Why balancing is needed

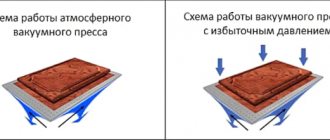

Uneven tire wear or damage to the disc leads to imbalance, that is, an imbalance in the distribution of wheel mass relative to the horizontal and vertical planes. There are two types of imbalance:

- Static, when the axis of rotation shifts relative to the axis of inertia and begins to move the center of gravity up and down.

- Dynamic, when the axis of rotation intersects with the axis of inertia, disrupting the horizontal distribution of the wheel mass. The disk makes a figure eight while the car is moving.

There are two types of imbalance: static and dynamic

Imbalance causes the wheels to vibrate while driving. Wheel imbalance, especially when driving at high speed, worsens handling, increases the braking distance, and leads to premature wear of chassis parts.

Unbalanced wheels cause loss of control when driving at high speed. But even if an accident does not happen, constant vibration causes the hub bearing to become unusable, and over time, the entire chassis system of the vehicle breaks down.

The purpose of the procedure is to restore balance to the wheels during rotation. The result of balancing is a uniform distribution of wheel mass relative to the axes of rotation.

How to understand that wheel balancing is needed

An experienced driver can easily identify a significant imbalance of wheels, as it directly affects the behavior of the car.

Typical symptoms of imbalance:

Signs of imbalance in movement: video

- Vibrations and shaking of the steering wheel, progressing with speed.

- Deterioration in controllability, deviation from the correct trajectory.

- Uneven wheel noise when driving on a flat road.

- Vibrations in the rear of the car (imbalance of the rear axle wheels).

- The tire tread pattern has uneven wear and there are “bald spots” on it.

Similar symptoms can occur with steering and suspension faults. Therefore, if balancing does not help eliminate the problems, then these components should be diagnosed.

The need for balancing is indicated by the presence of defects in tires and wheels that were not previously present during a visual inspection.

How often to carry out

There are no clear and specific recommendations for all cars on the frequency of balancing. It all depends on the operating conditions of the vehicle, the condition of the wheels, and other factors. Experts recommend balancing:

- While changing tires. In reputable service stations, the procedure is included in the price of the car.

- If the wheel hits an object or falls into a hole. Such situations lead to disc damage and wheel imbalance.

- After 15,000 km. During the season, few car enthusiasts accumulate such a number of kilometers, so a standard car only needs balancing when changing tires.

- Every 8,000 km for lovers of an aggressive driving style.

- Before traveling over 1500 km.

The principle of balancing wheels on a car

The general principle of wheel balancing is to detect deviations from the uniform distribution of mass relative to the center of the wheel and eliminate them by moving the tire and wheel and/or adding weights. If there are disc deformations, they are first corrected, and only then the balance is restored. Before performing the procedure, it is necessary to wash the surface of the wheel and remove small stones and other objects from the tread that may affect the weight distribution.

To perform vertical balancing, you need to find the lightest points on the circumference of the wheel and weigh them down. For longitudinal balancing, it is necessary to detect points that cause a displacement of the vectors of inertia forces, and similarly balance them by hanging weights. Tire offset helps less in this case, because it is usually the tire, and not the disk, that is more involved in causing the imbalance.

How to do wheel balancing

There are 4 main ways to balance car wheels, depending on the equipment:

Balancing wheels on professional equipment: video

- Static (manual) balancing . The wheel is mounted on an axle that allows free rotation and allows detection of mass displacement. To search for statistical imbalance, the wheel rotates in the vertical plane, while dynamic and combined imbalances rotate in the horizontal plane. If there is an imbalance, the wheel will constantly fall towards the point of overweight. The technology is simple and accessible, but has low accuracy ; the quality highly depends on the qualifications and experience of the master. Today, such a service is not provided by professional service stations, but can be found in garage workshops.

- Dynamic balancing on a stand . The wheel is fixed to the axis of the balancing stand, after which it is rotated, during which sensors detect and measure the imbalance. Next, the operator independently or based on the stand’s prompts (if this function is available) selects their installation locations. The procedure ends after the imbalance is zero.

