The house I rent is located on a plot with several apple trees. The trees are old and tall. The apples are hanging - you can’t reach them. You can’t even get them all from a stepladder.

There is no need to wait for full ripening. Apples themselves fall to the ground according to the law of attraction. All sorts of worms and the wind help.

Carrion is not stored for more than a week. Broken places rot. The worms are fattening.

Cooking jam requires an unlimited amount of sugar. And it takes a lot of time. And more than one bucket is filled with apples.

I wish I could squeeze the juice out of apples. Freshly squeezed juice will last for a couple of days in the refrigerator without sterilization.

And if it starts to ferment, add a little sugar and shut it down. Look, here is the wine for the New Year!

You can, of course, buy a factory-made juicer. Then squeeze it into filled cabinets in a cramped kitchen, and drag it around when moving.

And here in the yard there is a garage, a bunch of wooden planks. I also bought all sorts of jigsaw drills and jigsaws for work. Self-tapping screws in the garage are laid out on shelves.

All that remains is to file, drill, and twist. So this is my favorite thing!

I went online and watched videos on YouTube to see who made what. There are a lot of homemade apple crushers and juice presses. It doesn't seem complicated.

I bought a new two-ton car jack and galvanized mounting tape.

While I was assembling the devices, I didn’t have time to take pictures, so I’m only showing how it works and how it works.

I warn you!

If you are an esthete and lover of beauty, it is better to admire. Extracting juice in a garage is an unsightly sight.

Chopper (crusher) for apples, fruits, vegetables and grapes powered by a drill with your own hands

This is the cheapest method, since you do not need to buy an electric motor, order parts from a turner, etc. A chopper for apples and grapes can be made from a plastic bucket.

1) Plastic bucket

Buy a 20 liter bucket. Remove the plastic cover and handle - you will no longer need them.

2) Cutting knife

To make a knife, take 3mm stainless steel and sharpen it on an emery wheel. Weld a tube in the center and a hexagon to the end of the tube so that the knife axis can be well clamped in the chuck. On the back of the knife, weld a piece of metal that will cut the path downwards for the knife. (See photo)

3) Cover

Make a lid out of stainless steel or plywood with a hole in the middle. Make clips on the lid so that you can fix the lid on the bucket. Screw the centering sleeve made of friction plastic to the cover with 4 self-tapping screws. Cover the lid made of plywood with varnish.

4) Footrest

Screw the footrest to the bottom of the bucket so that the bucket does not rotate while chopping apples. The platform can be made of stainless steel or 10 mm plywood. Varnish the plywood.

5) Use only a powerful, high-quality drill or hammer drill in drilling mode.

To simplify the production of a crusher for apples and grapes, you can buy such a crusher entirely assembled in our online store or order from us the most difficult parts to manufacture and source materials (for example, a knife and a bushing). This is very convenient to do when purchasing a press, since everything will fit in one box and you will not have to overpay for the delivery of 2 goods. As a result, you will have a ready-made juice extraction kit. All that remains is to assemble the chopper with your own hands.

Tags: apple juice, fruit chopper, Calvados, cider

Comments 44

what kind of work are we talking about? There is also an episode in the video where whole apples are loaded into a bunker and chopped ones fall into a bucket. Should I have put another bucket through? so that it turns out full of grated apples? Or are you talking about the resulting juice? It's not clear from the question. If about juice, then I wrote in the comments here that there is a video on the channel with the operation of the previous chopper, and there the process is shown in its entirety, before showing the juice in bottles)) In the equipment set, only the chopper was replaced, the press remained the same, so I considered it unnecessary duplicate the same thing, lengthening the video and making it less watchable.

All clear. I rewatched the video.

Great, Kulibin! All that remains for me is to plant an apple orchard.

Bookmarked, let's sculpt.

For one liter of water + apple porridge + 1 kg of sugar = Pervach 65 degrees, after that it comes to 42 then 36 degrees of delicious vodka.

