.

On one side of the 50x50 profile I welded a pulley to provide a platform for supporting the car.

I welded a chain to the bolt, and screwed the chain itself to the disk, this is so that the bolt does not go anywhere))).

To give the stand the appearance of spray painting it, first, of course, primed it.

This turned out to be a useful, and most importantly necessary, fake. Now you can crawl under the car without fear.

All the best to you and good luck to everyone.

Author; Glavnyiy-Mehanik Sumy, Ukraine

Do-it-yourself homemade safety stand for a car from a wheel rim

You insert them into each other, then into a vice. Drill holes approximately every 3 cm to insert the bolt. Clean the disc and pipe blanks from rust using sandpaper or a drill attachment. We place the pipe in a standing position in the center of the disk, mark a square mark, and cut it out with a grinder. We insert a 6x6 pipe into the center of the disk (into the sawn hole) and weld it to the disk. We insert a 5x5 cm pipe inside, place a roller on top of the pipe and weld it. We paint all our parts and dry them. We weld a piece of chain to the bolt on one side, and screw the other side to the hole in the disk with any bolt. Our entire design is ready, we can begin testing.

This post may contain affiliate links. This means I earn a small commission from links used at no additional cost to you. See my privacy policy for more information.

Types of stands

Do-it-yourself car safety stands come in several types. They are divided into regulated and unregulated. The supports differ in the material from which they are made.

Car safety stands

A DIY wooden stand for a car is the simplest type of tripod. It is usually unregulated, but has sufficient reliability. Metal supports are often made or purchased. They are usually adjustable and fit both cars and trucks.

Unregulated

Non-adjustable tripods are cheap. This DIY wooden car stand is very quick to make. They are also made from other materials.

Adjustable

Adjustable stands for the car, purchased or made by yourself, are equipped with a mechanism that allows you to change the lifting height. It is very convenient to use. But ready-made devices are expensive. And making them is more difficult than ordinary supports. Metal or iron and wood are used for manufacturing.

Adjustable car stands

Such supports are used in garage auto repair shops. You can also use them to repair your car if the work is complex.

Rack for horizontal storage of wheels

Tires that are not separated from the rims can be stored horizontally.

The manufacture of shelves for such placement is distinguished by the possibility of using sheet material as a raw material and a smaller height, which is especially important in limited space. The sequence of work is similar to assembling the rack. The difference is that the longitudinal slats are replaced with sheet material, and the height between the shelves corresponds to the width of one or two wheels, depending on the design solution. To save space, such products are often wall-mounted or hanging.

DIY stand - ready-made diagrams

You can make a car stand with your own hands. Drawings and diagrams are available online. But you can draw the layout yourself.

As you can see from the photo of do-it-yourself car stands, they usually create simple tripods made of wood without adjustment. They are used for repair and maintenance of passenger cars. The supports are light but durable.

But there are also schemes of more complex structures that allow you to adjust the height. Their creation usually requires experience working with metal and takes a little longer. But this DIY car stand is suitable for complex repairs and heavy vehicles.

Safety stand for a car. With your own hands

This safety stand is needed in order to leave the car in a raised state after you have raised it with a jack.

For this device you will need:

First of all, cut two pieces of pipe equal in length.

Next, in a pipe with a larger diameter, use a drill to drill a hole near the end of the pipe.

It is necessary to attach a corner piece to the smaller of the pipe pieces. For ease of fastening, we suggest making a recess at the end of the pipe. It is convenient to make the recess using an angle grinder. Try to make the cut approximately in the middle of the edge.

We attach the corner piece to the pipe by welding.

Next, we place a smaller piece of pipe into a larger pipe and drill holes in 2 cm increments. These holes should coincide with each other in both pipes. To do this, fix the pipes relative to each other.

Now all that remains is to attach the larger piece of pipe with its end to the metal plate. The plate will act as a support for the entire safety post.

Thus, we have a telescopic retractable rack for fixing the car in a raised state. All that remains is to paint this homemade product and try it out.

Main stages of work

The first step is to make a mount for the grinder. To do this, the author cuts off two metal plates, drills holes in them and attaches them to the gearbox housing using bolts.

After this, you will need to cut another plate and weld it to the first two plates.

Next, the author welds a steel strip to the resulting fastening, the end of which is fixed to the body of the angle grinder using a clamp.

DIY car stand

Greetings, Samodelkins!

Many of you probably have a personal car and you most likely had to independently repair your iron horse, little by little, so to speak, without fanaticism. The author of the YouTube channel “TeraFox” is no exception.

Safety precautions for hanging wheels include installing a support under the car. This rule should not be neglected in any way, and the simplest, most accessible and most importantly free method is a tree stump.

But after all, we live in the 21st century, we want something more modern, functional and no less reliable. After quite a long period of thought, the master realized that everything had long been invented before him. All you have to do is go online and choose the most suitable option.