- Automatic powder balancing . The wheels are filled with a special powder (also known as granules and beads), which, under the influence of centrifugal forces, is distributed over the inner surface of the tire and balances the wheel. Under the influence of a static electric charge generated by friction, the powder adheres to the wheel and is held at the desired points. The method allows you to quickly balance the wheels of heavy equipment, it is relatively simple, but the granules themselves are expensive, their correct dosage is required depending on the size of the wheel and the magnitude of the imbalance.

- Final balancing on the car . The car wheel is jacked up and a balancing device equipped with a roller and sensors is attached to it. The roller spins the wheel to speeds of about 90–100 km/h, and sensors record the magnitude of the vibrations that occur and calculate the load attachment points and their mass. Since the hub, the brake drum or disc, and the drive axle shaft rotate together with the wheel, this balancing technology makes it possible to balance all arising inertial forces as accurately as possible and eliminate runout. The advantage of the method is high accuracy, the disadvantages are low prevalence and high price.

The table below presents a comparison of wheel balancing methods, which will help you weigh their pros and cons and find out which balancing of passenger car wheels will be the best choice, and what is the best way to balance truck wheels.

How wheels are balanced: description and comparison of technologies

| Balancing method | Advantages | Flaws | Peculiarities | Average price for the season* 21–22, rub. |

| Installing balance weights manually |

|

| Due to its low accuracy, the method is suitable for balancing small passenger wheels on cars moving at a speed of no higher than 100 km/h. | Free (only costs for weights) if done independently. Almost never found in professional services. |

| Adding balancing powder to the tire |

|

| Suitable only for vehicles with wheels with a diameter of 15 inches or more due to low accuracy. |

|

| Dynamic balancing of a car on a stand |

| Weights get lost when driving on bad roads and during washing, spoiling the aesthetic appearance of the wheel | The most common balancing method. Optimal for cars of all classes. |

|

| Final wheel balancing directly on the car |

|

| Recommended for fast sports cars, not available for heavy equipment (trucks, buses). |

|

*Average prices are indicated for two balancing of 4 wheels per year, when switching from summer tires to winter tires and vice versa.

**Before final balancing, a “rough” dynamic balancing may also be required to eliminate the most pronounced imbalance.

Signs of Imbalance

The main signal of imbalance is the appearance of vibration. The intensity of vibration transmitted into the cabin depends on the degree of imbalance. Sometimes at speed the car begins to literally tremble with its entire body.

The nature of the vibration indicates which wheels are unbalanced:

- the front ones give shock to the steering wheel;

- the rear ones make the rear seats vibrate.

Other signs of imbalance include increased fuel consumption, tire noise when driving, uneven tire wear, and regular flat tires.

How to balance a set of tires at home?

DIY balancing device

If a tire service is unavailable or if you want to save money, you can balance the wheels yourself using a machine that can be assembled in a garage. The simplest garage balancing stand consists of a hub securely mounted on a rigid support with a flat base.

Balancing must be done in the following order:

- Fasten the wheel, cleaned of dirt, to the hub and spin it by hand.

- During rotation, observe the beating of the rubber, the “figure eight” of the disk.

If there are strong pronounced deformations and runout, balancing is unlikely to help. - Wait until the wheel stops and is balanced, put a chalk mark at the top point.

- Turn the wheel 90 degrees (a quarter turn) in both directions several times, waiting for it to stop after each turn.

- If the wheel is in a different position each time, there is no pronounced static imbalance, it is “conditionally balanced.”

- If the mark is always at the top, the main point of imbalance has been identified, you can begin to eliminate it.

The faster the wheel returns to the top position, the more weight is needed. Its exact value can only be predicted experimentally. Without experience, you can start with a load weighing 20–30 grams. - To eliminate the imbalance, you need to hang (without fixing it securely) a weight opposite the mark and repeat step 4.

- If, after hanging the weight, the mark still appears at the top, its mass must be increased; if it now goes down, it must be reduced.

- It is necessary to adjust the weight of the weights until the wheel, after spinning 90 degrees, stops in any position. When the optimal set of weights has been selected, they can be fixed.

For a more uniform distribution of masses, you can use several weights: for example, instead of one for 40 grams on the outer side, attach 20 gram weights on the outer and inner sides opposite the mark.