It is not recommended to ferment apple raw materials according to the so-called “red scheme”. Apples contain a lot of pectin. upon its hydrolysis, methyl alcohol is released. It’s better to ferment pure juice, although this loses a lot of flavor

Everything is correct. Only I didn’t describe the whole process correctly. Apples were made into apple juice (juice cooker), and then the juice + water + yeast + sugar were poured into flasks (the flask was about 75 liters) and covered with warm clothes. Then the distillation process began. My grandparents did all this; you could say they were professionals. But alas, time does not stand still; they are no longer alive. And I myself have never done this since I haven’t actually consumed alcohol since August 28, 2003, even beer and kvass (and I used to drink it before).

Grandmother and Grandfather were advanced. they made alcohol from fruit raw materials, at a time when everything was made from sugar

Yes, not advanced. The whole house was so excited about some of the apple juice, some of the pears. One thing I only know is that you can drink 1.5 or even 2 liters for two, but there won’t be any hops.

I recently assembled and passed the tests, now I need to paint it

- Author: Maria Sukhorukikh

Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

DIY apple crusher

The feasibility of making a homemade crusher is supported by a number of advantages of the device. Processing the crop will take less time, and there will be almost no waste. All the juice will be squeezed out, and the remaining cake can be used to make jam and other food products. A home crusher does not require special investments, saves labor costs, and is ideal for a personal plot. If the device fails, it will not be difficult to repair it yourself, since all the parts are known and available.

What does it consist of?

The homemade design differs from store-bought crushers not only in appearance, but also in details. Performance can be improved through targeted assembly for specific needs.

An electric crusher will speed up and facilitate the process. To save money, you don’t have to buy a motor; a motor from an old washing machine will do. An approximate list of components: cutting disc (knife), electric motor with support, housing, cover, control unit.

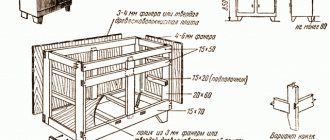

Diagram of a finished apple crusher, front and side views. Photo from profermu.com

1 – housing, 2 – stiffener, 3 – working shaft, 4 – bearing axle boxes, 5 – belt pulley, 6 – belt, 7 – electric motor, 8 – frame, 9 – rollers, 10 – control unit, 11 – transportation handle , 12 – housing mounting bolts with stiffening angles

What is needed for making

One of the options for the shredder begins with the manufacture of steps for the shaft and bearings from stainless steel (d 80 mm) on a lathe. An 8-sided gear shaft is machined on a milling machine. The grinder makes notches along the length of the teeth in the shape of triangles - this will improve crushing.

Drawing of manufacturing a gear shaft on a milling machine. Photo from profermu.com

The body of the crusher can be a top-loading washing machine. When cutting into 4 parts, you get 2 side and 2 end parts. The blanks are placed in a box, the seams are welded. Before welding the sidewalls, the lower part of the metal is slightly bent to obtain a gap from the housing wall to the working shaft.

Standard circular saw bearings secure the shaft. The metal corner is used to make the support frame. A plank base is suitable for the base. The control unit is an on/off button. Tensioning the belt is simple - first fix it with a bolt, then move the body along the guides. Rollers and a handle are screwed to the metal frame for comfortable transportation and operation of the chopper.

Apple chopper neck diagram. Photo from profermu.com

A homemade housing from a washing machine is bolted to the top of the frame. The motor is installed on the side to avoid juice splashing.

How to do

Now let's move on to the main thing - assembling the device at home. To begin, prepare the materials and tools you will need. We warn you right away that you will need a lathe and milling machine. Of course, few people have them in their personal household, but someone you know will definitely be able to help you. The machines do not require large amounts of work. You will need a welding machine and a grinder; they are much easier to get.

First of all, you will need a metal sheet d80 mm made of stainless steel. It is used to make steps for the gear shaft to exit from under the bearings. To pre-process the sheet you will need a lathe.

The next step is the manufacture of that same shaft. This is where the milling machine comes into play, with which you need to remove eight edges. Experienced engineers recommend making triangular notches on the teeth. This should improve productivity. A simple grinder is suitable for this work.

Drawing of manufacturing a gear shaft on a milling machine

An important stage of assembly is the manufacture of the body. The most suitable and often used basis for it is the outer casing of a Soviet top-loading washing machine. They were usually made of stainless steel, and the wall thickness was one and a half or two millimeters. Good parameters for a future shredder.

