An indicator assembled from several parts turns out to be completely non-inertial and relatively sensitive to, for example, determine the magnetization of a razor blade or a watch screwdriver. In addition, such a device will be useful in school to demonstrate the phenomenon of induction and self-induction.

What is the working principle of magnetic field indicator circuit? If a permanent magnet is carried near a coil, preferably with a steel core, its lines of force will intersect the turns of the coil. An EMF will appear at the coil terminals, the magnitude of which depends on the magnetic field strength and the number of turns of the coil. All that remains is to amplify the signal taken from the coil terminals and apply it, for example, to an incandescent lamp from a flashlight.

The sensor is an inductor L1 wound on an iron core. It is connected through capacitor C1 to an amplifier stage made on transistor VT1. The operating mode of the cascade is set by resistors R1 and R2. Depending on the parameters of the transistor (static transmission coefficient and reverse collector current), the optimal operating mode is set by variable resistor R1.

A composite transistor VT2-VT3 made up of transistors of different structures is included in the emitter circuit of the first stage transistor.

The load of this transistor is the HL1 signal lamp. To limit the maximum collector current of transistor VT3, there is a resistor R3 in the base circuit of transistor VT2.

As soon as a magnetized object is near the sensor core, the signal that appears at the coil terminals will intensify and the signal lamp will flash for a moment. The larger the object and the stronger its magnetization, the brighter the flash of the lamp.

Magnetic field indicator circuit, as a sensor, it is best to use a coil with a core from electromagnetic relays RSM, RES6, RZS9 or others, with a winding resistance of at least 200 Ohms. Please note that the greater the winding resistance, the more sensitive the indicator will be.

Good results are obtained with a homemade sensor. For it, take a piece of rod with a diameter of 8 and a length of 25 mm from 600NN ferrite (from the magnetic antenna of pocket receivers). At a length of approximately 16 mm, 300 turns of PEV-1 0.25 wire are wound in bulk onto the rod. 0.3, placing them evenly over the entire surface. The winding resistance of such a sensor is approximately 5 Ohms. The sensitivity of the sensor, necessary for the operation of the device, is ensured due to the high magnetic permeability of the core. Sensitivity also depends on the static current transfer coefficient of the transistors, so it is advisable to use transistors with the highest possible value of this parameter. In addition, transistor VT1 must have a small reverse collector current. Instead of MP103A, you can use KT315 with any letter index, and instead of MP25B, you can use other transistors of the MP25, MP26 series, with a transmission coefficient of at least 40.

Magnetic field indicator diagram and location of radio components. Mount some of the indicator parts on a board made of any insulating material (getinax, textolite, hardboard). Mounting is mounted; to solder the pins of the parts, install pins 8.10 mm long from thick (1.1.5 mm) tinned copper wire on the board. Instead of studs, you can rivet hollow rivets on the board or install small brackets made of tin from a tin can. Do the same in the future when making boards for surface mounting. Make connections between the studs with bare tinned mounting wire, and if the conductors intersect, put a piece of polyvinyl chloride tube or cambric on one of them.

Magnetic field indicator circuit board

After installing the parts, a sensor, a variable resistor, a signal lamp, a switch and a power source are soldered to the board with insulated conductors. Turning on the power, set the variable resistor slider to such a position that the lamp filament barely glows. If the thread is very hot even with the engine in the upper position according to the diagram, you should replace resistor R2 with another one with a higher resistance.

A small magnet is placed briefly in front of the sensor core. The lamp should flash brightly. If the flash is weak, this indicates a low transmission coefficient of transistor VT1. It is advisable to replace it.

Then you need to bring the end of a magnetized screwdriver closer to the sensor core. It is not difficult to magnetize it with a few touches of a relatively strong permanent magnet, such as a 1 W dynamic head magnet. With a magnetized screwdriver, the brightness of the warning lamp flash will be less than with a permanent magnet. The flash will be very weak if you use a magnetized safety razor blade instead of a screwdriver.

When the indicator is operating with a variable resistor, first set the lamp brightness as low as possible, and then bring the object being tested to the sensor core. When checking weakly magnetized objects, the brightness of the signal lamp is slightly increased so that its change is better visible.

As already mentioned, a magnetic field is formed around a current-carrying conductor. If you turn on, say, a table lamp, then such a field will be around the wires supplying the mains voltage to the lamp. Moreover, the field will be variable, changing with the network frequency (50 Hz). True, the field strength is low, and it can only be detected with a sensitive indicator - its structure will be discussed later.