The described method is a static balancing designed to shift the center of mass of the wheel as close as possible to the axis of its rotation. It allows you to eliminate very large imbalances with an accuracy acceptable for cars that do not drive fast, but is not suitable for fine adjustments of balance. This is acceptable wheel balancing for VAZ classics and other similar models.

More accurate balancing of car wheels at home is possible using a “spinning top” shaped device. The tool can be made on a lathe from a solid steel blank (moreover, steel is harder than the common ST-3) with a diameter of about 150 mm, so that the structure is monolithic and balanced.

Aluminum and other soft metals are not suitable because the ends of the spindle axle must be rigid and not deform or become dull under the weight of the wheel!

The tool should have a slight taper on one side that turns into a thread. The conical shape is needed so that the wheel self-centers when the nut is tightened.

The balancing process is carried out as follows:

Balancing a wheel at home: video

- Place the “top” in the central hole of the disk and tighten it with a nut.

- Place the wheel with the tip of the “top” on a flat, hard surface or in a stand with a recess.

- Move the wheel and release it, controlling the position in space. A balanced wheel should independently occupy a horizontal position and return to it after rocking. If there is an imbalance, it will not stay “in the horizon”.

- If an imbalance is detected, you need to take a weight and place it at the highest point of the wheel, and then repeat step 3. If the same section still rises with the load, its mass must be increased; if it begins to fall, decrease it.

- The weight of the weights is selected until the wheel on the spoke begins to take a horizontal position and returns to it after each rocking. The static balancing of the wheel is completed, and if high accuracy is not required, then it can be placed on the car. If you also need to eliminate dynamic imbalance, then you need a rigid tripod (for example, a laboratory one) with chalk and the following further actions:

- The wheel is manually spun on the top to the maximum possible speed.

- With the help of a small wooden block, lightly pressed against the upper edge of the top, the vibrations introduced during spinning are dampened.

- The tripod arm with the chalk attached is smoothly brought to the wheel rim until it makes the first contact.

- After several revolutions of the wheel (and touching the chalk), you need to stop it and see at what point the chalk touches the disk.

- At the point where the chalk touches, a weight should be secured (the weight is selected experimentally), and a second weight of the same weight should be secured on the diametrically and diagonally opposite side of the rim. This is necessary to prevent static imbalance.

- Experiment with the weights until the beating of the wheel goes away and it stops touching the chalk with one point.

Self-balancing in a garage cannot fully replace the procedure on modern equipment due to low accuracy. Therefore, if possible, it is better to visit a service station and eliminate the imbalance completely. This is more reliable, and taking into account the considerable labor required to balance large wheels, it is also much easier.

Balancing methods

Using the advice of experienced drivers, you can carry out balancing yourself the old fashioned way without using a special machine. This will take more time than a service technician would spend, but it will help save money.

If desired, wheel balancing can be done independently in a garage.

To perform the procedure yourself, you will need the following equipment and materials:

- jack;

- balancing weights;

- chalk or marker;

- a set of keys.

Interesting! To balance wheels on cast or forged wheels, it is advisable to purchase self-adhesive weights. But in winter, such weights can come unstuck due to temperature changes.

Balancing weights are required for balancing

Without removing the wheel

The self-balancing process consists of the following steps:

- Preparatory. The wheels are cleaned of dirt and stones stuck in the tires, the caps are removed, the pressure in the tire is reduced, and old weights are removed. The jack is installed on one side of the vehicle, freeing 2 wheels. Check the free rotation of the wheels. If the wheel is difficult to spin, you need to undo the cotter pin and loosen the hub nut.

- Determination of an easy point. The wheel is turned counterclockwise and waited for it to stop. Mark the top point. Then turn the wheels clockwise and mark the top point again. The midpoint between the two marks is the light point.

- Installation of weights. Using a hammer, weights weighing from 10 to 45 grams are placed on the found point, starting with the light ones. After this, they spin the wheel and wait for it to stop. The weights should be at the bottom. If it turns out wrong, the light weights are removed and heavier ones are added. It is not recommended to use more than 60 grams of weight on one wheel.

- Static balancing. As soon as the weights are at the bottom after stopping, they begin to move them apart in different directions. The wheel begins to rotate and the weights move apart. The goal of the process is to ensure that the wheel stops in a different position each time. Once this starts to happen, the weight is distributed evenly, that is, static balance is achieved.