The base must be divided into four equal parts. Now the welding machine comes into play to transform the individual parts into a single body. But before you start welding the side fragments, the lower part of the sheets should be bent a little so that there is a gap between the wall and the shaft.

The gear shaft must be well secured in order to rotate smoothly. For these purposes, simple bearing units are used.

Scheme of a finished apple crusher

The crusher needs a strong support frame. It is most often made from strong wooden boards. A base is attached to the bottom of the frame on which the waste container will be located. To attach the crusher to the support frame, metal angles welded using a welding machine are used.

The motor is the heart of the electric shredder. The motor can be purchased at specialized electronics stores. Or you can use a unit from the same old washing machine, provided that it is still working.

The main thing is to install the electric motor so that splashes and other processed products do not fall on it during operation of the chopper. For the motor to operate correctly, it must be equipped with a remote control that regulates the operation process. It is a simple mechanism with a button to turn the electronics on and off. You can also purchase a remote control at an electronics store.

By the way, many gardeners note that home crushers are often more reliable and more powerful than electronics from manufacturers. And with their help you can prepare not only juices, but also wines.

Why you should get a crusher

This device can be easily found and purchased online or in a store, but real craftsmen construct a crusher with their own hands, spending a minimum of money during the manufacturing process. Such a device is made from scrap materials.

A crusher is needed to crush apples into small pieces. This will make it easier to crush the apples and increase the juice yield. It is generally accepted that the finer the mass, the more productive the result of producing apple juice at home.

Caring for Apple Choppers

If you made an apple chopper with your own hands, then caring for it will be as easy as shelling pears. The most important rule is cleanliness. Wash the unit thoroughly after each use . Even all hard-to-reach places should be washed and cleaned. There should be no apples, since their remains can produce blossoms, and when the machine is started again, the blossoms will get into the mixture, and then into the juice, which will lead to its rapid spoilage.

Do not leave the shredder outside in the rain. Moisture will not only rust the metal, but also damage the engine. If your crusher is made of wood, then moisture is also contraindicated for it . After each use, unplug the shredder, wash it well and hide it indoors.

Shredder advantages

The universal crusher has a number of advantages:

- Processing large volume apples will take a minimum of time.

- The amount of waste is kept to a minimum. All the juice is squeezed out of the fruit, and a small amount of cake is used for the remainder.

- Designing a home shredder is a low-cost process.

- When processing fruits in this way, physical effort is reduced to a minimum.

- Small batches of apples are most convenient to process, which is ideal for household use.

- The equipment is practical and reliable.

- If the installation fails, you can repair it yourself, without resorting to the help of specialists, which significantly saves money.

To construct an apple crusher at home, use a standard set of tools. No special equipment is needed here. In addition, you will also need materials to manufacture the device, and if you do not have suitable parts on hand, you will have to make a purchase.

Shredders come in different types:

- metal;

- wooden;

- combined.

But the main thing is not what the installation is made of, but how it copes with functional tasks. So, let's look at how to make a crusher with your own hands.

Description

Of course, you can always go to a hardware store and purchase an electric juicer or food processor. But this requires considerable costs. You can build a hydraulic shredder with your own hands using the tools available in your garage.

First, let's talk about the main advantages of this device.

- Firstly, as already noted, this is a fairly cheap way to obtain juice at home. Secondly, using this equipment you can save time. Large quantities of fruit are processed in a short time.

- Thirdly, this method of squeezing is the most profitable, because it allows you to get almost all the juice contained in the apple. The amount of waste is minimal.

- Fourthly, a homemade shredder will allow you to save not only money, but also your own effort. After all, it requires the slightest physical effort from you.

- Fifthly, with the help of equipment you can quickly put into use surplus crops.

- And finally, sixthly, due to its simplicity, the chopper is durable and reliable. If for some reason it does break down, you can always fix it yourself using improvised means.

There are three types of apparatus, depending on the materials from which it is made:

- wood;

- metal;

- combined.

However, specific materials do not play a big role in the operation of the shredder. The main thing is that they are of high quality and able to withstand the required load.