The situation is completely different with a working soldering iron. Its heating winding (spiral) is made in the form of a coil, and a fairly powerful magnetic field is formed around it, which can be detected with a relatively simple indicator.

Schematic diagram of an alternating magnetic field indicator

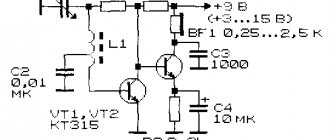

The input part of the indicator resembles the same part of the previous device: the same inductor L1 with capacitor C1, the same construction of the circuit of the first stage on transistor VT1. Only the chain of two resistors in the transistor base circuit is replaced by one resistor R1, the resistance of which is specified during the setup of the device. The transistor is based on a germanium pnp structure.

Magnetic field indicator circuit

An indicator assembled from several parts turns out to be completely non-inertial and relatively sensitive to, for example, determine the magnetization of a razor blade or a watch screwdriver. In addition, such a device will be useful in school to demonstrate the phenomenon of induction and self-induction.

What is the working principle of magnetic field indicator circuit? If a permanent magnet is carried near a coil, preferably with a steel core, its lines of force will intersect the turns of the coil. An EMF will appear at the coil terminals, the magnitude of which depends on the magnetic field strength and the number of turns of the coil. All that remains is to amplify the signal taken from the coil terminals and apply it, for example, to an incandescent lamp from a flashlight.

The sensor is an inductor L1 wound on an iron core. It is connected through capacitor C1 to an amplifier stage made on transistor VT1. The operating mode of the cascade is set by resistors R1 and R2. Depending on the parameters of the transistor (static transmission coefficient and reverse collector current), the optimal operating mode is set by variable resistor R1.

A composite transistor VT2-VT3 made up of transistors of different structures is included in the emitter circuit of the first stage transistor.

The load of this transistor is the HL1 signal lamp. To limit the maximum collector current of transistor VT3, there is a resistor R3 in the base circuit of transistor VT2.

As soon as a magnetized object is near the sensor core, the signal that appears at the coil terminals will intensify and the signal lamp will flash for a moment. The larger the object and the stronger its magnetization, the brighter the flash of the lamp.

Magnetic field indicator circuit, as a sensor, it is best to use a coil with a core from electromagnetic relays RSM, RES6, RZS9 or others, with a winding resistance of at least 200 Ohms. Please note that the greater the winding resistance, the more sensitive the indicator will be.

Good results are obtained with a homemade sensor. For it, take a piece of rod with a diameter of 8 and a length of 25 mm from 600NN ferrite (from the magnetic antenna of pocket receivers). At a length of approximately 16 mm, 300 turns of PEV-1 0.25 wire are wound in bulk onto the rod. 0.3, placing them evenly over the entire surface. The winding resistance of such a sensor is approximately 5 Ohms. The sensitivity of the sensor, necessary for the operation of the device, is ensured due to the high magnetic permeability of the core. Sensitivity also depends on the static current transfer coefficient of the transistors, so it is advisable to use transistors with the highest possible value of this parameter. In addition, transistor VT1 must have a small reverse collector current. Instead of MP103A, you can use KT315 with any letter index, and instead of MP25B, you can use other transistors of the MP25, MP26 series, with a transmission coefficient of at least 40.

Magnetic field indicator diagram and location of radio components. Mount some of the indicator parts on a board made of any insulating material (getinax, textolite, hardboard). Mounting is mounted; to solder the pins of the parts, install pins 8.10 mm long from thick (1.1.5 mm) tinned copper wire on the board. Instead of studs, you can rivet hollow rivets on the board or install small brackets made of tin from a tin can. Do the same in the future when making boards for surface mounting. Make connections between the studs with bare tinned mounting wire, and if the conductors intersect, put a piece of polyvinyl chloride tube or cambric on one of them.

Magnetic field indicator circuit board

After installing the parts, a sensor, a variable resistor, a signal lamp, a switch and a power source are soldered to the board with insulated conductors. Turning on the power, set the variable resistor slider to such a position that the lamp filament barely glows. If the thread is very hot even with the engine in the upper position according to the diagram, you should replace resistor R2 with another one with a higher resistance.

A small magnet is placed briefly in front of the sensor core. The lamp should flash brightly. If the flash is weak, this indicates a low transmission coefficient of transistor VT1. It is advisable to replace it.