The procedure is carried out in this sequence with each wheel. To check the correctness of the balancing, you need to drive the car at least ten kilometers at a speed of more than 90 km/h. If you don’t feel any jolts or tapping while moving, it means everything was done correctly. If the procedure is performed incorrectly, specific shocks to the steering wheel appear.

For your own confidence, at the first self-performed balancing, you can undergo diagnostics at a service station. If the specialists confirm that everything was done correctly, in the future you can carry out the procedure yourself.

Important! Self-balancing in the garage is only permissible if there is a static imbalance. Eliminating dynamic imbalance requires the use of equipment. Experts recommend contacting a service center if your car has worn tires and old bent wheels. Without special equipment, it is impossible to balance such wheels yourself.

At a homemade stand

You can make the balancing process easier by making a homemade stand in the garage. In this case, you do not have to remove the brake pads from the wheel and loosen the step nut.

A homemade stand simplifies the process of wheel balancing

The stand is mounted from an old hub with a working bearing. The hub is installed on the frame so that the wheel rotates freely and the entire structure is firmly held on the surface. It is convenient to use vertical metal posts as a frame, between which the wheel is attached. Further balancing actions coincide with the previous method of performing the procedure.

On the machine

Even an experienced motorist in a garage carries out balancing “by eye”. Therefore, there can be no complete confidence in the correctness of the process. In specialized workshops, balancing is performed on computer-controlled machines.

Modern service stations are equipped with CNC balancing machines

The machine consists of a cone-shaped support for mounting a wheel, a rotating electric motor and sensors. The wheel rotates when performing tire mounting, and at the same time the computer detects vibration and pressure. Sensor readings help to accurately calculate the weight and location of weights.

The workshops are equipped with two types of machines:

- Manual - in which the master measures the wheel with a ruler and manually enters the data.

- Automatic - information is read by sensors and displayed on the monitor in digital or graphical form.

Based on the type of supports used, machines are divided into:

- Soft, measuring wheel parameters, taking into account the vibrations of the supports.

- Rigid, measuring pressure and rotor phase.

Interesting! On rigid machines you can test various parts, but the quality and accuracy of measurements is reduced for this reason.

Most modern services are equipped with automatic balancing machines. The master puts the wheel on the shaft, tightens it with bolts and unscrews it. Sensors determine the points of axial runout. The computer determines the intensity of the push and calculates the mass of the load that must be attached to the calculated point. The computer will also inform you if the wheel cannot be balanced.

Balancing with granules

One of the newest methods of wheel balancing is the use of special granules instead of weights. The essence of the technique is to pour special granules into the tire, which slide while driving in the internal space. This free movement eliminates imbalance when driving at speed.

Modern wheel balancing techniques involve the use of microbeads

The advantage of this method is that the granules are poured once, and they perform their intended function throughout the life of the tire. The disadvantage of this balancing method is the high cost of the granules. Therefore, balancing in this way has not gained popularity at present.

Video: DIY wheel balancing

Homemade balancing machine for car wheels. Do-it-yourself wheel balancing

Not only the comfort of the driver and passengers, but also their safety, as well as the serviceability of other components and mechanisms of the car depend on the condition of the car’s wheels. In addition, it significantly affects fuel consumption.

One type of vehicle chassis maintenance is wheel balancing. Why this procedure is needed, how it is performed and with what frequency, we will explain in this article. We will also consider the possibility of implementing it on our own in a garage.

Wheel balancing: what is it for?

Several thousand years have passed since the invention of the wheel, but even today, in the age of high technology, it is not possible to make it ideal. In addition, during movement it is constantly affected by many factors leading to mechanical deformation.

This applies to both the disk and the tire. The slightest flaws associated with the uneven distribution of their mass around the circumference lead to imbalance. This, in turn, leads to vibration, which has a destructive effect on the wheel bearing and other elements of the chassis.

But is wheel balancing necessary if the car is quite reliable? Here's a simple example: at a speed of 100 km/h and an imbalance of 15-20 g on a 14-inch wheel, the load on the disc will be similar to hitting it with a three-kilogram hammer at intervals of 800 times per minute. Now imagine that you drive 100 kilometers this way. What do you think will happen to the chassis of your most reliable car?