Do-it-yourself electric chopper (crusher) for apples and fruits for juice (1st option)

1) Grinding cylinder

Carve a wooden cylinder with a diameter of about 160 mm and a height of 160-180 mm. The large diameter of the cylinder is necessary so that the apples do not need to be pressed and pushed during the chopping process. The cylinder itself will capture them. Drill a through hole in the middle and glue in a shaft (stainless steel circle 10-12mm). Screw stainless steel screws into the cylinder in a checkerboard pattern so that the heads of the screws protrude by 7-8mm. The cylinder can also be made from stainless pipe. Place the bearings on the ends of the shaft and screw them to the housing.

Connect the shaft to the electric motor through pulleys and a belt drive.

2) Electric motor

– Motor power 0.55 kW

– Speed 1400-1500 rpm,

– So that it can be connected to a regular outlet, it is better to take a single-phase motor.

When working with the shredder, be sure to use a grounded electrical network!!!

3) Housing

Make the body of the chopper from wood or stainless steel so that the reservoir for filling the apples gradually narrows towards the chopping cylinder.

Caring for Apple Choppers

Smooth pieces in a short time

During operation and storage of the crusher, several rules must be followed. This will keep the device in working condition for a long time, the quality of the processed raw materials will be consistently high.

- The raw materials supplied to the unit container must be cleared of dry grass, branches or other solid third-party objects. It is advisable to remove the peel from the fruit; this will extend the life of the working parts, reducing the load on them.

- If an electric mechanism is provided, then wash and clean the movable parts only after de-energizing the system by unplugging it from the outlet.

- It is not recommended to turn on the device near children, animals or leave the device unattended.

- If foreign objects get into the crusher and block it, they are removed only after the working process is stopped.

- It is best to remove dirt using soft sponges and non-abrasive cleaning agents. This will protect the main parts of the structure from destruction.

- To store equipment, it is necessary to allocate a dry, ventilated room, ensuring that the ventilation holes of the unit’s engine are protected from contact with moisture.

Assembly of other elements

A high-quality apple crusher should have devices for adjusting the start. Despite the “high-tech” name, there is nothing complicated about it - we just mean a switch button. The electric motor is placed on the side of the main structure of the crusher.

With high-quality design and careful operation, homemade crushers are often superior to branded products. You need to think through everything so that washing even the farthest corners of the shredder is not difficult.

How to quickly chop apples at home to extract juice

Reading time 6 minutes

In order to prepare apple juice at home, the fruit must first be crushed. The necessary tools are not always at hand, so you can use them in different ways. You just need to know which ones. It’s not difficult to make an apple chopper yourself; the main thing is to know the sequence of work and have all the accessories at hand. Therefore, we will talk specifically about improvised means for chopping apples, which you can make with your own hands at home.

Description of the device and its functions

A crusher is a device with a manual or electric drive.

It consists of a chute for supplying raw materials, a chamber with a grater, disk, knives or drum for chopping and a device for discharging cut fruits into a prepared container.

Depending on the design, units may have different performance, purpose and cost.

For domestic use, there are models up to 10 thousand rubles, and to ensure industrial scale for such a crusher you will need to pay over 30 thousand rubles.

Design options

For processing apples with a soft structure, high-speed knife drum devices are used. Grinding is carried out through the interaction of pressing pads with several rows of comb knives of different thicknesses.

Hard fruits are crushed more efficiently by hammer machines. It is based on a shaft with hammers that crush the raw materials as a result of their movement. The rotor location can be horizontal or vertical.

As a rule, professional and semi-professional machines are equipped for filtration with a special replaceable sieve.

Depending on the required volume of raw materials at the output, a sieve with the required mesh size is selected.

Case manufacturing

For the base, a case from an old top-loading washing machine is suitable, namely its outer part, made of stainless steel with a wall thickness of up to 2 mm. During the processing process, the workpiece is cut into four parts, obtaining 2 end and side parts. The elements are folded into one structure and secured with a welding machine. Before the side parts are finally welded, the metal sheets at the bottom are slightly bent, creating a small gap between the rotating shaft and the wall of the structure.