Then you need to bring the end of a magnetized screwdriver closer to the sensor core. It is not difficult to magnetize it with a few touches of a relatively strong permanent magnet, such as a 1 W dynamic head magnet. With a magnetized screwdriver, the brightness of the warning lamp flash will be less than with a permanent magnet. The flash will be very weak if you use a magnetized safety razor blade instead of a screwdriver.

High frequency radiation indicator

The circuit of the high-frequency radiation indicator is shown in Fig. 1. The signal from the antenna reaches a detector made of a germanium diode. Next, through an L-shaped LC filter, the signal enters the base of the transistor, in the collector circuit of which a microammeter is connected. It is used to determine the power of high-frequency radiation.

Rice. 1. Diagram of a high-frequency radiation indicator.

Hall sensor module KY-003

This module is designed to detect a magnetic field using the Hall effect. This effect consists in the fact that a transverse potential difference 3 appears in a conductor with direct current placed in a magnetic field.

Dimensions 28 x 15 mm, module weight 1.2 g. The board has two mounting holes with a diameter of 2 mm at a distance of 10 mm from each other. A three-pin connector is used for connection. The central contact is +5V power supply, the “-” contact is common, the “S” contact is informational. When the magnetic field induction exceeds the specified value at the information output of the module, the high logic level changes to low. The module has an LED that lights up when the sensor is triggered. As an illustration, you can load the LED_with_button [4] program onto the Arduino UNO board and connect this module instead of the button.

The module triggers only on the north pole of the magnet, the trigger threshold is quite high, the magnet must be brought close. The current consumption is 6.3 mA in standby mode and is 11 mA when triggered.

Among the disadvantages, it should be noted that it is quite difficult to find the mutual configuration of the magnet and the sensor for reliable operation.

Since the module responds to a certain threshold value of the magnetic field, the most obvious application of such a sensor would be to use this sensor instead of a reed switch. Although the reed switch is a very reliable device, its design still contains moving mechanical contacts; in contrast, the Hall sensor does not have any moving parts. For example, you can install this module on a door jamb, install a magnet on the door leaf opposite it, you will get a door opening sensor for an alarm or a smart home, similarly, you can organize the counting of wheel revolutions by attaching a magnet to it and placing this sensor in close proximity to it.

Magnetic field of a current-carrying conductor

An electric current flowing through a current-carrying conductor creates a magnetic field in the space surrounding it. The greater the current passing through the conductor, the stronger the magnetic field that arises around it.

The magnetic lines of force of this field are located in concentric circles, in the center of which there is a current-carrying conductor.

The direction of the magnetic field lines around a current-carrying conductor is always in strict accordance with the direction of the current passing through the conductor.

The direction of magnetic field lines can be determined by the gimlet rule : if the translational movement of the gimlet (1) coincides with the direction of the current (2) in the conductor, then the rotation of its handle will indicate the direction of the magnetic field lines (4) around the conductor.

When the direction of the current changes, the magnetic field lines also change their direction.

As you move away from the conductor, the magnetic field lines are less frequent. Consequently, the magnetic field induction decreases.

The direction of current in a conductor is usually represented by a dot if the current is going towards us, and a cross if the current is directed away from us.

To obtain strong magnetic fields at low currents, they usually increase the number of current-carrying conductors and make them in the form of a series of turns; such a device is called a coil.

In a conductor bent in the form of a coil, the magnetic fields generated by all sections of this conductor will have the same direction inside the coil. Therefore, the intensity of the magnetic field inside the coil will be greater than around a straight conductor. When the turns are combined into a coil, the magnetic fields created by the individual turns add up. In this case, the concentration of field lines inside the coil increases, i.e., the magnetic field inside it intensifies.

The greater the current passing through the coil, and the more turns there are in it, the stronger the magnetic field created by the coil. The magnetic field outside the coil also consists of the magnetic fields of individual turns, but the magnetic field lines are not so densely located, as a result of which the intensity of the magnetic field there is not as great as inside the coil.

The magnetic field of a current-carrying coil has the same shape as the field of a straight permanent magnet: magnetic lines of force exit from one end of the coil and enter the other end. Therefore, a current-carrying coil is an artificial electric magnet. Typically, a steel core is inserted inside the coil to enhance the magnetic field; such a coil is called an electromagnet.

The direction of the magnetic induction lines of a current-carrying coil is found using the right-hand rule :

if you mentally clasp the current coil with the palm of your right hand so that four fingers indicate the direction of the current in its turns, then the thumb will indicate the direction of the magnetic induction vector.