To prevent such situations, the wheels are balanced. We figured out why it is needed. Now let's look at what imbalance is and what types there are.

Making a stand

After prolonged use, individual parts of the device may malfunction. Conventionally, the origin of the breakdown can be divided into mechanical disorders and problems with electrical components. In the latter case, problems with the sensors are detected. Mechanical problems most often occur after falls or strong impacts.

Problems with the machine can be detected by the following signs:

- Normal balancing requires several cycles of operation.

- The parameters of the tested disks are determined incorrectly.

The main task of the balancing machine is to determine the balance of the geometric center of the wheel with its mass. An unbalanced part makes any job difficult and can lead to serious damage. Eliminating imbalance allows you to:

- Increase the service life of bearings.

- Prevent premature wear of tires.

- Increase the service life of suspensions.

There are several options by which you can correct imbalance of wheels or other parts:

- Balancing rings - used in the process of repairing metalworking machines.

- Adjusting screws - special pins are screwed into the unbalanced part, through which it is adjusted.

- Drilling is the most popular balancing option. This is done by creating holes that change the weight of the parts being processed.

A do-it-yourself balancing machine is made so as not to remove the pads and not touch the hub nut. The work takes place with the wheel removed. To assemble the machine you need:

- Turn the shaft. A thread is applied to one end of it and a place for the cone is prepared. At the other end of the shaft, places for bearings are machined

- The stand is made from a pipe with a diameter of 52 mm. A support table is installed in the middle to support the wheel while being mounted on the shaft.

- Indicators are installed on the side and top of the rack to record wheel runout.

A homemade wheel balancing machine is used as follows:

- Place a clean wheel and tire on it, use a nut and a cone to secure it.

- Check both types of runout with old weights

- Remove the weights, spin the disk

- Mark a heavy place with a plus - it will go down, mark a light place with a minus - it will go up

- Rotate the dial 90 degrees

- In the place where there is a minus mark, install weights on the rim

- Turn the disk 45 degrees - if it remains in this position, then the balancing is complete

- Check the results of the procedure again, secure the weights

There are several options for making machines with your own hands, with the help of which the wheels on a car are balanced. If you have the necessary parts and knowledge of electronics, you can make an automated device. An electric motor is used to spin the disks.

Read more: Film on a car: choosing a coating and how to apply it yourself

Currently, the majority of stands carry out the balancing procedure automatically. The wheel is put on the shaft, clamped with bolts and unscrewed, while the end runout is measured automatically. As a result, the computer identifies problem areas and shows the weight of the weight that needs to be attached to the specified point.

It should be noted that due to the use of a high-tech stand, the process is significantly simplified.

A sketch of the wheel is displayed on a special display and the area where the weight needs to be attached is shown; the technician just has to follow the recommendations and avoid making serious mistakes.

But there are also exceptions; in particularly serious cases, it is not possible to balance the wheel with the help of weights, then the corresponding inscription is displayed on the display.

By attaching a weight of suitable weight, the master thereby gets rid of the uneven distribution of weight, due to which the eccentricity is reduced and the moment of inertia is significantly reduced, and as a result, the runout disappears.

The concept of imbalance and its types

Imbalance is a violation of the normal balance of a wheel caused by tire wear or deformation of the wheel rim. There are two types of this phenomenon: static and dynamic.

In the first case, the axis of rotation takes a parallel position with respect to the axis of inertia, shifting the center of gravity in a certain direction. Visually, static imbalance can be determined by lifting one side of the car, spinning the freely rotating wheel and observing it.

Before it stops rotating, it will make several pendulum movements in different directions and stop when its center of gravity is at the lowest point. Such symptoms are not critical for the car, but are fraught with uneven tire wear and increased fuel consumption.

Whether it is necessary to balance the wheels in this case is, of course, up to you to decide, but over time, a static imbalance can develop into a dynamic one, and then fuel and tires alone will not do the trick.

Errors during the procedure

If the balancing process is carried out in violation of the technology, then the vibration problem, at best, will not be solved, and at worst, it will further worsen. The most common mistakes:

- Balancing when there is dirt on the wheel. Even pebbles stuck in the tread can be disrupted by additional imbalance. The overall picture, even with precise equipment, will be disrupted, and it will not be possible to bring the wheel to zero.