For smooth rotation, the shaft is well secured using bearing units similar to those installed in circular machines. In order for a home-made apple crusher to stand securely, it is attached to a support frame, for the manufacture of which metal corners are used.

For the base of the machine, wooden blanks from durable rock are taken. A plank base is placed at the bottom, on which a container is subsequently placed to receive the processed mass at the outlet, which later needs to be placed under the apple press.

Improving the device

For ease of operation, tighten the belt, which is secured using a special bolt for clamping and by means of the main block along the guides.

Rollers and a handle are screwed to the frame, which makes it easy to transport the chopper.

The apple crusher body can be avoided from bending by attaching it to the upper corners of the frame using bolts.

Note!

To avoid splashing when processing apples, make sure that the container in which you collect the puree at the end is wide. When designing, make sure the frame is low, otherwise processed food will flop into the basin and splash around.

How to upgrade

A home chopper is quite simple and easy to use. However, there are several ways to improve the operation process.

- Mobility.

Not all areas can have a convenient place for the crusher. Someone has to move it often, and the structure weighs a lot. To make this task easier, screw rollers to the frame. It can also be equipped with a handle. Together these pieces will provide easy transportation. - Strengthening.

During operation, the crusher body may bend. You can avoid this by bolting it to the top corners of the frame. - Convenience.

To ensure this, it is recommended to tighten a special belt. It can be secured with a special bolt for clamping, as well as using the main block along the guides. - Reduced splashing.

It will cause you a lot of problems. As already mentioned, the electric motor must be protected from liquid ingress. To do this, you should use the widest possible dishes. The frame should be slightly lower so that the products do not fall from a great height.

You can find drawings in various reference materials and specialized Internet resources. They will significantly facilitate the assembly processes and reflect improvements to the device.

How to care for your home crusher

If you managed to make a shredder, then the hardest part is over. Don’t worry about caring for and cleaning the crusher yourself – it’s as easy as shelling pears.

The main rule for operating devices that come into contact with food is the cleanliness of the units. After each grinding, thoroughly rinse the surface of the device, clean and dry even in hard-to-reach places - these are the main areas of accumulation of bacteria and mold, which not only lead to rapid spoilage of the juice, but are also dangerous to human health.

Important! Before you start cleaning, turn off the power to the crusher!

To be able to enjoy delicious juice both in summer and in winter, it is enough to design a home apple crusher and learn how to squeeze the juice. Assembling such a unit is quite simple. You will receive undoubted advantages and significantly save money.

Conclusion

To enjoy delicious apple juice in summer and winter, just make a homemade chopper and squeeze out the juice. Making an apple crusher is very simple and quick, plus you will spend a minimum of money . Scrap materials, an old washing machine and you already have your own apple chopper. With this device you can chop not only apples, but also pears and other fruits. An apple chopper will become simply an indispensable thing in the house; with just a little effort, your efforts will be rewarded.

Some tips:

- Although the knives are strong and wear-resistant, they are made of high-carbon steel. This means they are more susceptible to corrosion, so try to keep the knives dry, clean and periodically lubricate them, for example, with castor oil

- In order to guarantee the crushed fraction, use sieves with cells of a given diameter from 2 to 6 mm. For chickens - fine grinding, for crushing calves - coarser.

- To chop grass or hay: before putting them in the chopper, fold them into small bunches - this is faster and more convenient.

- If the sieve becomes clogged when crushing grain, there is only one explanation - damp grain. Having received porridge, instead of crushed grains, stop the process, clean the sieve, knife, change the grain to dry.

- Experiment : when crushing grain, by choosing different speeds of rotation of the knife, you can achieve the desired fraction sizes; when cutting root vegetables, apples, pumpkins, watermelon rinds, you can also get thinly sliced “chips” or “porridge” - everything is in your hands

- Keep your books: measure how much grain you took, how much crushed grain came out, weigh the rolls of hay sold to you - often what they sell weighs not 500 kg, but 250-350 kg.