To determine the direction of the magnetic field lines created by a turn or coil, you can also use the gimlet rule :

if you rotate the handle of the gimlet in the direction of the current in the coil or coil, then the translational movement of the gimlet will indicate the direction of the magnetic induction vector.

Electromagnets have found extremely wide application in technology. The polarity of an electromagnet (the direction of the magnetic field) can also be determined using the right-hand rule.

Module based on reed switch KY-021

The sensor is a normally open reed switch with an additional resistance of 10 kOhm 5.

The module dimensions are 24 x 17 mm, weight 1.2 g. A three-pin connector is used for connection. The central contact is +5V power supply, the “-” contact is common, the “S” contact is informational.

Effect of currents on magnets

Magnets act on electric currents. In turn, the currents affect the magnets.

Consider the experiment that Oersted conducted. The scientist placed a straight wire above the magnetic needle (Fig. 1) parallel to the plane of the needle. He began to pass current through the conductor. In this case, the arrow, capable of rotating about a vertical axis, was deflected and installed normally to the conductor. Oersted changed the direction of current flow, the arrow rotated 180 °. The same effect occurred when the conductor was moved under the arrow. Oersted's experiment showed the connection between electrical and magnetic phenomena.

Figure 1. Oersted's experiment. Author24 - online exchange of student work

Hall Sensor Module (Linear) KY-024

The module is designed to measure the strength of a constant magnetic field 10.

The module dimensions are 44 x 15 x 13 mm, weight 2.8 g, the module board has a mounting hole with a diameter of 3 mm. The sensing element is the Hall sensor SS49E. Power supply is indicated by LED L1.

The sensor has four contacts. “A0” is an analog output, the voltage at which varies depending on the magnetic field induction. Power terminals “G” – common wire, “+” – +5V power supply. There is a low logic level at the digital input “D0”; if the magnetic field strength does not exceed a specified threshold, when the sensor is triggered, the low level changes to high. The response threshold of the digital channel of the sensor can be changed using a multi-turn trimming resistor. When the sensor is triggered, LED L2 lights up.

Current consumption is 9 mA in standby mode and 11 mA when triggered.

The module only responds to the north pole of the magnet. Maximum sensing distance 6 mm.

The analog channel allows you to organize the measurement of quantitative characteristics of the magnetic field. The readings on the Arduino UNO analog port vary from 550 to 200 units depending on the distance to the magnet (the AnalogInput2 program was loaded into the Arduino UNO memory).

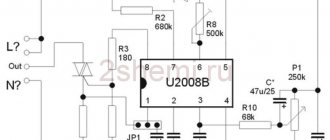

Mains voltage indicator on the standby multivibrator

The standby multivibrator (Fig. 9) is used to indicate the mains voltage [MK 7/88-12]. The indicator operates when its antenna approaches the network wire (220 V) at a distance of 2...3 cm. The generation frequency for the ratings shown in the diagram is close to 1 Hz.

Rice. 9. Circuit of the mains voltage indicator on the standby multivibrator.

Module with reed switch KY-025

The sensitive element of the module is a regular reed switch, working together with a comparator on the LM393YD chip; according to the sellers, 13 this allows you to reduce the current flowing through the contacts of the reed switch, and thereby increase its resource.

The module dimensions are 45 x 18 x 13 mm, weight 2.8 g, similar to the previous case, the module board has a mounting hole with a diameter of 3 mm. Power is indicated by LED L1.

When the reed switch is activated, LED L2 lights up. Current consumption is 3.7 mA in standby mode and 5.8 mA when triggered.

It is unclear what sensitivity threshold should be regulated by a variable resistor; apparently these modules with the LM393YD comparator are standard and various sensors are soldered to them depending on the purpose of a particular module. Of course, the module works discretely like a button, which can be verified using the LED_with_button program [4]. The supply voltage +5V is constantly present at pin “A0”. Power terminals “G” – common wire, “+” – +5V power supply. There is a low logic level at the digital input “D0”; when the reed switch is triggered, the low level changes to high. The feasibility of this module, according to the author, is controversial, given that even in the simplest case of turning on a reed switch such as the KY-021 module, the current flowing through the reed switch contacts is significantly less than one milliampere.

Indicators for troubleshooting New Year's electrical garlands

The following two designs according to the schemes of D. Bolotnik and D. Priymak (Fig. 3 and 4) are intended for troubleshooting in New Year's electrical garlands [R 11/88-56].

