Owners of country houses, when heating them with wood, note that wet material burns longer, and the walls of the stove heat up more strongly. As a result, a “perpetual log” device appeared for artificially moistening combustion products. The principle of operation of the device is extremely simple: water is poured into a container and placed together with firewood in the stove. As it burns, the water evaporates and saturates the flue gases with steam. This increases combustion duration and heat transfer. You can make a steam generator with your own hands using ready-made drawings and diagrams.

How it works

Eternal logs can reduce wood waste by almost half. It all depends on the design of a particular stove. Most often, the savings figure reaches thirty percent, but sometimes fifty.

The specific heat capacity of steam is greater than that of air. If for air the indicator reaches one kJ, then for steam it reaches two.

It must be said that such a log is not suitable for all stoves that burn wood. An eternal log is perfect for a potbelly stove with a straight chimney. But if you have a brick stove with a duct chimney made in the wall, then problems may arise in the form of condensation from unburned steam. In this case, you need to inspect the chimney inspection hatches and make sure that there is no sticky soot there. If it is absent, then the use of eternal logs is quite acceptable.

If you do everything according to the instructions, you will definitely end up with an eternal log.

Device and features

A wood stove that does not have the ability to regulate the volume of combustion air will use up fuel too quickly. This increases the temperature of the exhaust gases and heat loss. Water vapor entering this zone helps reduce the intensity of combustion. The latter is formed in a steel container (steam generator) - an “eternal log”. Water is poured into it before putting firewood into the stove, and it is placed at the bottom of the firebox.

The use of a steam generator in a closed firebox is associated with the danger of a thermal explosion. During operation, it is necessary to ensure the cleanliness of the surface and promptly clean the steam outlets.

Efficiency and savings

When lighting a fire outdoors or a fire in a stove, you may notice that wet wood burns more slowly than dry wood. This is explained by the fact that the heat of combustion of the fuel is spent on heating and evaporating water. The operating principle has found application in heating a private home. The idea of the device is to use water as a moderator to increase the burning time of one load of fuel. In this case, during combustion, wood partially wastes thermal energy to produce steam.

Depending on the design of the furnace and steam generator, you can get, in %:

- increase in burning time – up to 50;

- increase in heat transfer of flue gases – up to 15;

- reduction in wood consumption for heating – up to 30.

Operating principle

The steam generator consists of a metal pipe, hermetically welded at the ends, support legs, a filler neck and holes in the upper part. The principle of operation is the formation of steam: heat from burning logs is transferred to water through the walls. The liquid boils and exits in a gaseous state through the upper holes. The steam irrigates the firewood, thereby reducing the intensity of combustion. At the same time, it transfers heat from burning coals to the heat-releasing surfaces of the furnace. Application sequence:

- Water is poured into the pipe through the neck and the plug is closed.

- Place the steam generator on the grate.

- Firewood is being stacked.

- They ignite the fuel.

Why does it work

Using an everlasting log increases the duration and quality of combustion of one load of firewood. Fire and heat can last up to 50 percent longer, depending on the design of the stove. Personally, for me, combustion is extended by up to 30 percent. My friends with other stove parameters have seen savings of 15 percent or more, which is explained by the inappropriate parameters of the dimensions of the log itself for their firebox. This result is achieved due to the fact that the specific heat capacity of water vapor is higher than that of air. This is a physical fact that has long been proven. For air this indicator is 1 (kJ/(kg K), and for steam it reaches 2 (kJ/(kg K).

I would also like to note that eternal logs are not suitable for all types of wood stoves. It is ideally compatible with ordinary potbelly stoves with a direct chimney. If a brick stove has a duct chimney in the wall, then in certain cases there is a possibility of condensation of unburnt steam. If you want to use eternal logs with this stove design, I advise you to inspect the inspection hatches of the chimney for the appearance of sticky soot. If it is not there, then the log is suitable and you can safely use it.

Anyone who has fired a stove, steam stove or potbelly stove at least once knows perfectly well how quickly firewood burns out. Even today, many dachas have solid fuel stoves. In order to maintain a constant temperature, such stoves should be refueled regularly. However, there is one clever method that will make logs burn 30 to 50 percent longer while still producing the same amount of heat.