- If you want good milk yield in winter, pamper your cows , and don’t just steam the hay overnight: add chopped fodder beets, carrots, raw potatoes, pumpkin, Jerusalem artichoke. If you have silage, diversify the cow’s menu with it. The need of poultry and cattle for protein and high-calorie feed can be satisfied with meal. Due to the rise in price of imported soybean meal, it is worth paying attention to equally effective and less expensive rapeseed meal and cake. Research mineral supplements, test, for example, the famous felucene

How to quickly chop apples at home

Now it’s worth considering what devices are most often used for chopping apples at home. But before any chopping process, do not forget to wash the apples, peel them and cut them into small pieces.

To make devices that help chop apples at home, metal and wood are most often combined.

Using a press

You can make it yourself from a jack and additional materials purchased at a hardware store.

The manufacturing sequence can be viewed on the Internet. If you have a ready-made press for fruits and berries, then get to work. First, the cut fruits are placed in cloth bags or wrapped like an envelope. After this, the workpieces are placed in a container through drainage grates. The pressure is lowered from above, and the finished juice flows into the pan.

The remaining cake becomes dry and compressed. It will no longer be possible to use it, but if you have a vegetable garden, you can pour the remains of the pressed apples into the compost pit; they will serve as a good material for fertilizing the soil.

However, to make a high-quality fruit squeeze, it is not enough to have all the materials on hand. The oak beams that serve as the basis for the barrel for the press will have to be ordered from a carpentry shop, then they will be the same size. You also need to buy stainless steel and build a frame to support the press. There is a lot of hassle in making it. Sometimes it’s easier to buy a ready-made device than to build it yourself.

Special attachment for drill

Pre-chopped apples produce a more tasty and healthy juice.

Another way to save money on juicers and grinders is to use a drill. It will be used to drive the future crusher. You will need a small drill with a power of 350 watts. The hopper into which the blocks will be poured is made of laminated chipboard. The raw materials are ground using a drum. The hopper is simply placed on top and is not secured by anything, this makes it easy to remove it and clean the device from any remaining apples.

To make a desktop, take a piece of laminated table top. A hole is cut in it, and wooden blocks 60 × 40 mm are screwed on both sides of it. Oak planks are attached to them using self-tapping screws. A hole is drilled in the planks into which a pin is inserted with a crusher drum mounted on it.

The resulting crusher crushes fruit well. After which you can proceed to squeezing the juice.

Construction mixer

Most construction mixers are not much different from a regular drill.

Therefore, the sequence of making an apple crusher will be the same as with a drill. A wooden block on a long pin is installed at the end of the mixer. Screw the screws onto the wooden sleeve in any order. Place the apples in a can and start crushing them.

Remember about aftercare, so the tool will last longer. The main thing is to keep it clean. Rinse the device after each use, especially hard-to-reach areas. If this is not done, the bloom from previous apples will remain on the parts, and if it gets into new blanks, this will speed up the deterioration of the product.

Before you start washing, do not forget to turn off the power to the device.

Do not leave the device outside; moisture is contraindicated for it in any case, even if it is made not of metal, but of wood.

Specifications:

| Modification | Optimus |

| Dry grain up to, (kg/hour) | 155 |

| Root vegetables up to, (kg/hour) | 280 |

| Grass up to, (kg/hour) | 54 |

| Hay/straw up to, (kg/hour) | 30 |

| Voltage, (V) | 220 |

| Net power of the electric motor, (W) | 750 |

| Power consumption, (W) | 1200 |

| Overall dimensions, mm) | 780x330x330 |

| Net weight no more, (kg) | 10 |

| Hopper volume (dm3) | 7,7 |

| Electrical safety class | I |

| Warranty period, (months) | 6 |

You can read the instructions for Farmer "Optimus" DKU-05 here:

Another simple idea

How did you make an apple chopper with your own hands in the old days? They took a small one and put washed apples there. For chopping, a special sharp spatula was used, similar to a modern shredding knife.

Having learned how to make an apple chopper with your own hands, you can try to make other devices for the convenience of preparing various preparations. Fortunately, everyone has the materials for this.

For apples (made with your own hands, of course, will be much cheaper than store-bought) will greatly simplify work in the kitchen. After all, with the help of this simple device you can chop not only apples, but also other types of fruits, vegetables and berries.