Rice. 3. Indicator diagram for troubleshooting New Year's electrical garlands.

The indicator (Fig. 3) is generally a resistor with controlled resistance. The role of such resistance is again played by the drain channel - the source of the field-effect transistor, supplemented by a two-stage DC amplifier.

The indicator (Fig. 4) is made according to the circuit of a controlled low-frequency generator. It contains a threshold device, an amplifier and a detector of the signal induced in the antenna by an alternating electric field.

Rice. 4. Indicator of low-frequency electric fields according to the circuit of a controlled low-frequency generator.

All these functions are performed by one transistor - VT1. Transistors VT2 and VT3 are used to assemble a low-frequency generator operating in standby mode. As soon as the device's antenna is brought closer to the source of the electric field, transistor VT1 turns on the sound generator.

Hall sensor module KY-035

This module is an SS49E chip, without any additional devices [14]. The installation of the microcircuit on the board in this case can only be explained by the requirements of unification when creating this set of sensors.

The module dimensions are 29 x 15 mm, weight 1.2 g. A three-pin connector is used for connection. The central contact is +5V power supply, the “-” contact is common, the “S” contact is informational.

The current consumed by the module is about 6 mA and does not depend on the state of the sensor.

In the absence of an external magnetic field, a voltage equal to half the supply voltage is present at the information output. An external constant magnetic field causes the voltage at the information output to increase or decrease depending on the polarity of the magnet. You can easily verify this using the AnalogInput2 program

Using this module, you can control the distance to the source of the magnetic field, count the number of revolutions, etc. The microcircuit is sensitive to a magnetic field with induction in the range of 600-1000 Gauss [15].

Additional features

What can be added to increase functionality? The volume control is two potentiometers between the output from the circuit and the headphone jack. Power switch - the circuit is now on all the time until the battery is disconnected.

During testing, it turned out that the device is very sensitive to the field source. You can hear, for example, how the screen on your mobile phone is updated, or how beautifully the USB cable sings while transferring data. When attached to a switched-on loudspeaker, it works like a regular and quite accurate microphone that collects the electromagnetic field of the coil of a working speaker.

It looks good for cables in the wall, like a locator. You just need to raise the bass by increasing all 4 capacitances to 10 µF. The disadvantage is that there is quite a lot of noise and the signal is also too weak - you need some kind of additional power amplifier, for example on the PAM-8403.

useful links

- https://ru.wikipedia.org/wiki/Hall_Effect

- https://arduino-kit.ru/catalog/id/modul-datchika-holla

- https://www.14core.com/wiring-hall-effect-sensor-switch-magnet-detector-module/

- https://robocraft.ru/blog/arduino/57.html

- https://arduino-kit.ru/catalog/id/modul-na-osnove-gerkona

- https://www.zi-zi.ru/module/module-ky021

- https://2shemi.ru/mehanicheskie-datchiki-dlya-arduino/

- https://electrosam.ru/glavnaja/slabotochnye-seti/oborudovanie/gerkony/

- https://electrik.info/main/school/419-gerkony-sposoby-upravleniya.html

- https://arduino-kit.ru/catalog/id/modul-datchika-holla-_lineynyiy_

- https://www.zi-zi.ru/module/module-ky024

- https://arduino-kit.ru/catalog/id/modul-magnitnyiy-datchik-s-gerkonom

- https://www.zi-zi.ru/module/module-ky025

- https://arduino-kit.ru/catalog/id/modul-datchika-holla_

- https://ru.wikipedia.org/wiki/Gauss_(unit)

All documentation and program files are located in a common archive. Review prepared by Denev.

Source

Build process

Assembly requires the use of a breadboard of at least 15 x 24 holes, and special attention is paid to the layout of the elements on it. The photographs show the recommended location of each radio element and what connections to make between them. Jumpers on a printed circuit board can be made from cable fragments or cut off legs from other elements (resistors, capacitors) that remain after their installation.

After soldering the coils, you can install capacitors C1 and C2. Their capacitance is 2.2 μF and determines the lower cutoff frequency of sounds that will be heard in the headphones. The higher the capacitance value, the lower the sounds reproduced in the system. Most powerful electromagnetic noise lies at 50 Hz, so it makes sense to filter it out.

You can put any operational amplifier with standard pins into the socket, for example OPA2134, NE5532, TL072 and others.