Testing the invention

To save on heating costs,

making should be tested in practice.

It is enough to set aside 2 days to find out whether less firewood is actually used. For the first day, it is recommended to use eternal logs

, and for the second day, you should make do with only firewood.

When carrying out the test, it is necessary to rely on certain indicators - the same amount of firewood in kilograms per load, the time it takes to reach a temperature of 50 degrees, the period when combustion ends. For the eternal log reviews

are mostly positive, so it is important to conduct an independent experiment.

For testing, you should take 10 kg of oak firewood. Water is poured into the log, and then the structure is placed in a boiler or oven. It is recommended to take already hot liquid. Then the standard ignition of the furnace is carried out. The first day the invention is used, and on the second day all manipulations are carried out without a log.

When summing up, it becomes clear that the invention helps to quickly reach the 50 degree mark. For the eternal log reviews

This advantage has often been noted. The total burning time with the invention increases by 15-20%. It also takes a longer period for residual heat to form.

You should not be skeptical about the inventions of folk craftsmen. The use of everlasting logs shows good results. If desired, the indicators can be improved and greater savings achieved. Only by practical means will it be possible to find out how much water to pour into the pipe and how long it takes for it to boil away.

Eternal log: refinement and testing

There is such a topic. Video on the Internet. A version is described of why supplying steam in the firebox allows you to increase the burning time of wood.

As I understand it, the point is this: Superheated steam from the “Eternal Log” can, passing through hot, burning wood, essentially through carbon, disintegrate into hydrogen and oxygen.

I'm not good at chemistry. The hydrogen then burns. This is additional fuel in the stove. You need a temperature of degrees, but everything is correct.

If you simply place a “jar with holes” in the oven and pour water into it, there will really be little benefit: the water will take away heat for evaporation, and raw, not superheated steam will simply fly away into the chimney. The benefit of such a device is doubtful. But - if you make another shell of thick iron around the standard “eternal log” - the steam will overheat between the walls and participate in the combustion process. Since I have a “vertical” boiler, I made the log vertical from what I had on hand on the farm.

What makes you think that some additional fuel is taken? It’s just that what exists burns more slowly and with greater losses.

In the end, is this a myth or reality?

What can we say about this? All this, of course, is not true, the laws of physics have not been repealed and the law of conservation of energy still exists. Accordingly, in order to obtain additional energy in one place, you need to spend this energy in another. You also always need to make sure that the holes are always open, otherwise a water hammer may occur and the entire firebox will turn around.

There is only one piece of advice - a well-built stove will save fuel and keep you warm for a long time. But to do this, you need an experienced village stove maker who can determine the volume of the house and build a stove of the required size.

Source

How often should cleaning be done using Chimney Sweeper logs?

It is recommended to carry out the cleaning procedure regularly, at least twice a year. The frequency of cleaning largely depends on how often the stove or fireplace is used. For example, if the fireplace is lit once daily, it is enough to carry out preventive cleaning twice a season, using one block each time. If the fireplace (stove) is lit no more than once a week, one log for the heating season is quite enough.

Despite the emergence of new types of boilers and stoves, wood heating remains relevant for heating summer cottages and small houses. The efficiency of its operation and fuel consumption depend on the correct organization of the system. But besides this, it is important to know how to heat your stove or boiler with wood so that the house is warm.

Manufacturing

We take a pipe with a diameter of 76 mm and cut it to the length of the block. If you have a large combustion chamber in your stove (and you can load a lot of firewood into it), then it is recommended to use a pipe as thick as possible. There is nothing complicated in the process of making the device itself. First, you need to cut two circles along the diameter of the pipe from the prepared sheet metal and weld its ends hermetically. The stable legs should be welded crosswise.

After this, we make a filling hole by drilling a hole in the top of the tube and welding the nut. A bolt prepared in advance is screwed onto it and becomes a lid. It is recommended to weld a metal rod to the head so that it can be turned without using a key.