- Balancing a wheel with a broken tire or wheel geometry. If the disc has even minor dents or distortions, it must first be rolled on a special machine. Straightening the disc with a hammer or other impact instruments is unacceptable.

- Incorrect torque of the hub bolt on the balancing machine. Excessive force will lead to the wheel being misaligned and the balancing will be incorrect.

- Violation of technology for installing a tire on a disk. Often, even experienced installers perform work in violation of technology. As a result, the wheel is given additional inertia.

- Misalignment during installation of the wheel on the vehicle axle. This problem occurs due to incorrect tightening of the bolts. Even if a properly balanced wheel is installed skewed, it will vibrate.

In order to avoid such troubles, you need to carefully choose a car service and supervise the work of the technicians. Qualified specialists guarantee their work and show the balancing results on the machine display. If the master prohibits the presence of the car owner during work or does not provide a guarantee, it is advisable to refuse his services.

Wheel balancing is an important element of monitoring the technical condition of a vehicle. A timely procedure will help not only improve safety and driving comfort, but also extend the life of the vehicle by preventing premature wear of chassis parts.

- Author: Andrey

Rate this article:

- 5

- 4

- 3

- 2

- 1

(11 votes, average: 4.8 out of 5)

Share with your friends!

Home →

With your own hands →

Homemade device

It is possible to make a calibrating machine at home, but only the mechanical part. Electrical equipment and measurement sensors should be purchased ready-made. The device drawings should be selected in accordance with the features of the future use of the machine. The best option for creating a balancing machine is presented in these step-by-step instructions:

- We create a shaft. It should be turned so that at one end there is a ready-made place for mounting bearings, and at the other there is a thread for installing a washer.

- We install bearings. It is best to use those that have already been used, but have not yet used up the main resource. Such parts will create minimal resistance.

- We form the apparatus stand. For these purposes, it is best to use a pipe with a diameter of 5.2 centimeters. At the upper end of the support we mount it from above and from the side.

- For convenient placement of the part, we recommend creating a support platform.

Video: DIY wheel balancing machine.

When balancing is not possible

There are situations when the correct wheel balance, even if all recommendations for the procedure are followed, cannot be established. This can happen for the following reasons:

- A foreign object has entered the wheel. For example, there is a screw or nut between the disk and the tire. In this case, re-flashing the wheel solves the problem.

- Poor quality tire. If the layers of rubber on a tire are not applied evenly, balance will not be achieved. The tire will have to be replaced or the wheel assembly will need to be spot balanced using professional equipment.

- The wheel rim is deformed. Most often, stamped discs have non-ideal geometry. Especially Russian-made ones. The problem is solved by rolling or replacing the disc.

The total weight of weights installed on a new wheel should not exceed 60 grams. If to achieve balance you have to install weights weighing more than 60 grams, it is worth checking the correct assembly of the wheel, the geometry of the disk and the quality of the tire.

An additional check for correct wheel balancing is carried out while driving. If at a speed of 90-100 mph you do not feel tapping, jolts on the steering wheel or vibration, then all actions have been performed correctly. To confirm the results of the work, it is advisable for a beginner to undergo diagnostics at a service station. If the experts determine that the wheels are in balance, you can safely carry out the procedure yourself in the future.

FAQ

Why is wheel balancing done?

Wheel balancing prevents wheel runout, which negatively affects handling and ride comfort, and also shortens the life of tires and suspension parts.

How often should wheels be balanced?

The average wheel balancing interval is 10,000–15,000 km. Wheels also need to be balanced when reinstalling a tire on a rim or after a severe impact to the wheel as a result of falling into a hole or hitting an obstacle.

What happens if you don't balance your wheels?

Wheel imbalance leads to increased vibrations when accelerating, deviation from the correct trajectory, accelerated wear of the tread, hub bearings, ball joints, silent blocks and other parts in the suspension.

How to check wheel balancing?

To balance wheels, it is best to use a professional stand, which will accurately detect points of imbalance and determine its magnitude.

How to recognize unbalanced wheels?

Unbalanced wheels cause vibrations and beating in the steering wheel, increase tire noise, and can cause the car to sway vertically on a flat road.