It's no secret that all fruit juices contain beneficial substances. In addition, they are also very tasty, so both adults and children especially love them. Today, the most common juice is apple juice. There are a lot of apples growing in our country, and the juice from them is both tasty and healthy. Therefore, many people are wondering how to make juice with their own hands, without preservatives and flavoring additives. After all, unfortunately, you can’t buy one like this in stores.

In order to solve this issue, you need, firstly, to use a so-called fruit chopper, and secondly, a juicer, which is perfect for apples. With the apple crusher mentioned above, you can get more juice. At the same time, you will put much less effort into preparing it.

In our article we will look at how to make an apple crusher with your own hands (its drawings will also be provided to your attention).

Let's sum it up

To make apple processing easier, a crusher is the best solution.

With its help, labor costs are reduced, productivity increases, and waste is reduced.

Everyone loves homemade apple juice because it is not only delicious, but also healthy. But where can you get real apple juice, without chemicals and preservatives? You can hardly buy it in stores. The only solution to this problem is to make your own homemade apple juice . However, in order to get it, you need to overcome a number of small difficulties. To make your work easier, you will need an apple chopper and a juicer. Thanks to the chopper, you will spend a minimum of time and effort getting homemade apple juice. In this article we will look at ways to make a homemade apple chopper.

Materials and tools

Most of the components of the shredder can be selected from supplies available in the household. For example, the frame is perfectly assembled from metal corners, channels and pipes. An electric motor is usually purchased or taken from a mini-tractor. The cutter used must necessarily have large teeth, and the circular saws must have a diameter of 100 to 200 millimeters. If the work is done on a shaft, then gears are purchased in quantities of a couple of pieces, the same applies to the pulley, as well as to the shaft itself - there should be two of them. Knives can be made from car springs if you have a milling machine.

The tools you should prepare are a hammer drill, wrenches, a grinder, as well as a welding device and a set of fasteners.

Review of store models

You can find many different models of apple crushers in online stores and on the market.

We offer a wide range of manual, electric and other types of fruit and vegetable choppers.

Inexpensive, low-performance electric models are the most popular for household use. This is due to ensuring that sufficient quantities of raw materials are processed with the least amount of effort.

Below we will consider popular apple crushers of different price categories.

Farmer

The domestic manufacturer Miass offers a 0.15 kW shredder with an engine speed of up to 1.5 thousand per minute. The unit is powered from a network with a voltage of 220 V.

The volume of the working chamber is only 0.5 liters, which provides an average productivity of 60 kg per hour of operation. The main elements are made of stainless steel.

The device weighs about 8 kg, and its dimensions do not exceed 35 cm on any side. Thus, it is a compact device for home use. The cost is about 10 thousand rubles.

Shredder

Hungarian equipment provides very good performance and can even be used on farms.

The device is capable of processing up to 600 kg of apples in an hour, operating at a speed of 2.8 thousand revolutions per minute. It is powered by a 220 V network and consumes 1.1 kW of electricity per hour. It features a high degree of grinding of raw materials.

The size of the loading pipe is 18 cm. The height dimensions reach 1.27 m with a total weight of the apparatus of 25 kg. Cost: 19 thousand rubles.

Kubanets

Thanks to high-quality stainless steel in the production of cutting elements, the equipment can be used on farms and personal lands for fruit processing.

If the unit is used as a grain crusher, then its productivity reaches up to 1 ton per hour. Kubanets is powered by a 220 V network with a power consumption of 1.5 kW per hour.

When operating for apple processing, engine rotation speed: 3 thousand revolutions per minute.

The device weighs 45 kg, is 1.1 m high and 0.75 m wide. You can buy it for about 27-28 thousand rubles.

Breadwinner

The domestic device from the manufacturer Sormat has a powerful productivity reaching 750 kg per hour.

This covers the needs of even a farm that specializes in processing apples into juice and other products.

The unit is equipped with a motor with a power of 1.05 kW, operating from a 220 V network. With a device height of 1.25 m, its weight is 15 kg.

The equipment includes special dull knives that tear fruits and vegetables. This significantly increases the juice yield due to its increased efficiency.

The cost on the market ranges from 20 to 22 thousand rubles.