Primus

The most perfect and convenient way to organize a log stove. It gives a high concentration of flame and can be made in a “mini version” with a height of 20-30 cm. In order to organize a “Primus”, you will need several logs, and not necessarily from one log.

Operating procedure:

Cut the block to the specified size.

We divide it into 4-6 parts with an ax or saw or select suitable logs.

We gouge out the core and make notches (chips).

We connect the logs with wire so that we get a “well” inside. If the logs are large, you can make 2 of them shorter than the others. This will provide an influx of oxygen for pyrolysis during installation of the pot or pan.

The cold hearth before lighting should look like this:

Load the chips into the free space inside the stove.

Set it on fire and use it. Pay attention to the flame - pure pyrolysis combustion.

Larger options can be used for general purposes.

The optimal length of a log (chock) is two of its diameters. The ability to cook food and boil water is available for the first 2 hours after ignition, until the logs burn out.

Video on how to make a primus stove

How to make it yourself

Due to the simple design and the absence of complex-shaped components, even a craftsman without experience in the manufacture of metal products can make a steam generator. Tools you will need:

The main part of the steam generator is the housing. It is advisable to make it from a pipe with a thick wall (6-7 mm). The diameter and length are selected according to the size of the firebox. Steam generators that are too large will not fit into the oven, and in small ones the water will quickly evaporate. For the neck, you need to prepare a nut and bolt M 12. At the ends of the pipe, two disks 5-6 mm thick are welded, which are equal in diameter to its outer size. The support legs are made from any rolled metal: pieces of reinforcement, a circle, a corner, etc. The main thing is that the steam generator must be stably placed in the firebox.

Eternal logs to save firewood: myth or reality?

Owners of country houses, when heating them with wood, note that wet material burns longer, and the walls of the stove heat up more strongly. As a result, a “perpetual log” device appeared for artificially moistening combustion products. The principle of operation of the device is extremely simple: water is poured into a container and placed together with firewood in the stove. As it burns, the water evaporates and saturates the flue gases with steam. This increases combustion duration and heat transfer. You can make a steam generator with your own hands using ready-made drawings and diagrams.

Water more actively transfers more heat from the wood to the walls of the stove than dry air

After a while, when the water boils, steam is formed, which quickly comes out of the holes. Warm air and steam mix inside the stove to form a mixture, the heat capacity of which is almost twice that of ordinary air, as a result of which the stove warms up better.

Is it necessary to put firewood together with Chimney Sweeper logs?

The use of the “Chimney Sweeper” product is completely acceptable without “support” in the form of coals or wood firewood. However, hot coals left over from the previous fireplace firebox (stove) or dry firewood placed before cleaning the chimney using a Chimney Sweeper log will significantly enhance the effect of using this product. When cleaning the chimney with a “Chimney Sweeper” log in combination with firewood (coals), a block of the product is laid out on top.

Forbidden! Burn more than one log in combination with hot coals.

How to make an “eternal log” in a garage

What is an “eternal log”? This is a stove made of a metal pipe supported on several legs, the inlets of which are welded on both sides. The legs are made in such a way as to prevent the structure from independently rotating around its own axis. Several holes are made at the top of the pipe, which are closed with an improvised plug made from a nut and screw. These holes are intended for pouring water.

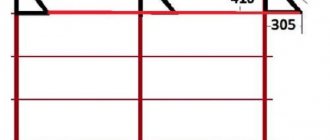

An approximate design drawing is shown in the image:

Eternal log (diagram)

The principle of operation of such a furnace is that when the flame temperature reaches 100 degrees Celsius, the water begins to boil, which leads to steam escaping through the holes. This in turn reduces the temperature inside the combustion chamber, thereby increasing the burning time of the log.

A similar effect can be compared to a fire made from raw wood. On average, the use of the described design allows you to increase the burning period of one log by about one and a half times.

It is not at all necessary to make a stove suitable for creating an “eternal log” yourself. Offers for its sale can be found in many online stores. On average, the price tag ranges from 1.5 to 3 thousand rubles. depending on the size and material of manufacture.