The choice was made, the material was purchased. For this homemade product we will need two square pipes 30 by 30 and 40 by 40, wall thickness 3mm. Since there are no specific sizes, the author decides to do everything approximately, by eye, so to speak. The first step is to mark the fortieth pipe. Then we will cut off the required total length for two pieces, which in turn will also have to be cut at an angle, but closer to the edge. The parts are ready and absolutely symmetrical to each other. And now it’s the turn of the 30th pipe. It fits and exits perfectly into the fortieth pipe, therefore, the fortieth pipe can be used as a template for marking the thirtieth pipe and trim off the excess using a grinder. Out of 30 pipes we also received 2 parts. Now let's return to the 40th pipe. We need one more piece with angled edges. This is what we have at this stage. It turns out to be a kind of house; the crossbar will need to be welded to the upper sections along the edges. This is what we will do now. And everything would be fine, but there is a very small nuance in the form of a 4mm gap between the pipes. This is too much, 2mm everywhere, we need to fix it. The author found a 2 mm metal plate. It was decided to make spacers in the form of strips from it. This is the only way to reduce the gap, although if we initially took pipes 40 and 35 with a wall thickness of 2 mm, then this point could be eliminated. But still, the 35th pipe is more difficult to buy, they don’t sell it everywhere, plus a 3mm wall is still more impressive than 2mm, so that’s how it is. The gap is reduced, the movement is free, that's what we needed to get. Next, the strips must be carefully welded at points to the pipes. Using a core, we mark future holes along the edges and drill, starting with a small diameter. To make the holes coincide with each other, we hold the pipe in the pipe. We finish drilling with the tenth diameter of the drill. A bolt test shows that the idea was a success, a clear match. Using exactly the same principle, you need to make holes in the rack. And on the opposite counter there are absolutely the same manipulations. So far everything is going according to plan. Next, we disassemble the workpieces into parts and begin marking on the internal guide posts, starting from the top hole by 30mm and then repeating. A total of 4 such holes need to be drilled. So, the main part is ready, of course the stops are missing. The remainder of the 30th pipe will be used for these purposes. The parts are welded, the only thing is that we leave untouched those areas where the strut reinforcements will be located, in simple terms, gussets. Next we need a piece of 4 mm sheet. All that remains is to mark it and cut out the missing parts. The scarves are ready, positioned along the posts with an inclination relative to the surface. We immediately weld everything into place. In front of you is an old broken jack: The teeth at the base could not stand it, the lead screw was severely deformed. The reason for this breakdown was that once the author of today's homemade product raised the car too high, and it simply slid to the side, jumping off the jack and thereby damaging it. But at the moment we only need the rubber band from the top of the jack. Under the elastic band, I need to make a special base with sides. A 50 x 20mm profile pipe is perfect for this. This is what happened in the end. Now you need to make a hole in the crossbar for this base. You also need to drill a hole in the center of the base itself. And now, all the parts are ready. It's time to start assembling. And the same pin from the jack will also come into use, we’ll just correct the chamfer a little. Next, the lower part of the cross member must be strengthened using a thrust plate. To do this, we mark the same remainder of the 4 mm plate, cut it out, and then weld it. But this is not the final element of our design. Now let's put everything together and see what we ended up with. There are 4 holes in the stand and of course there are not enough latches. You can, of course, come up with something out of bolts, but perhaps not this time. We protect the tenth round timber from corrosion, cut it into 60mm pieces in the required quantity, core it and straight to the machine. And now the 4 studs are ready, all that remains is to make a chamfer. Now we need rings from cheap Chinese keychains. They are great for a new task. And how is this not a harsh keychain for a locksmith? And finally the production approached the final stage - painting. The paint is completely dry, then assembly follows. This is such an unusual stand. And of course it needs to be tested in operation. To do this, you need to move to the garage. We start by removing the cross member and placing it between the jack and the fulcrum on the stiffener, like this: Then we thread the posts through and secure them with studs. That's it, you can lower it, the stand works. Now let's raise the car higher by increasing the height of the pillars. Once secured, lower the jack. At the same time, the author noticed a displacement of the stands relative to the floor due to the support rubber. When you lift the car, it moves a little, as if sliding on an elastic band. This requires a specific clamp. Let's make a new stop with pieces of round timber on the plate.

Design features

Diagrams and design drawings for tire maintenance can satisfy any requirements of the car owner. It can be:

- racks and shelves of various configurations;

- hooks and stands;

- specialized cabinets in which you can create your own microclimate, ideal for keeping a particular set of tires in the garage.

Some of them are universal and suitable for any tire, others are highly specialized and designed for special conditions.

Racks and shelves

A rack for storing wheels in a garage gives the owner the following advantages:

- the ability to equip a rack with wheels with additional shelves designed for various tools;

- depending on the size of the garage and the amount of free space, the size and shape of the stand can be easily adjusted during assembly;

- the design has a large margin of safety at a relatively low cost.

Hooks and stands

Convenient devices for storing wheels in the garage, with the following advantages:

- easily and quickly made independently;

- take up little space and can be placed in any free corner of the garage;

- the stand, unlike a shelf or rack, can be easily moved from place to place and, in case of repair, it does not need to be dismantled or disassembled;

- materials for their manufacture are readily available and relatively cheap.

Note! Wheel hooks can be made as permanent brackets that attach to the wall, or as a removable piece that can be hung from a metal cable or rope, which is very convenient.

Specialized cabinets

If there is desire, time and money, the garage owner can equip the room with a special cabinet for storing wheels. Advantages of cabinets:

- the design does not spoil the appearance of the room;

- placed in any free space. It is not necessary to install it on the floor; you can make special fastenings and hang it on the wall;

- storing the wheels in a special cabinet will ensure that a jar of oil or other liquid that is in your garage will not accidentally be knocked over on them. This will significantly extend the life of the tires.

Wooden stands instead of a pit in the garage

brazh

Regular participant

Often there is a need to crawl under the car. For example, to change the oil. But not everyone has a hole in their garage. I don't have it either. Therefore, you must use a safe way to lift the car and secure it in this position. Climbing under a car that is only supported by jacks is very dangerous! Most often, people use special stands, as in the figure below.

The following ramps are also popular (at least in America):

But it seemed to me safer to make wooden stands for the wheels. I found the most information on this topic, again, on American sites. At the end of this post I have provided links to the most interesting articles.

Advantages of wooden stands: 1) Safety. Some people use bricks, which is not recommended at all, because... At any moment, the brick can crumble and you will merge with your favorite car. The tree, before breaking, will begin to crunch. Those. More often than not, there will be some indication that something is wrong. The likelihood that the car will slide off such stands is very low (if you follow safety precautions). 2) Easy to make stands. 3) The relative cheapness of this option.

But there are also some disadvantages: 1) You cannot remove the wheels. 2) Wooden stands take up quite a lot of space in the garage.

It is interesting to note the fact that American firefighters use approximately the same stands when they need to fix a heavy object (for example, a car). Only firefighters use separate blocks (wood cribbing) so that they can build various stands:

My version of wooden coasters looks like this:

On top I screwed 2 sheets of plywood, each 10mm thick (I had unnecessary pieces in the garage). I inserted scraps from the boards into the holes in the top of this entire structure for additional strength of the top layer. I screwed all the boards together with self-tapping screws.

The car is placed on stands like this: first the front is placed, and then the rear of the car (or vice versa). Many cars have points where you can jack up the entire front or rear at once. There are no such points on my Passat, so I first lift the front on the right side, and then on the left. The same is done with the rear. When I lift the right side, and then start to lift the left, the car’s suspension tries to “bring together” the wheels. For this reason, the stand on the side opposite to the rise begins to tilt and may tip over. Is it dangerous! Be careful and control this situation! After this, you have to return to the left side again and adjust the stand:

Be sure to use wheel chocks when lifting the car!

This is what the Passat looks like with the front end raised on stands. There is enough space to work. It's not scary to crawl under such a car.

Rules for storing car wheels

Not every car owner knows that they need to follow the rules for storing wheels, otherwise they quickly become unusable and can fail at the most inopportune moment. Different sets of tires have specific storage conditions, but general rules can also be identified, the observance of which will be relevant in any situation:

- Do not store wheels near heating or cooling devices. Significant temperature changes occur near them, which cause condensation to accumulate and deformation of the rubber.

- Make sure that the wheels are not exposed to moisture, oil or acidic liquids.

- Store tires in a cool, dry place.

- If the wheels are wrapped in film, do not forget to periodically remove and ventilate them. Otherwise, dampness will begin to accumulate inside, which will negatively affect the material in the future.

Now let's look at the individual storage features of different sets.

Summer tires

Summer tires are made from materials whose composition is different from winter tires, and accordingly, the storage conditions will be different. The peculiarity of storing summer tires is that the room temperature should be kept around 20 o, with a relative humidity level not exceeding 60%. Small deviations from these indicators are acceptable.

Winter tires

Winter tires do not tolerate high temperatures well. Therefore, beware of installing racks and fixtures for storing it in:

- rooms with high temperatures;

- places exposed to direct sunlight.

Storing wheels on disks adds additional nuances to the preservation process. The thing is that when stored vertically, the tires, under the influence of the weight of the rims, will begin to deform. This will reduce their quality of adhesion to the road surface, which can lead to an emergency situation.

It is recommended to store assembled tires in a horizontal position, on top of each other, or suspended on a rope that is threaded through the center of the disk.

Note! When storing tires for the winter, they must be well inflated. The pressure inside the wheels should be working or slightly below normal.

No disks

If you store tires separately from wheels, follow these rules:

- keep them upright;

- once a month, rotate the tire 20-180 o;

- It is allowed to store the wheels in a suspended state, stringing them on a rope or metal cable.